Niobium alloy surface Ni-Cr oxidation-resistant coating and preparation method thereof

An anti-oxidation coating and niobium alloy technology, which is applied in the field of Ni-Cr anti-oxidation coating on the surface of niobium alloy and its preparation, can solve the problems of affecting the anti-oxidation performance of the coating, low coating temperature and high cost, and achieve excellent Anti-high temperature oxidation performance, effect of compact coating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

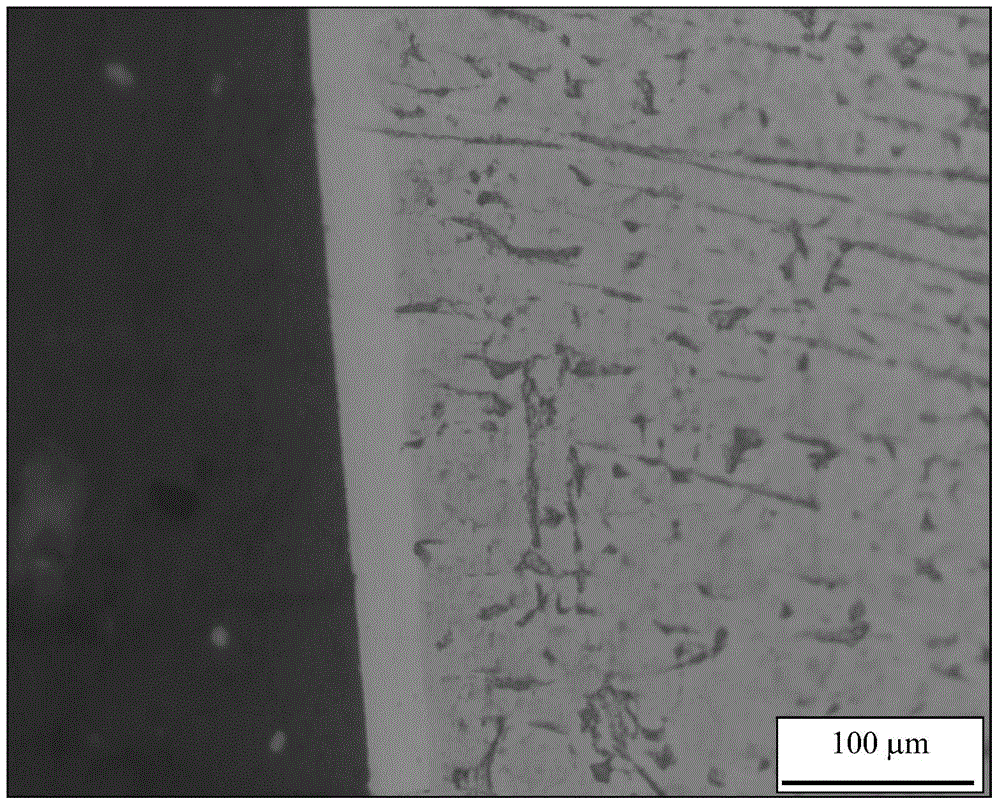

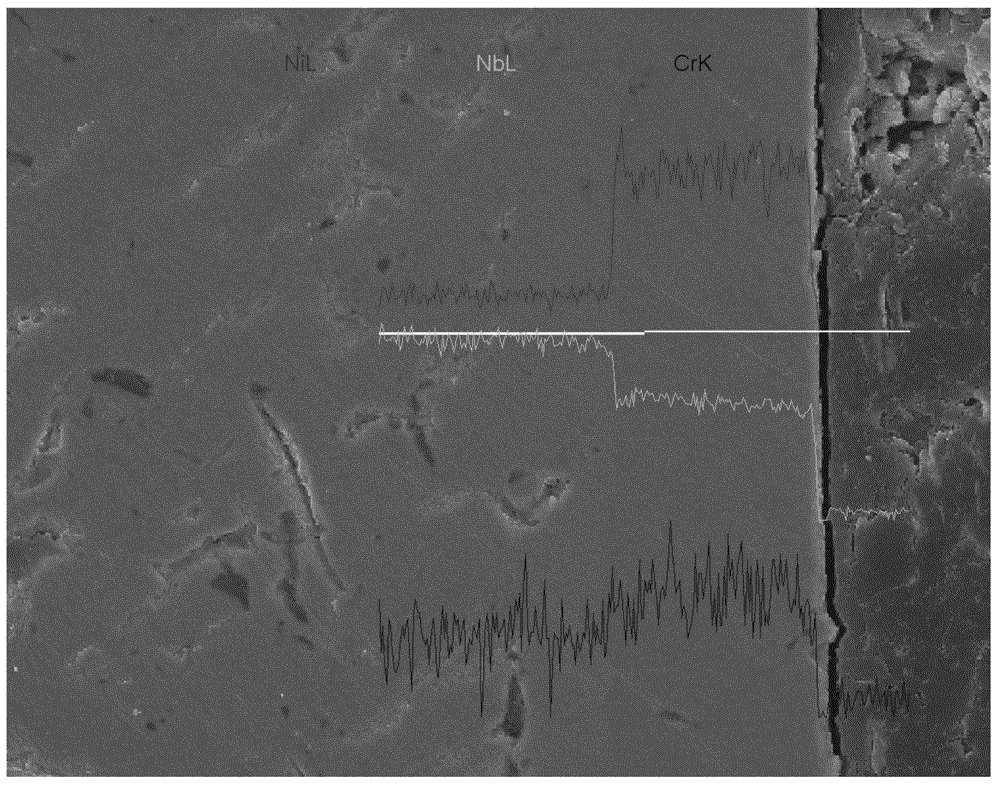

[0020] Embodiment 1: Preparation of Ni-35Cr-10Nb coating on the surface of Nb-Zr alloy rod

[0021] Prepare a Nb-1Zr alloy rod with a length of 100 mm and a diameter of 10 mm. After degreasing with acetone, cleaning the surface, and pickling (the pickling process refers to the QJ2910-97 standard), electroplate Ni. The thickness of the Ni layer is about 10 μm, and then electroplate The Cr is about 8μm. After the plated niobium alloy rod is cleaned and dried, it is placed on the laser surface alloying treatment table. After testing, the pulse current is 160A, the pulse width is 2.5ms, the frequency is 8Hz, and the laser surface alloying line speed is 2.5 mm / s, the distance between the alloying tracks is 1.0mm. After the treatment, the sample is cut along the circumference of the alloy rod. After the sample is mounted, polished and corroded, it is placed under the Axiovert200MAT optical microscope for observation. The cross-sectional structure of the coating is as follows: Pictur...

Embodiment 2

[0022] Embodiment 2: Preparation of Ni-40Cr-5Nb coating on the surface of C-103 alloy pipe

[0023] Prepare a C-103 alloy (Nb-10Hf-Ti) tube with an outer diameter of 30 mm, a wall thickness of 3 mm, and a length of 100 mm. After the surface is cleaned and pickled, the outer surface is electroplated with Ni. The thickness of the Ni layer is about 90 μm, and then electroplated with Cr About 85μm, after cleaning and drying the plated niobium alloy rod, put it on the laser surface alloying treatment table. After testing, the pulse current is 280A, the pulse width is 3.0ms, the frequency is 6Hz, and the laser surface alloying line speed is 2mm / s, the distance between alloying tracks is 1.0 mm, and a coating with a thickness of about 180 μm and a coating composition close to Ni-40Cr-5Nb is prepared. The coating structure is uniform and dense, and it is well bonded to the substrate. The coating has a high Cr content and a good interface Bonding and coating compactness ensure good hi...

Embodiment 3

[0024] Embodiment 3: Ni-30Cr-5Nb coating is prepared on the surface of Cb752 alloy plate

[0025]Prepare a Cb752 alloy (Nb-10W-2.5Zr) plate with a size of 50mm×50mm×5mm. After surface cleaning and pickling, Ni is electroplated on the outer surface. The thickness of the Ni layer is about 100 μm, and then Cr is about 60 μm. After the niobium alloy rod was cleaned and dried, it was placed on the laser surface alloying treatment table. After testing, the pulse current was 260A, the pulse width was 3.5ms, the frequency was 10Hz, and the laser surface alloying line speed was 3.0mm / s. The spacing is 1.0 mm, and a coating with a thickness of about 170 μm and a coating composition close to Ni-30Cr-8Nb is prepared. The coating structure is uniform and dense, and it is well bonded to the substrate. The high Cr content in the coating and good interface bonding and dense coating It ensures the good high temperature oxidation resistance of the coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com