Patents

Literature

68results about How to "Increase Cr content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-speed rail train aluminum profile and preparation method thereof

The invention discloses a high-speed rail train aluminum profile which comprises the following metals in percentage by mass: 0.1-0.2% of Cu, 0.20-0.40% of Mn, 1.0-2.0% of Mg, 0.1-0.3% of Cr, 4.0-6.0% of Zn, 0.1-0.2% of Zr, at most 0.10% of Ti, at most 0.30% of Fe, at most 0.35% of Si, at most 0.1% of V, at most 0.15% of all impurities, and the balance of Al. The invention also discloses a preparation method of the high-speed rail train aluminum profile. The high-speed rail train aluminum profile has obvious higher yield strength, tensile strength, elongation percentage and the like than the existing aluminum alloy.

Owner:龙口市丛林铝材有限公司

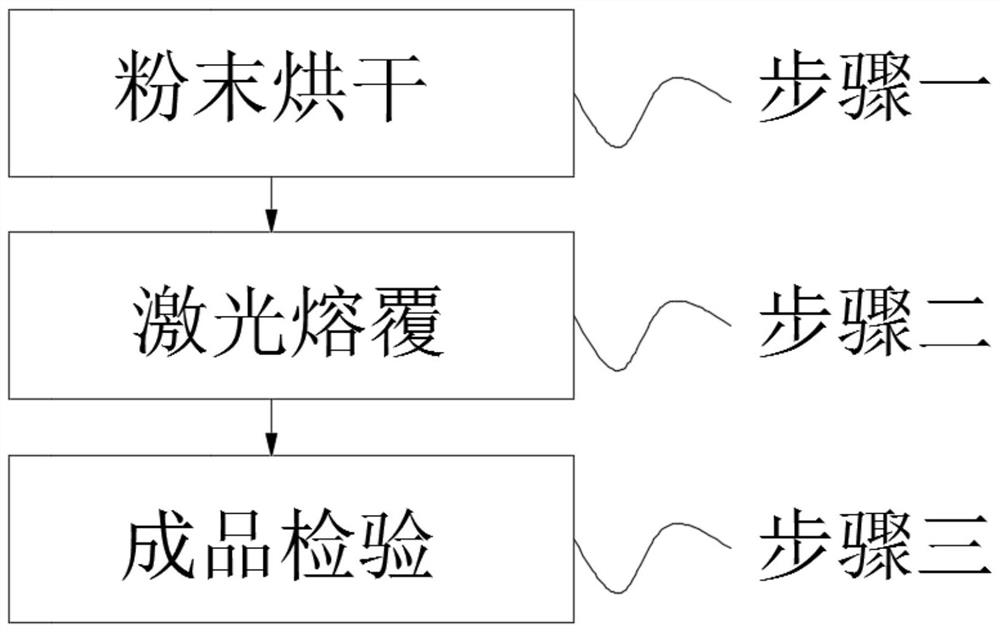

Method for preparing Fe-Mn-Si shape memory alloy coating via laser cladding

InactiveCN103409748ASimple preparation processSuitable for mass industrial productionMetallic material coating processesShape-memory alloyAlloy

The invention discloses a method for preparing a Fe-Mn-Si shape memory alloy coating via laser cladding. The Fe-Mn-Si shape memory alloy coating comprises raw materials including pure iron powder, nickel power, manganese powder, silicon powder, chromium powder, vanadium powder, terrae rare, quartz, wood flour, starch and the like, via the laser cladding way, the Fe-Mn-Si shape memory alloy coating prepared by the method has an excellent mechanical property, and particularly has the characteristics of good abrasion resistance, low stress residue, high fatigue strength. The self-designed cladding power preparation process is simple and suitable for industrial mass production, the cladding process is simple and easy to implement, and the obtained functional coating has greater market application prospects.

Owner:DALIAN MARITIME UNIVERSITY

Special steel for hardware tool and preparation method thereof

The invention discloses a special steel for a hardware tool and a preparation method thereof. The steel comprises the following chemical components in percentage by weight: 0.50-0.60% of C, 0.17-0.37% of Si, 0.20-0.50% of Mn, 0.008-0.020% of P, 0.001-0.005% of S, 0.25-0.60% of Cr, 0.20-0.35% of Ni, 0.07-0.25% of Cu, 0.010-0.030% of Ti, and the rest amount of iron and inevitable impurities. The preparation method is performed by a general clean steel process, and comprises the steps of steel smelting, LF furnace refining, continuous casting, casting blank heating, rolling, cooling and reeling. All alloy element components in the steel are designed to properly increase the carbon content and decrease the content of such noble metals as Ni and Cr; the process of smelting and rolling is controlled to obtain the special steel for the hardware tool with high-hardness surface and low-hardness-toughness heart material matrix; and the steel can satisfy the performance needed by the hardware tool and the target of optical economic benefit.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

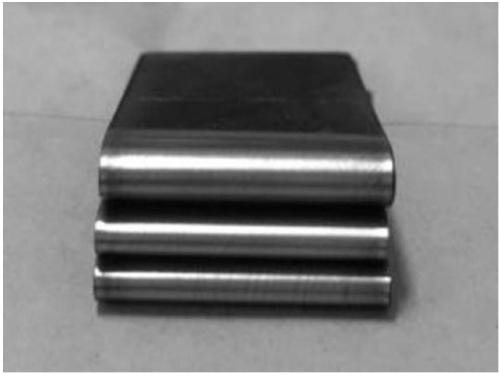

Hot roll for rolling titanium plate and manufacturing method of hot roll

The invention discloses a hot roll for rolling a titanium plate, and a manufacturing method of the hot roll. The hot roll comprises the following chemical constituents in percentage by weight: 0.30-0.50% of C, 0.60-2.00% of Si, 0.20-1.00% of Mn, 4.50-6.00% of Cr, 0.05-0.65% of Ni, 1.00-2.00% of Mo, 0.50-1.50% of V, less than or equal to 0.025% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. The manufacturing method of the hot roll for rolling the titanium plate comprises the processing steps of steel ingot refining, roll blank forging, thermal refining, induction quenching treatment, tempering treatment and the like. Compared with the traditional hot roll made of a Cr3 material, the hot roll is good in abrasive resistance, corrosion resistance and thermal crack resistance, and the service life of the hot roll can be prolonged by above 70%.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

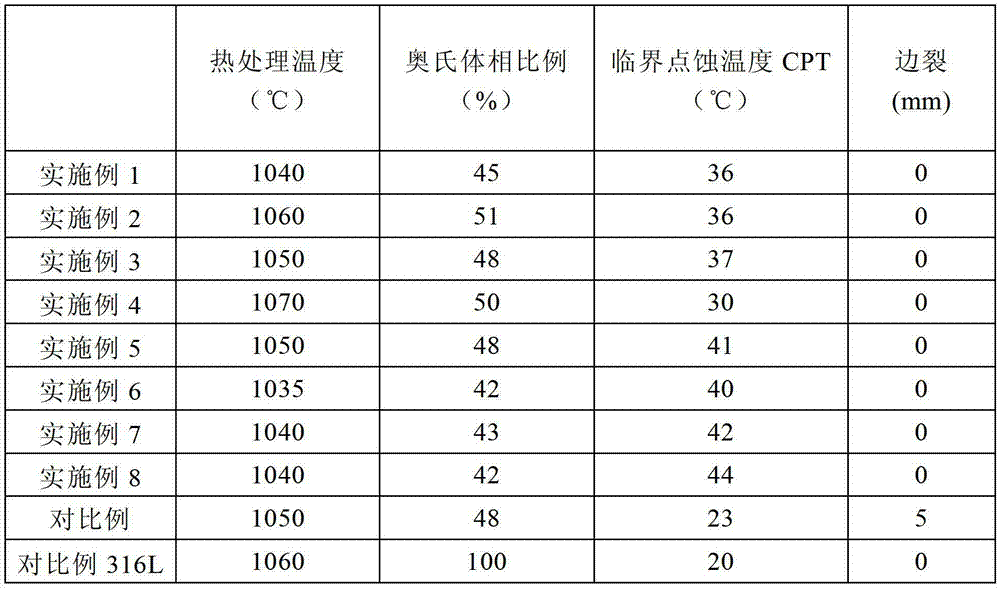

Duplex stainless steel with excellent thermoplasticity and corrosion resistance and manufacturing method thereof

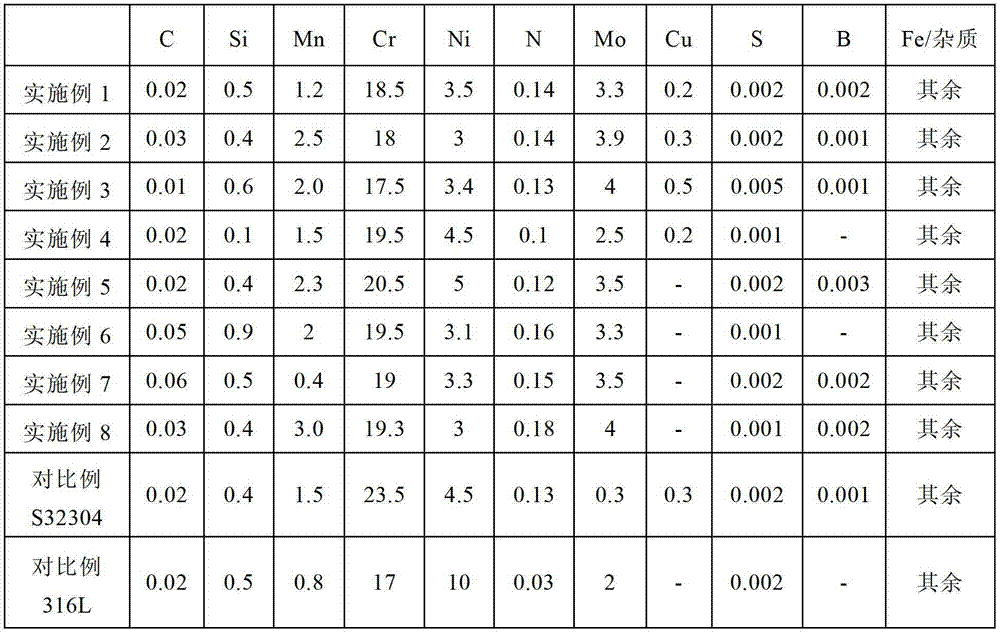

The present invention discloses a duplex stainless steel with excellent thermoplasticity and corrosion resistance and a manufacturing method thereof. The duplex stainless steel comprises chemical compositions of, by weight percentage, 0.01-0.06 % of C, 0.1-1.0 % of Si, 0.4-3.0 % of Mn, 17.5-20.5 % of Cr, 3.0-5.0 % of Ni, 0.1-0.18 % of N, 2.5-4.0 % of Mo,less than or equal to 0.005 % of S, less than or equal to 0.005 % B, less than or equal to 1.0 % of Cu, and the balance being Fe and inevitable impurities. According to the invention, a content of the Mo is increased to 2.5-4.0 %, a content of the Cr is reduced to 17.5-20.5 %, a content of the N is controlled at 0.1-0.18 %, and the trace elements S and B are also in control. The duplex stainless steel has excellent thermoplasticity and corrosion resistance, can be produced into hot-rolled and cold-rolled strip steels in mass and used in fields of construction, heat exchange, etc., and can partially replace costly 316 and 317 austenitic stainless steel.

Owner:BAOSTEEL STAINLESS STEEL

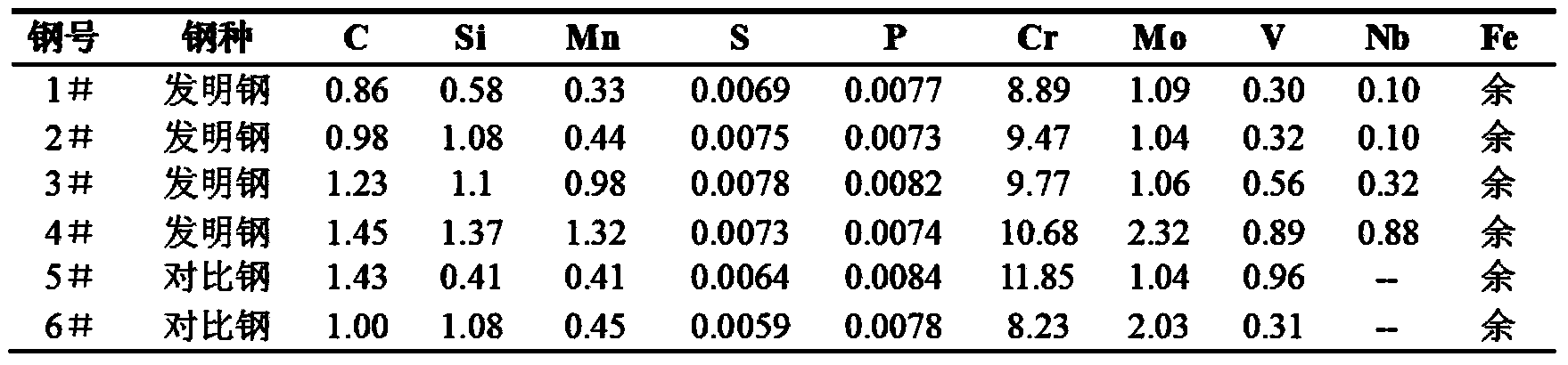

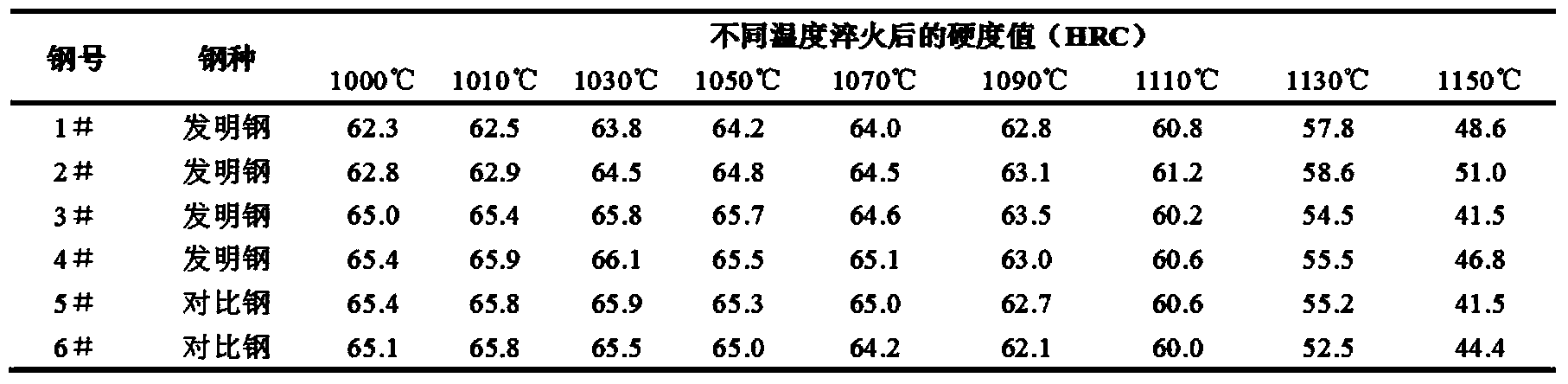

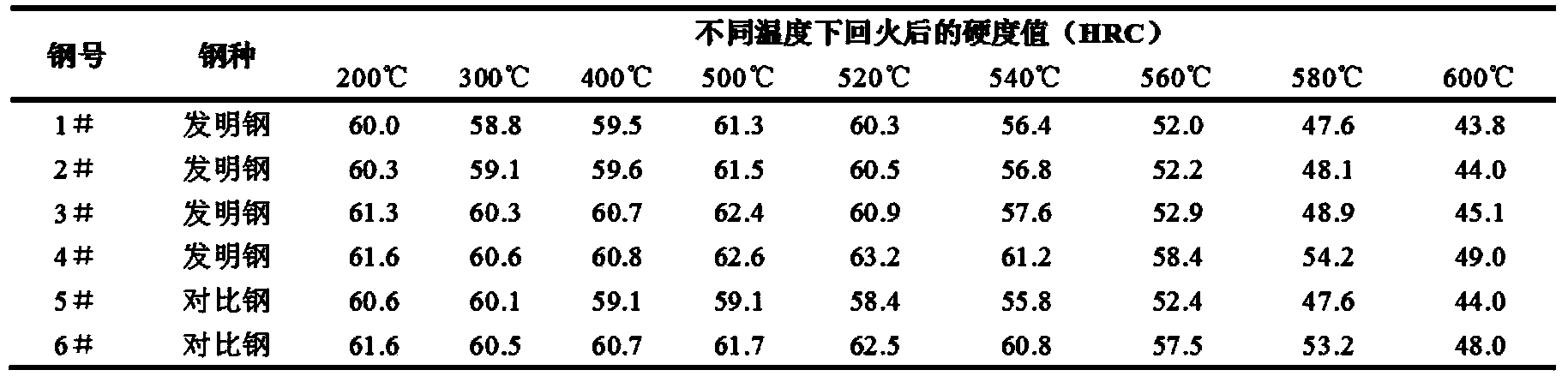

High-toughness and high-wear-resistant cold-work die steel

The invention discloses a high-toughness and high-wear-resistant cold-work die steel, belonging to the field of tool and die steels. The steel comprises the following chemical components in percentage by weight: 0.8-1.5% of C, 0.5-1.5% of Si, less than or equal to 0.030% of S, less than or equal to 0.030% of P, less than or equal to 1.5% of Mn, 0.8-2.5% of Mo, 8.0-11.0% of Cr, 0.1-1.0% of V, less than or equal to 1.0% of N, and the balance of Fe and inevitable impurities. Compared with the prior art, the high-toughness and high-wear-resistant cold-work die steel disclosed by the invention keeps high wear resistance, and has higher toughness and bending strength and good comprehensive performances at the same time. Compared with a Cr12 type cold-work die steel, the high-toughness and high-wear-resistant cold-work die steel reduces the Cr content, and ensures that a material has higher toughness. Compared with a Cr8 type cold-work die steel, the high-toughness and high-wear-resistant cold-work die steel increases the Cr content, increases the wear resistance, and reasonably controls the C / Cr ratio, thus achieving the purposes of obtaining a better carbide distribution state than the Cr8 type cold-work die steel, and ensuring that the material has better toughness. The content of elements Mn and Si is increased so as to improve the hardness and enhance the wear resistance. By adopting relatively high Nb<+>V composite alloying, the effects of V in the steel are increased, and the secondary hardening effect is improved.

Owner:CENT IRON & STEEL RES INST

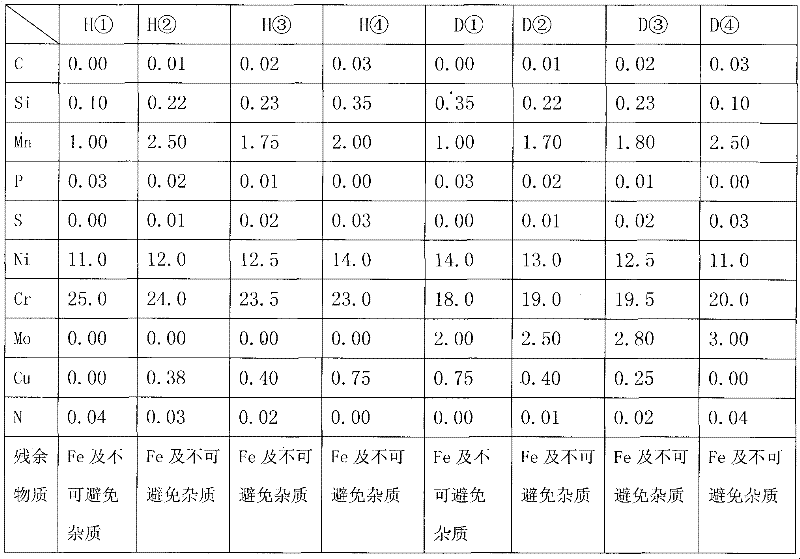

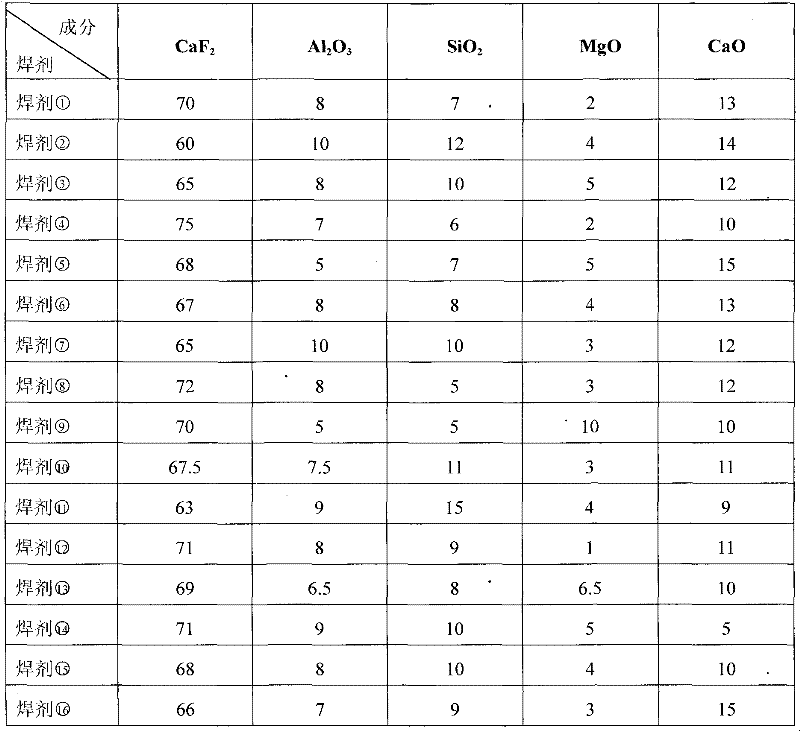

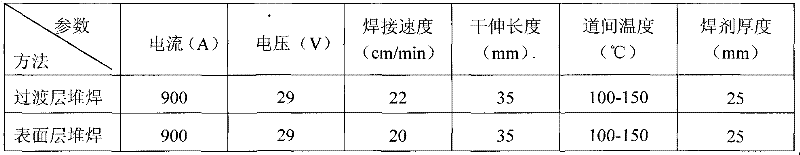

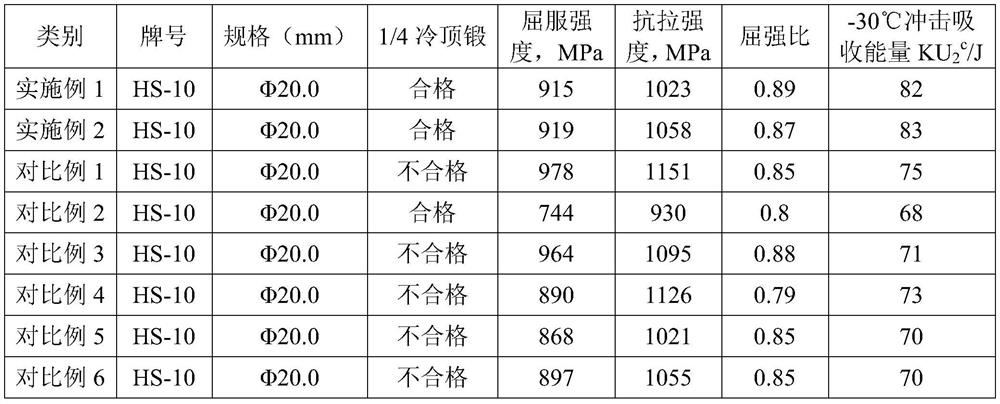

Stainless steel band electrode electroslag surfacing welding strip and welding flux

ActiveCN102233494AWeld firmlyImprove efficiencyWelding/cutting media/materialsSoldering mediaSlagCorrosion resistant

The invention discloses a stainless steel band electrode electroslag surfacing welding strip and a welding flux. The Mo element is not added into a transition layer welding strip, but the surfacing metal has sufficient Mo; and the welding strip and the welding flux can be matched to be applied to large-scale surfacing on the inner wall or the outer wall of a container and can meet corrosion-resistant and high-temperature-resistant requirements. When the welding strip and the welding flux are matched for surfacing, the dilution rate is ultralow and is 5 to 12 percent and the production efficiency is high; slag is easy to remove, a formed welding bead is attractive and welding defects do not exist; the intergranular corrosion resistance is excellent; and cracks do not exist during surfacingbending.

Owner:KUSN GINTUNE WELDING

Fatigue-resistant corrosion-resistant aluminum profile for automobile and preparation method of aluminum profile

InactiveCN104630582AHigh yield strengthHigh tensile strengthUltimate tensile strengthCorrosion resistant

The invention discloses a fatigue-resistant corrosion-resistant aluminum profile for an automobile. The aluminum profile comprises the following metals in parts by weight: 90 parts of Al, 0.1-0.2 part of Cu, 0.20-0.40 part of Mn, 1.0-2.0 parts of Mg, 0.1-0.3 part of Cr, 4.0-6.0 parts of Zn, 0.1-0.2 part of Zr and 0.1-1 part of V. The invention further discloses a related preparation process. The prepared aluminum profile has the advantages of fatigue resistance and corrosion resistance; and compared with the conventional aluminum profile, the aluminum profile disclosed by the invention has high yield strength and tensile strength and has wide application prospects in the automobile.

Owner:湖州宏叶铝塑材料有限公司

Tin-containing high-nitrogen martensitic stainless steel alloy material and manufacturing method thereof

The invention relates to a tin-containing high-nitrogen martensitic stainless steel which is prepared from the following components in percentage by mass: at most 0.04% of C, at most 1.0% of Si, at most 2.0% of Mn, at most 0.02% of P, at most 0.02% of S, 0.05-0.3% of N, 12.0-18.0% of Cr, 0.05-1.0% of Sn, and the balance of Fe and inevitable impurity. The content of tin varies as the content of Cr varies, and the maximum content of tin must be 3.4% less than the content of Cr. The martensitic stainless steel has excellent mechanical properties, favorable corrosion resistance and excellent processability, can be processed into products in various shapes, and is applicable to the fields of general industrial machinery and the like.

Owner:SHANGHAI UNIV

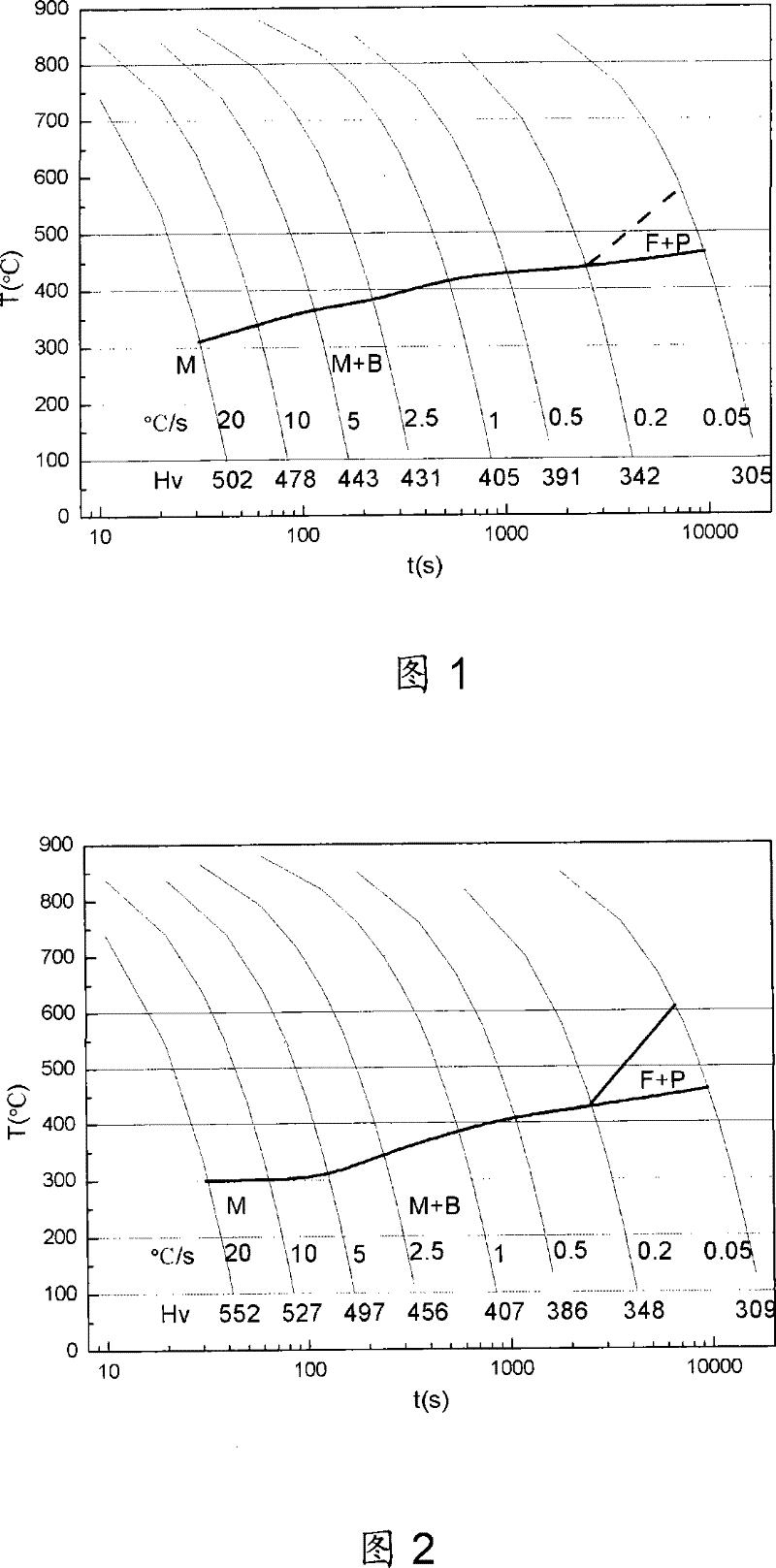

Cold heading steel wire rod for annealing-free 10.9-grade fastener and manufacturing method of cold heading steel wire rod

The invention belongs to the technical field of cold heading steel, and particularly relates to a cold heading steel wire rod for an annealing-free 10.9-grade fastener and a manufacturing method of the cold heading steel wire rod. The cold heading steel wire rod for the annealing-free 10.9-grade fastener comprises the following main chemical components of, in percentage by weight, 0.25%-0.29% of C, less than or equal to 0.10% of Si, 0.95%-1.15% of Mn, 0.40%-0.50% of Cr, 0.020%-0.050% of Al, less than or equal%-0.025% of P and S, and less than or equal%-0.20% of Ni and Cu. The manufacturing method comprises a converter smelting process, an LF refining process, an RH vacuum refining process, a square billet continuous casting process and a wire rod rolling process. By optimizing the element composition design of the C, the Mn, the Cr and the like and combining a controlled rolling and controlled cooling scheme, a hot-rolled wire rod has high cold heading performance, the content of C is larger than or equal to 0.25%, B is not added, and the requirements of foreign users for producing special annealing-free 10.9-grade high-strength fasteners are met.

Owner:ZENITH STEEL GROUP CORP +1

High-strength nitrogen-containing economical austenite stainless steel and manufacturing method thereof

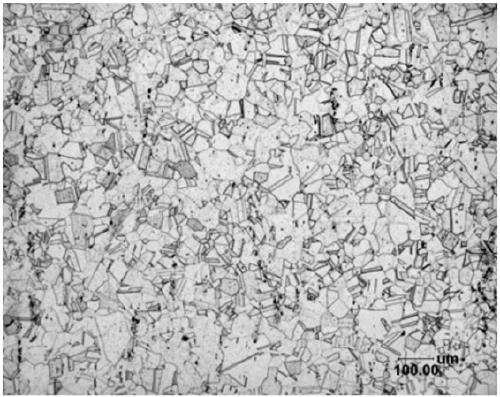

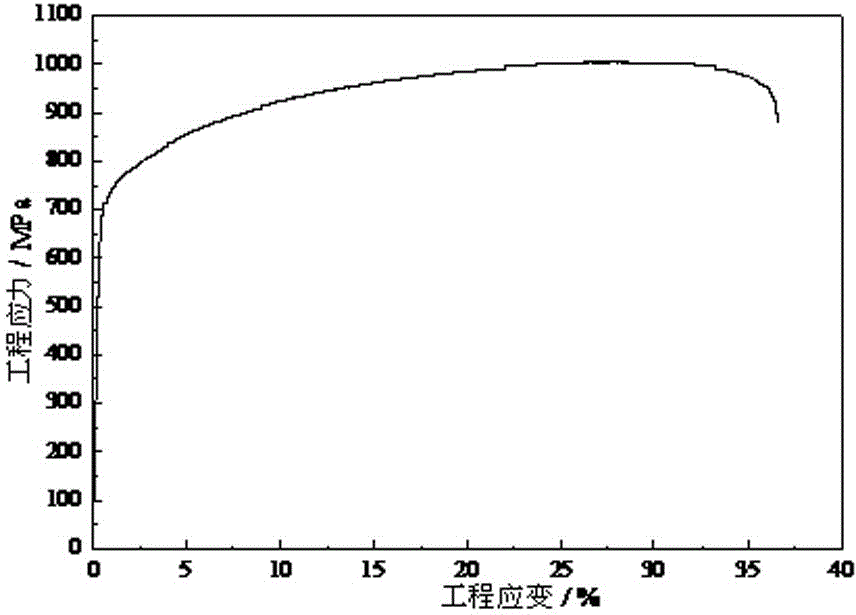

The invention relates to a high-strength nitrogen-containing economical austenite stainless steel and a manufacturing method thereof. The chemical components of the stainless steel, by weight, of 0.05-0.15% of C, 0.3-1% of Si, 8.5-11.0% of Mn, 14.0-16.0% of Cr, 1.0-2.5% of Ni, 0.10-0.25% of N, less than 0.08% of P, less than 0.01% of S, 0.5-2.0% of Cu, 0.1-0.5% of Mo, and the balance Fe and inevitable impurities, wherein Md <30 / 50> is greater than or equal to 20 DEG C. In the manufacturing process of the high-strength nitrogen-containing economical austenite stainless steel, through cold rolling twice and flexible annealing, crystal grains are refined through production and inversion of deformation martensites, and finally, the crystal grains of which the dimension is smaller than 500nm are obtained, so that the intensity of materials is greatly improved; and the obtained high-strength nitrogen-containing economical austenite stainless steel has the following specific properties that the yield strength is greater than or equal to 650MPa, the tensile strength is greater than or equal to 1000MPa, and the elongation rate is greater than or equal to 35%, and the high-strength nitrogen-containing economical austenite stainless steel is suitable for preparation of high-strength fine-specification precision strip steels.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

High-strength and high-corrosion-resistance austenitic stainless steel and manufacturing method thereof

The invention discloses high-strength and high-corrosion-resistance austenitic stainless steel and a manufacturing method thereof. The austenitic stainless steel comprises raw materials including, bymass percent, smaller than or equal to 0.1% of C, smaller than or equal to 2% of Si, smaller than or equal to 7% of Mn, smaller than or equal to 0.1% of S, smaller than or equal to 0.1% of P, 28%-35%of Cr, 26%-32% of Ni, 3%-8% of Mo, 0.2%-0.5% of N and the balance Fe and inevitable impurities, wherein Ni / Mn >= 4, and PREN=(Cr+3.3*Mo+16*N)>=43. Through selection of the high Cr content, the high Mocontent, the high N content and the high Ni content, a solid-solution-state austenite structure with high dislocation density is obtained, and the strength of the austenitic stainless steel is greatly improved.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Ferrochromium-based powder core wire and preparing method and application thereof

The invention provides a ferrochromium-based powder core wire and a preparing method and application thereof. The ferrochromium-based powder core wire is made by making a stainless steel band be coated with a powder core, wherein the powder core is formed by mixing, by weight, 40%-60% of Cr, 5%-15% of B, 1%-5% of Si, 1%-5% of W, 2%-10% of Nb and the balance Fe which are all powder; the weight ratio of the powder core to the stainless steel band is (0.43-0.67) to 1; when a ferrochromium-based amorphous coating is prepared by adopting the electric arc spraying technique, oil removing and rust removing processing needs to be performed on the surface of a base body firstly, and then sand blasting and other preprocessing are performed. The ferrochromium-based powder core wire can be used for the ferrochromium-based amorphous coating which is high in amorphous content and hardness and excellent in corrosion resistant and abrasion resistant performance, and the coating is particularly suitable for site construction of large steel structures and the like and can be applied to various industrial fields like corrosion prevention and abrasion resistance.

Owner:HOHAI UNIV

A kind of high-strength and high-conductivity cucrzrmg series copper alloy wire material and preparation method thereof

ActiveCN108060323BHigh strengthIncrease the number ofConductive materialMetal/alloy conductorsPower flowIngot casting

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

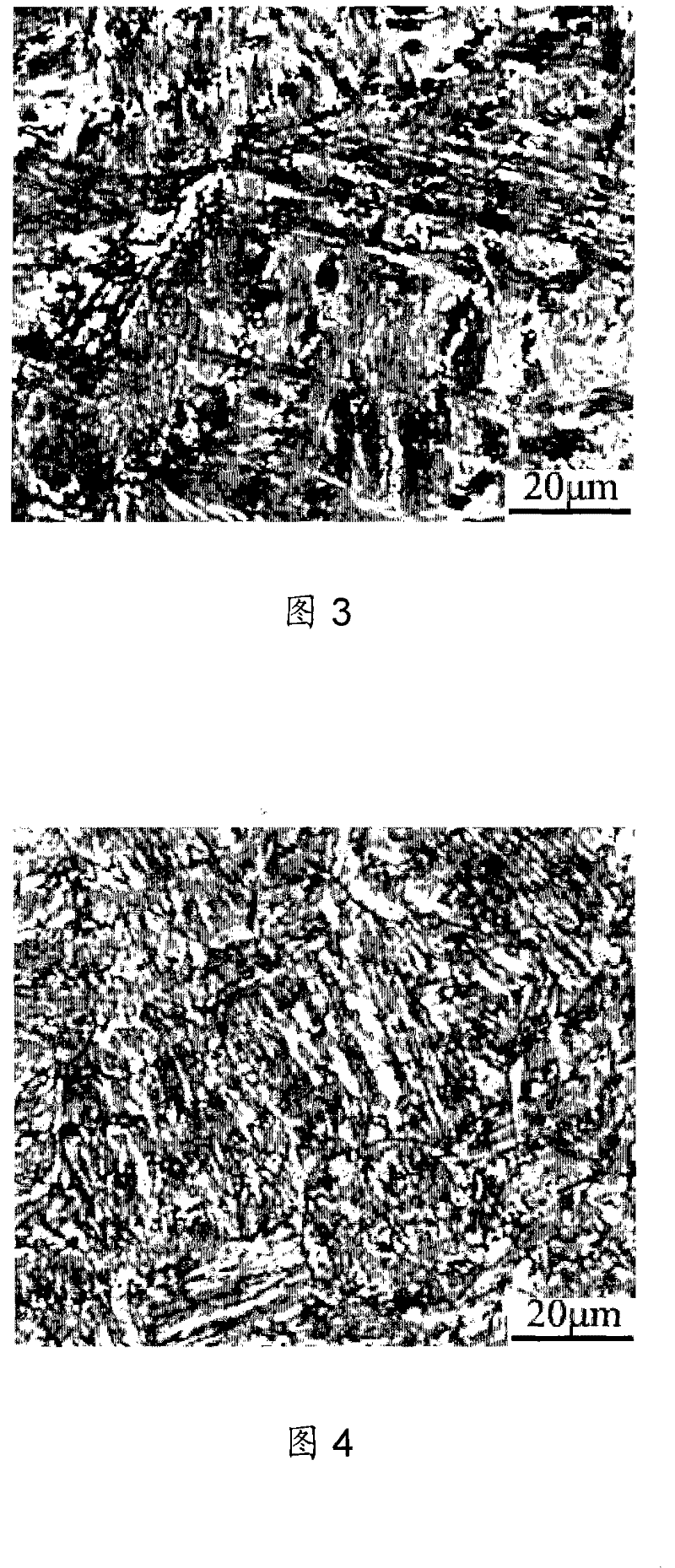

Novel non-quenched-and-tempered plastic die steel plate and preparation method thereof

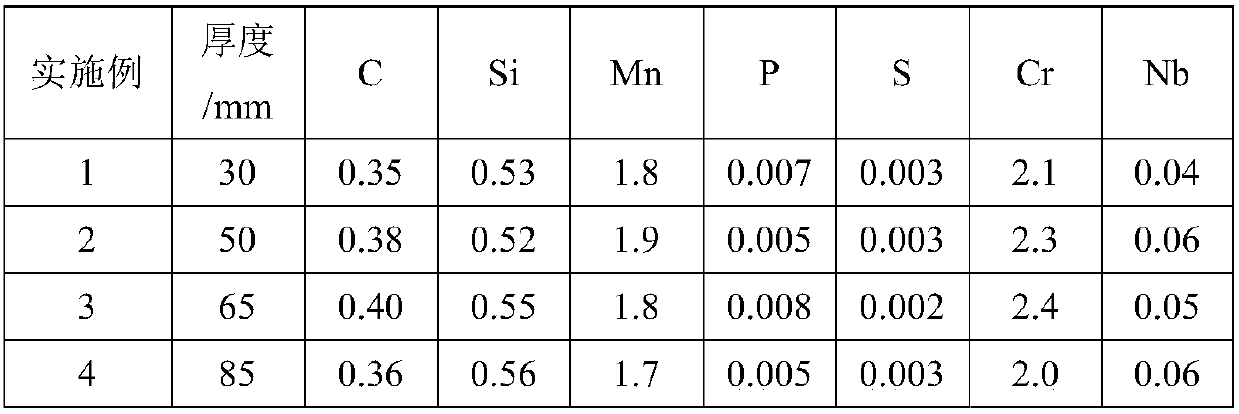

The invention provides novel non-quenched-and-tempered plastic die steel plate and a preparation method thereof. The steel plate is prepared from the following components in percentage by weight: 0.35to 0.40 percent of C, 0.52 to 0.56 percent of Si, 1.7 to 1.9 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 2.0 to 2.3 percent of Cr, 0.04 to 0.06percent of Nb and the balance of Fe and unavoidable impurities. The preparation method comprises the following steps: heating a plate blank at temperature of 1,200 to 1,220 DEG C; carrying out open rolling at open rolling temperature of 1,100 DEG C, and carrying out final rolling at final rolling temperature of 890 to 930 DEG C; after rolling, carrying out air cooling to 200 to 300 DEG C, and carrying out tempering at 550 to 580 DEG C; and carrying out net heat preservation for 1.5 to 2.0 min / mm. By optimal component design and cooperation with hot rolling and tempering processes, the shortcoming of high quenching crack sensitivity of plastic die steel is overcome; and meanwhile, a prehardening effect is achieved, and the energy consumption is reduced.

Owner:ANGANG STEEL CO LTD

Method and apparatus for recovering PGM and ferro-chrome from PGM bearing chromite ore

InactiveCN105164285AMineral processing is easySave energyFurnace typesProcess efficiency improvementHydrometallurgyFerrochrome

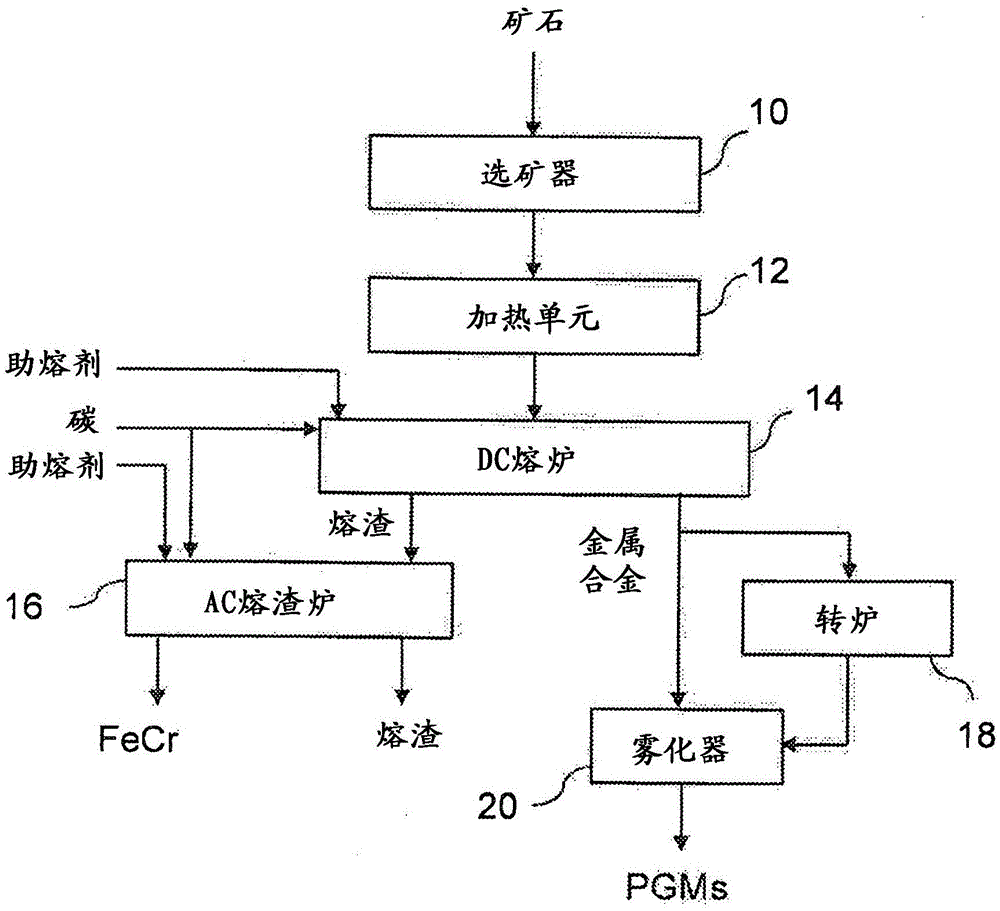

In a method for recovering PGMs and ferrochrome from platinum group metals bearing chromite ore, a concentrate is prepared that contains most of PGMs and chromite of the ore and the concentrate is subjected to a heating step to dry and / or preheat the concentrate, after which the preheated concentrate is smelted under reducing conditions in a DC smelting furnace (14) to produce molten metal alloy containing the PGMs of the feed and molten slag containing the chromium of the feed. The molten slag is tapped from the smelting furnace (14) into an AC slag furnace (16), where iron and chromium are reduced to produce a ferrochrome alloy. PGMs are recovered from the metal alloy tapped from the smelting furnace (14) utilizing hydro-metallurgical processes.

Owner:OUTOTEC FINDLAND OY

RH decarburization method of ultralow-carbon and high-chromium corrosion resisting steel

The invention discloses a RH decarburization method of ultralow-carbon and high-chromium corrosion resisting steel. In the decarburization process, an oxygen content in molten steel is kept within 0.01-0.05%; and meanwhile, the temperature of the molten steel in the decarburization process is not lower than 1620 DEG C, so that a carton content of the molten steel in ending of RH decarburization is reduced below 0.005%, and the burning loss of a chromium element in the molten steel is not higher than 2%. The method, provided by the invention, can produce the ultralow-carbon and high-chromium corrosion resisting steel with a chromium content of above 7%; the carton content of the molten steel in ending of RH decarburization is reduced below 0.005%; and the burning loss of the chromium element in the molten steel is not higher than 2%.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

High-nitrogen nickel-saving type duplex stainless steel thin strip and preparation method thereof

ActiveCN105925917AImprove performanceImprove corrosion resistanceSolution treatmentSS - Stainless steel

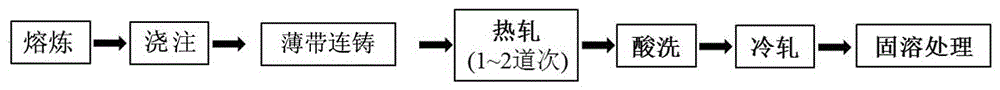

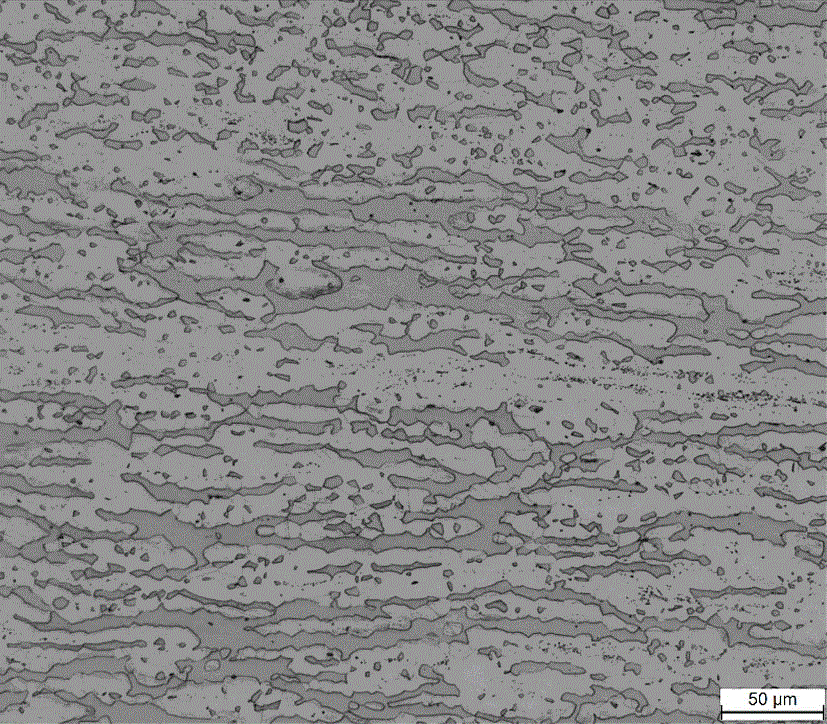

The invention provides a high-nitrogen nickel-saving type duplex stainless steel thin strip and a preparation method thereof. The high-nitrogen nickel-saving type duplex stainless steel thin strip comprises, by mass, 0.0001%-0.03% of C, 22.1%-26.0% of Cr, 7.1%-10% of Mn, 0.46%-0.7% of N, 0.0001%-0.1% of Ni and the balance Fe and other inevitable impurities. The preparation method comprises the steps that firstly, materials are selected and proportioned according to the components, and molten steel is obtained through melting; secondly, the molten steel is poured into a tundish; thirdly, thin strip continuous casting is conducted on the molten steel, so that a cast strip with the thickness being 2-4 mm is formed; fourthly, hot rolling is conducted on the cast strip by 1-2 passes, so that an edge crack-free hot-rolled stainless steel strip with the thickness being 1.6-2.4 mm is obtained; fifthly, the hot-rolled stainless steel strip is pickled in sequence, and cold rolling is conducted after a surface oxidation layer is removed, so that a cold-rolled stainless steel thin strip with the thickness being 0.4-1.0 mm is obtained; and finally, solution treatment is conducted, and then the high-nitrogen nickel-saving type duplex stainless steel thin strip is obtained.

Owner:NORTHEASTERN UNIV

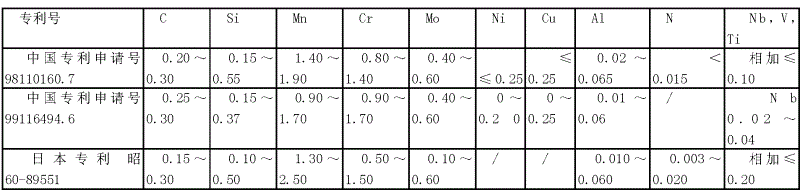

High-performance marine mooring chain steel and manufacturing method thereof

InactiveCN101519751BImprove compactnessImprove uniformityMetal rolling arrangementsIngotMaterials science

The invention relates to high-performance marine mooring chain steel and a manufacturing method thereof. The method comprises the following steps: a. tapping compositions comprise the following by weiThe invention relates to high-performance marine mooring chain steel and a manufacturing method thereof. The method comprises the following steps: a. tapping compositions comprise the following by weight percentage: C: 0.16 to 0.27, Mn: 0.40 to 1.45, Si: 0.15 to 0.50, Cr: 1.25 to 2.50, Ni: larger than 0 and less than 1.20, Mo: 0.20 to 0.60, Al: 0.01 to 0.06, N: 0.004 to 0.015, S: not larger than 0ght percentage: C: 0.16 to 0.27, Mn: 0.40 to 1.45, Si: 0.15 to 0.50, Cr: 1.25 to 2.50, Ni: larger than 0 and less than 1.20, Mo: 0.20 to 0.60, Al: 0.01 to 0.06, N: 0.004 to 0.015, S: not larger than 0.005, P: not larger than 0.015, Cu: larger than 0 and less than 0.50, and the balance of Fe; b. a steel ingot or a continuous casting billet is casted after the steps of primary smelting in an electri.005, P: not larger than 0.015, Cu: larger than 0 and less than 0.50, and the balance of Fe; b. a steel ingot or a continuous casting billet is casted after the steps of primary smelting in an electric stove or a converter, external refining and vacuum degassing; c. the charging temperature of a heating oven is not larger than 900 DEG C, the heating rate is not larger than 150 DEG C / h; when beingc stove or a converter, external refining and vacuum degassing; c. the charging temperature of a heating oven is not larger than 900 DEG C, the heating rate is not larger than 150 DEG C / h; when beingraised to 1100 to 1300 DEG C, the temperature is kept for more than 40 minutes, cogging bloom or rolling by a finisher is carried out, and the finishing temperature is not larger than 1050 DEG C; andraised to 1100 to 1300 DEG C, the temperature is kept for more than 40 minutes, cogging bloom or rolling by a finisher is carried out, and the finishing temperature is not larger than 1050 DEG C; andd. after heated at the temperature of 1000 to 1250 DEG C, the cogged ingot is hot-rolled or forged into round steel, the finishing temperature is not larger than 1050 DEG C, and after rolling, the sted. after heated at the temperature of 1000 to 1250 DEG C, the cogged ingot is hot-rolled or forged into round steel, the finishing temperature is not larger than 1050 DEG C, and after rolling, the steel is air-cooled, slow cooled or softening heat-treated at the temperature of not less than 600 DEG C. The performance of finished products achieves or exceeds the requirement of level 4.5 and level 5el is air-cooled, slow cooled or softening heat-treated at the temperature of not less than 600 DEG C. The performance of finished products achieves or exceeds the requirement of level 4.5 and level 5 of mooring chain steel.of mooring chain steel.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

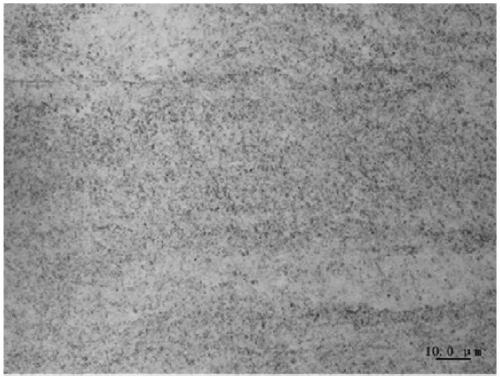

Super high nitrogen martensite stainless steel and preparation method thereof

InactiveCN102134688AImproved high temperature thermoplasticityIncrease Cr contentSolution treatmentBreaking strength

The invention relates to a super high nitrogen martensite stainless steel and a preparation method thereof, belonging to the technical field of steel alloy material. The super high nitrogen martensite stainless steel comprises the components by mass percent: less than or equal to 0.03% of C, less than or equal to 0.01% of S, less than or equal to 1.0% of Si, less than or equal to 0.015% of P, 16-18% of Cr, 3.4-4.5% of Ni, 3.5-4.5% of Cu, 0.15-0.25% of N, 0.001-0.01% of B, 0.005-0.20% of rare earth Ce or Y and the balance of Fe. The traditional smelting technique method is adopted and comprises the steps of: adding Fe-Ce or Fe-Y intermediate alloy in the smelting process, pouring for moulding, carrying out solution treatment within the temperature range of 950-1200 DEG C after hot forging, forming martensite structure, and finally carrying out ageing treatment. Therefore, at the room temperature, the super high nitrogen martensite stainless steel has the tensile break strength within the range of 1290-1450MPa, the yield strength within the range of 1150-1350MPa, the elongation at break within the range of 18-28% and the reduction of cross section within the range of 50-65%.

Owner:SHANGHAI UNIV

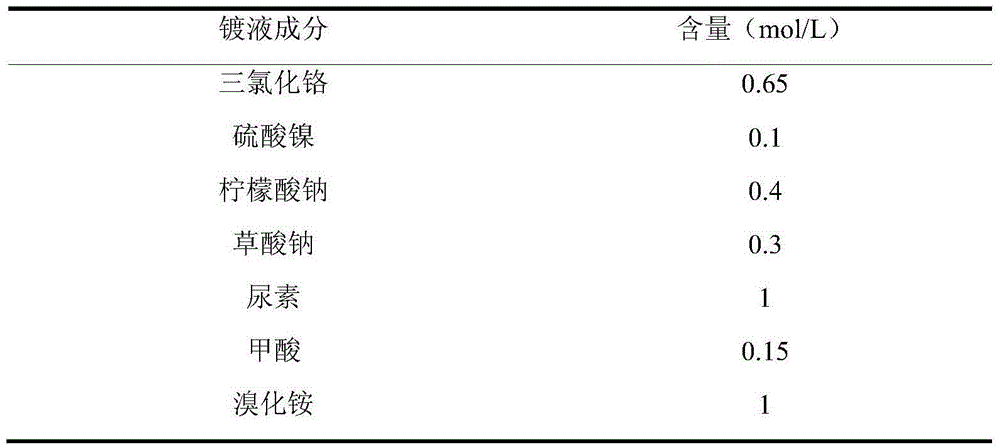

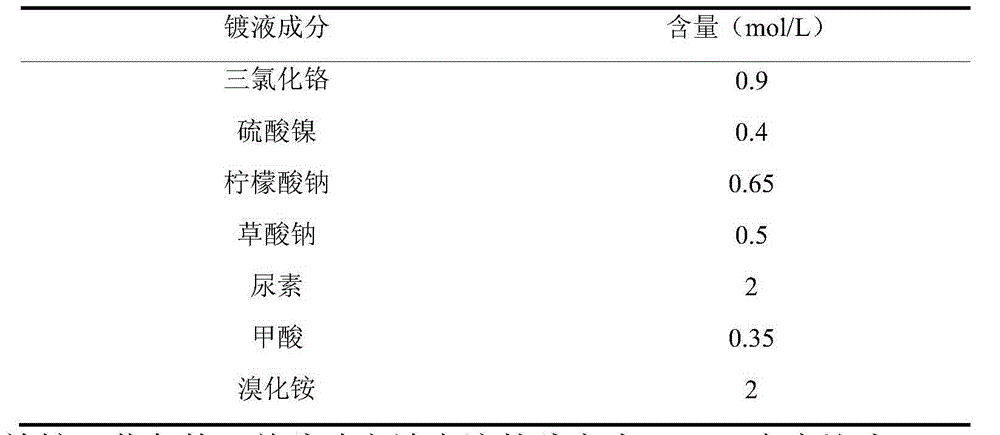

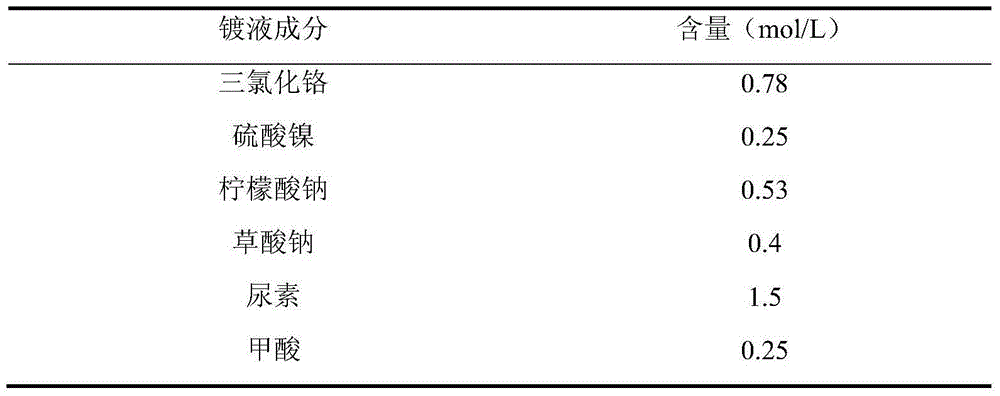

Cr-Ni alloy plating solution and electroplate method

The invention discloses a Cr-Ni alloy plating solution and an electroplate method. The Cr-Ni alloy plating solution comprises the following components by content: 0.65-0.9mol / L chromium trichloride, 0.1-0.4mol / L nickel sulfate, 0.15-0.35mol / L formic acid, 0.4-0.65mol / L citrate, 0.3-0.5mol / L oxalate, 1-2mol / L urea and 1-2mol / L ammonium bromide. According to the invention, citrate, oxalate and urea are selected as a coordination agent, citrate, oxalate and urea are better coordinated with trivalent chromium and bivalent nickel through cooperative effect; methylsulfonate is taken as a buffering agent and a coordination promoter; ammonium bromide is taken as conducting salt, wherein the bromide ions can inhibit generation of hexavalent chromium ions and precipitation of chlorine. The current efficiency of the Cr-Ni alloy plating solution is higher, and a coating layer has the advantages of high Cr content, large thickness, and strong coating bonding force.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

Special steel for hardware tools and preparation method thereof

ActiveCN104032229BImprove red hardnessPlay a role in diffusion strengtheningChemical compositionEconomic benefits

The invention discloses a special steel for a hardware tool and a preparation method thereof. The steel comprises the following chemical components in percentage by weight: 0.50-0.60% of C, 0.17-0.37% of Si, 0.20-0.50% of Mn, 0.008-0.020% of P, 0.001-0.005% of S, 0.25-0.60% of Cr, 0.20-0.35% of Ni, 0.07-0.25% of Cu, 0.010-0.030% of Ti, and the rest amount of iron and inevitable impurities. The preparation method is performed by a general clean steel process, and comprises the steps of steel smelting, LF furnace refining, continuous casting, casting blank heating, rolling, cooling and reeling. All alloy element components in the steel are designed to properly increase the carbon content and decrease the content of such noble metals as Ni and Cr; the process of smelting and rolling is controlled to obtain the special steel for the hardware tool with high-hardness surface and low-hardness-toughness heart material matrix; and the steel can satisfy the performance needed by the hardware tool and the target of optical economic benefit.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Powder material suitable for laser cladding reinforcement of cutting pick sheath layer

PendingCN113943900AHigh hardnessImprove toughnessTransportation and packagingMetal-working apparatusCarbideOxidation resistant

The invention discloses a powder material suitable for laser cladding reinforcement of a cutting tooth sheath layer. The material for cladding comprises the following components of C, Cr, W, Mo, Ti, Nb, Fe and other alloy elements, and the following specific components of 0.6-1.0 wt% of C, 13-18 wt% of Cr, 2-5 wt% of W, 1-3 wt% of Mo, 0.2-0.8 wt% of Ti, 0.1-0.4 wt% of Nb and the balance of Fe. In the formula, about 0.2-0.4 wt% of carbon forms martensite, the rest martensite forms a compound with W, Mo, Ti and Nb, the carbon is melted and dissolved in the martensite to form carbon martensite, the hardness and toughness of the material are improved, meanwhile, the Cr content is high, the Cr is dissolved in the martensite in a solid mode, the oxidation resistance is improved, C interacts with W, Mo, Ti and Nb, fine and dispersed single or composite carbides are separated out in situ, the hardness and wear resistance of a cladding layer are improved, therefore the comprehensive strengthening effects of martensite strengthening, fine grain strengthening, in-situ carbide fine and dispersed precipitation strengthening and the like are generated, the average hardness of a strengthening layer reaches HRC65-67, and the service life is prolonged by 1-2 times compared with an existing cutting pick.

Owner:上海盖泽激光科技有限公司

Low-cost and high-strength oxidation-resistant iron-nickel based alloy and preparation method thereof

InactiveCN112375954AExcellent resistance to steam oxidationReduced processing performanceSolid state diffusion coatingFernicoChemical composition

The invention discloses a low-cost and high-strength oxidation-resistant iron-nickel based alloy and a preparation method thereof. The alloy is high in strength, has good high-temperature steam oxidation resistance at 650-700 DEG C, and is low in production cost and obvious in cost performance advantage. The alloy comprises the following chemical components of: C, Cr, Fe, Co, Mo, W, Al, Si, Ti andNi; and the content of the components is as follows: the content of C is smaller than 0.08% and greater than 0, the content of Cr is smaller than or equal to 18% and greater than or equal to 14%, thecontent of Fe is smaller than or equal to 48% and greater than or equal to 37%, the content of Al and Si is smaller than or equal to 3.0% and greater than or equal to 0.5%, the content of Ti is smaller than or equal to 2.2% and greater than or equal to 2%, the content of Co is smaller than or equal to 1.5%, the content of Mo and W is smaller than or equal to 1.5% and greater than or equal to 0.4%, and the balance is Ni. During steam oxidation of the alloy in a range of 650-700 DEG C, a compact oxide layer containing a chromium oxide / aluminum oxide double-layer structure is obtained through selective oxidation.

Owner:HUANENG POWER INTERNATIONAL +1

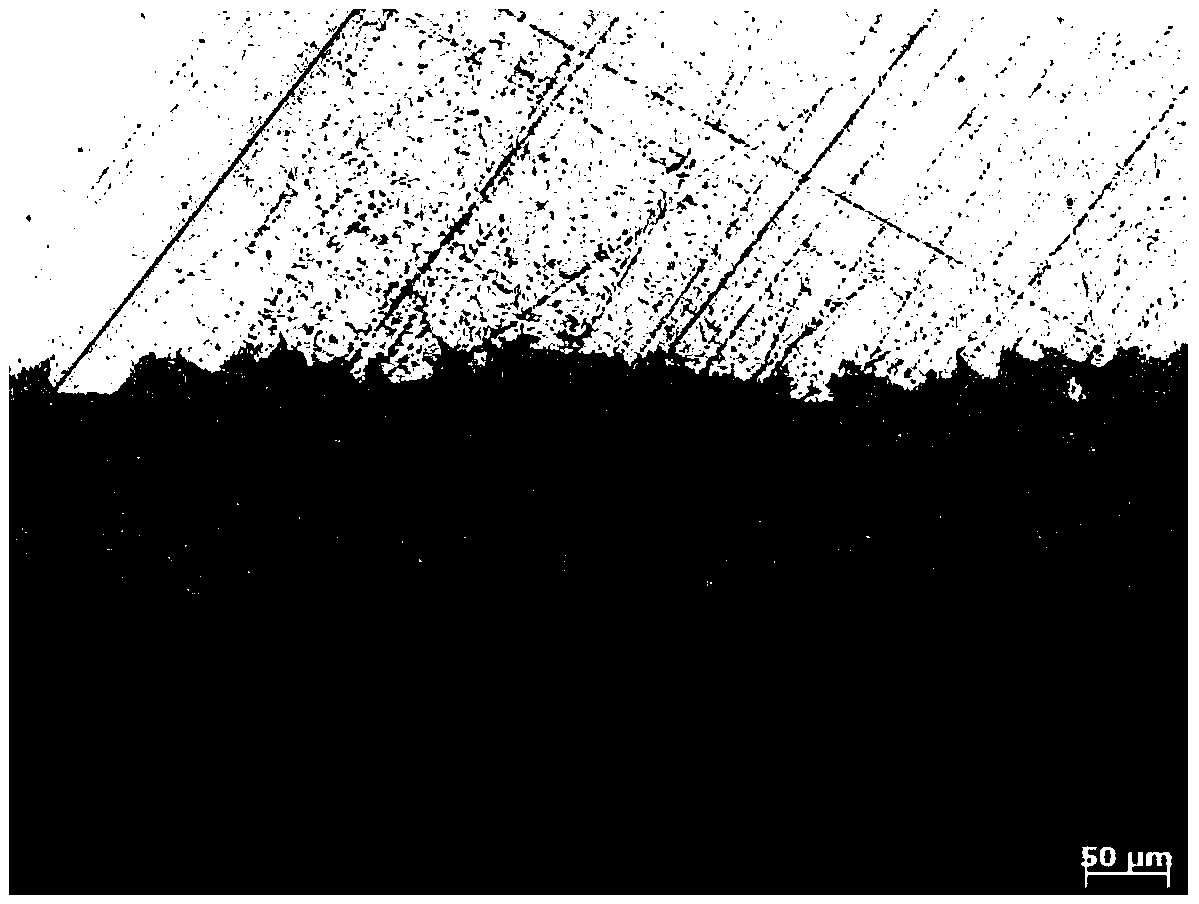

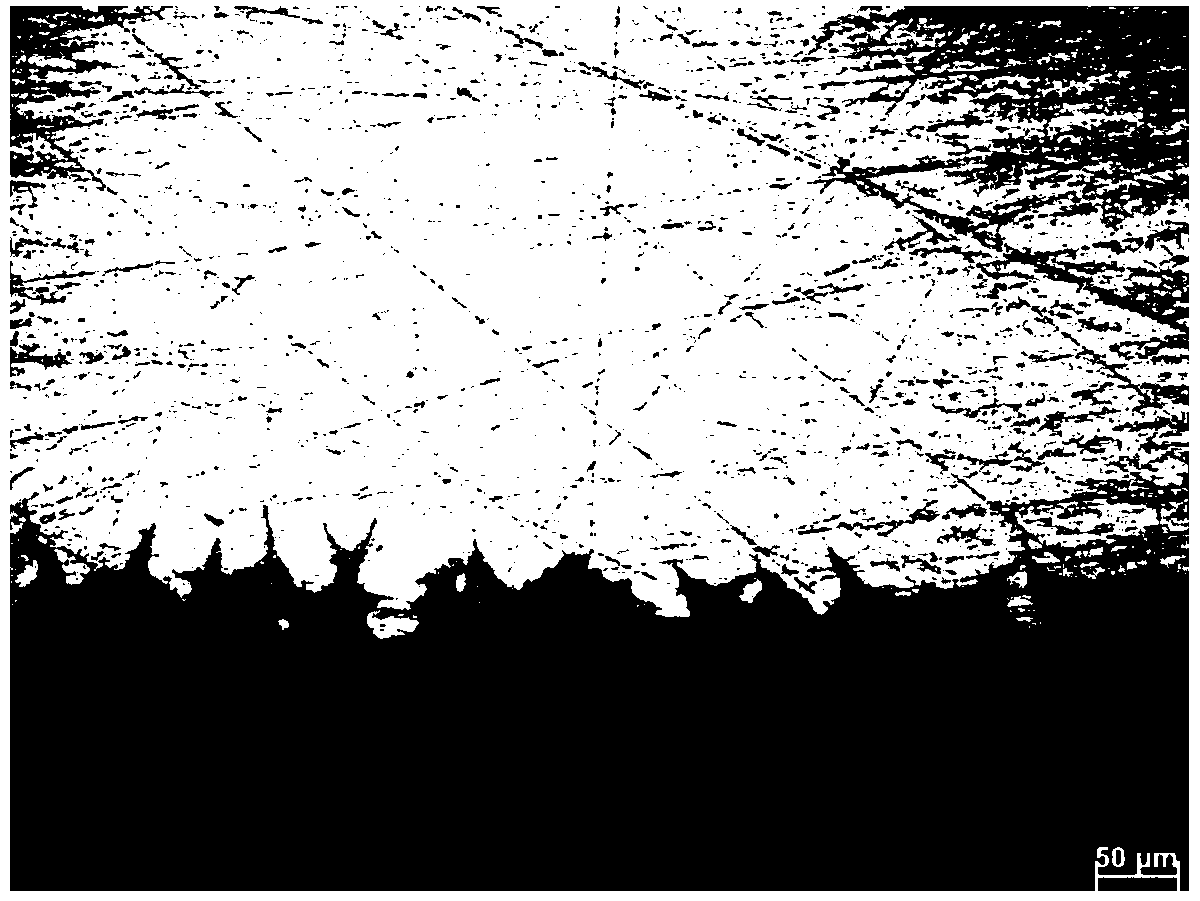

Economical long-perforation-service-life top for seamless steel pipe and manufacturing method of top

ActiveCN110616364ALow costImprove bindingMandrelsSolid state diffusion coatingChemical compositionMetallurgy

The invention relates to an economical long-perforation-service-life top for a seamless steel pipe and a manufacturing method of the top. The chemical components of the top are prepared from, by mass,0.15-0.25% of C, 0.20-0.50% of Si, 0.60-1.60% of Mn, 0.50-1.00% of Cr, 2.80-3.20% of Ni, 0.20-0.40% of Mo and the balance Fe and other unavoidable impurities. The surface of the top is generated witha layer of oxidation film, the thickness of the oxidation film is 80-200 microns, and metal particles with rich Ni are dispersed in the oxidation film. The oxidation film and a substrate are bound ina canine tooth staggering mode, the canine tooth density of the top is higher than that of a traditional top, it is sufficiently explained that the binding force of the oxidation film and the substrate is high, and therefore the oxidation film does not easily fall off in the top perforation process. The perforation service life of the top is greatly prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD

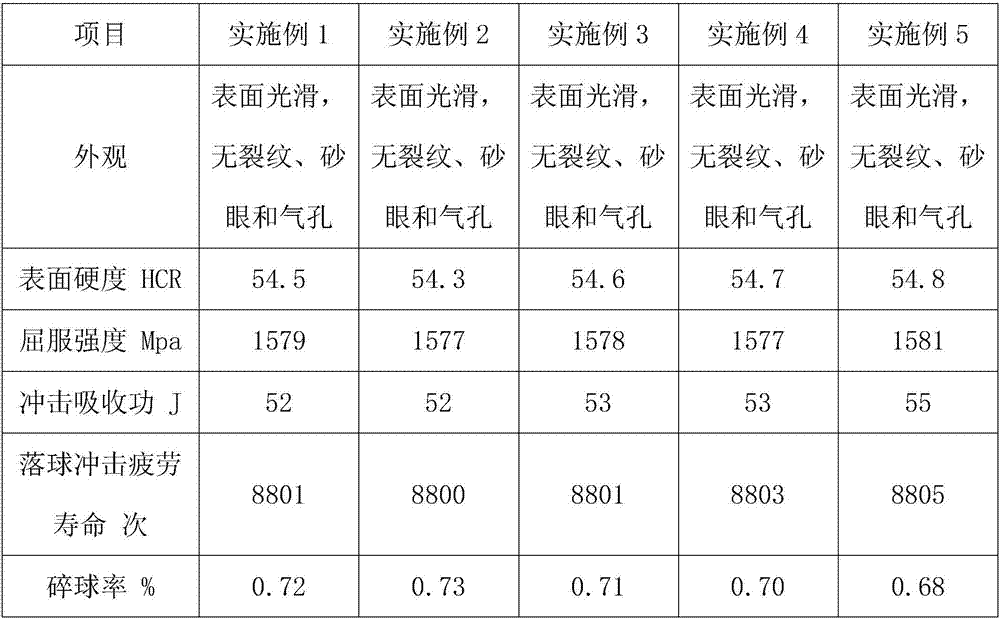

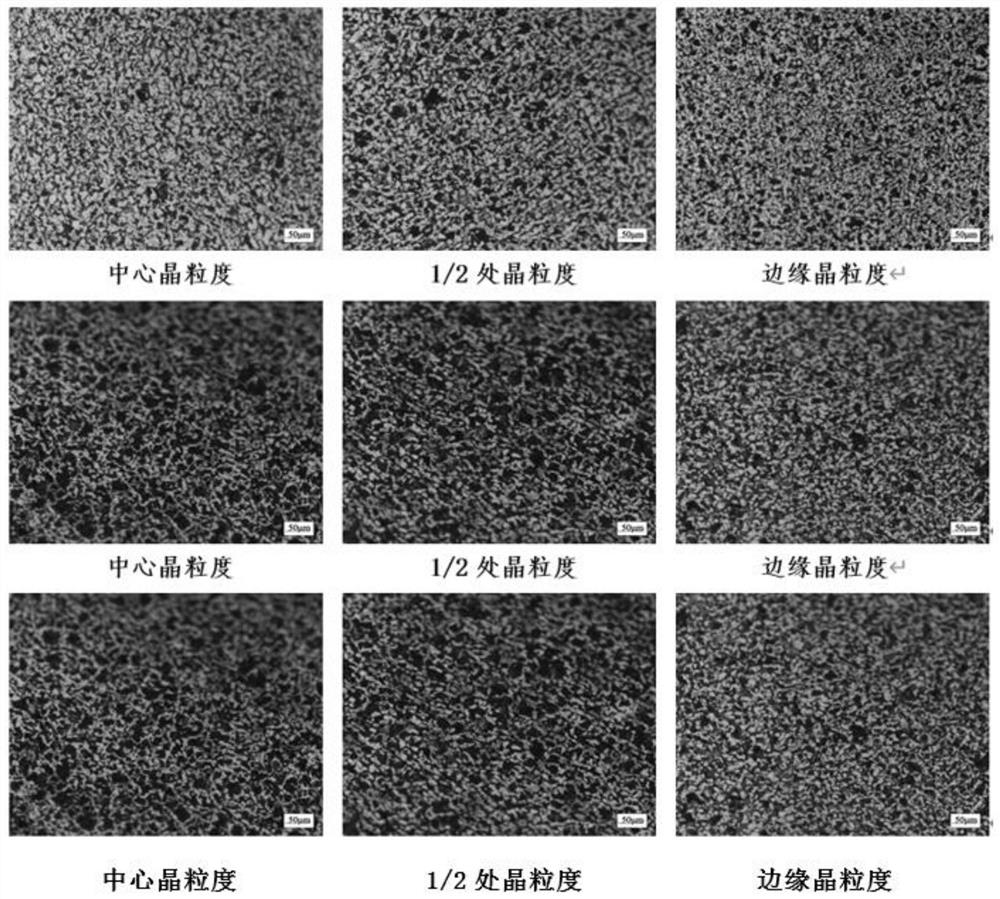

High-hardness low-carbon bearing steel ball

InactiveCN107012405APromote precipitationImprove stabilitySolid state diffusion coatingFurnace typesSteel ballUltimate tensile strength

The invention discloses a high-hardness low-carbon bearing steel ball. The high-hardness low-carbon bearing steel ball comprises the following components by weight percent: 0.1% to 0.2% of C, 13% to 14% of Cr, 1% to 1.5% of W, 3% to 4% of Co, 0.22% to 0.28% of V, 0.3% to 0.4% of Si, 0.1% to 0.3% of Mn, 0.2% to 0.3% of Ni, 0.006% to 0.008% of B, 0.015% or less of S, 0.015% or less of P, and Mo, and the balance being Fe, wherein Mo weight percent equals to Ni weight percent * (Co weight percent-W weight percent)* 100. The high-hardness low-carbon bearing steel ball is high in hardness, high in strength, good in toughness and good in fatigue resistance.

Owner:芜湖市永帆精密模具科技有限公司

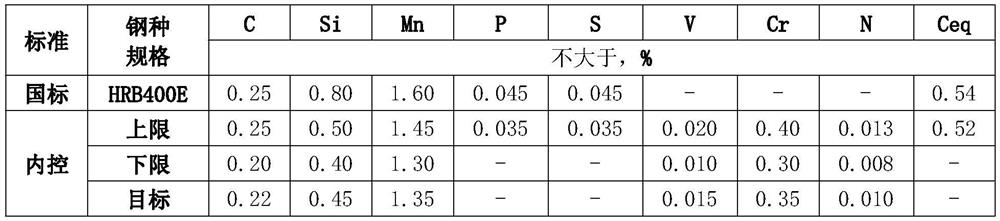

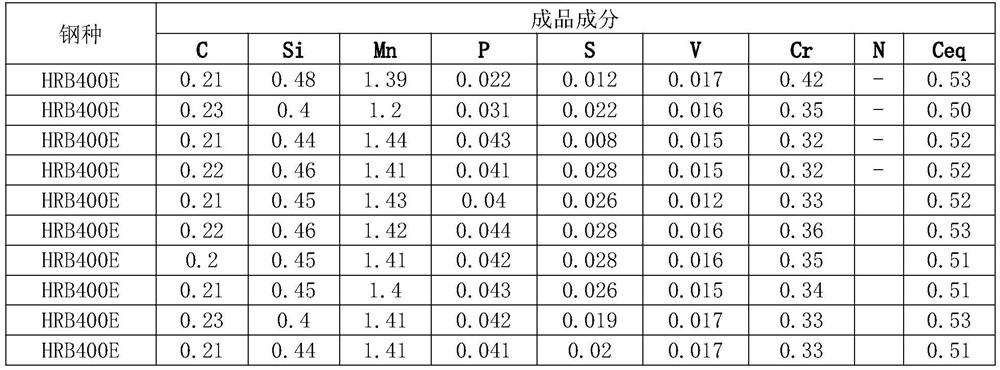

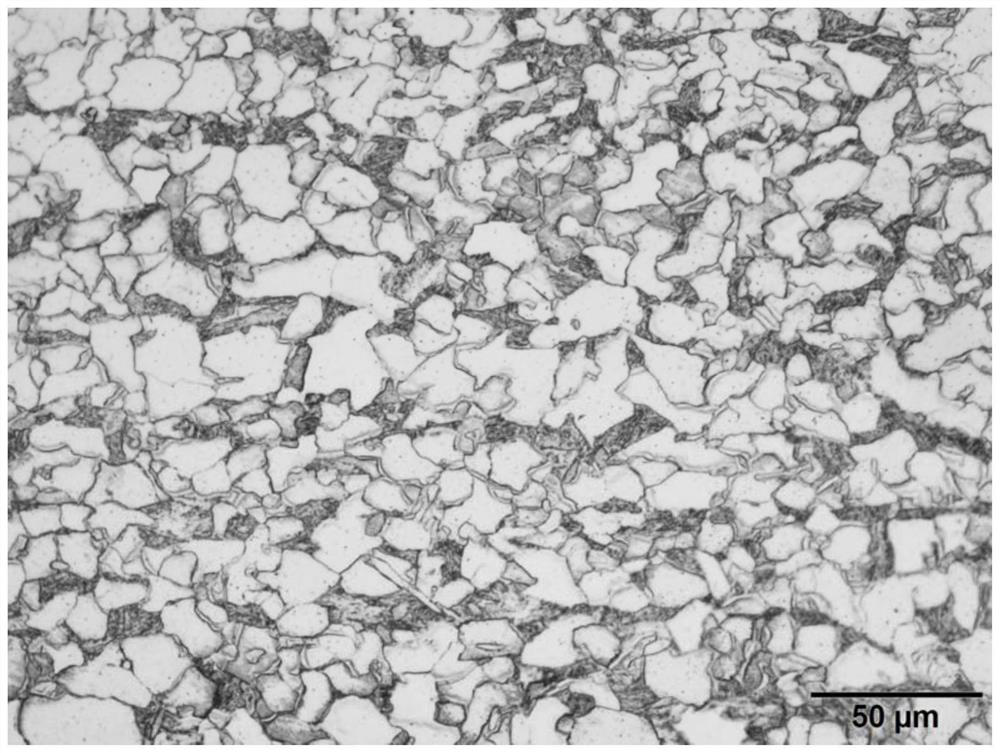

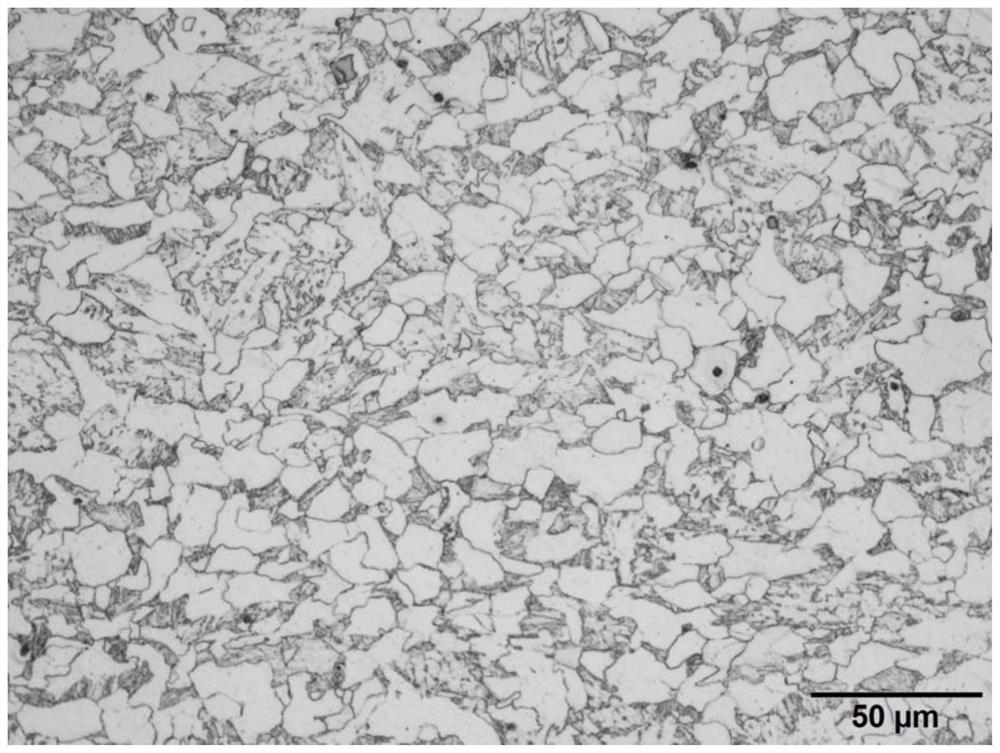

HRB400E ribbed steel bar produced by replacing vanadium with chromium and method

The invention provides an HRB400E ribbed steel bar produced by replacing vanadium with chromium and a method. The HRB400E ribbed steel bar produced by replacing the vanadium with the chromium comprises the following components of, in percentage by weight, 0.20% to 0.25% of C, 0.40% to 0.50% of Si, 1.30% to 1.45% of Mn, 0.010% to 0.020% of V, 0.30% to 0.40 of Cr, P less than or equal to 0.035%, S less than or equal to 0.035%, 0.008% to 0.013% of N, Ceq less than or equal to 0.52% and the balance Fe and residual elements. The method comprises the following steps of 65t converter smelting, 70t LF refining, 170 * 170 mm continuous casting, heating in a heating furnace, high-pressure water descaling, rolling through 18 continuous rolling units, cooling through a cooling bed, shearing, test, inspection, packaging and finished product delivery. According to the method involved in the invention, through the procedures of heating, rolling and cooling control, low-temperature heating and the like, the purpose of controlling the growth degree of austenite is achieved, and therefore austenite grains are refined, finally, a microstructure is controlled, the strength and plasticity of the steel bar are improved, the performance of steel is stabilized, and the purpose of rolling is to crush the austenite grains, so that the purpose of refining the grains is achieved.

Owner:青海西钢特殊钢科技开发有限公司 +1

A kind of low-alloy high-strength high-weathering structural steel for highway guardrail and preparation method thereof

ActiveCN112647018BGood weather resistanceImprove mechanical propertiesTemperature control deviceFurnace typesAlloyPearlite

The invention relates to the field of manufacturing structural steel for highway guardrails, in particular to a low-alloy, high-strength, high-weathering structural steel for highway guardrails and a preparation method thereof. In terms of mass percentage, the chemical composition of structural steel is: C≤0.12%; Si≤0.65%; Mn≤1.20%; P: 0.07~0.12%; S≤0.030%; Cu: 0.20~0.55%; Cr: 0.30~1.25 %; Ni: 0.12~0.65%; Nb≤0.03%; Al≤0.05%, Fe is the balance. On the basis of the existing low-alloy high-strength weather-resistant steel, the present invention improves the compactness of the rust layer by optimizing the P element, thereby improving the weather-resistant performance of the structural steel; increasing the Cr content, increasing the compactness of the rust layer and the pearlite content, and improving the structure The weather resistance and mechanical properties of steel; increase the Nb element, refine the grain size of steel, and improve the comprehensive mechanical properties of materials. The invention can meet the requirements of the road guardrail on weather resistance and strength performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Solder and Repair Welding Method for Casting Defects of K418b Superalloy Guide

ActiveCN112453754BImprove high temperature performancePromote formationArc welding apparatusWelding/cutting media/materialsWeld seamSuperalloy

The invention belongs to the field of welding technology, and relates to a solder used for casting defects of a K418B superalloy guide and a repair welding method; the solder composition and mass percentage are: C: 0.03-0.07; Cr: 21.5-24.0; Nb: 3.2-4.2 ; Mo: 8.5~10.5; Ti: 0~0.5; Al: 0~0.5; P: ≤0.015; S: ≤0.015; O: ≤0.015; N: ≤0.01; Frequency pulse argon arc welding technology, supplemented by pre-weld preheating, post-weld slow cooling and post-weld spot shot peening, can repair casting defects on the guide, and can be used for K418B casting superalloy casting shrinkage porosity, shrinkage cavity, Repair welding of defects such as undercasting, wear and cracks; the welding fluidity of the solder is good, the weld shape is good, the repaired welding joint has no cracks and unfused defects after fluorescence and X-ray inspection, and the average strength of the repaired welding joint at room temperature reaches 885MPa, It is better than the technical requirements of the part material standard.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com