Low-cost and high-strength oxidation-resistant iron-nickel based alloy and preparation method thereof

A nickel-based alloy, low-cost technology, applied in metal material coating process, solid-state diffusion coating, coating and other directions, can solve the problems of unfavorable oxidation resistance of alloys, unsatisfactory corrosion resistance, difficult processing, etc., and achieve excellent Enhanced effect of steam oxidation resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

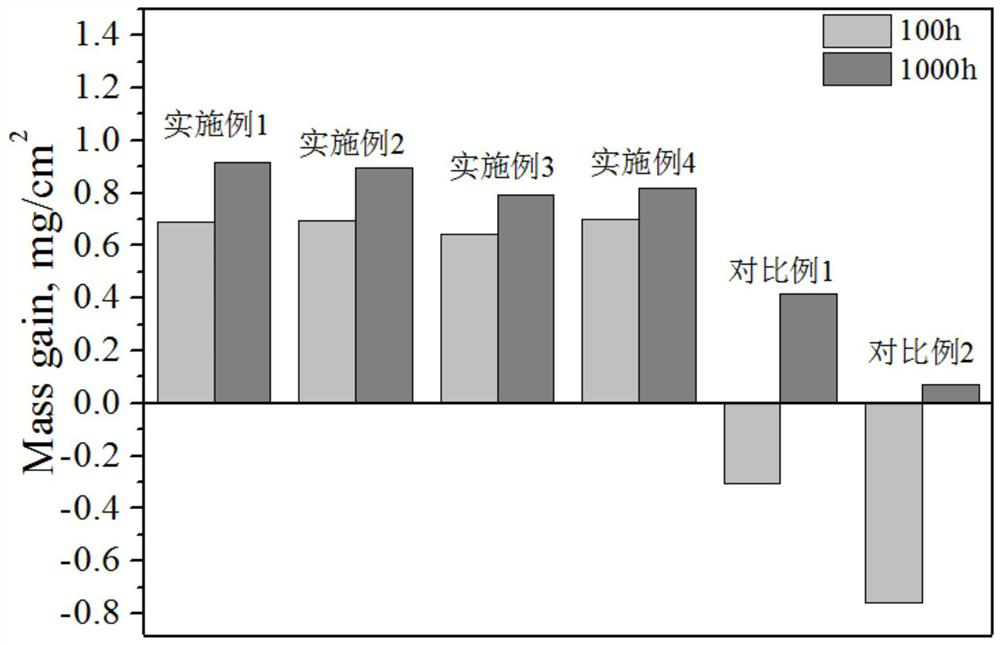

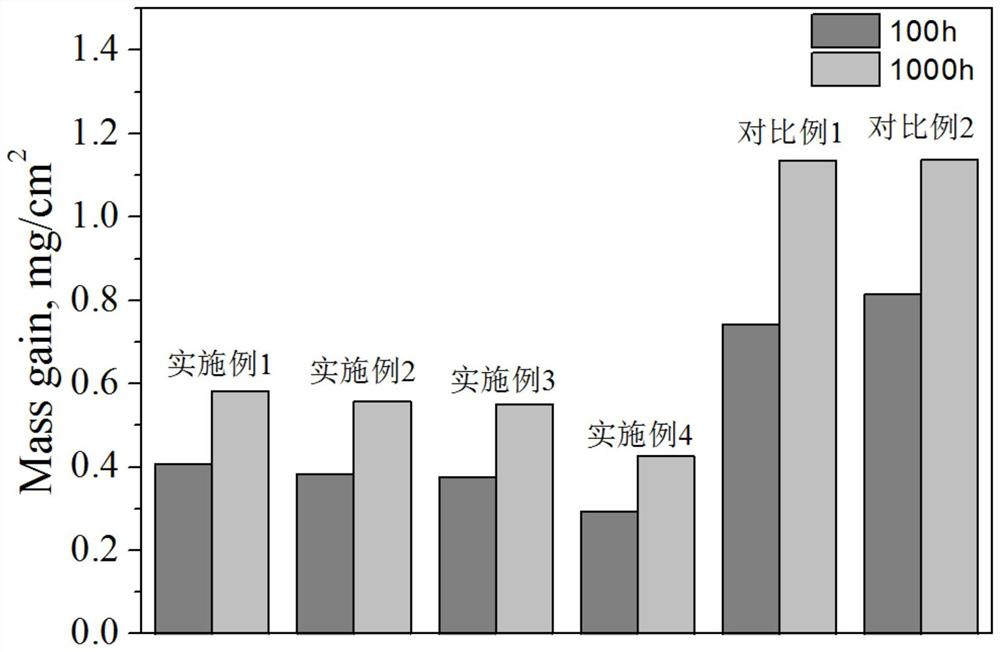

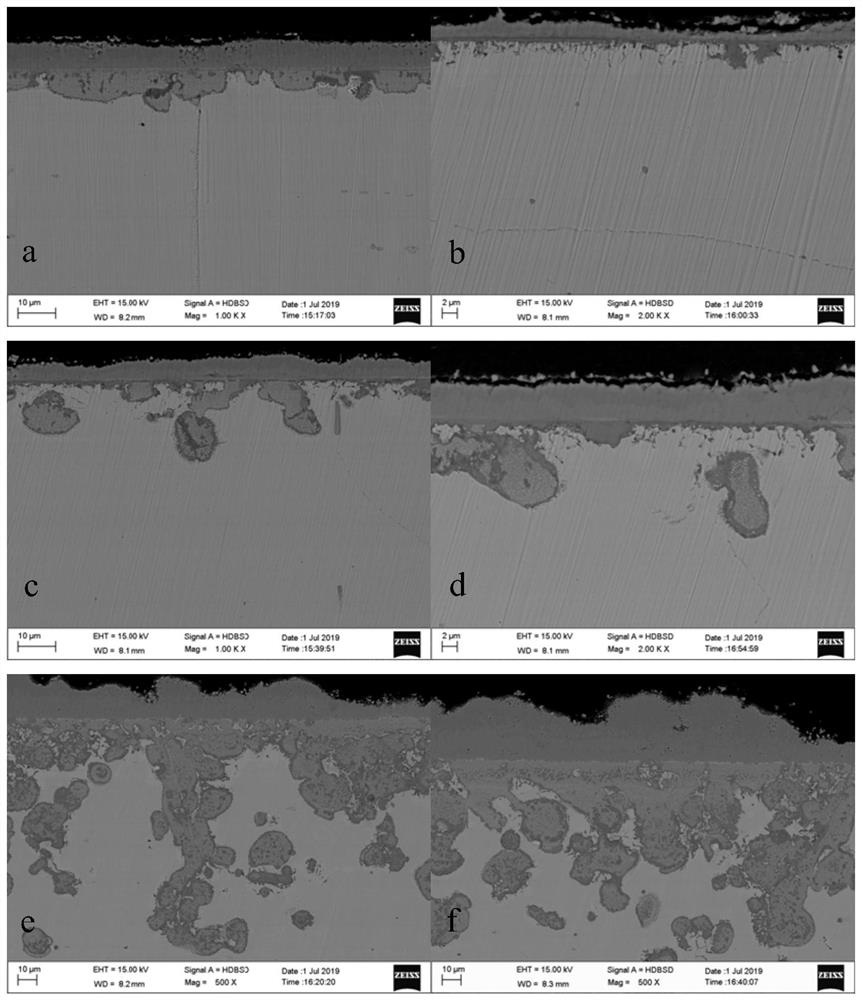

[0030] A low-cost, high-strength steam-resistant iron-nickel-based alloy of the present invention mainly includes the following chemical components: C, Cr, Fe, Co, Mo, W, Al, Si, Ti and Ni; wherein, by mass fraction, 0<C <0.08%, 14%≤Cr≤18%, 37%≤Fe≤48%, 0.5%≤Al+Si≤3.0%, 2%≤Ti≤2.2%, Co≤1.5%, 0.4≤Mo+W≤1.5 %, the balance being Ni. During the steam oxidation of the alloy in the range of 650-700 ° C, a dense oxide layer containing chromium oxide / alumina double-layer structure can be obtained through selective oxidation, thereby achieving excellent oxidation resistance. After 1000 hours of steam oxidation at 700°C, the maximum thickness of the oxide layer does not exceed 4 μm. It has good strength, low production cost, and obvious cost-effective advantages.

[0031] A further improvement of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com