Header of 630 DEG C steam parameter ultra-supercritical unit boiler

An ultra-supercritical unit and steam parameter technology, which is applied in the header field, can solve the problems that the safe operation reliability of the unit cannot be guaranteed, and the anti-steam oxidation performance cannot meet the requirements of use, so as to improve the anti-steam oxidation performance and the anti-steam oxidation performance. Good, the effect of reducing the wall thickness of the header

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

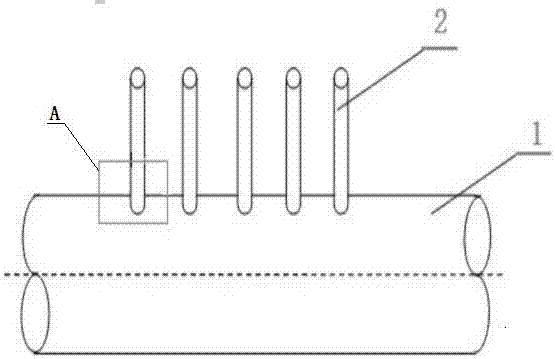

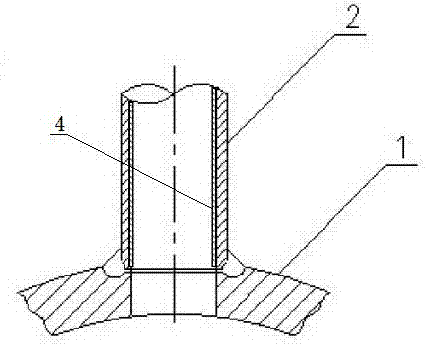

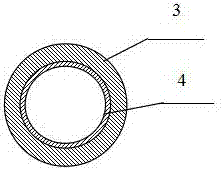

[0017] A header for a 630°C steam parameter ultra-supercritical unit boiler, which consists of: a header body and a header pipe joint, one end of the pipe joint is welded to the high-temperature heating surface tube, and the other end is plugged into the header body Full-penetration fillet seam welding, the header body adopts G115 large-diameter pipe, and the pipe joint adopts G115 small-diameter pipe with nickel-based alloy P87 laser cladding on the inner wall of the pipe joint.

Embodiment 2

[0019] According to the header of the 630°C steam parameter ultra-supercritical unit boiler described in Example 1, the main component of the G115 material is iron, the Cr content in the alloy composition is 9.0%, the W content is 3.0%, and the Co content is 3% %, the G115 metallographic structure of the material is tempered martensite.

Embodiment 3

[0021] According to the header of the 630°C steam parameter ultra-supercritical unit boiler described in Example 1 or 2, the thickness of the laser cladding nickel-based alloy P87 is 0.3mm, and the main body of the laser cladding nickel-based alloy P87 is The composition is nickel, the content of Cr in the alloy composition is 9.0%, the content of Mo is 2.0%, the content of Nb is 1%, and the content of Fe is 38%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com