Powder material suitable for laser cladding reinforcement of cutting pick sheath layer

A technology of laser cladding and powder materials, applied in metal material coating process, coating, transportation and packaging, etc., can solve problems such as alloy head peeling and tooth body wear, increase hardness and toughness, save use cost, Excellent red hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

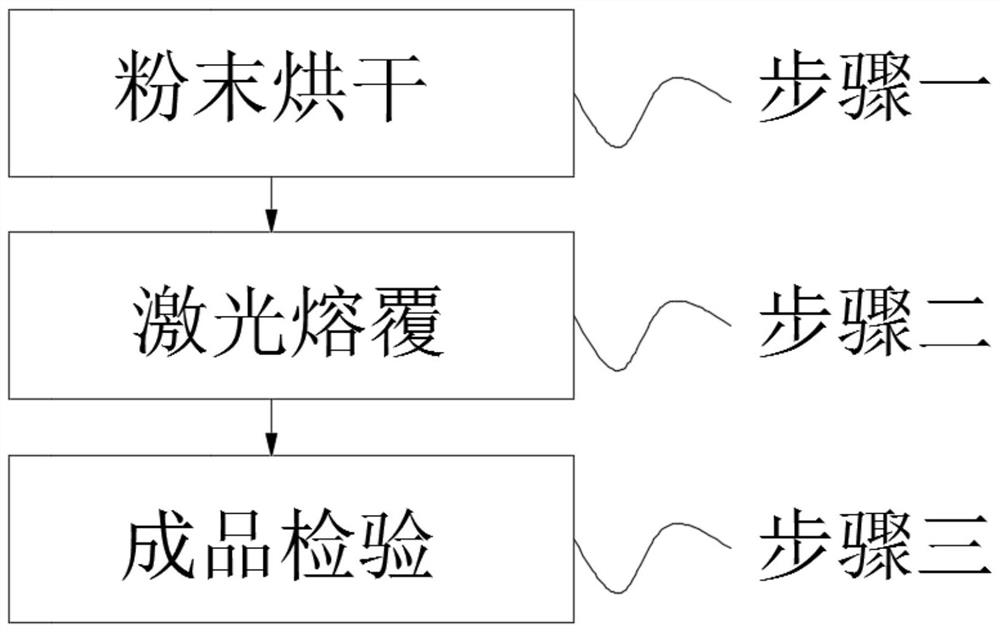

Method used

Image

Examples

Embodiment 1

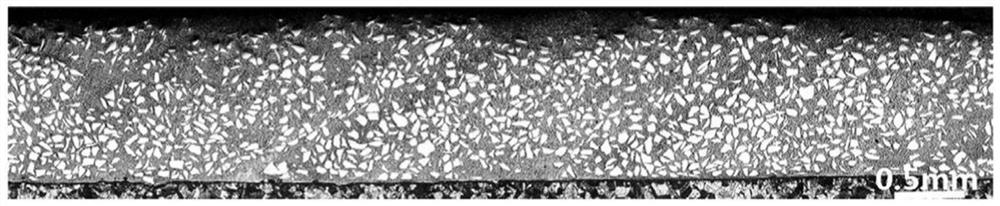

[0023] A powder material suitable for laser cladding strengthening of the sheath layer of the pick. The material components used for cladding include: C, Cr, W, Mo, Ti, Nb, Fe and other alloying elements; the specific composition is: 0.6wt%C , 13wt% Cr, 2wt% W, 1wt% Mo, 0.2wt% Ti, 0.1wt% Nb and 83.1wt% Fe, and the powder was prepared by vacuum atomization, inert gas protection gas atomization and water atomization Prepared by one of the powder methods, the powder is spherically distributed, the sphericity is ≥80%, and the oxygen content is ≤180ppm. The powder is strengthened by martensitic strengthening and in-situ carbide fine dispersion precipitation, and the average hardness of the strengthening layer reaches HRC65- 67. The particle size of the powder is between 15-150 μm, the fluidity of the powder is 25-38s / 100g, the carbon content in the powder is relatively high, after the carbon melts and solidifies, it dissolves into the martensite to form a medium carbon martensite, a...

Embodiment 2

[0029] A powder material suitable for laser cladding strengthening of the sheath layer of the pick, the material components used for cladding include: C, Cr, W, Mo, Ti, Nb, Fe and other alloying elements; its specific composition is: 1wt%C, 18wt% Cr, 5wt% W, 3wt% Mo, 0.8wt% Ti, 0.4wt% Nb and 71.8wt% Fe, Fe is a pure iron block with no rust on the surface, no impurities and high purity, C, Cr, W, Mo, Ti and Nb all exist in the form of pure substances, and the purity of C, Cr, W, Mo, Ti and Nb is 99.8%, and the powder preparation adopts vacuum air atomization method, inert gas protection gas atomization method and It is prepared by one of the water atomization powder making methods, the powder is distributed in a spherical shape, the sphericity is ≥80%, and the oxygen content is ≤180ppm. The hardness reaches HRC65-67, the powder particle size is between 15-150μm, the powder fluidity is 25-38s / 100g, and the carbon content in the powder is relatively high. After the carbon melts a...

Embodiment 3

[0035] A powder material suitable for laser cladding strengthening of the sheath layer of the pick. The material components used for cladding include: C, Cr, W, Mo, Ti, Nb, Fe and other alloying elements; the specific composition is: 0.8wt%C , 15wt% Cr, 3wt% W, 2wt% Mo, 0.5wt% Ti, 0.3wt% Nb and 78.4wt% Fe, Fe is a pure iron block with no rust on the surface, no impurities, and high purity, C, Cr, W , Mo, Ti and Nb all exist in the form of pure substances, and the purity of C, Cr, W, Mo, Ti and Nb is 99.8%, and the powder preparation adopts vacuum air atomization method and inert gas protection gas atomization method It is prepared by one of the water atomization powder making methods. The powder is distributed in a spherical shape, the sphericity is ≥80%, and the oxygen content is ≤180ppm. The powder is strengthened by martensitic strengthening and in-situ carbide fine dispersion precipitation. The average hardness reaches HRC65-67, the powder particle size is between 15-150μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com