High-performance marine mooring chain steel and manufacturing method thereof

A manufacturing method and high-performance technology, applied in metal rolling and other directions, can solve problems such as unsatisfactory heat treatment process and insufficient performance of mooring chain steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

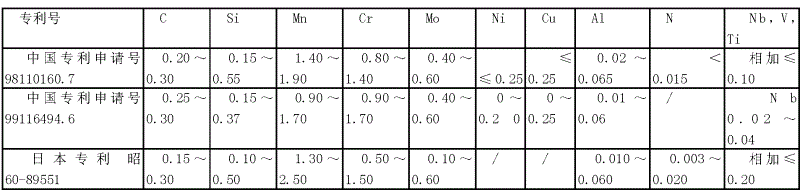

[0081] Example 3 contains niobium, and the structure coarsening temperature is increased; Example 7 has been quenched twice.

[0082] The composition of Comparative Example 1-1 is that the Mn is higher than the upper limit, and the yield strength ratio after tempering at 600°C is unqualified and greatly exceeds 0.92.

[0083] In Comparative Example 1-2, the composition of Mn is higher than the upper limit, the tempering temperature is increased to 610°C, the tensile strength is close to the lower limit of the fifth-grade steel, and the yield strength ratio is still unqualified.

[0084] The composition of Comparative Example 1-3 is that Mn is higher than the upper limit, and the tempering temperature is increased to 620°C, the tensile strength is lower than the lower limit of the fourth-grade semi-steel, which is unqualified; the yield ratio is still unqualified.

[0085] The composition of Comparative Example 2-1 is that Cr is lower than the lower limit, and the yield strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com