High-nitrogen nickel-saving type duplex stainless steel thin strip and preparation method thereof

A technology of duplex stainless steel and stainless steel, which is applied in the field of steel rolling, can solve problems such as poor strength and corrosion resistance of duplex stainless steel strips, poor coordination of two-phase deformation, and pore defects, and achieve excellent mechanical properties and corrosion resistance. Effect of element segregation and simplification of hot rolling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

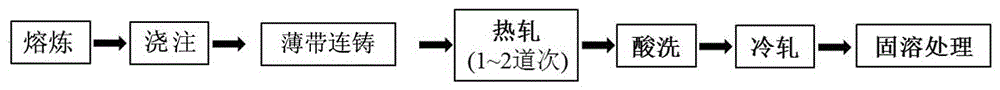

[0027] A high-nitrogen nickel-free duplex stainless steel thin strip, the composition of which is: C=0.015%; Cr=23.2%; Ni=0.01%; Mn=7.1%; N=0.56%; the balance is iron and others unavoidable impurities. The specific preparation process is as figure 1 shown, follow the steps below:

[0028] (1) Select electrolytic chromium, electrolytic manganese, For pure iron and Fe(CrN) alloy, electrolytic chromium, electrolytic manganese and pure iron are smelted first, and then Fe(CrN) alloy is added for smelting to obtain molten steel;

[0029] (2) Pouring molten steel into the tundish at a pouring temperature of 1500°C;

[0030] (3) Introduce the molten steel into the molten pool, so that the molten steel is exported with the rotation of the crystallization roller to form a casting belt, wherein the rotation speed of the crystallization roller is 40m / min, and the cooling rate is ≥10 3 °C / s; the cast strip is water-cooled to room temperature within 10s after it comes out of the roll, a...

Embodiment 2

[0036] A high-nitrogen nickel-free duplex stainless steel thin strip, the composition of which is: C=0.02%; Cr=22.4%; Ni=0.03%; Mn=7.5%; N=0.48%; the balance is iron and others unavoidable impurities. The specific preparation process is as figure 1 shown, follow the steps below:

[0037] (1) Select electrolytic chromium, electrolytic manganese, For pure iron and Fe(CrN) alloy, electrolytic chromium, electrolytic manganese and pure iron are smelted first, and then Fe(CrN) alloy is added for smelting to obtain molten steel;

[0038] (2) Pouring molten steel into the tundish at a pouring temperature of 1480°C;

[0039] (3) Introduce the molten steel into the molten pool, so that the molten steel is exported with the rotation of the crystallization roller to form a casting belt, wherein the rotation speed of the crystallization roller is 50m / min, and the cooling rate is ≥10 3 °C / s; the cast strip is water-cooled to room temperature within 10s after it comes out of the roll, an...

Embodiment 3

[0045] A high-nitrogen nickel-free duplex stainless steel thin strip, the composition of which is: C=0.018%; Cr=25.1%; Ni=0.02%; Mn=9.7%; N=0.62%; the balance is iron and others unavoidable impurities. The specific preparation process is as figure 1 shown, follow the steps below:

[0046] (1) Select electrolytic chromium, electrolytic manganese, For pure iron and Fe(CrN) alloy, electrolytic chromium, electrolytic manganese and pure iron are smelted first, and then Fe(CrN) alloy is added for smelting to obtain molten steel;

[0047] (2) Pouring molten steel into the tundish at a pouring temperature of 1520°C;

[0048] (3) Introduce the molten steel into the molten pool, so that the molten steel is exported with the rotation of the crystallization roller to form a casting belt, wherein the rotation speed of the crystallization roller is 60m / min, and the cooling rate is ≥10 3 °C / s; the cast strip is water-cooled to room temperature within 10s after it comes out of the roll, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com