Method for preparing Fe-Mn-Si shape memory alloy coating via laser cladding

A fe-mn-si, laser cladding technology, applied in the field of alloy coating, can solve the problems of not completely preventing cracks, lack of theoretical breakthroughs, etc., and achieve the effect of low residual stress, excellent comprehensive mechanical properties, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

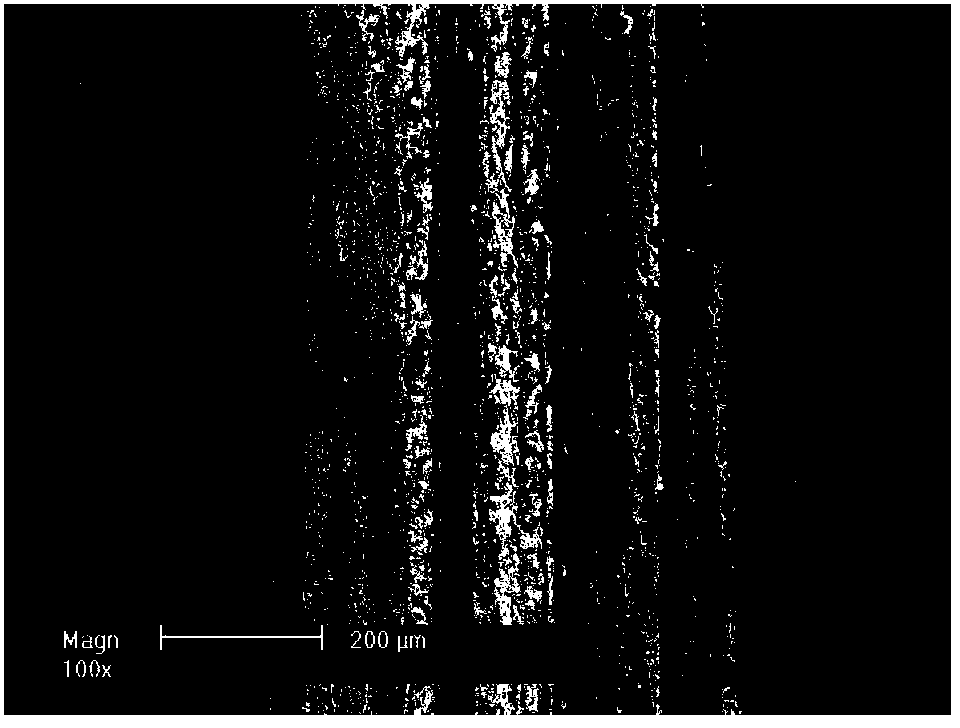

Embodiment 1

[0046] The raw material powder is configured according to the following mass percentages: 17% manganese powder, 5% silicon powder, 10% chromium powder, 5% nickel powder, 0.5% vanadium powder, La 2 o 32% powder, 2% quartz, 2.5% wood powder, 3% starch, and the rest is pure iron powder. Pour the proportioned powder into the ball mill, and the ball milling time is 4h. Before cladding, the cladding powder needs to be vacuum-dried at 150℃×2h, and then the powder is pre-washed with a scraper with a groove of 1.5mm×10mm×45mm. Place it on the base material with a preset thickness of 1.5mm, use a laser with a power of 2.5Kw and a laser spot diameter of 3mm to clad the above powder, the scanning speed is 800mm / min, and the overlapping rate of multi-pass cladding is 50%.

Embodiment 2

[0048] Carry out embodiment 1 repeatedly by the same step as described, but configure raw material powder by following mass percentage in embodiment 2: manganese powder 17%, silicon powder 5%, chromium powder 10%, nickel powder 5%, all the other compositions are pure Iron powder.

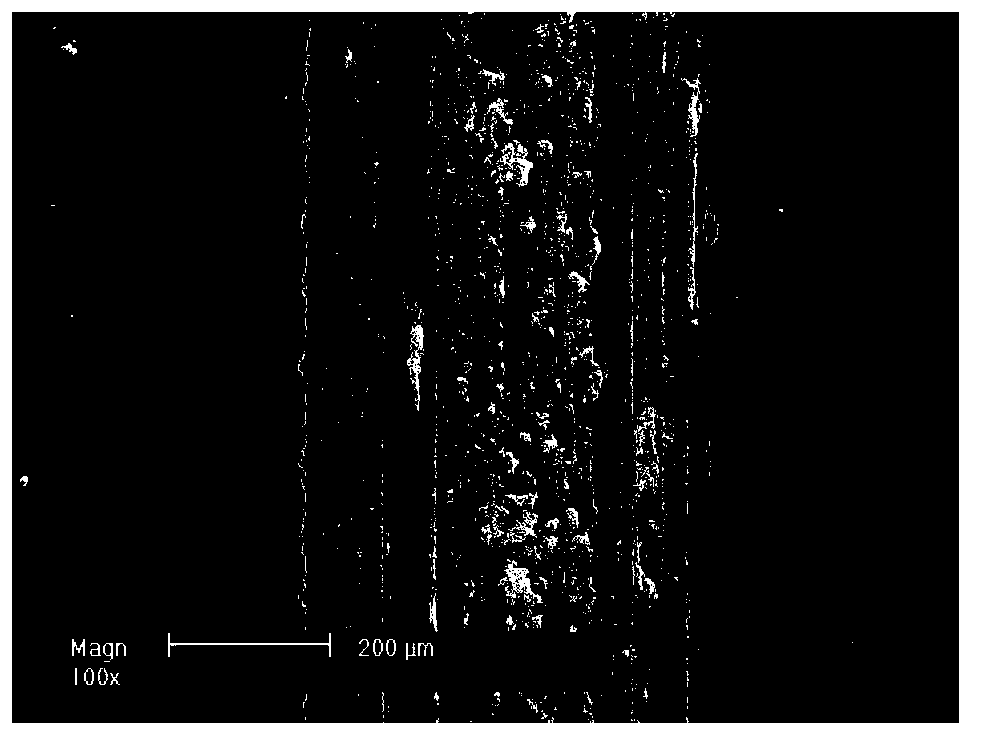

Embodiment 3

[0050] Carry out embodiment 1 repeatedly by described same step, but configure raw material powder by following mass percent in embodiment 3: manganese powder 17%, silicon powder 5%, chromium powder 10%, nickel powder 5%, quartz 2%, 2.5% wood flour, 3% starch, and the rest are pure iron powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com