HRB400E ribbed steel bar produced by replacing vanadium with chromium and method

A ribbed steel bar, hot-rolled ribbed steel bar technology, applied in the field of metallurgy, can solve problems such as insignificant effect, low yield strength, and large proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

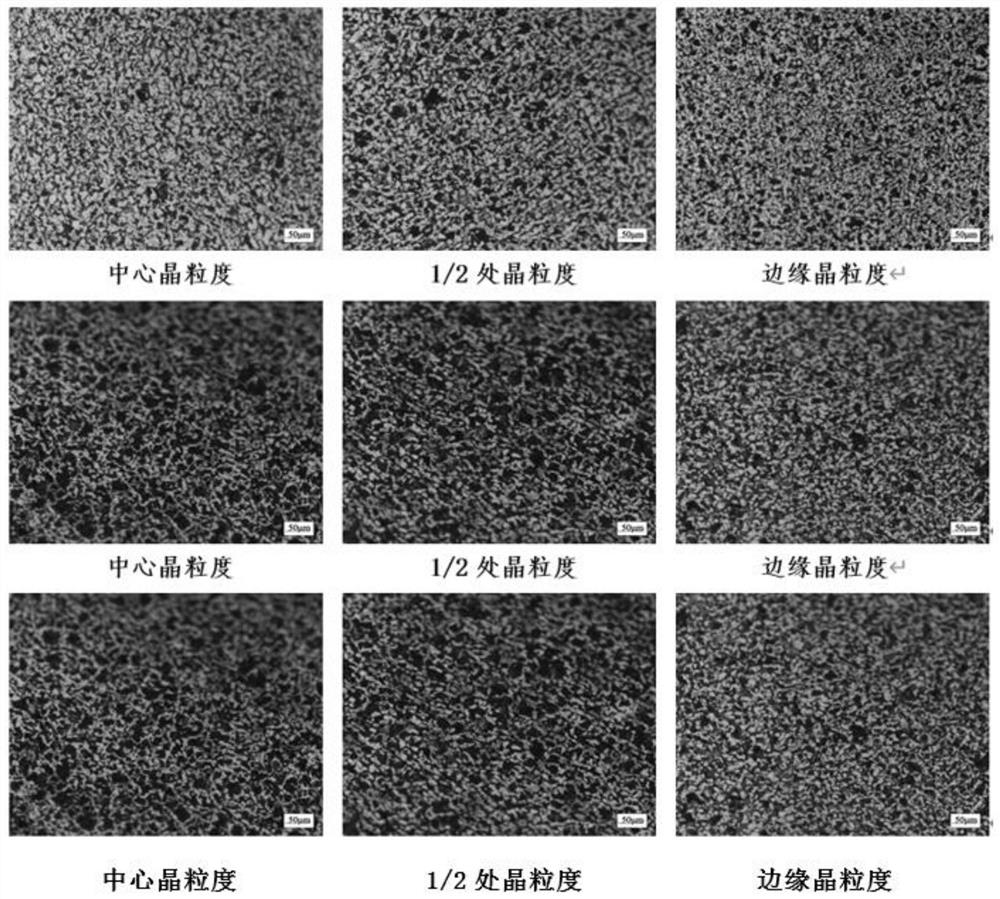

Image

Examples

Embodiment

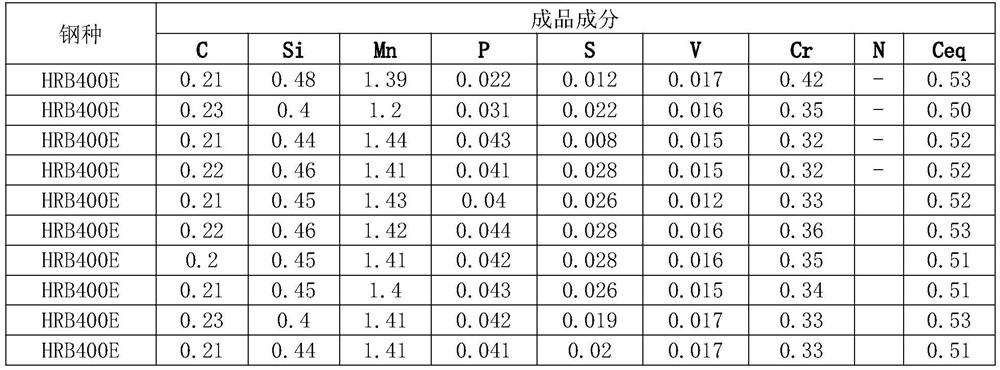

[0032] This example relates to a method for producing HRB400E ribbed steel bars by substituting chromium for vanadium, including: 65t converter smelting→70t LF refining→170×170mm continuous casting→heating furnace heating→high pressure water descaling→rolling by 18 continuous rolling mills → cooling bed cooling → cutting → inspection → inspection → packaging → delivery of finished products.

[0033] The performance parameters of the HRB400E ribbed steel bar finally produced in the embodiment of the present invention are: the yield strength of the steel bar is 430-490 MPa, the tensile strength is 540-650 MPa, the elongation after fracture A≥18%, and the maximum elongation Agt≥12%.

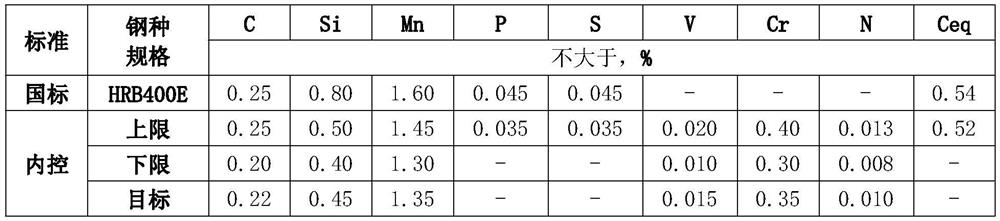

[0034] The main measures taken in the embodiment of the present invention are precipitation strengthening and fine-grain strengthening by replacing some vanadium microalloying elements with chromium alloys. The nitrogen content in the steel is required to be within the range of 80ppm to 130ppm. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com