Cold heading steel wire rod for annealing-free 10.9-grade fastener and manufacturing method of cold heading steel wire rod

A manufacturing method and technology of cold heading steel, applied in the field of cold heading steel, can solve the problems of increasing product difficulty and failing to meet 10.9 level fasteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

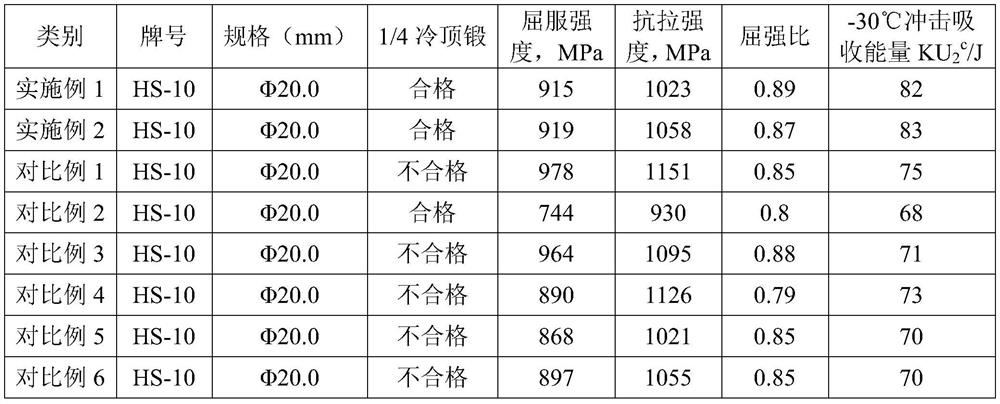

Examples

Embodiment 1

[0030] 1. Composition design

[0031] The chemical composition is designed by weight percentage as C: 0.25%, Si: 0.05%, Mn: 0.99%, Cr: 0.44%, Al: 0.037%, P: 0.012%, S: 0.011%, Ni: 0.02%, Cu : 0.09%.

[0032] 2. Converter smelting

[0033] Steel-making raw materials are added to the converter (steel-making raw materials are molten iron, pig iron and scrap steel, wherein pig iron accounts for 93% of the total weight of steel-making raw materials, scrap steel accounts for 7% of the total weight of steel-making raw materials, and the total loading of steel-making raw materials is 125t / furnace ), bottom-blown argon stirring in the whole process of smelting converter smelting, tapping temperature is 1590°C, tapping C is controlled at 0.09-0.11%, tapping P, S≤0.010%; Carbon agent, slag.

[0034] 3. LF refining

[0035]In the early stage of the LF refining process, aluminum particles are used to strengthen deoxidation and desulfurization, and aluminum wires are used to adjust the ...

Embodiment 2

[0043] The chemical composition in Step 1 of Example 1 is replaced by weight percentage as the chemical composition design is C: 0.29%, Si: 0.09%, Mn: 1.14%, Cr: 0.49%, Al: 0.030%, P: 0.010%, S: 0.013%, Ni: 0.06%, Cu: 0.10%, and other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com