Epoxy resin fiber reinforced concrete for repair and preparation method thereof

A technology of epoxy resin fiber reinforced concrete, which is applied in the field of new epoxy fiber reinforced concrete for repair and its preparation, can solve the problems of long curing time of repair technology, weak bonding, and difficulty in floor surface construction, etc. Achieve the effect of flexible control of thickness, not easy to peel and bulge, and ensure construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

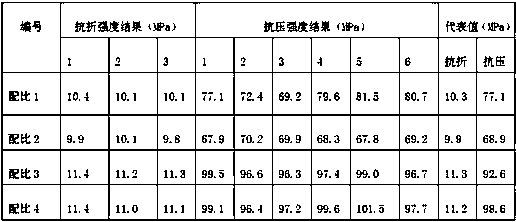

[0030] An epoxy resin fiber reinforced concrete for repair, the raw materials are refined quartz sand, epoxy resin, curing agent, basalt fiber chopped strands, the weight percentage of each component can be: refined quartz sand 55% to 70%, epoxy resin 17% to 33% resin, 9% to 11% curing agent, 1% to 4% chopped basalt fiber yarn; the content of the present invention will be further explained and supplemented in combination with the proportions of 4 examples below.

[0031] Proportion 1:

[0032] Refined quartz sand 55%,

[0033] Epoxy 33%,

[0034] Curing agent 9%,

[0035] Basalt fiber chopped strand 3%;

[0036] Proportion 2:

[0037] Refined quartz sand 60%,

[0038] Epoxy 30%,

[0039] Curing agent 9%,

[0040] Basalt fiber chopped strand 1%;

[0041] Proportion 3:

[0042] Refined quartz sand 65%,

[0043] Epoxy 17%,

[0044] Curing agent 11%,

[0045] Basalt fiber chopped strand 2%;

[0046] Proportion 4:

[0047] Refined quartz sand 70%,

[0048] Epoxy 15%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com