Preparation method of graphene film

A graphene film and metal substrate technology, applied in the field of graphene film preparation, can solve problems such as difficulty in controlling the thickness of the graphene film, uneven thickness of the graphene film, and inability to mass-produce, and achieves low production cost, short time, The effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

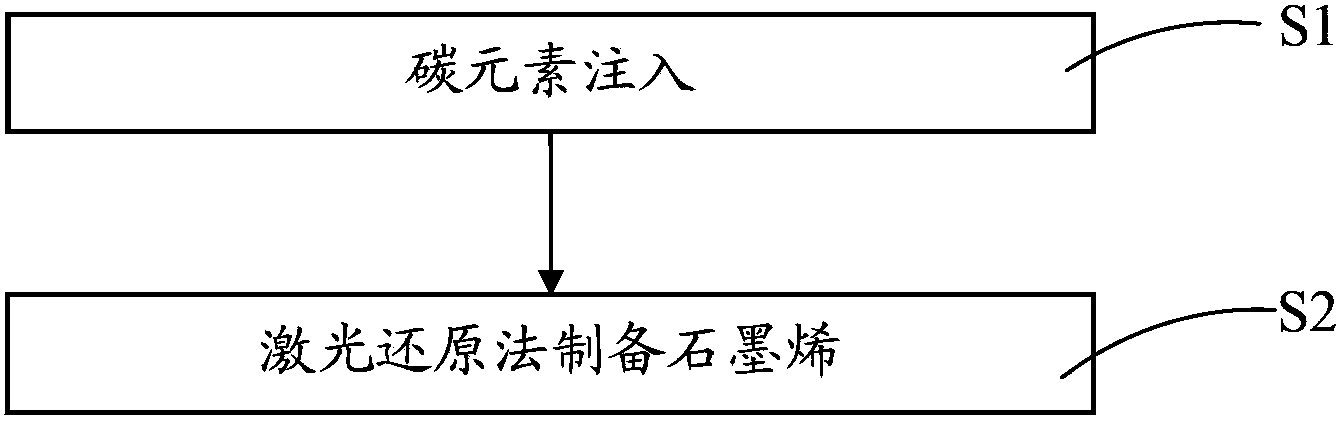

[0013] The example of the present invention provides a method for preparing a graphene film with high efficiency, low energy consumption and uniform thickness. The preparation method technological process of this graphene thin film please refer to figure 1 , including the following steps:

[0014] S01. Carbon element implantation: In an oxygen-free environment, carbon elements are implanted into the surface of the metal substrate by ion implantation; wherein, the amount of ion implantation is 1×10 -6 ~1×10 -5 g / cm 2 , the injection energy is 800-1500eV;

[0015] S02. Preparation of a graphene film: after the metal substrate is cooled, corrode it with an etching solution to obtain a graphene film.

[0016] Specifically, in the above step S01, the oxygen-free environment is to inject carbon into the surface layer of the metal substrate under oxygen-free conditions, prevent the participation of oxygen, and improve the purity of the graphene film generated in subsequent steps....

Embodiment 1

[0027] S11. First soak the 50 μm nickel foil substrate in hydrochloric acid with a concentration of 0.5mol / L for 30 minutes to remove surface impurities, then use ethanol, acetone and deionized water to ultrasonically remove oil stains for 20 minutes in an ultrasonic cleaner, and then place in a vacuum Dry in a drying oven at 80°C for 5 minutes;

[0028] S12. Take out the substrate that has been dried through the steps, and put it into the ion implantation equipment. After sealing the equipment, nitrogen gas is introduced as a protective gas. Using the method of high-speed ion implantation, carbon elements are implanted into the surface layer of the nickel foil, and the ion implantation The amount is 3×10 -6 g / cm 2 , the injection time is 5 minutes, and the injection energy is 800eV;

[0029] S13. After the ion implantation in step S12 is completed, start the cooling water circulation system to accelerate the cooling rate of the nickel foil. After the nickel foil is cooled t...

Embodiment 2

[0033]S21. First soak the 65 μm nickel foil substrate in nitric acid with a concentration of 1mol / L for 30 minutes to remove surface impurities, then use ethanol, acetone and deionized water to ultrasonically remove oil stains for 20 minutes in an ultrasonic cleaner, and then place it in vacuum drying Oven drying at 80°C for 8 minutes;

[0034] S22. Take out the substrate that has been dried through the steps, put it into the ion implantation equipment, seal the equipment and pass in argon as a protective gas, and use the high-speed ion implantation method to implant carbon elements into the surface of the nickel foil. The amount injected is 1×10 -6 g / cm 2 , the injection time is 20 minutes, and the injection energy is 1500eV;

[0035] S23. After the ion implantation in step S12 is completed, start the cooling water circulation system to accelerate the cooling rate of the nickel foil. After the nickel foil is cooled to the greenhouse, a graphene film is precipitated on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com