Preparation method of multifunctional nano-crystalline cellulose composite separation filter membrane and application thereof

A nano-cellulose, multi-functional technology, applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of high preparation cost, complicated preparation process, difficult to handle, etc., and achieve low cost and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

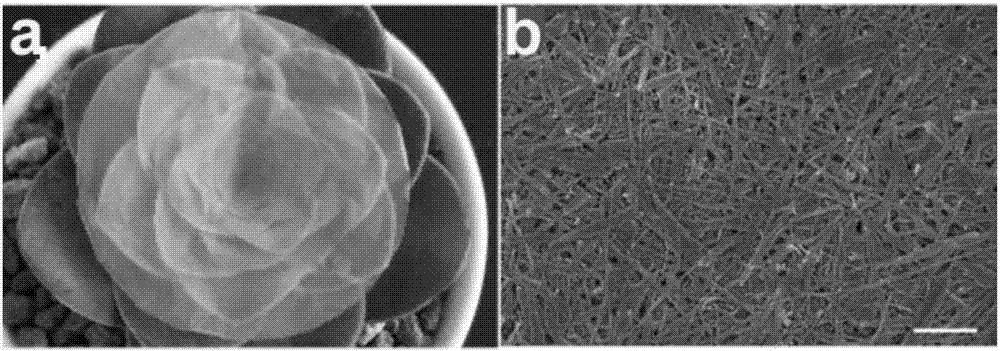

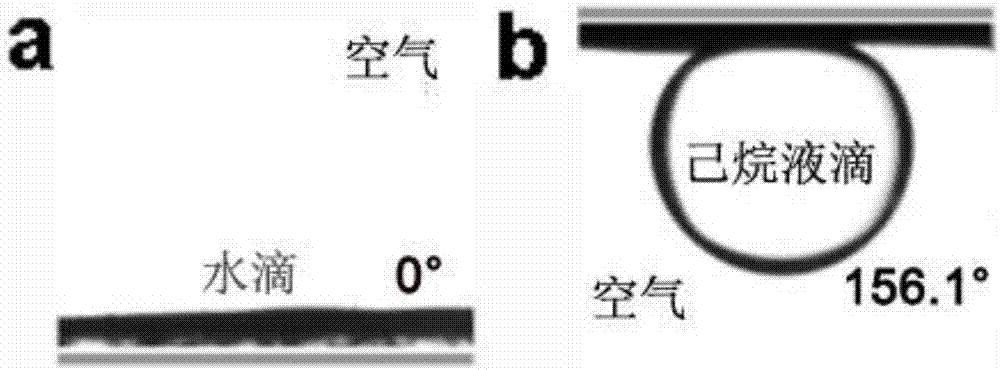

Method used

Image

Examples

Embodiment 1

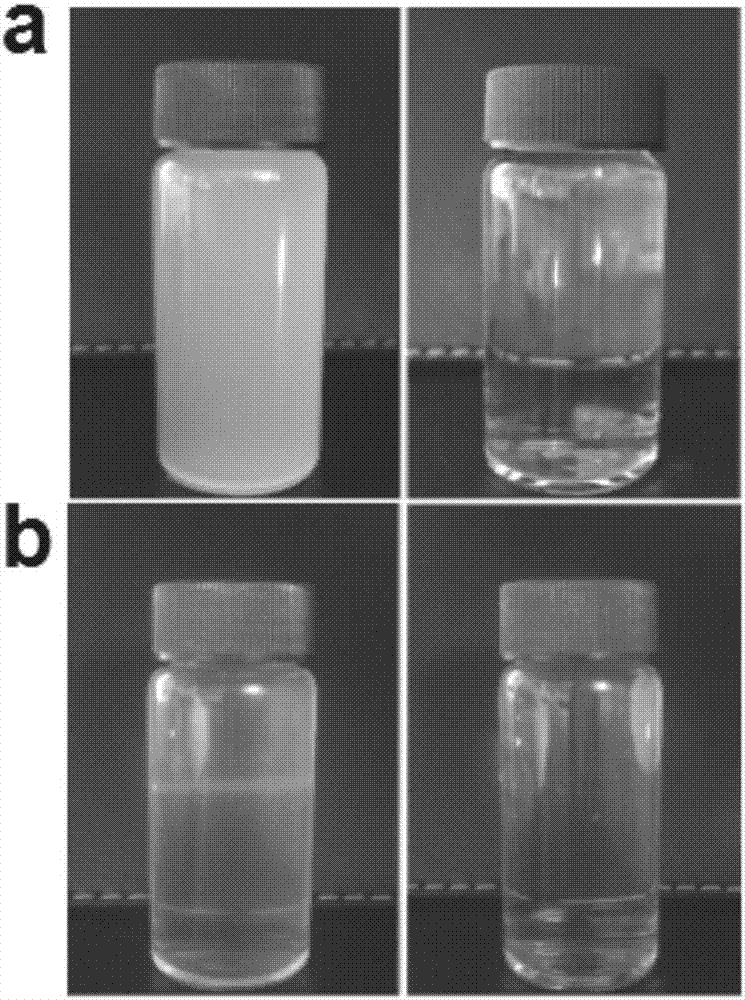

[0032] The composite nanocellulose aqueous dispersion with a mass ratio of nanocellulose to attapulgite of 1:1 is suction-filtered into a 0.34 g m -2 The nanocellulose membrane obtained. The membrane was used for oil-water emulsion separation test to separate micron-sized soybean oil emulsion. The mass ratio of soybean oil to water is 1:99. The membrane is conducive to demulsification, effectively retains emulsified oil droplets, and achieves the purpose of oil-water separation. The separation efficiency of the filter membrane is 99.9%, and the flow rate is 140.8±17.2L m -2 h -1 ·MPa -1 .

Embodiment 2

[0034] The composite nanocellulose aqueous dispersion whose mass ratio between nanocellulose and attapulgite is 1:1 is made into 1.36g m -2 nanocellulose membrane. Use this membrane to carry out the oil-water emulsion separation test, to separate the nano-scale soybean oil emulsion, first make a micron-scale emulsion with a mass ratio of soybean oil to water of 1:99, dilute it by 100 times and then process it into a nano-scale soybean oil emulsion. The film has It is conducive to demulsification, effectively intercepts emulsified oil droplets, and achieves the purpose of oil-water separation. The separation efficiency of the filter membrane is 99.9%, and the flux is 1765.9±61.5L m -2 h -1 ·MPa -1 .

Embodiment 3

[0036] The composite nanocellulose aqueous dispersion whose mass ratio between nanocellulose and attapulgite is 1:1 is made into 1.36g m -2 nanocellulose membrane. Use this membrane to carry out the oil-water emulsion separation test, to separate the nano-scale hexane emulsion, first make a micro-scale emulsion with a mass ratio of hexane to water of 1:99, dilute it by 15 times and then process it into a nano-scale hexane emulsion. The membrane has It is conducive to demulsification, effectively intercepts emulsified oil droplets, and achieves the purpose of oil-water separation. The separation efficiency of the filter membrane is 99.9%, and the flow rate is 2264.4±61.5L m -2 h -1 ·MPa -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com