Rollable annular frame type hole digging device with sliding grooves

A rolling ring and chute technology, which is applied in the field of a rolling ring frame type burrowing device, can solve the problems of inconvenient practical application, heavy equipment, and large artificial physical strength consumption, and achieves compact overall structure, flexible and convenient use, and easy portability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment the specific embodiment of the present invention is described in further detail:

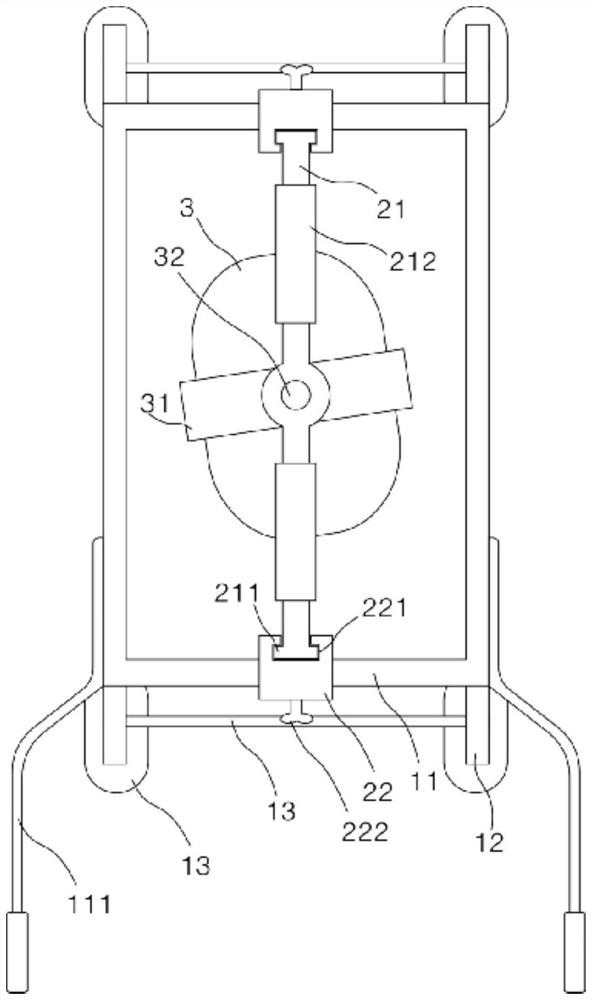

[0015] Such as figure 1 As shown, an embodiment of a rollable ring frame type hole digging device with a chute includes a rectangular frame and an excavating device arranged in the middle of the rectangular frame. The rectangular frame includes: an installation frame 11, and an The legs 12 are provided with wheels 121, the rear of the installation frame 11 is equipped with an armrest 111, the legs 12 are inclined 10 degrees to the outside, and a connecting plate 13 is arranged between the two legs 12 on the front and rear sides, and the connecting plate 13 It is arranged horizontally with the installation frame 11, and a corner plate is connected between the connecting plate 13 and the legs 12, and the corner plate forms a triangular support structure with the connecting plate 13 and the legs 12; The support rod 31 and the shaft handle 32, the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com