A kind of amyloid nanocellulose composite film and its preparation method and application

An amyloid and nanocellulose technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of high cost, no separation membrane, excessive energy and time consumption, etc., to enhance the repelling ability, promote Separation and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

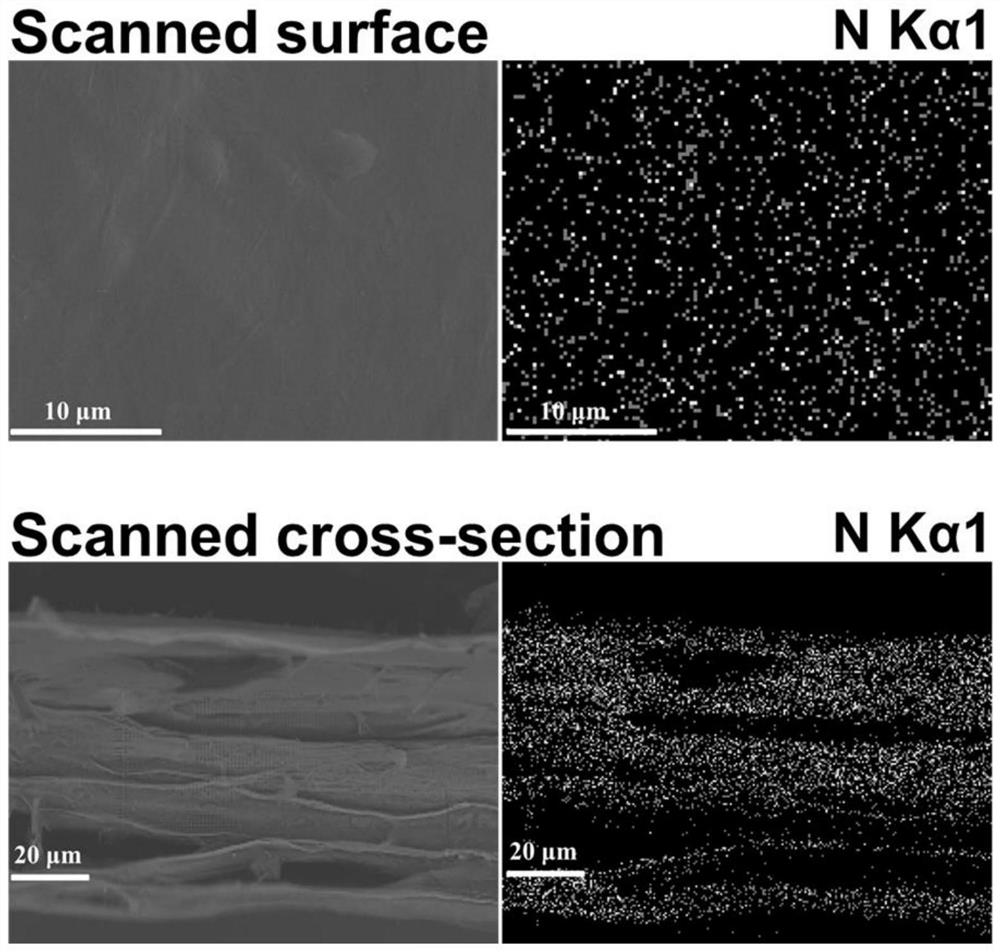

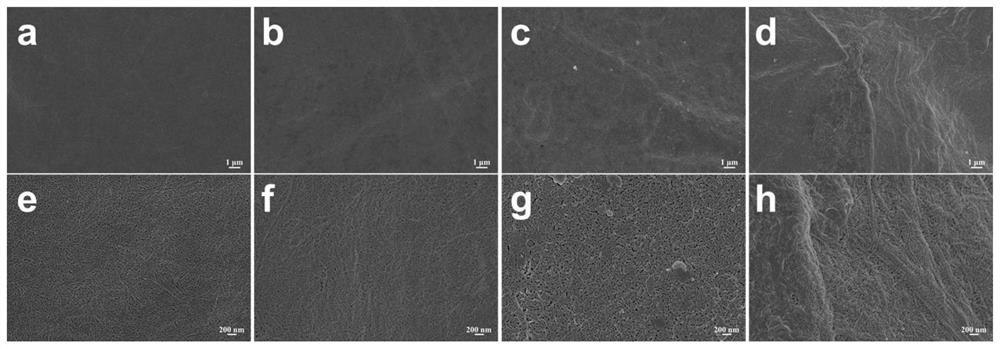

[0030] LYS / TOCN nanocomposites were prepared by in situ synthesis of amyloid lysozyme nanospheres on the surface of TOCNs. TOCN suspension (0.5wt%), lysozyme (2mg mL -1 , the solvent is the 10mM HEPES buffer of pH 7.2), TCEP buffer (50mM, the solvent is the 10mM HEPES buffer of pH 7.0), is added in the reaction vessel in proportion, makes the quality of lysozyme be the total amount of lysozyme and TOCN 2wt%. The reaction was stirred (400 rpm) at room temperature under an air atmosphere for 1 h. Finally, the resulting amyloid nanocellulose aqueous dispersion was stored at 4°C.

[0031] The composite amyloid nanocellulose aqueous dispersion was filtered through a common filter membrane with a pore size of 0.22 μm, dried at 40°C for 10 minutes to remove water, and finally peeled off from the MCE carrier to obtain a self-supporting 22.5g m -2 The LYS / TOCN composite film.

[0032] Separation test using the obtained composite membrane:

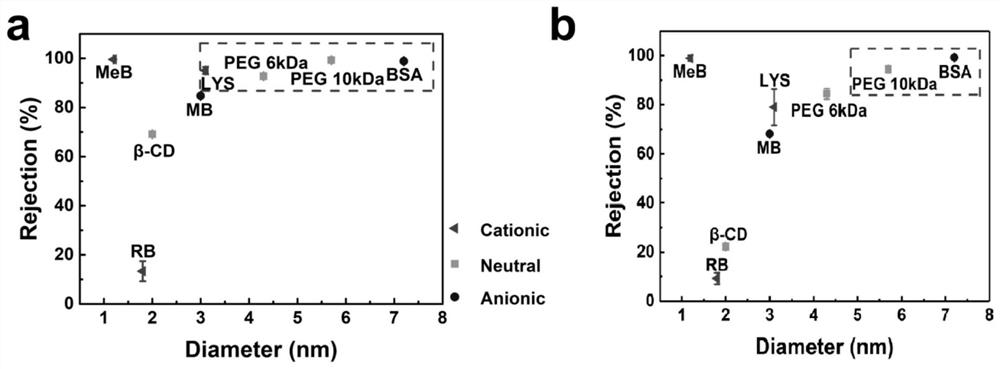

[0033] The membrane was used for the dy...

Embodiment 2~3

[0039] The preparation method is the same as that of Example 1, except that the mass of lysozyme in the composite film is 4wt% and 30wt% of the total amount of lysozyme and TOCN, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com