Preparation method of quick dissociative type thermosensitive hyaluronic acid hydrogel

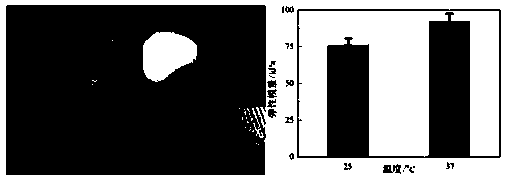

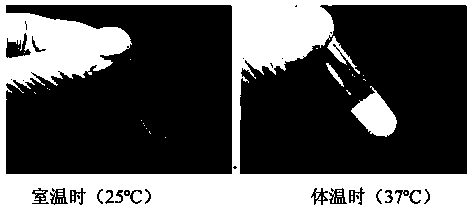

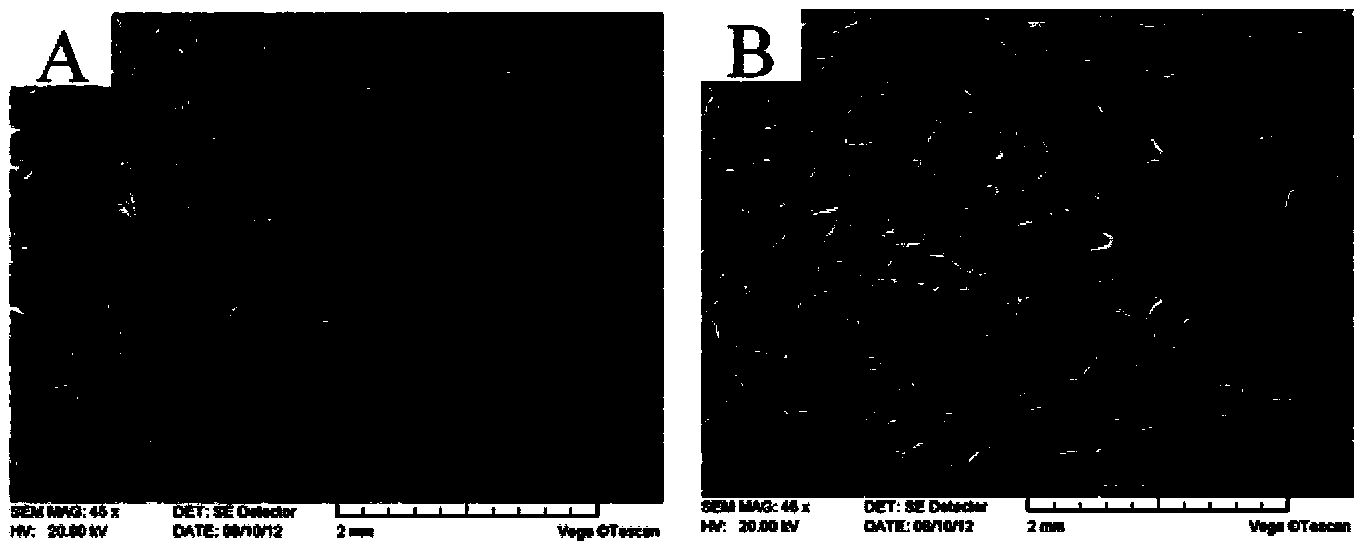

A hyaluronic acid, temperature-sensitive technology, applied in the field of biomedical materials, can solve the problems of unsatisfactory hydrogel uniformity, stability and durability, unable to meet the needs of rapid cell-matrix separation, etc., and achieve flexible control of pore size Narrow size, pore size distribution, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) First, dissolve hyaluronic acid with a molecular weight of 300,000 in high-purity water to prepare a hyaluronic acid solution with a mass concentration of 4%;

[0032]2) Next, add 50% of the mass of hyaluronic acid to the solution, which is a temperature-sensitive macromolecular cross-linking poly(N-isopropylacrylamide) with a molecular weight of 20,000 and a narrow molecular weight distribution containing disulfide bonds and double-terminal amino groups. After the joint agent is stirred and dissolved, adjust the pH value to 5 with hydrochloric acid or NaOH solution;

[0033] The temperature-sensitive macromolecular crosslinking agent of poly(N-isopropylacrylamide) of narrow molecular weight distribution containing disulfide bonds and double-terminal amino groups is synthesized by the following steps:

[0034] a) Add chain transfer agent S,S'-bis(α,α'-methyl-α"-acetic acid) trithiocarbonate in sequence in anhydrous and oxygen-free organic solvent 1,4-dioxane, mono B...

Embodiment 2

[0040] 1) First, dissolve hyaluronic acid with a molecular weight of 50,000 in high-purity water to prepare a hyaluronic acid solution with a mass concentration of 3%;

[0041] 2) Next, add 30% of the mass of hyaluronic acid to the solution, which is a temperature-sensitive macromolecular cross-linking poly(N-isopropylacrylamide) with a molecular weight of 50,000 and a narrow molecular weight distribution containing disulfide bonds and double-terminal amino groups. After the joint agent is stirred and dissolved, adjust the pH value to 5.5 with hydrochloric acid or NaOH solution;

[0042] The temperature-sensitive macromolecular crosslinking agent of poly(N-isopropylacrylamide) of narrow molecular weight distribution containing disulfide bonds and double-terminal amino groups is synthesized by the following steps:

[0043] a) Add chain transfer agent S,S'-bis(α,α'-methyl-α"-acetic acid) trithiocarbonate and monomer N-isopropylpropene to tetrahydrofuran, an anhydrous and oxygen-...

Embodiment 3

[0048] 1) First, dissolve hyaluronic acid with a molecular weight of 200,000 in high-purity water to prepare a hyaluronic acid solution with a mass concentration of 4%;

[0049] 2) Next, add 60% of the mass of hyaluronic acid to the solution, which is a temperature-sensitive macromolecular cross-linking poly(N-isopropylacrylamide) with a molecular weight of 30,000 and a narrow molecular weight distribution containing disulfide bonds and double-terminal amino groups. After the joint agent is stirred and dissolved, adjust the pH value to 4 with hydrochloric acid or NaOH solution;

[0050] The temperature-sensitive macromolecular crosslinking agent of poly(N-isopropylacrylamide) of narrow molecular weight distribution containing disulfide bonds and double-terminal amino groups is synthesized by the following steps:

[0051] a) Add chain transfer agent S,S'-bis(α,α'-methyl-α"-acetic acid) trithiocarbonate in sequence in anhydrous and oxygen-free organic solvent 1,4-dioxane, mono ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com