Technological method capable of enhancing ore dressing efficiency and ore dressing index

A process method and index technology, applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc., can solve the problems of low recovery rate, low concentrate grade, waste of useful mineral resources, etc. Save energy and costs, improve production capacity, and improve the effect of dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

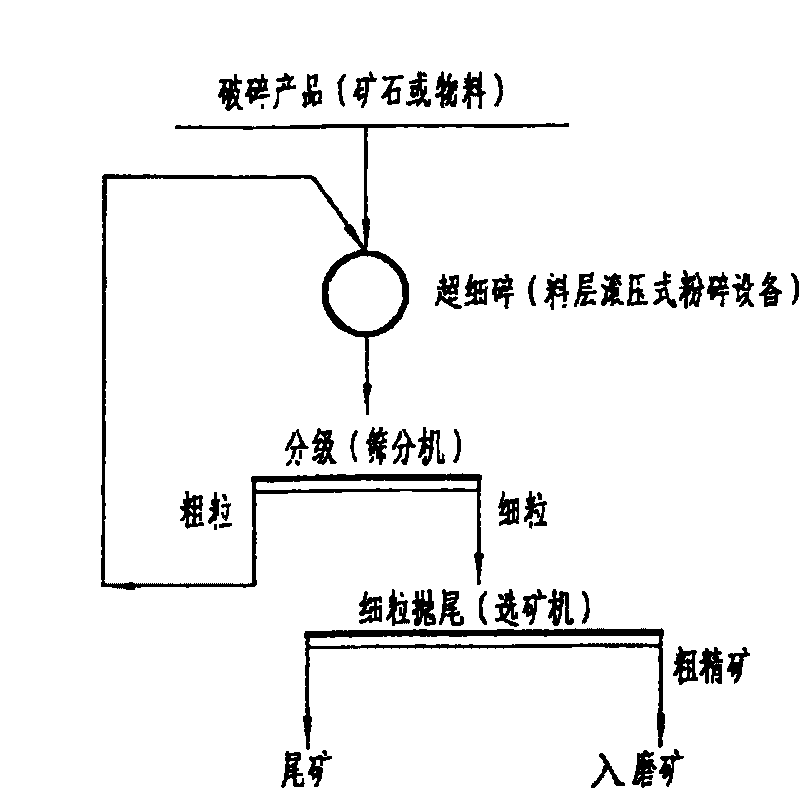

[0016] as attached figure 1 As shown, the ore or material is ultra-finely crushed (or coarsely ground) by material layer rolling crushing equipment, and the ultra-finely crushed product enters the classification process. Generally, a screening machine can be used for classification here. The under-screen particle size of the screening machine is based on the mineral. The particle size of the embedded cloth is determined, which can be selected within 1-10 mm. The coarse-grained products on the sieve can be returned to the material layer rolling crushing equipment for ultra-fine crushing again. The fine particles under the sieve enter the fine-grained tailing concentrator, and the concentrator can It is magnetic separation, electric separation, optical separation, gravity separation or flotation, etc. The tailings selected by the tailings throwing concentrator can be sent to the tailings stockpile, and the selected coarse concentrate can enter the next process, which is grinding...

Embodiment 2

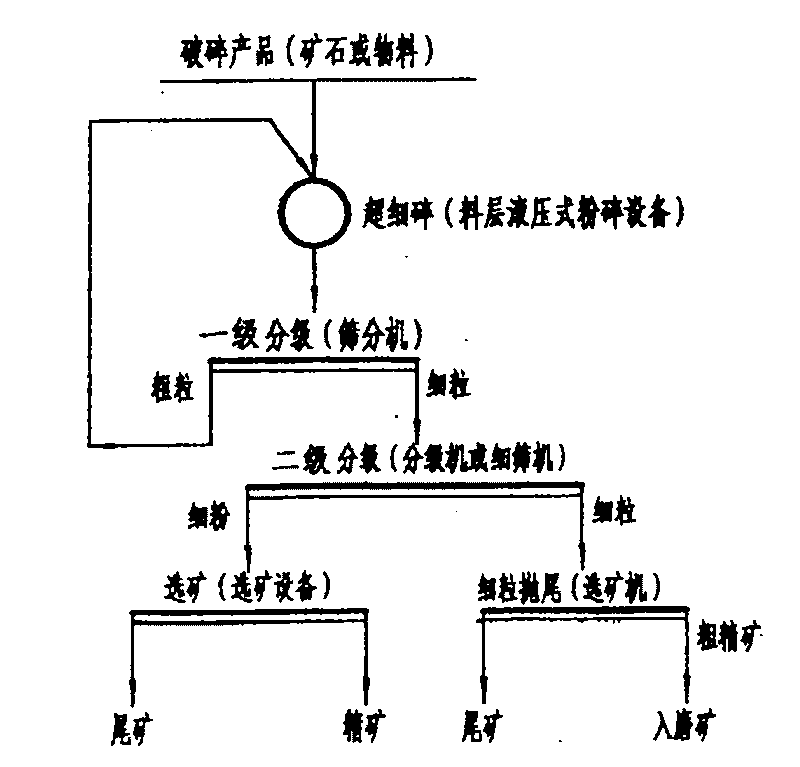

[0018] as attached figure 2 As shown, the main process of embodiment 2 is basically the same as that of embodiment 1, and the difference is that embodiment 2 classifies the fine-grained product after the ultra-fine crushing classification again, and the fine powder after the classification is independently beneficiated, thus Part of the concentrate can be obtained, and part of the tailings can be removed. In this way, the grade of concentrate and the recovery rate of concentrate can be further improved, and the production capacity of the grinding process can be increased and unnecessary ore over-grinding can be reduced.

Embodiment 3

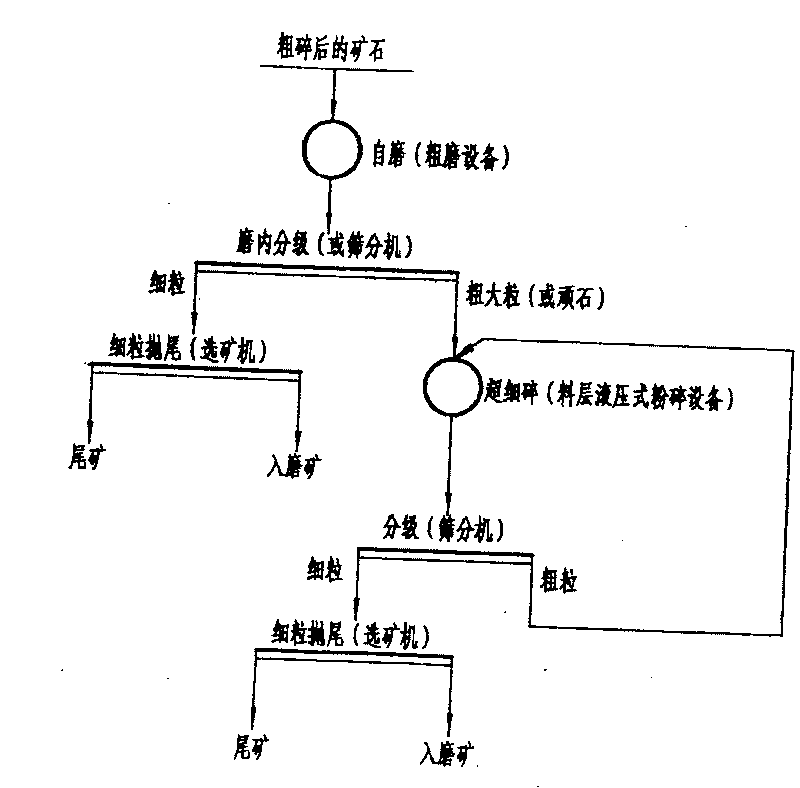

[0020] as attached image 3 As shown, after the ore is coarsely crushed, it enters the self-grinding machine (or other one-stage grinding equipment) as a one-stage grinding, and the coarse particles discharged from the self-grinding machine or the coarse particles that are classified enter the ultra-fine crushing (or Coarse grinding) treatment, the following process and attached figure 1 The difference is that the fine particles discharged from the mill are separately fine-grained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com