Method for manufacturing long-term efficient anti-reflection micro-nano structure on copper surface and application

A technology of micro-nano structure and copper surface, used in manufacturing tools, ion implantation plating, coating, etc., can solve the problems of failure of anti-reflection effect and degradation of reflectivity, and achieves a large selection range, high-efficiency anti-reflection characteristics, long-term The effect of the high-efficiency anti-reflection feature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Main structure and principle of the present invention

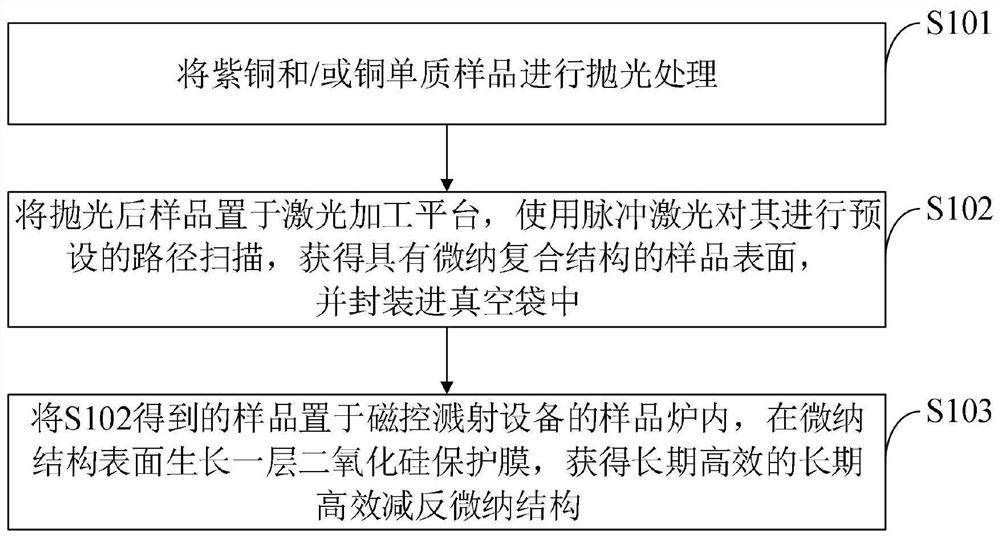

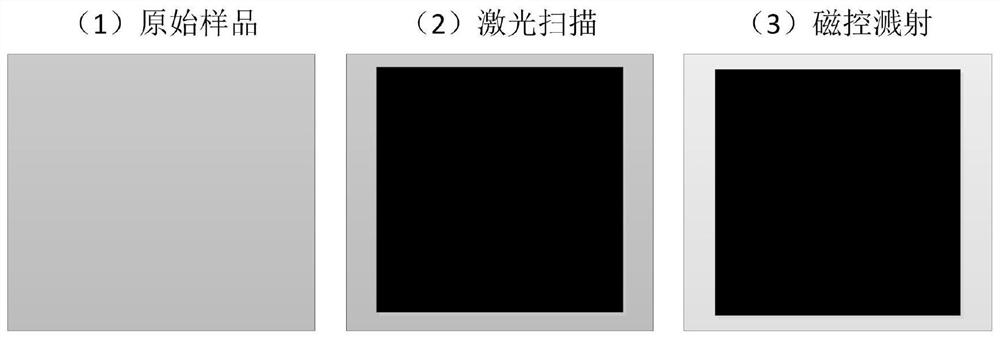

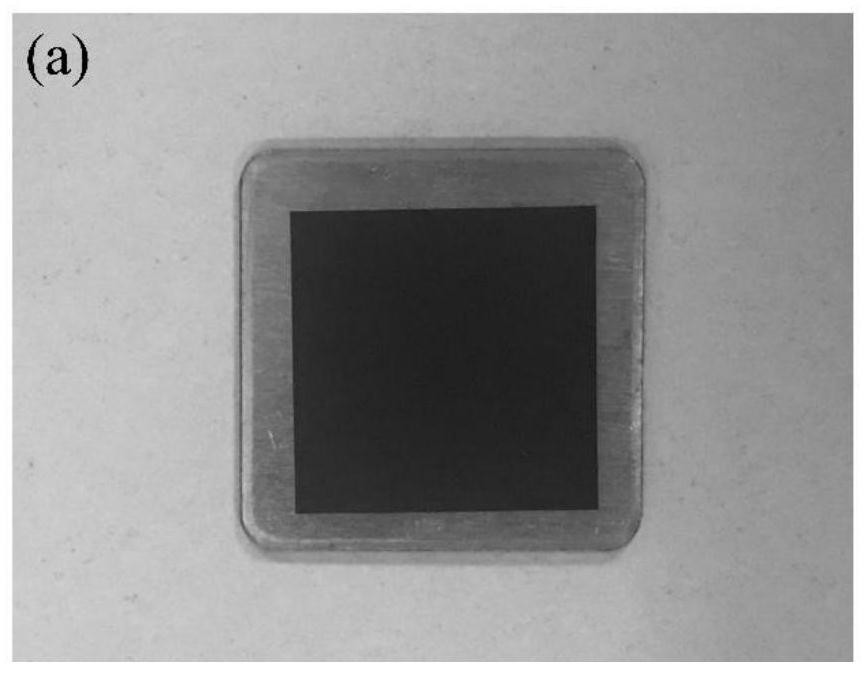

[0043] Schematic diagram of the preparation process of long-term anti-reflection structure on copper surface. figure 2 shown.

[0044] 2. The purpose of the invention

[0045] The purpose of the present invention is to provide a long-term high-efficiency anti-reflection micro-nano structure and its preparation method on the copper surface. The pulsed laser is used to scan the surface of the copper element, and a regular micro-nano composite structure can be prepared on the copper surface, and then inert on the surface of the micro-nano structure. Thin film growth, so that it has long-term and efficient anti-reflection function characteristics. In addition, the selection range of the processing laser in the present invention is large, which expands the scope of application.

[0046] The present invention uses nanosecond, picosecond and femtosecond lasers to prepare various micro-nano processing on the surface...

Embodiment 2

[0057] The method for manufacturing a long-term high-efficiency anti-reflection micro-nano structure on a copper surface provided by the embodiment of the present invention, the specific steps are:

[0058] (1) Use a polishing machine to mechanically polish the surface of the copper element to obtain a processed sample.

[0059] (2) A nanosecond laser is used to scan the two-dimensional groove on the surface of the copper sample to obtain an anti-reflection micro-nano structure surface. The distance between the two-dimensional grooves is 30 μm; the parameters of the nanosecond laser are: repetition frequency 100 kHz, center wavelength 532 nm, pulse width 10 ns, and laser power 20 W.

[0060] (3) Coating a silicon dioxide protective layer on the surface of the sample obtained in step (2) by magnetron sputtering to obtain an anti-reflection micro-nano structure surface with an inert protective layer. The parameters of the magnetron sputtering are: pressure 0.5Pa, argon flow rat...

Embodiment 3

[0062] The method for manufacturing a long-term high-efficiency anti-reflection micro-nano structure on a copper surface provided by the embodiment of the present invention, the specific steps are:

[0063] (1) Use a polishing machine to mechanically polish the surface of the copper element to obtain a processed sample.

[0064] (2) Use a picosecond laser to scan the surface of the copper sample with a square grid to obtain an anti-reflection micro-nano structure surface. The side length of the square grid is 20 μm; the parameters of the picosecond laser are: repetition frequency 200 kHz, center wavelength 1030 nm, pulse width 10 ps, and laser power 2000 mW.

[0065] (3) Coating a silicon dioxide protective layer on the surface of the sample obtained in step (2) by magnetron sputtering to obtain an anti-reflection micro-nano structure surface with an inert protective layer. The parameters of the magnetron sputtering are: pressure 0.5Pa, argon flow rate 38L / min, power 160W. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com