Composite white light LED and preparation method

A technology of LED chips and white light, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of energy loss, low luminous efficiency of composite white light LED, unfavorable light energy extraction, etc., achieve low cost, save quantum dot materials, Reduce the effect of total reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

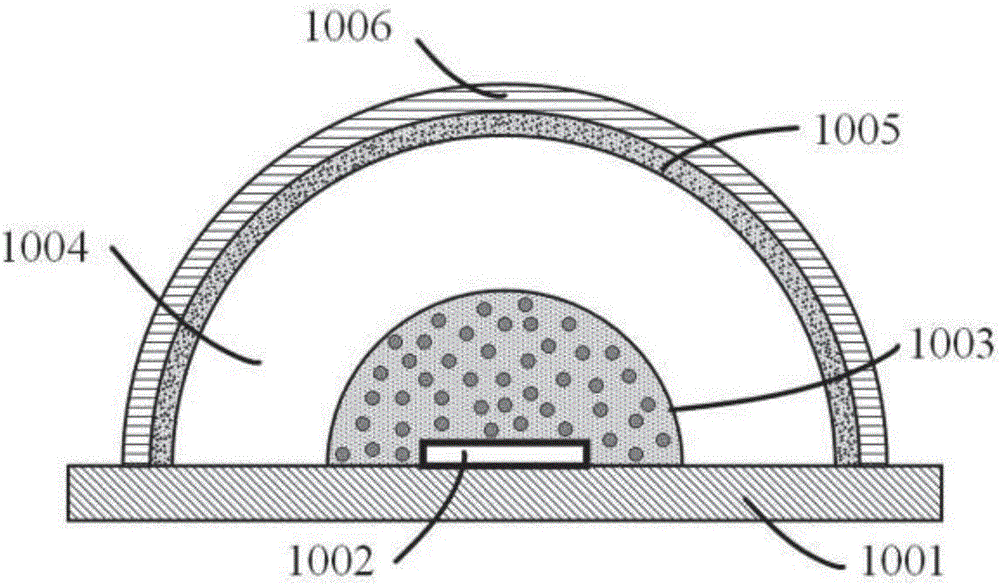

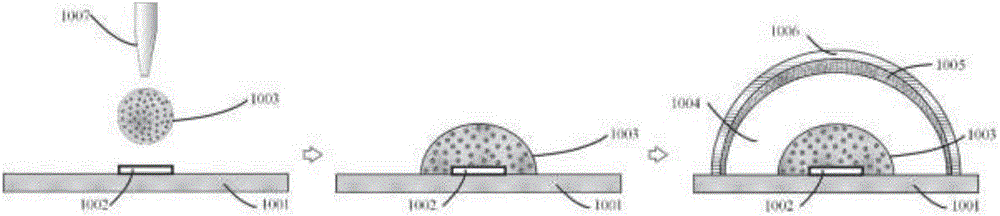

[0040] The preparation method of this composite white light LED comprises the following steps, such as figure 2 Shown:

[0041] S1. Apply fluorescent powder glue. Apply the fluorescent powder colloid 1003 directly above the LED chip 1002 through the dispensing device 1007 to cover the LED chip 1002 to form a hemispherical or spherical shape, then put it into an oven, and heat at 150°C for 1 hour , to cure the phosphor glue;

[0042] S2. Prepare the quantum dot light-transmitting shell. Mix 2mL of methyl methacrylate solution with 0.01g of azobisisobutyronitrile powder, add quantum dots, and ultrasonically oscillate for 10 minutes, then place the mixed solution in a water bath at 70°C for 10 minutes, and then absorb 3~ 40 μL was injected into the inner surface of the light-transmitting housing 1006, and then placed in a heating box at 45°C for 12 hours to solidify the solution;

[0043] S3. Package of compound white light LED. The light-transmitting housing 1006 obtained ...

Embodiment 1

[0045] S1. Apply fluorescent powder glue. In this embodiment, phosphor particles with a particle size of 12 μm and a light emission wavelength of 555 nm are used. The colloid of the phosphor glue is heat-curable silica gel of A / B component, and the curing temperature is 150° C. The chip size used is 0.5 mm x 0.5 mm x 0.1 mm. First, mix 0.1g of phosphor particles with 0.5g of glue A and 0.5g of glue B and stir them evenly, then put them into a vacuum box to vacuum for 30 minutes; then apply the prepared phosphor colloid on the top of the LED to form a radius Hemispherical shape of 1.5mm; put it into an oven and heat at 150°C for 1 hour to solidify the phosphor colloid;

[0046] S2. Prepare the quantum dot shell. In this embodiment, a light-transmitting housing with a diameter of 30 mm is used, and its material is polycarbonate (PC), with a light transmittance of 95%. The composition of quantum dots is CdSe / ZnS, and the emission wavelength is 630nm. First, mix 2mL of methyl ...

Embodiment 2

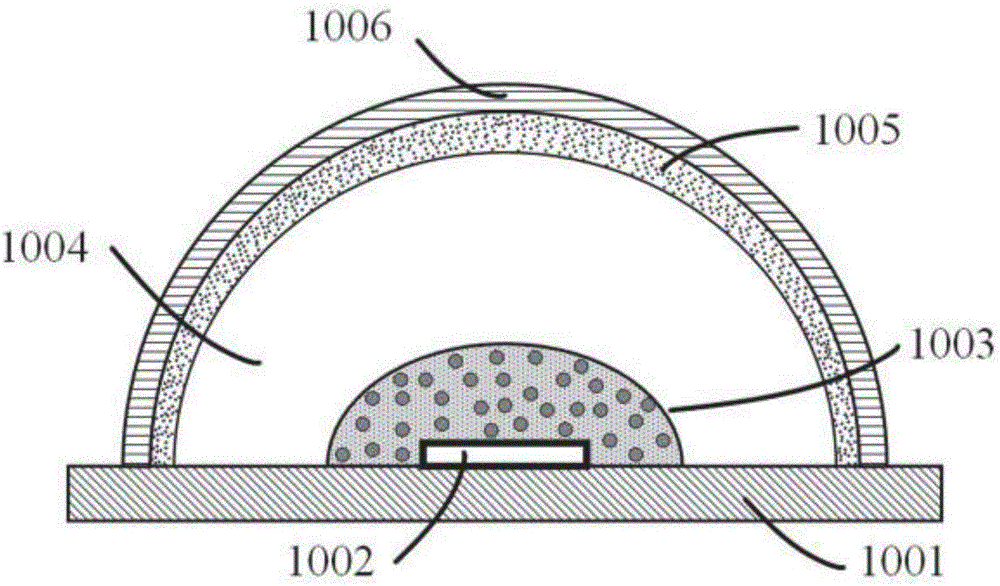

[0049] Repeat Example 1 with the same steps as described, the difference is that the phosphor powder adopts an average particle diameter of 18um, and the phosphor powder with a luminous wavelength of 540nm, and the quantum dot adopts a CdSSe / ZnS quantum dot with a luminous wavelength of 630nm; 0.2g phosphor powder The particles are mixed with 0.5g glue A and 0.5g glue B to make phosphor colloid, and then the prepared phosphor colloid is spot-coated on the LED to form a spherical shape with a bottom radius of 1.5mm and a height of 1.2mm ; After mixing 2mL methyl methacrylate solution with 0.01g azobisisobutyronitrile powder, add 5mg quantum dots to prepare a mixed solution, take 30 μL mixed solution and inject it into the light-transmitting shell, and finally obtain the quantum dots in the quantum dot shell. The middle thickness of the dot film is about 1.2mm, and the edge thickness is about 0.9mm. The resulting composite white LED such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Luminous wavelength | aaaaa | aaaaa |

| Base radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com