Matt glaze and preparation method of matt glaze surface

A technology of matte glaze and matte glaze, which is applied in the field of ceramic glazes, and can solve the problems of high gloss, light pollution, and poor matte effect of matte glazes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a matte glaze, which includes: matte dry particle glaze, nano-carbon and main body glaze;

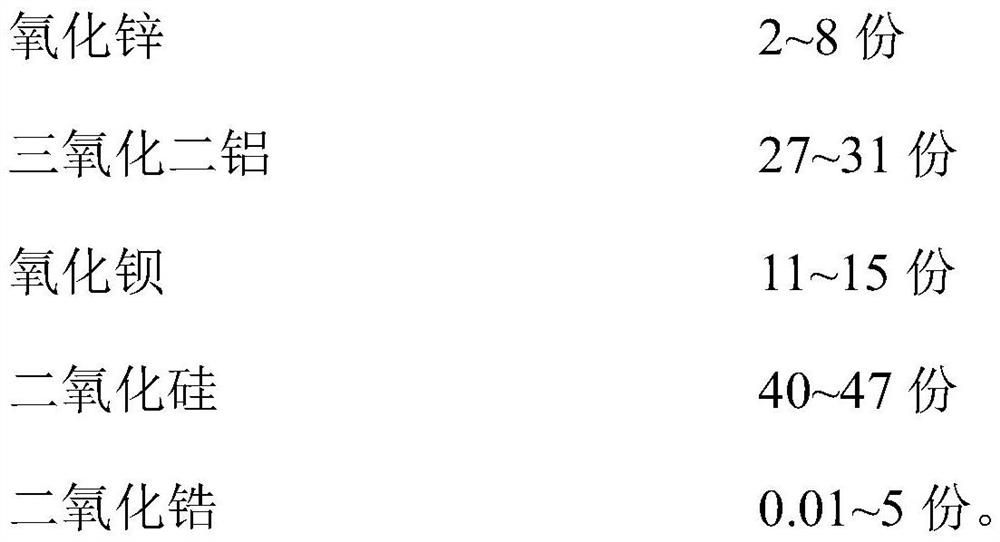

[0053] The composition of described dull dry glaze comprises by mass parts:

[0054]

[0055] The composition of described main body glaze comprises by mass fraction:

[0056]

[0057] The size of the nano-carbon in the matte glaze is 50-100nm; the mass ratio of the matte dry glaze to the main body glaze is 0.1:1; the mass ratio of the nano-carbon to the main body glaze is 0.01:1.

[0058] This embodiment provides a method for preparing a matte glaze using the above matte glaze, the preparation method comprising the following steps:

[0059] (1) Mix matt dry glaze and vinyl silane, and bake at 250°C to form a matt dry glaze with vinyl silane attached to the surface;

[0060] (2) Mix the main body glaze and the matte dry glaze with vinyl silane attached on the surface, mix the materials and melt at 450°C, then carry out the cloth, and burn at 650°C...

Embodiment 2

[0062] This embodiment provides a matte glaze, which includes: matte dry particle glaze, nano-carbon and main body glaze;

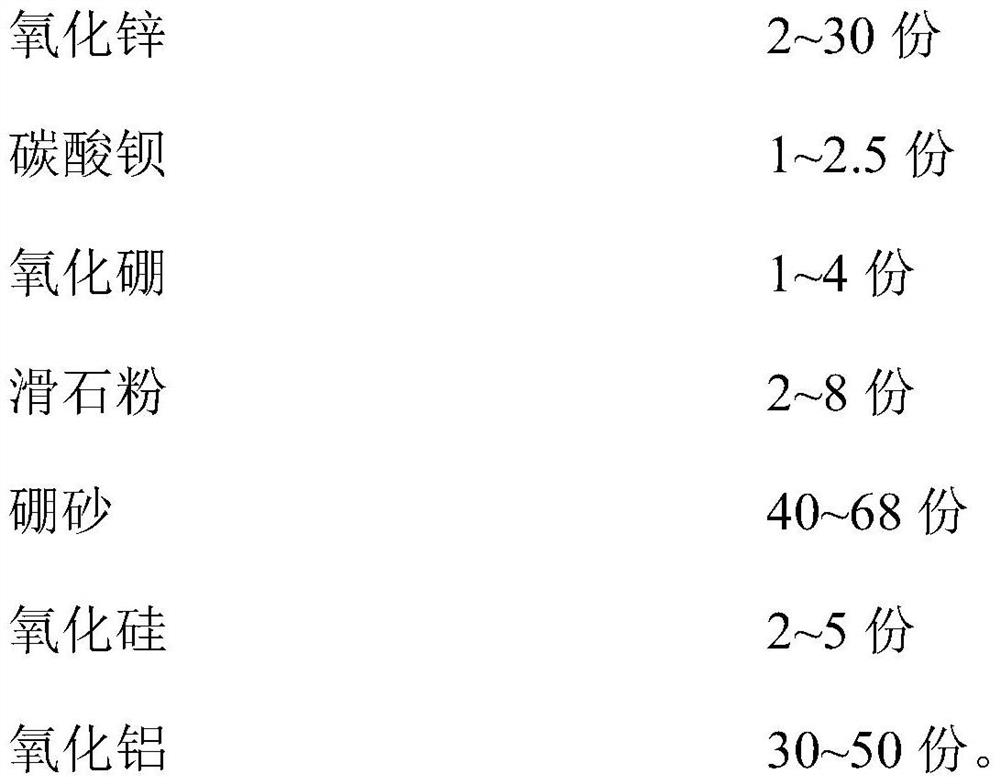

[0063] The composition of described dull dry glaze comprises by mass parts:

[0064]

[0065] The composition of described main body glaze comprises by mass fraction:

[0066]

[0067]

[0068] The size of the nano-carbon in the matte glaze is 1-35nm; the mass ratio of the matte dry granular glaze to the main body glaze is 0.2:1; the mass ratio of the nano-carbon to the main body glaze is 0.005:1.

[0069] This embodiment provides a method for preparing a matte glaze using the above matte glaze, the preparation method comprising the following steps:

[0070] (1) Mix matte dry glaze and vinyl silane, and bake at 300°C to form a matte dry glaze with vinyl silane attached to the surface;

[0071] (2) Mix the main body glaze and the matte dry glaze with vinyl silane attached on the surface, mix the materials and melt at 500°C, then carry out the cl...

Embodiment 3

[0073] This embodiment provides a matte glaze, which includes: matte dry particle glaze, nano-carbon and main body glaze;

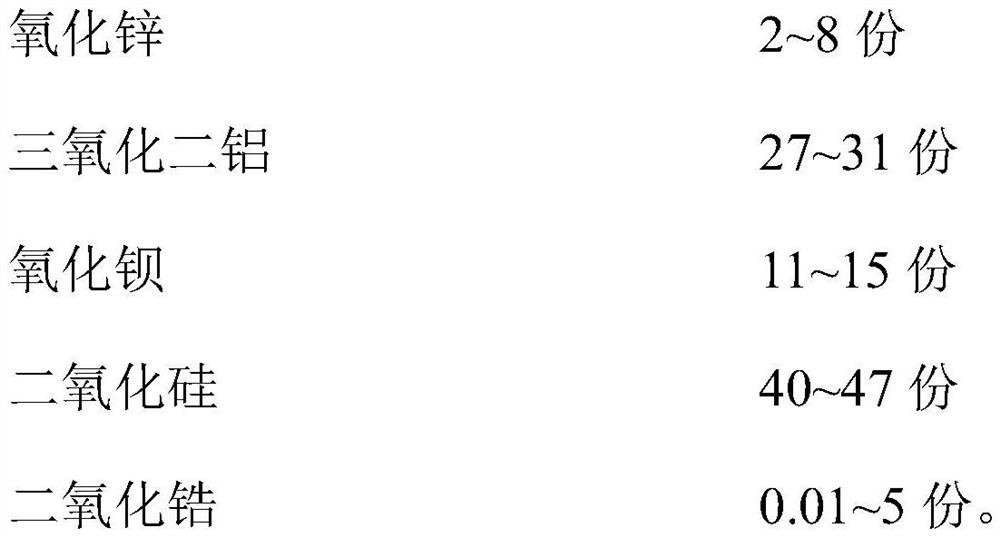

[0074] The composition of described dull dry glaze comprises by mass parts:

[0075]

[0076] The composition of described main body glaze comprises by mass fraction:

[0077]

[0078]

[0079] The size of the nano-carbon in the matte glaze is 20-45nm; the mass ratio of the matte dry glaze to the main body glaze is 0.08:1; the mass ratio of the nano-carbon to the main body glaze is 0.008:1.

[0080] This embodiment provides a method for preparing a matte glaze using the above matte glaze, the preparation method comprising the following steps: (1) mixing the matte dry granular glaze and vinyl silane, and firing at 200°C to form Matte dry grain glaze with vinyl silane attached on the surface;

[0081] (2) Mix the main body glaze and the matte dry glaze with vinyl silane attached on the surface, mix the materials and melt at 400°C, then carry out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com