Organic light-emitting display panel

A technology of light-emitting display and panel, applied in the direction of electrical components, diodes, electric solid-state devices, etc., can solve the problem of low luminous efficiency of devices, and achieve the effect of reducing total reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

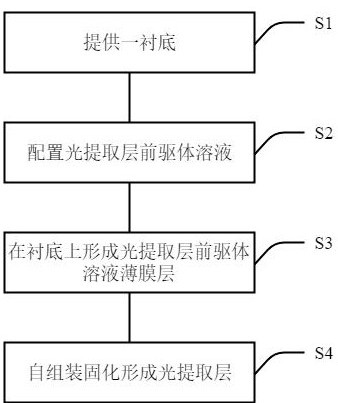

[0036] Embodiment 1 of the present application provides a method for preparing an optical film, the optical film is a composite optical film, including an optical coupling layer and a light extraction layer, and the light extraction layer has a long-range ordered porous network patterned in an array structure, the light extraction layer contains quantum dots used as light conversion materials, the quantum dots are distributed on the mesh edge of the mesh patterned structure of the light extraction layer, and the holes are through holes or arc-shaped depressions. like figure 1 Shown, this preparation method comprises:

[0037] S1. Provide a substrate;

[0038] Exemplarily, the substrate can be used as a light coupling layer of a composite optical film. However, the substrate can also be used only as a film-forming substrate of a composite optical film, and an optical coupling layer is additionally provided on the side of the film-forming substrate close to the light extractio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width at half peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com