Coated glass and preparation method thereof

A technology of coated glass and glass, which is applied in the direction of coating, etc., can solve problems such as damage, reflection, and wear-through of the film layer, and achieve the effects of small surface reflection, increased wear resistance, and reduced glass reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

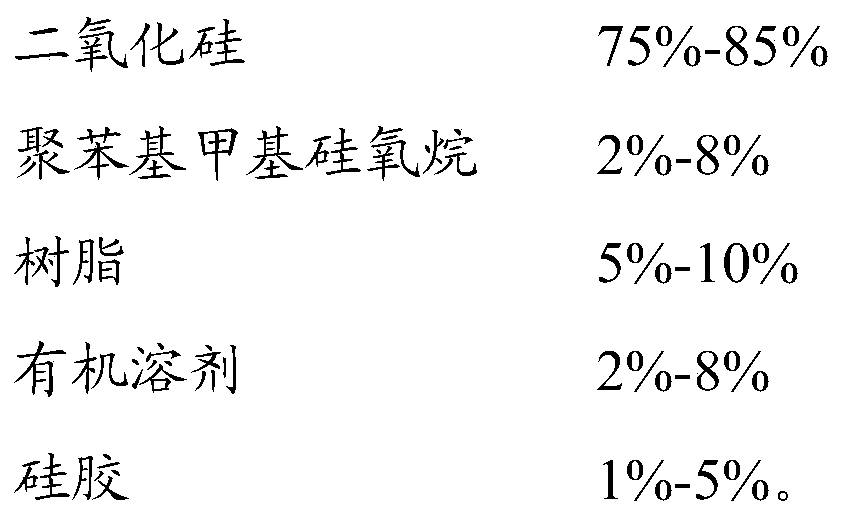

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of coated glass, comprising the following steps:

[0029] 1. Pre-processing.

[0030] Take the clean glass and polish the air surface; then clean the air surface of the glass to remove the ions on the surface.

[0031] It can be understood that conventional methods can be used to polish and ion-clean the glass. However, mixing polishing powder with water to make a polishing liquid with a concentration of 5%-10% by mass, coating it on the air surface of the glass and scrubbing with a brush has a relatively good effect. Good polishing effect is conducive to the adhesion of subsequent film layers. Similarly, conventional methods can be used for ion cleaning of glass, such as rinsing with deionized water, or cleaning with an ion blower, etc. However, performing ion cleaning in the above two ways at the same time has a better effect of removing ions.

[0032] 2. Spray coating.

[0033] When controlling spraying and atomization, the pressure of the noz...

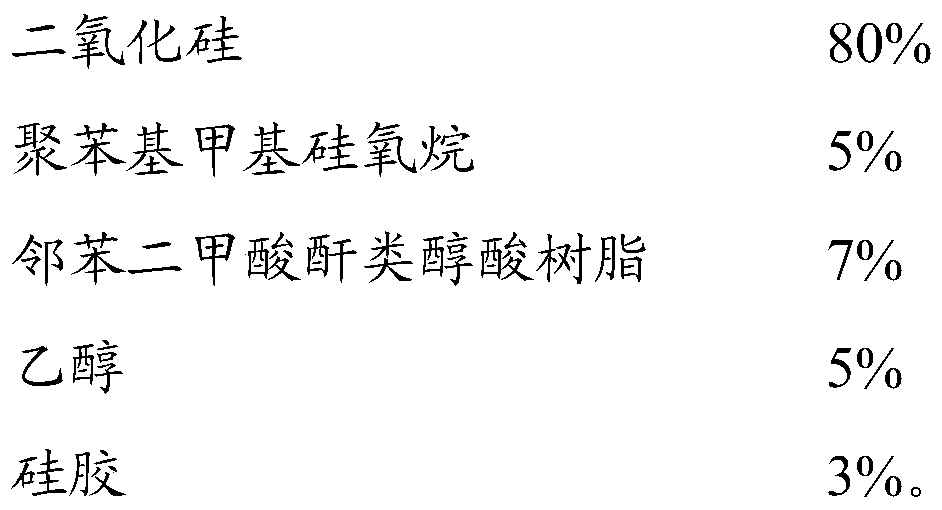

Embodiment 1

[0039] A kind of coated glass is prepared by the following method:

[0040] 1. Pre-processing.

[0041] 1. Polishing: Take float glass, wash it with water and then dry it to get clean and dry glass. Mix water with glass polishing powder to make a polishing solution with a concentration of 7.5% by mass, and then apply it evenly on the glass surface, and then clean the machine and let the brush in the machine rotate forward / reversely for 3 times. Then flush and polish the air surface.

[0042] 2. Ion cleaning: Rinse the air surface of the glass with deionized water, and then clean the air surface of the glass with an ion blower to remove the ions on the surface.

[0043] 2. Spray coating.

[0044] Carry out film layer spraying with automatic spraying equipment (commercially available), the pressure of nozzle is 4Mpa when controlling spraying atomization, and flow rate is 15g / m 2 , Spray the film layer material on the air surface of the glass to form a rough film layer.

[0...

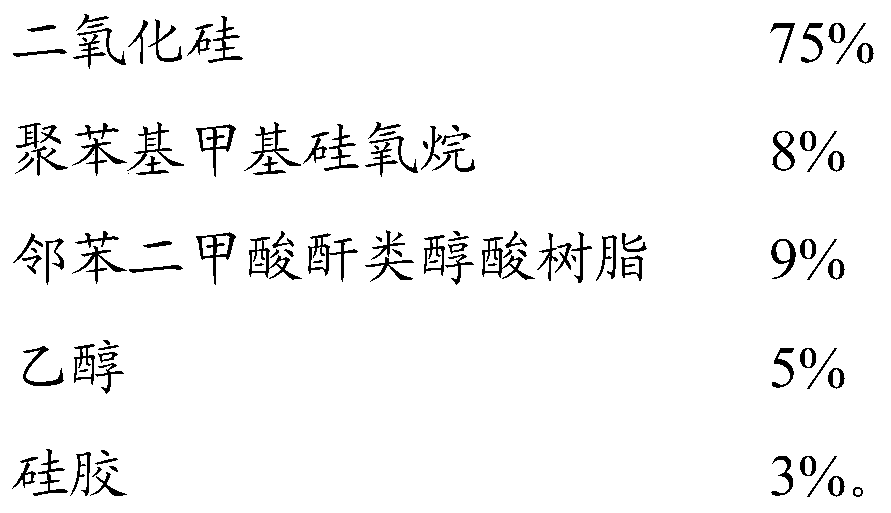

Embodiment 2

[0051] A kind of coated glass, its preparation method is basically the same as the coated glass of embodiment 1, the difference is: in the step of spraying the film layer, the pressure of the nozzle is 6Mpa when the spraying atomization is controlled, and the flow rate is 20g / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com