Composite isolation membrane and formation method thereof

A technology of separator and microporous membrane, applied in electrical components, circuits, battery pack components, etc., can solve the problems of high internal resistance, low capacity and poor wettability of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

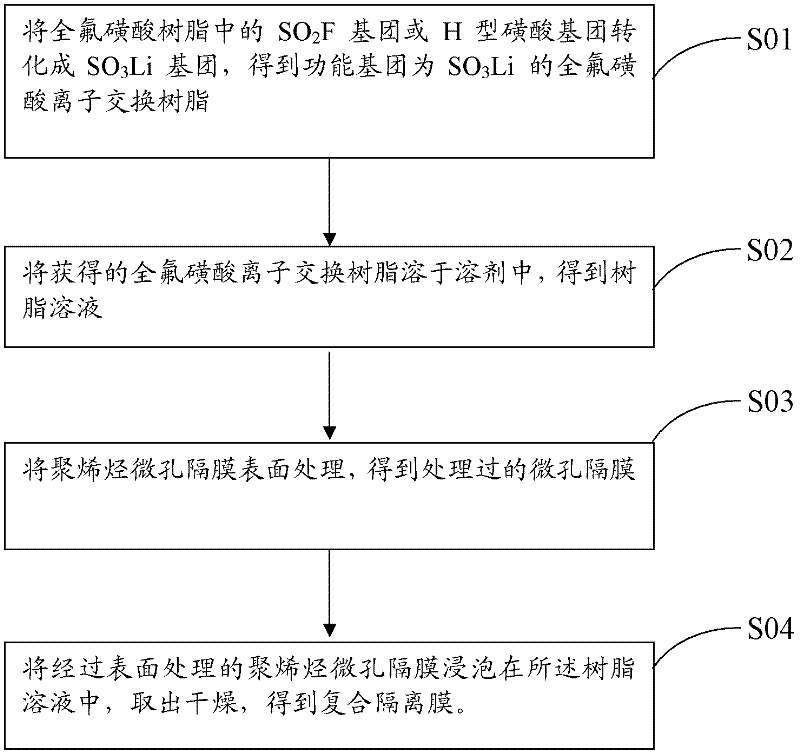

Method used

Image

Examples

Embodiment 1

[0038] Get 1g of perfluorosulfonic acid resin (DuPont Nafion) and put it into a container, add a LiOH aqueous solution with a mass concentration of 27%, make the resin fully immersed in the solution, and reflux at 100 ° C for 48 hours to remove the SO in the resin 2 F group converted to SO 3 Li group, fully washed with water until the pH value is neutral, and the functional group obtained is SO 3 Li's perfluorosulfonic acid ion exchange resin with ion exchange function. Weigh the converted resin, place it in a three-necked container (such as a three-necked flask), add the solvent dimethyl sulfoxide, and blow nitrogen to remove the air therein. Heating to above 170°C, insulated and stirred for 2.5 hours to dissolve to obtain a uniform and clear resin solution with a mass concentration of about 5%. Dissolve 0.02g of benzophenone in 20ml of acetone in a beaker, and completely soak the double-layer polypropylene microporous diaphragm (40 microns) in the acetone in which the phot...

Embodiment 2

[0040] Get 1g of perfluorosulfonic acid resin (DuPont Nafion) and put it into a container, add a LiOH aqueous solution with a mass concentration of 27%, make the resin fully immersed in the solution, and reflux at 100 ° C for 48 hours to remove the SO in the resin 2 F group converted to SO 3 Li group, fully washed with water until the pH value is neutral, and the functional group obtained is SO 3 Li's perfluorosulfonic acid ion exchange resin with ion exchange function. Weigh the converted resin, place it in a three-necked container (such as a three-necked flask), add the solvent dimethyl sulfoxide, and blow nitrogen to remove the air therein. Heating to above 170°C, insulated and stirred for 2.5 hours to dissolve to obtain a uniform and clear resin solution with a mass concentration of about 5%. Prepare CrO in a beaker 3 , concentrated H 2 SO 4 and H 2 O The treatment solution with a mass ratio of 1:3:4, completely soak the double-layer polypropylene microporous diaphra...

Embodiment 3

[0042] Get 1g of perfluorosulfonic acid resin (DuPont Nafion) and put it into a container, add a LiOH aqueous solution with a mass concentration of 27%, make the resin fully immersed in the solution, and reflux at 100 ° C for 48 hours to remove the SO in the resin 2 F group converted to SO 3 Li group, fully washed with water until the pH value is neutral, and the functional group obtained is SO 3 Li's perfluorosulfonic acid ion exchange resin with ion exchange function. Weigh the converted resin, place it in a three-necked container (such as a three-necked flask), add the solvent dimethyl sulfoxide, and blow nitrogen to remove the air therein. Heating to above 170°C, insulated and stirred for 2.5 hours to dissolve to obtain a uniform and clear resin solution with a mass concentration of about 5%. Prepare CrO in a beaker 3 , concentrated H 2 SO 4 and H 2 O mass ratio is 1: 5: 10 treatment solution, soak double-layer polypropylene microporous membrane (40 microns) in this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com