Antibacterial alginate hydrocolloid dressing and preparation method thereof

An antibacterial alginate and hydrocolloid technology, applied in the field of medical devices, can solve the problems of negative biological effects, unclear adverse reactions, and application limitations, and achieve beneficial healing, strong liquid absorption and moisturizing properties, and prevent bacterial invasion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

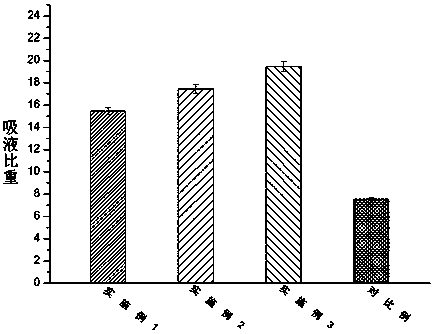

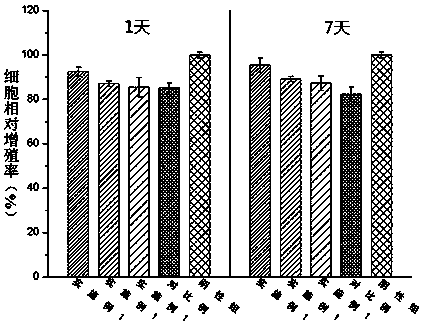

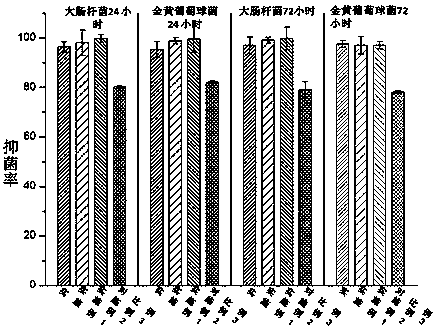

Examples

preparation example Construction

[0031] (1) Preparation of gelatin-modified alginate composites

[0032] Weigh a certain amount of gelatin and calcium chloride and dissolve them in distilled water at 50°C in turn to prepare a gelatin calcium chloride solution with a gelatin concentration of 20%wt and a calcium chloride concentration of 2%wt; weigh a certain amount of modified Sodium alginate and polyethylene glycol are dissolved in distilled water successively, and the polyethylene glycol modified sodium alginate solution that the concentration of polyethylene glycol is 20%wt, and the concentration of modified sodium alginate is 5%wt is prepared; Then Mix the gelatin calcium chloride solution with the polyethylene glycol modified sodium alginate solution in a volume ratio of 1:0.6-1 to obtain a gelatin modified alginate composite material;

[0033] (2) Preparation of polyvinyl alcohol antimicrobial peptide D2A21 fiber membrane

[0034] Weigh a certain amount of polyvinyl alcohol, add it to distilled water, h...

Embodiment 1

[0038] Prepare a kind of antimicrobial alginate hydrocolloid dressing by the above method according to the present invention, wherein: its molecular weight of the polyethylene glycol used in the preparation process is 5000, the polyvinyl alcohol molecular weight used is 80000, its particle diameter of used antimicrobial peptide D2A21 The distribution is 150-250 nm; the electrospinning machine used is the TL-BM-700 electrospinning machine produced by Shenzhen Tongli Micro-Nano Co., Ltd., and the spinning parameters are set as follows: high-voltage power supply voltage: 15kV, rotation speed of the rotary yarn collector : 1500rpm, output pump flow rate: 50 mL / h; in parts by weight, it consists of 10 parts of gelatin, 5 parts of modified sodium alginate, 10 parts of polyethylene glycol, 20 parts of polyvinyl alcohol and 10.05 parts of antimicrobial peptide D2A2 .

Embodiment 2

[0040]Prepare a kind of antimicrobial alginate hydrocolloid dressing by the above method according to the present invention, wherein: its molecular weight of the polyethylene glycol used in the preparation process is 5000, the polyvinyl alcohol molecular weight used is 80000, its particle diameter of used antimicrobial peptide D2A21 The distribution is 150-250 nm; the electrospinning machine used is the TL-BM-700 electrospinning machine produced by Shenzhen Tongli Micro-Nano Co., Ltd., and the spinning parameters are set as follows: high-voltage power supply voltage: 15kV, rotation speed of the rotary yarn collector : 1500rpm, output pump flow rate: 50 mL / h; in parts by weight, it consists of 20 parts of gelatin, 10 parts of modified sodium alginate, 15 parts of polyethylene glycol, 30 parts of polyvinyl alcohol and 10.075 parts of antimicrobial peptide D2A2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com