Lithium ion battery diaphragm and preparation method

A lithium-ion battery and diaphragm technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of high closed-cell temperature of the diaphragm, high thermal shrinkage at high temperature, and low film-breaking temperature, and reduce the closed-cell temperature. , The effect of high temperature thermal shrinkage is small, and the effect of increasing the film breaking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

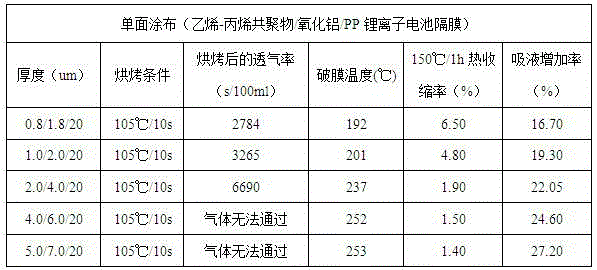

Embodiment 1~3 and Embodiment 10

[0027] The diaphragm base material is 20um dry-process PP film produced by Foshan Yingbolai Technology Co., Ltd., with an air permeability of 365.2s / 100ml and a heat shrinkage rate of 24.5% at 150°C / 1h;

[0028] Polyolefin: choose ethylene-propylene copolymer that can close the pores at 105°C;

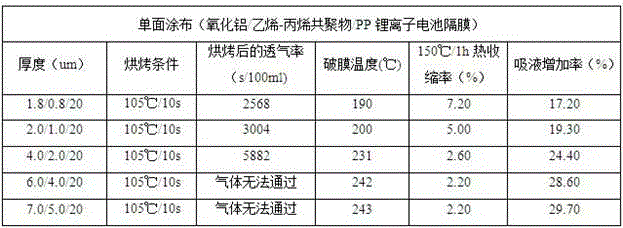

Embodiment 4~6

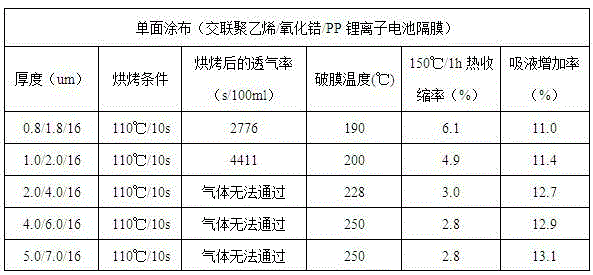

[0031] Diaphragm base material: 16um dry-process PP film produced by American Celgard Company is selected, its air permeability is 230.6s / 100ml, and the heat shrinkage rate at 150℃ / 1h is 21.0%;

[0032] Polyolefin: choose cross-linked polyethylene that can close the pores at 110°C;

[0033] Nano-ceramic material: choose zirconia.

Embodiment 7~9

[0035] Diaphragm base material: use 25um dry-process PP film produced by Xinxiang Zhongke Technology Co., Ltd., with an air permeability of 428.2s / 100ml and a heat shrinkage rate of 28.5% at 150°C / 1h;

[0036] Polyolefin: select random copolymerized polypropylene which can close the pores at 140°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| membrane rupture temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com