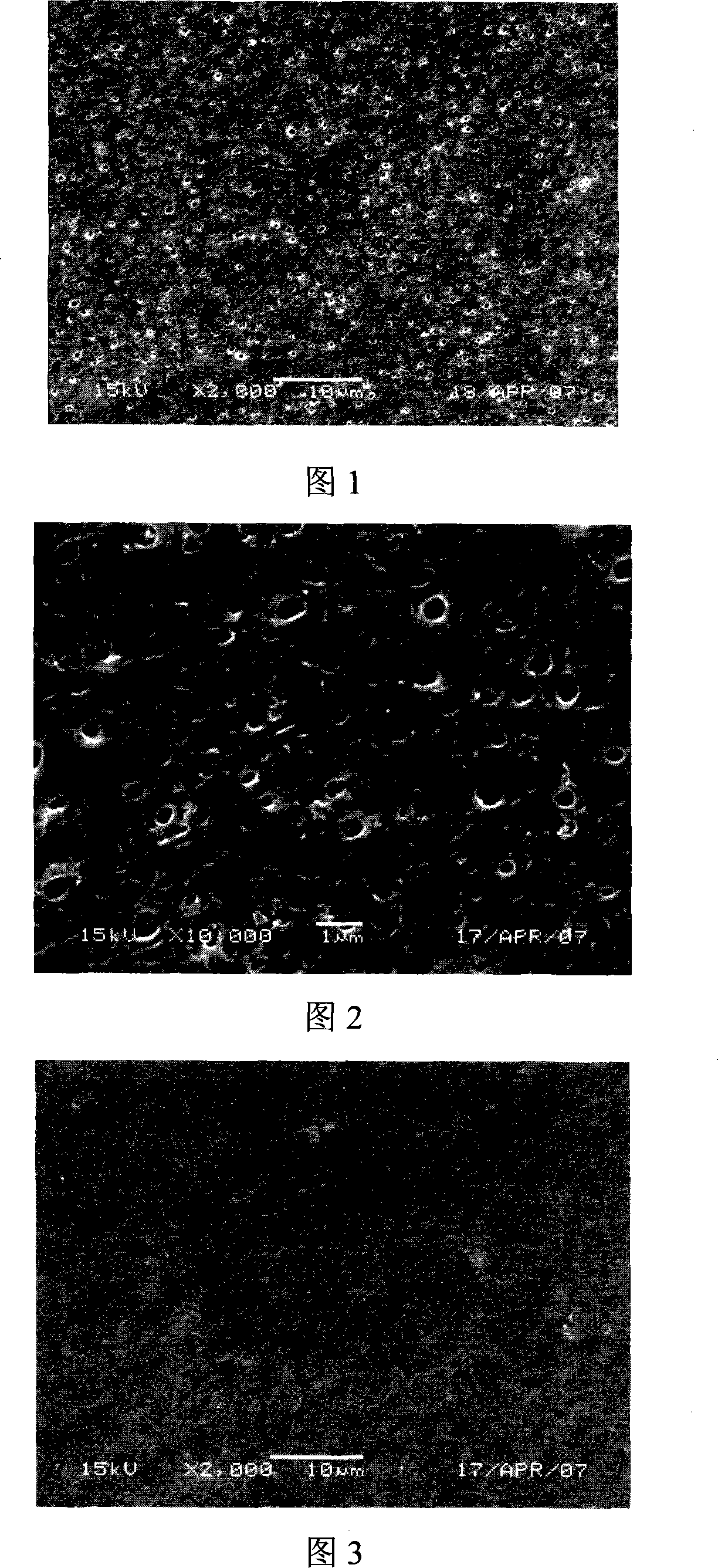

Micro joint gel state lithium ion battery polymer electrolyte film and its making method

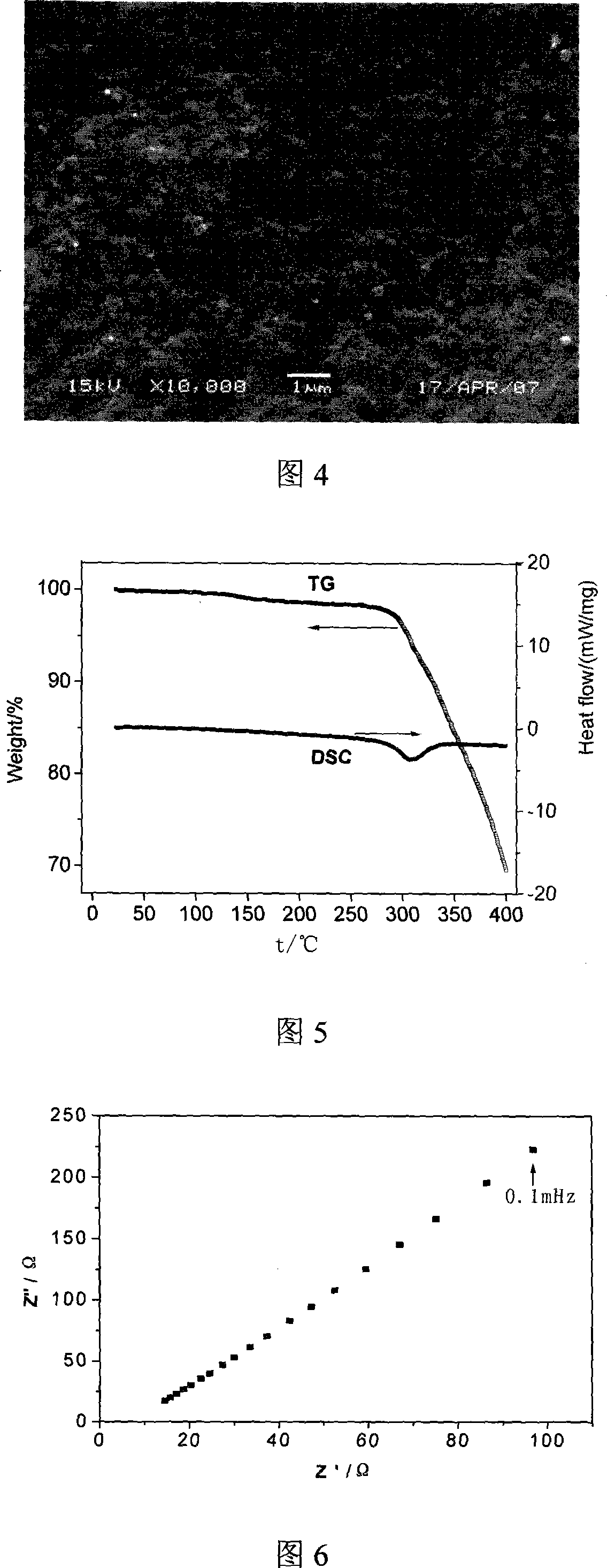

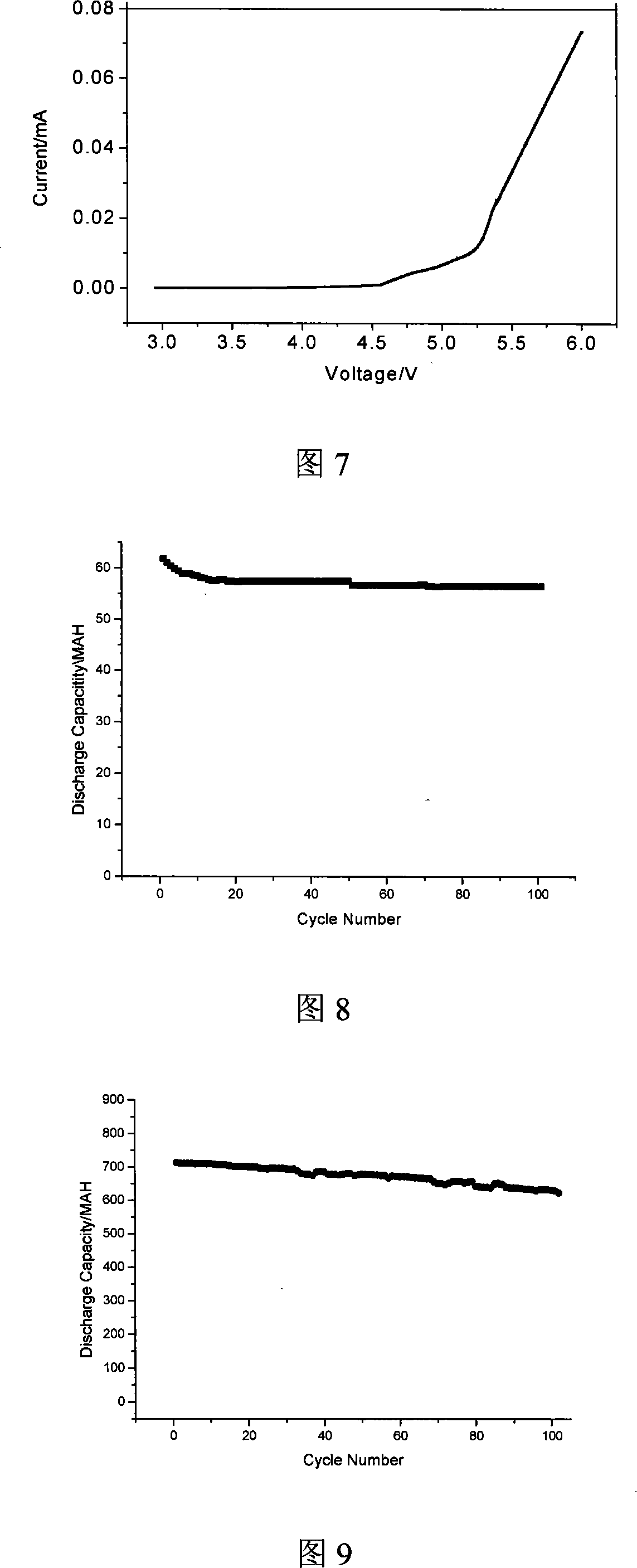

A technology for lithium ion batteries and electrolyte membranes, which is applied in the field of micro-crosslinked polymer membranes containing nitrile groups and carboxyl groups and their preparation, can solve the problems of poor mechanical properties, difficulty in large-scale industrial production, and low electrical conductivity, and achieves good The effect of microporous structure and liquid absorption rate, good ion transport performance, excellent thermal stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A. Under the nitrogen environment of normal temperature and pressure, the polymer dispersant polyvinyl alcohol of 0.1% by weight, the inorganic dispersant of 0.1% by weight are the gas phase white carbon black below 300 nanometers and the deionization of 71.24% by weight Add water into the reactor with temperature control, pressure control and stirring, stir and dissolve at 500r / min, and then raise the temperature to 60°C;

[0041] B, 0.03% weight part polymerization initiator azobisisobutyronitrile and 0.03% weight part molecular weight are the macromolecular crosslinking agent polyethylene glycol dimethacrylate of 200 to be added to 28.5% weight part polymer monomer In the mixed solution of methyl methacrylate and acrylonitrile, wherein the mass ratio of methyl methacrylate to acrylonitrile is 2:8, stirring and dissolving;

[0042] C. Slowly add B to the above-mentioned A reactor, drop it within 30 minutes, then react at 60°C for 5 hours, filter, wash with deionized w...

Embodiment 2

[0063] With embodiment 1, just the macromolecular dispersant polyvinyl alcohol of 0.1% weight part and the nanoscale gas phase silica of the inorganic dispersant of 0.1% weight part in the A step are changed into the polymer dispersant polyvinyl alcohol of 0.3% weight part Ethylene glycol and 0.2% by weight of the inorganic dispersant nano-TiO 2 ; The deionized water of 71.24% by weight is changed to the deionized water of 64.24% by weight; The stirring speed of 100r / min is changed to 400r / min, and the temperature is raised to 70°C;

[0064] 0.03% by weight of the polymerization initiator azobisisobutyronitrile in the B step is replaced by 0.5% by weight of benzoyl peroxide; 0.03% by weight of the polymer cross-linking agent polyethylene glycol dimethyl Acrylate is replaced by 0.5% by weight of polyethylene glycol dipropyl acrylate with a molecular weight of 20,000; 28.5% by weight of the mixed solution of methyl methacrylate and acrylonitrile of the polymer monomer is replace...

Embodiment 3

[0070] With embodiment 1, just the macromolecule dispersant polyvinyl alcohol of 0.1% weight part and the fumed white carbon black of the inorganic dispersant nanometer level of 0.1% weight part in the A step, change the polymer dispersant fiber of 0.2% weight part Plain ether and the magnesium carbonate of the inorganic dispersant nanoscale of 0.15% weight part; The deionized water of 71.24% weight part is changed into the deionized water of 67.75% weight part; 100r / min stirring speed is changed into 250r / min, is warming up to 65 ℃;

[0071] 0.03% by weight of the polymerization initiator azobisisobutyronitrile in the B step is changed to add 0.2% by weight; 0.2% weight part molecular weight is the polyethylene glycol diethyl acrylate of 10000; The methyl methacrylate of 28.5% weight part polymer monomer and the mixed solution of acrylonitrile are changed into the mixed solution of 31.5% weight part; Wherein methyl The mass ratio of methyl acrylate to acrylonitrile is 3:7; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com