Separator for nonaqueous electrolyte cell, nonaqueous electrolyte cell, and method for manufacturing nonaqueous electrolyte cell

A non-aqueous electrolyte and battery technology, used in non-aqueous electrolyte batteries, electrolyte battery manufacturing, batteries, etc., can solve the problems of insufficient adhesion and peeling between the substrate and the PVDF layer, and achieve high manufacturing yield and battery performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0214] (production of diaphragm)

[0215] As the polyvinylidene fluoride-based resin, a vinylidene fluoride-hexafluoropropylene copolymer (manufactured by Kureha Chemical Co., Ltd.-KF9300) was used, and as an acrylic resin, a copolymer of methyl methacrylate-methacrylic acid ( PMMA; manufactured by Mitsubishi Rayon Co., Ltd. - ACRYPET MD001). The polyvinylidene fluoride resin and acrylic resin were mixed at a mass ratio of 75 / 25, and the components of the polyvinylidene fluoride resin and acrylic resin were dissolved in a mixed solvent containing dimethylacetamide and tripropylene glycol (di In methylacetamide / tripropylene glycol=80 / 20 mass ratio), the components of polyvinylidene fluoride resin and acrylic resin were made into 3.8 mass %, and the slurry for coating was produced.

[0216] This slurry for coating was coated equally on both sides of a polyethylene microporous membrane (porous substrate; TN0901: manufactured by SK Corporation) with a film thickness of 9 μm, a Gu...

Embodiment 2~6

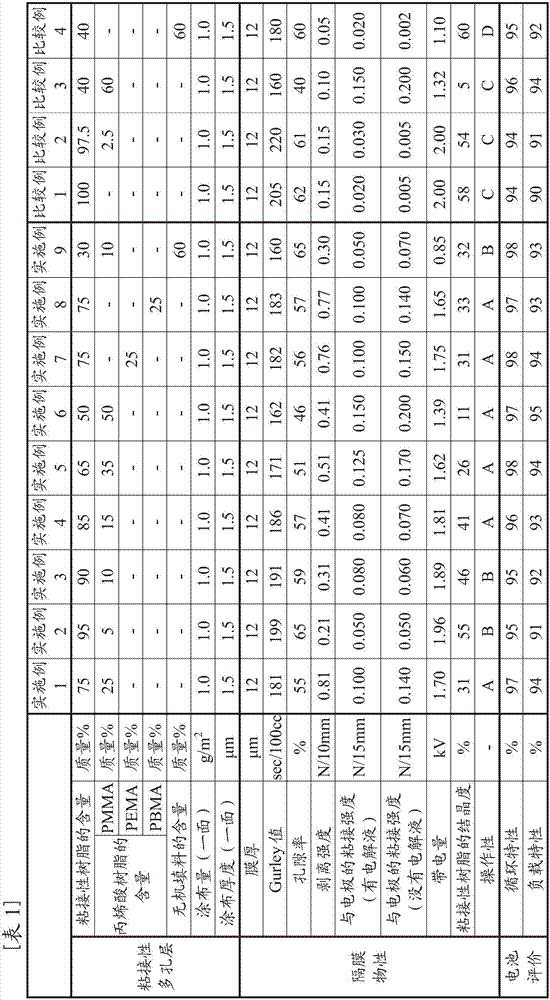

[0226] In Example 1, the content ratio (mass ratio) of the polyvinylidene fluoride-based resin and the acrylic resin was changed as shown in Table 1, except that, in the same manner as in Example 1, a non-aqueous electrolyte battery was obtained. diaphragm.

Embodiment 7

[0228] A separator for a non-aqueous electrolyte battery was produced in the same manner as in Example 1 except that the acrylic resin in Example 1 was changed to polyethyl methacrylate (PEMA; Aldrich - PEMA).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gurley value | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| Gurley value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com