Composite porous membrane, method for producing composite porous membrane and battery separator using same

A technology of a porous membrane and a manufacturing method, which is applied in battery pack parts, chemical instruments and methods, separators/films/diaphragms/spacers, etc., can solve the problem that it is difficult to combine the adhesion and breathability of the heat-resistant resin layer. The range of resistance increases, the adhesion of the heat-resistant resin layer is reduced, and it is difficult to ensure safety, etc., to achieve the effect of excellent ion permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

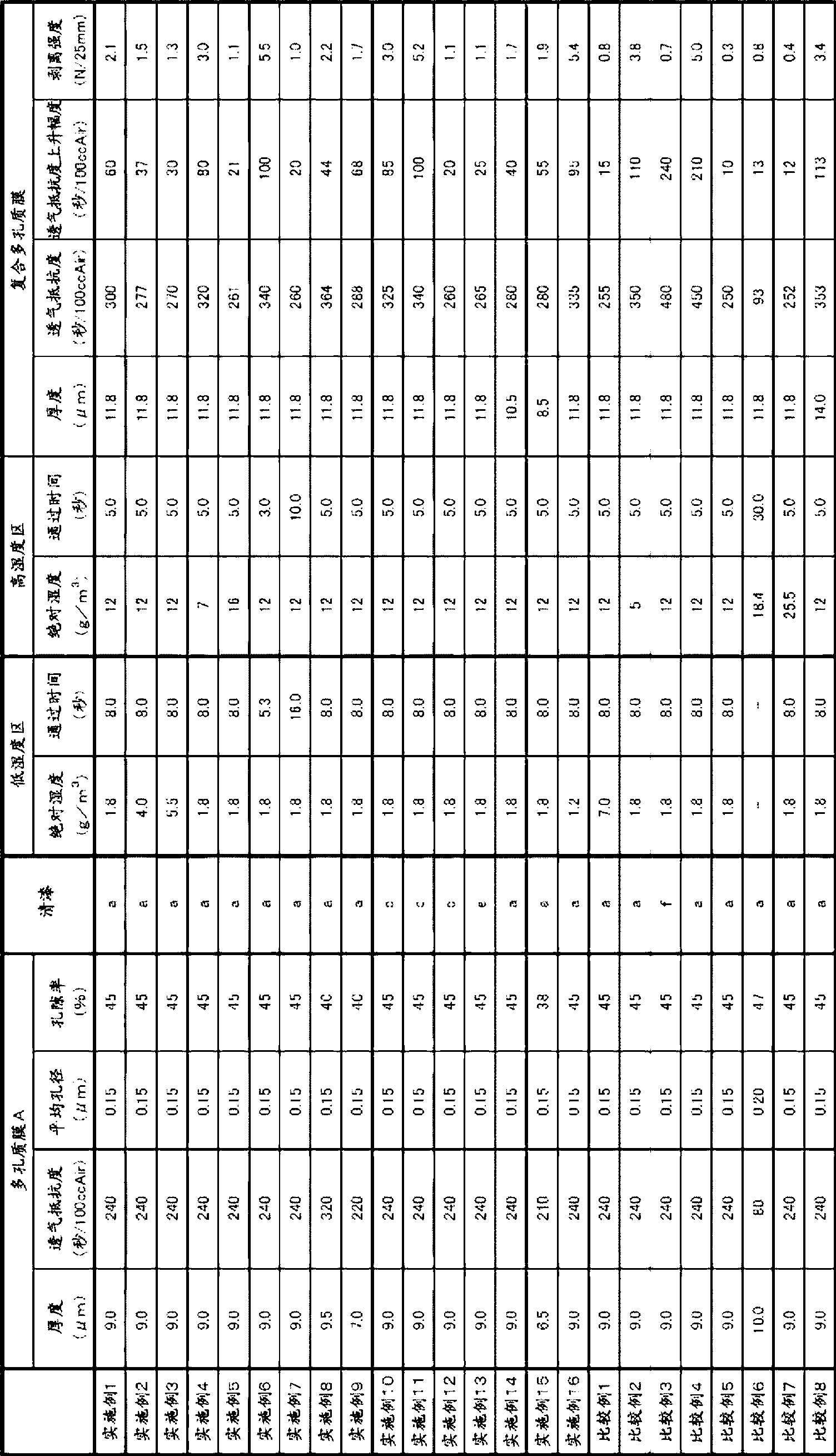

Examples

Embodiment 1

[0120] In a 4-neck flask equipped with a thermometer, a cooling tube, and a nitrogen inlet tube, mix 1 mole of trimellitic anhydride (TMA), 0.8 moles of o-toluene diisocyanate (TODI), 2,4-toluene diisocyanate (TDI) 0.2 mol and 0.01 mol of potassium fluoride were added together with N-methyl-2-pyrrolidone at a solid content concentration of 20%, and after stirring at 100°C for 5 hours, N-methyl-2-pyrrolidone was added at a solid content concentration of 14%. Base-2-pyrrolidone was diluted to synthesize a polyamide-imide resin solution (a). The obtained polyamide-imide resin had a logarithmic viscosity of 1.35 dl / g and a glass transition temperature of 320°C.

[0121] 48 parts by mass of the polyamideimide resin solution (a) was diluted with 39 parts by mass of N-methyl-2-pyrrolidone, and then 13 parts by mass of ethylene glycol was added to prepare the varnish (a) (solid content concentration 5.5 weight%). Apply varnish (a) to the corona-treated surface of a polyethylene tereph...

Embodiment 2

[0123] Make the absolute humidity in the low humidity area 4.0g / m 3 , except that, in the same manner as in Example 1, a composite porous membrane was obtained.

Embodiment 3

[0125] Make the absolute humidity in the low humidity area 5.5g / m 3 , except that, in the same manner as in Example 1, a composite porous membrane was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Logarithmic viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com