Preparation method of array magnetic reduced graphene oxide-carbon nanofiber

A technology of carbon nanofibers and oxidized stones, which is applied in the fields of fiber chemical characteristics, structural parts, textiles and papermaking, etc., can solve the problems that the specific surface area of RGO cannot be fully utilized, the specific surface area of electrode materials is reduced, and the charge storage capacity is reduced. Achieve the effects of increasing conductivity, preventing agglomeration and compounding, and increasing load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of arrayed magnetic RGO@carbon nanofibers

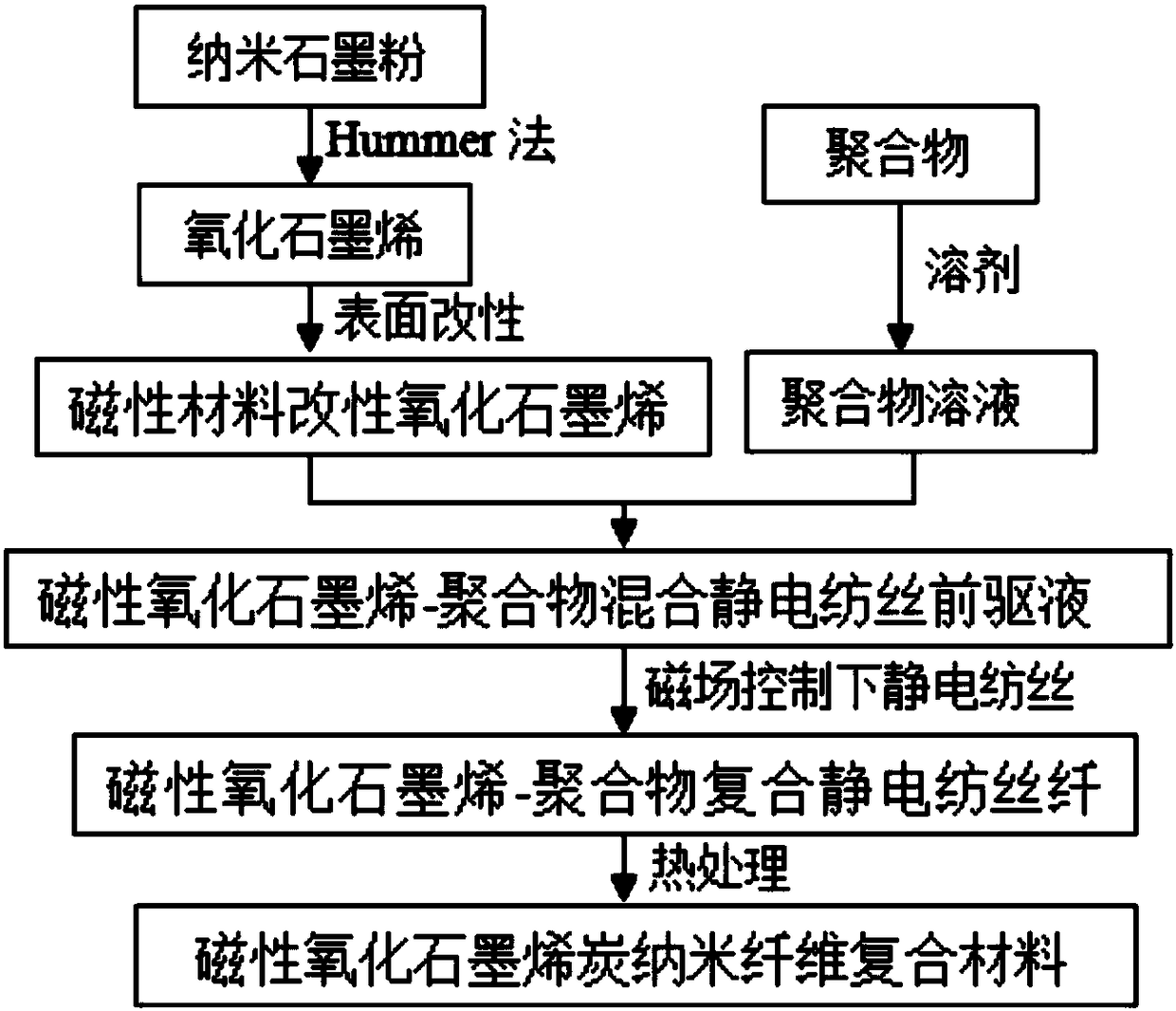

[0034] process such as figure 1 As shown, the specific preparation steps are as follows:

[0035] 1. Preparation of graphene oxide

[0036] Graphene oxide was prepared by the Hummer method; 10.0 g of 10,000 mesh nano-flake graphite was taken as a raw material, and slowly added to a glass container containing 150 mL of concentrated sulfuric acid under stirring, and the temperature was maintained at (0±1) °C; then, slowly added The mixture of 5.0g sodium nitrate and 30.0g potassium permanganate is maintained at (0±1)°C under stirring, and the reaction is completed within 2 hours; in a constant temperature water bath at (35±3)°C, keep stirring for 30 minutes, and slowly add 460mL water, raise the temperature to 98°C, maintain at this temperature for 15 minutes, dilute to 1400mL with warm water, pour 100mL of H 2 o 2 (5wt%), filtered while hot, fully washed the filter cake with 5wt% HCl until there was no...

Embodiment 2

[0048] 1. Preparation of graphene oxide

[0049] Graphene oxide was prepared by the Hummer method; 10.0 g of 12000 mesh nano flake graphite was taken as a raw material, and slowly added to a glass container containing 200 mL of concentrated sulfuric acid under stirring, and the temperature was maintained at (0±1) °C; then, slowly added The mixture of 5.0g sodium nitrate and 30.0g potassium permanganate is maintained at (0±1)°C under stirring, and the reaction is completed within 2 hours; in a constant temperature water bath at (35±3)°C, keep stirring for 30 minutes, and slowly add 460mL water, raise the temperature to 98°C, maintain at this temperature for 15 minutes, dilute to 1400mL with warm water, pour 100mL of H 2 o 2 (5%), filtered while hot, fully washed the filter cake with 5% HCl until there was no SO in the filtrate 4 2- (with BaC1 2 solution detection), at 50°C at P 2 o 5 After drying in vacuum for 24h in the presence, graphene oxide was obtained;

[0050] 2....

Embodiment 3

[0061] 1. Preparation of graphene oxide

[0062] Graphene oxide was prepared by the Hummer method; 10.0 g of 15,000 mesh nano flake graphite was taken as a raw material, and slowly added to a glass container containing 230 mL of concentrated sulfuric acid under stirring, and the temperature was maintained at (0±1)°C; then, slowly added The mixture of 5.0g sodium nitrate and 30.0g potassium permanganate is maintained at (0±1)°C under stirring, and the reaction is completed within 2 hours; in a constant temperature water bath at (35±3)°C, keep stirring for 30 minutes, and slowly add 460mL water, raise the temperature to 98°C, maintain at this temperature for 15 minutes, dilute to 1400mL with warm water, pour 100mL of H 2 o 2 (5%), filtered while hot, fully washed the filter cake with 5% HCl until there was no SO in the filtrate 4 2- (with BaC1 2 solution detection), at 50°C at P 2 o 5 After drying in vacuum for 24h in the presence, graphene oxide was obtained;

[0063] 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com