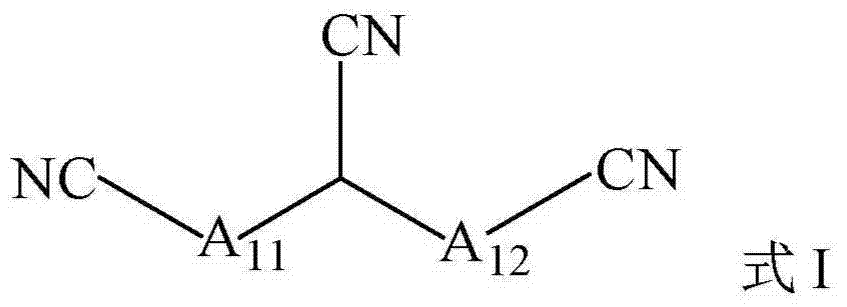

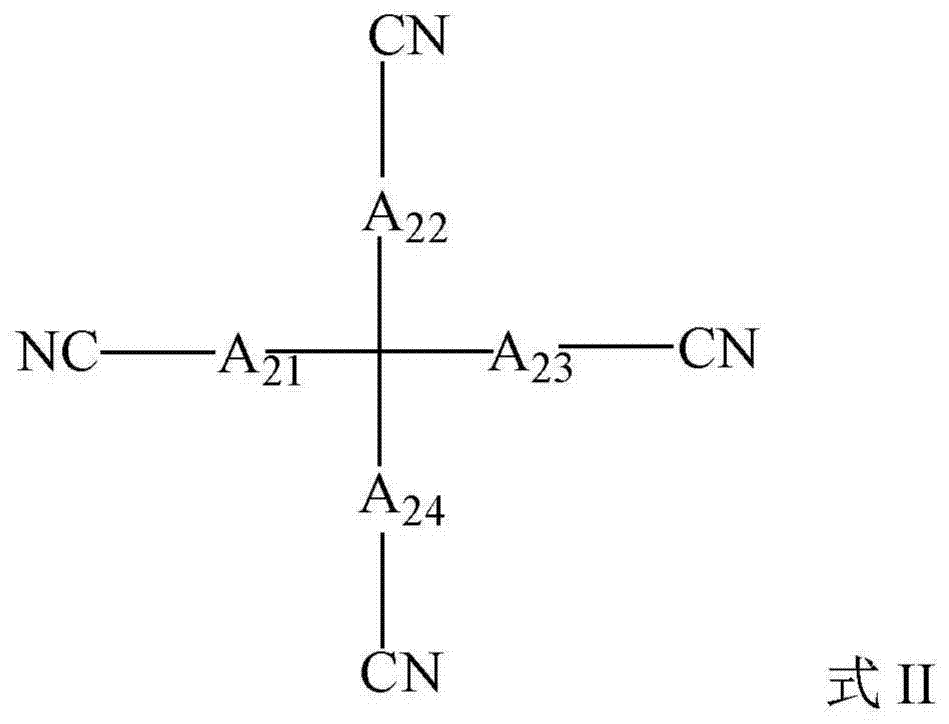

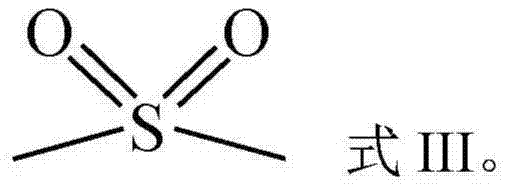

Electrolyte additive and application thereof in lithium ion battery

An electrolyte additive and additive technology, applied in the field of lithium ion batteries, can solve the problems of battery rate and cycle performance attenuation, lithium ion migration and diffusion kinetic performance reduction, interface impedance increase and other problems, achieve excellent high temperature storage performance, improve high temperature cycle performance and low temperature discharge performance, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation of embodiment 1 electrolyte L1~L18

[0045] In an argon-protected glove box, the organic solvent is stirred and mixed according to a certain ratio to obtain the solvent of the electrolyte. Slowly add the lithium salt, after the lithium salt is dissolved, add the additive, stir evenly until there is no precipitation, suspended matter or stratification, continue stirring for 1 hour to obtain the electrolyte. According to the type and proportion of the organic solvent, the type of lithium salt and its concentration in the electrolyte, the type of additive and its concentration in the electrolyte, the obtained electrolytes are respectively denoted as L1-L18.

[0046] The relationship between the serial number of the obtained electrolyte and the type and proportioning of the organic solvent, the type of lithium salt and its concentration in the electrolyte, the type of additive and its concentration in the electrolyte is as shown in Table 1.

[0047] Table 1...

Embodiment 2

[0051] Embodiment 2 The making of lithium-ion battery

[0052] Preparation of positive electrode sheet

[0053] The positive electrode active material lithium cobalt oxide LiCoO 2 , conductive agent conductive carbon black Super-P, binder polyvinylidene fluoride (abbreviated as PVDF, the mass percentage of polyvinylidene fluoride in the binder is 10%) in solvent N-methylpyrrolidone (abbreviated as PVDF Disperse uniformly in NMP) to make positive electrode slurry. The solid content in the positive electrode slurry is 75wt%, and the solid content includes 96wt% lithium cobaltate, 2% PVDF and 2wt% conductive carbon black Super-P. The positive electrode slurry is evenly coated on the positive electrode current collector aluminum foil with a thickness of 16 μm, and the coating amount is 0.018g / cm 2 . After drying at 85°C, cold pressing, trimming, cutting, and slitting were performed, and then dried at 85°C for 4 hours under vacuum, and the tabs were welded to obtain the positi...

Embodiment 3

[0059] Example 3 Lithium-ion battery high temperature storage performance test

[0060] Take 5 lithium-ion secondary batteries C1-C18 and DC1-DC6 prepared in Example 2 respectively, and test their high-temperature storage performance. The specific method is: at 25°C, first charge the batteries to 4.45V, further charged with a constant voltage of 4.45V to a current of 0.05C, and then discharged the battery to 3.0V with a constant current of 0.5C, the discharge capacity of this time is the discharge capacity of the battery before high-temperature storage; The current charges the battery to 4.45V, continues to charge at a constant voltage of 4.45V until the current is 0.05C, and then places it at 60°C for 35 days. After storage, discharge to 3.0V at a constant current rate of 0.5C, charge at a constant current rate of 0.5C to 4.45V, and continue to charge at a constant voltage of 4.45V until the current reaches 0.05C. Calculate the thickness expansion rate, internal resistance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com