Novel electrolyte of lithium-ion battery and preparation method thereof

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems affecting battery high temperature performance, battery cycle performance, battery system performance, etc., to increase the infiltration effect and improve the platform Effect of improving efficiency and high-temperature discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

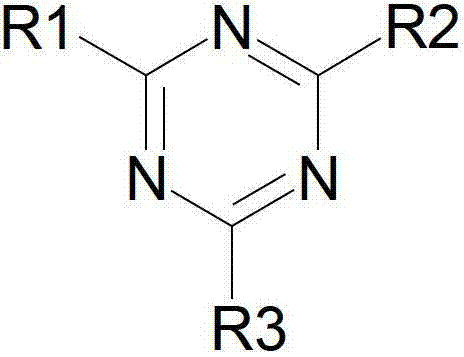

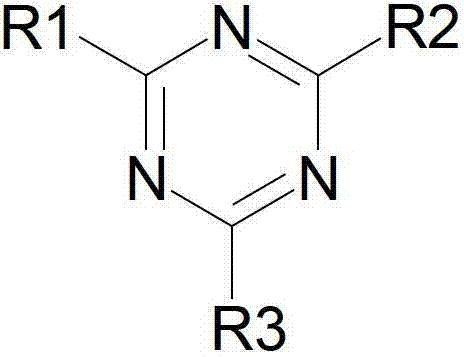

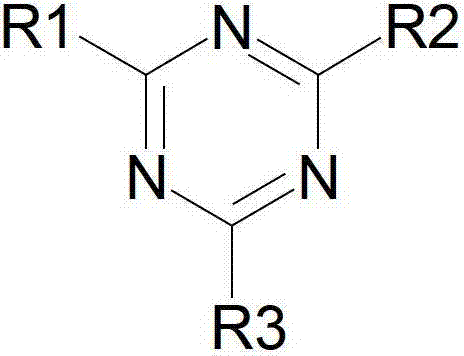

[0023] An electrolyte solution for a lithium-ion battery. Under the condition that the negative electrode sheet of the lithium-ion battery is compressed under high pressure, the electrolyte solution for the lithium-ion battery is composed of 75% to 85% of organic solvent and 10% of lithium salt. ~15%, the additive is 5%~10%, and described additive comprises an organic compound, can form good SEI film in battery, and wherein, the structural formula of this organic compound is expressed as:

[0024]

[0025] The added amount of the organic compound is 0.1%-3% of the total weight. Among them, the three substituent groups of R1, R2, and R3 cannot be hydrogen atoms at the same time, and R1, R2, and R3 can be fluorine atoms, benzene rings, alkane with less than 4 carbon atoms or alkane groups with perfluorinated bands.

[0026] In this embodiment, the organic compound is m-fluoromethyl-s-triazine, which accounts for 1% of the total weight.

[0027] The organic solvents include: ...

Embodiment 2

[0035] The difference between the second embodiment and the first embodiment is that the organic compound is trifluoroethyl-s-triazine, which accounts for 1% of the total weight.

[0036] The organic solvent is a mixture composed of ethylene carbonate (EC), diethyl carbonate (DEC) and methyl ethyl carbonate (EMC), wherein the weight percentage between them is 1:1:1 , accounting for 82.5% of the total weight of the electrolyte; the lithium salt is lithium hexafluorophosphate (LiPF 6 ), accounting for 12.5% of the total weight of the electrolyte; the additives include vinylene carbonate (VC) and trifluoroethyl-s-triazine, which account for 4% and 1% of the total weight respectively.

[0037] The preparation method of the lithium-ion battery electrolyte in the second embodiment is the same as the preparation method in the first embodiment above, and will not be repeated here.

[0038]The trifluoroethyl-s-triazine can form a good SEI film with additives such as vinylene carbona...

Embodiment 3

[0040] The difference between the third embodiment and the first embodiment above is that the organic compound is bis-perfluoroethane-s-triazine, which accounts for 3% of the total weight.

[0041] The organic solvent is a mixture composed of ethylene carbonate (EC), diethyl carbonate (DEC), and methyl ethyl carbonate (EMC), wherein the weight percentage between them is 1:1:1, accounting for 81.5% of the total weight of the liquid; the lithium salt is lithium hexafluorophosphate (LiPF 6 ), accounting for 12.5% of the total weight of the electrolyte; additives include vinylene carbonate (VC), bis-perfluoroethane-s-triazine and propane sultone (PS), which accounted for 2% and 3% of the total weight, respectively and 1%.

[0042] The preparation method of the lithium-ion battery electrolyte in the third embodiment is the same as that in the first embodiment above, and will not be repeated here.

[0043] The bisperfluoroethane-s-triazine can form a good SEI film with additives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com