Valve-controlled type lead-acid storage battery

A lead-acid battery, valve-controlled technology, applied in the field of electrochemistry, can solve the problems of reduced battery discharge performance, increased internal voltage drop, increased battery internal resistance, etc., to improve low-temperature discharge capacity, low-temperature discharge performance, Effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

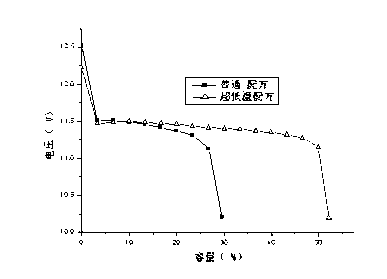

Image

Examples

Embodiment 1

[0021] Valve-regulated lead-acid batteries, which include positive and negative plates;

[0022] The active substances in the lead paste of the positive plate are by weight percentage: lead powder: 81%, short fiber: 0.10%, deionized water: 10%, sulfuric acid with a density of 1.4g / mL: 7.9%, colloidal graphite: 1.0% %.

[0023] The active substances in the lead paste of the negative plate are by weight percentage: lead powder: 79%, short fiber: 0.3%, deionized water: 9.6%, sulfuric acid with a density of 1.4g / mL: 7.8%, acetylene black: 0.5% %, humic acid: 1%, lignin: 1%, barium sulfate: 0.8%.

Embodiment 2

[0025] Valve-regulated lead-acid batteries, which include positive and negative plates;

[0026] The active substances in the lead paste of the positive plate are by weight percentage: lead powder: 68%, red lead: 10.65%, short fiber: 0.15%, deionized water: 11%, sulfuric acid with a density of 1.4g / mL: 10% %, activated carbon: 0.4%.

[0027] The active substances in the lead paste of the negative plate are by weight percentage: lead powder: 82%, short fiber: 0.1%, deionized water: 9.4%, sulfuric acid with a density of 1.4g / mL: 6.8%, acetylene black: 0.1% %, humic acid: 0.8%, lignin: 0.3%, barium sulfate: 0.5%.

Embodiment 3

[0029] Valve-regulated lead-acid batteries, which include positive and negative plates;

[0030] The active substance in the lead paste of the positive plate is by weight percentage: lead powder: 75%, red lead: 5%, short fiber: 0.1%, deionized water: 11%, sulfuric acid with a density of 1.4g / mL: 8 %, titanium dioxide: 0.9%.

[0031] The active substances in the lead paste of the negative plate are by weight percentage: lead powder: 79%, short fiber: 0.2%, deionized water: 9.6%, sulfuric acid with a density of 1.4g / mL: 9%, acetylene black: 0.4% %, humic acid: 0.9%, lignin: 0.3%, barium sulfate: 0.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com