Frame type double-row-pile cement-soil wall foundation pit enclosure structure and construction method thereof

A technology for foundation pit enclosure and cement-soil walls, which is applied to foundation structure engineering, underwater structures, sheet pile walls, etc., can solve problems such as unenvironmental protection of construction, waste of materials, bending stiffness, and failure to effectively control support deformation. , to achieve the effect of improved lateral stiffness, high bearing capacity, civilized and environmentally friendly construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

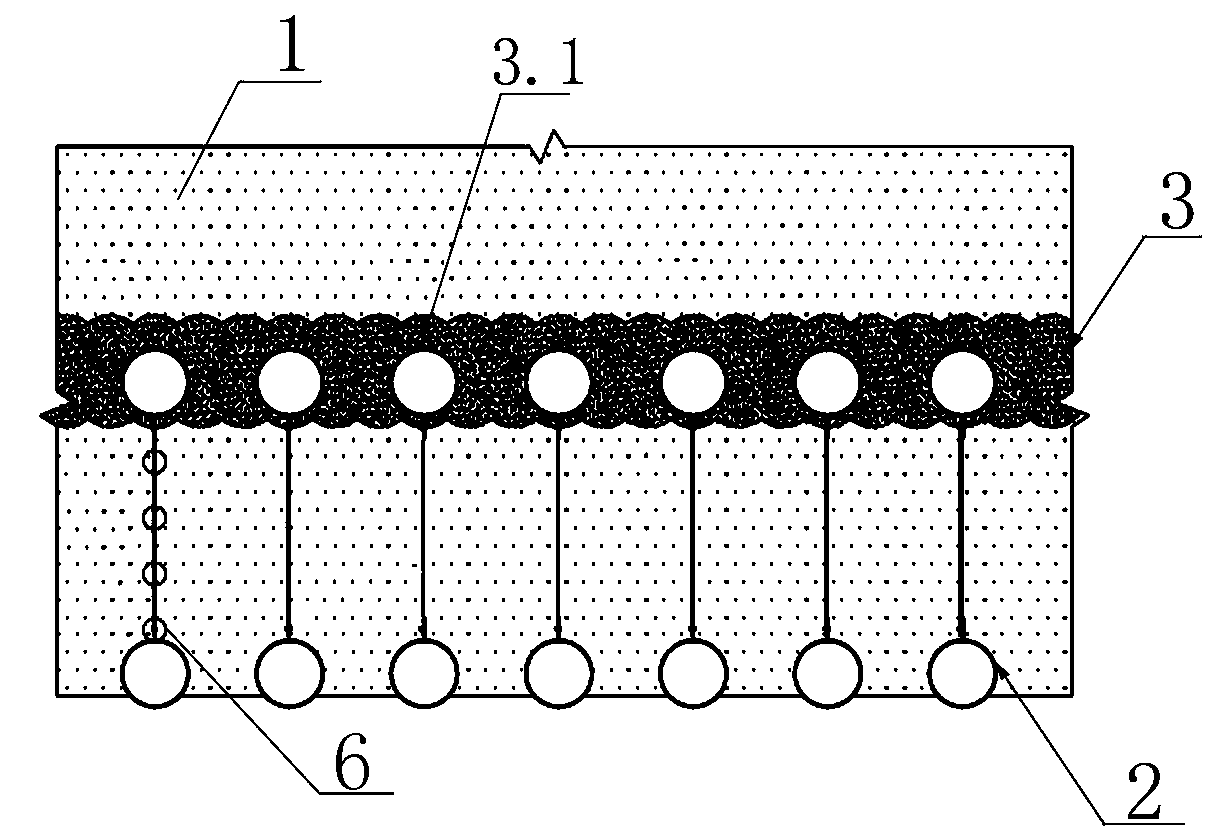

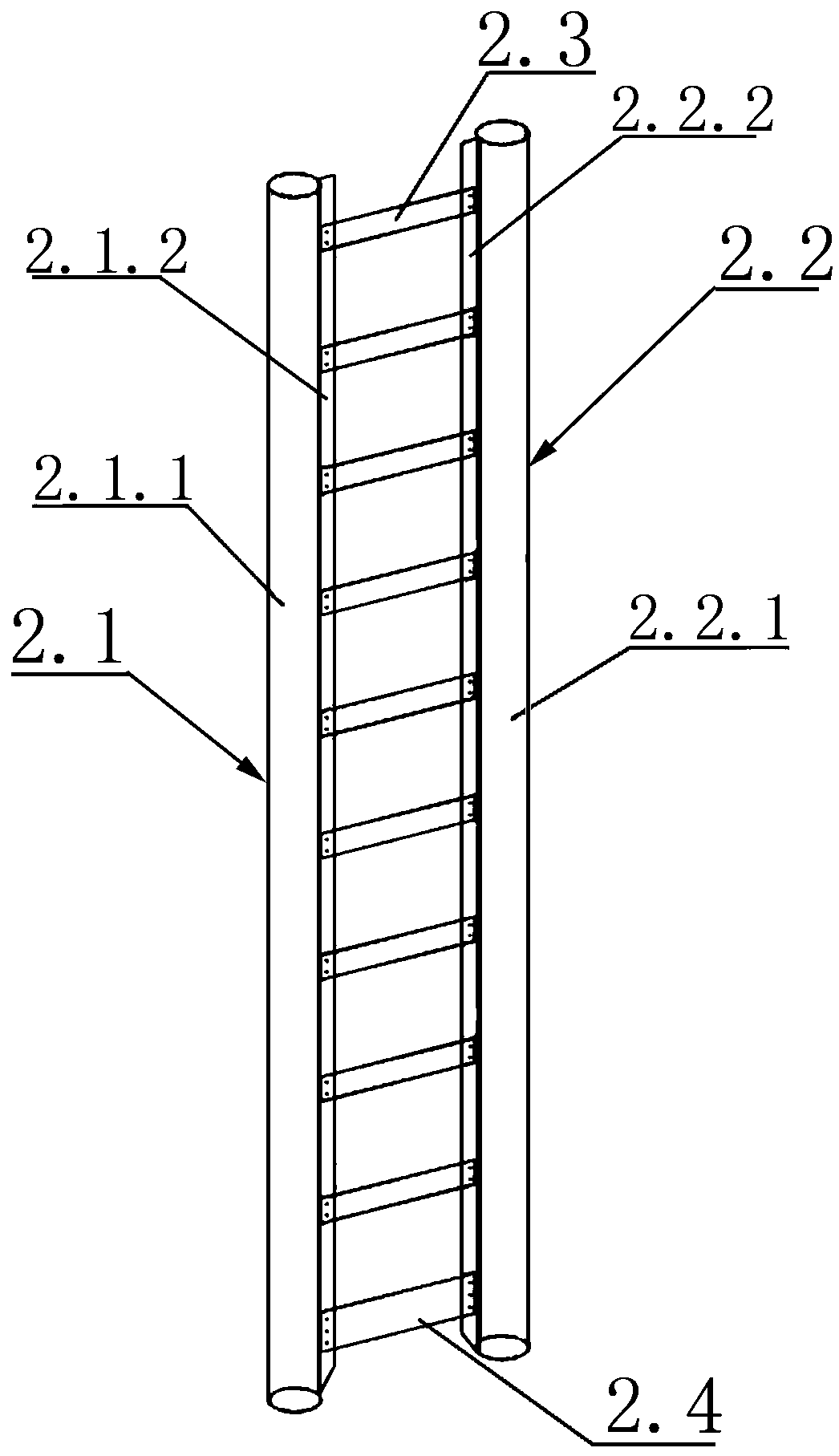

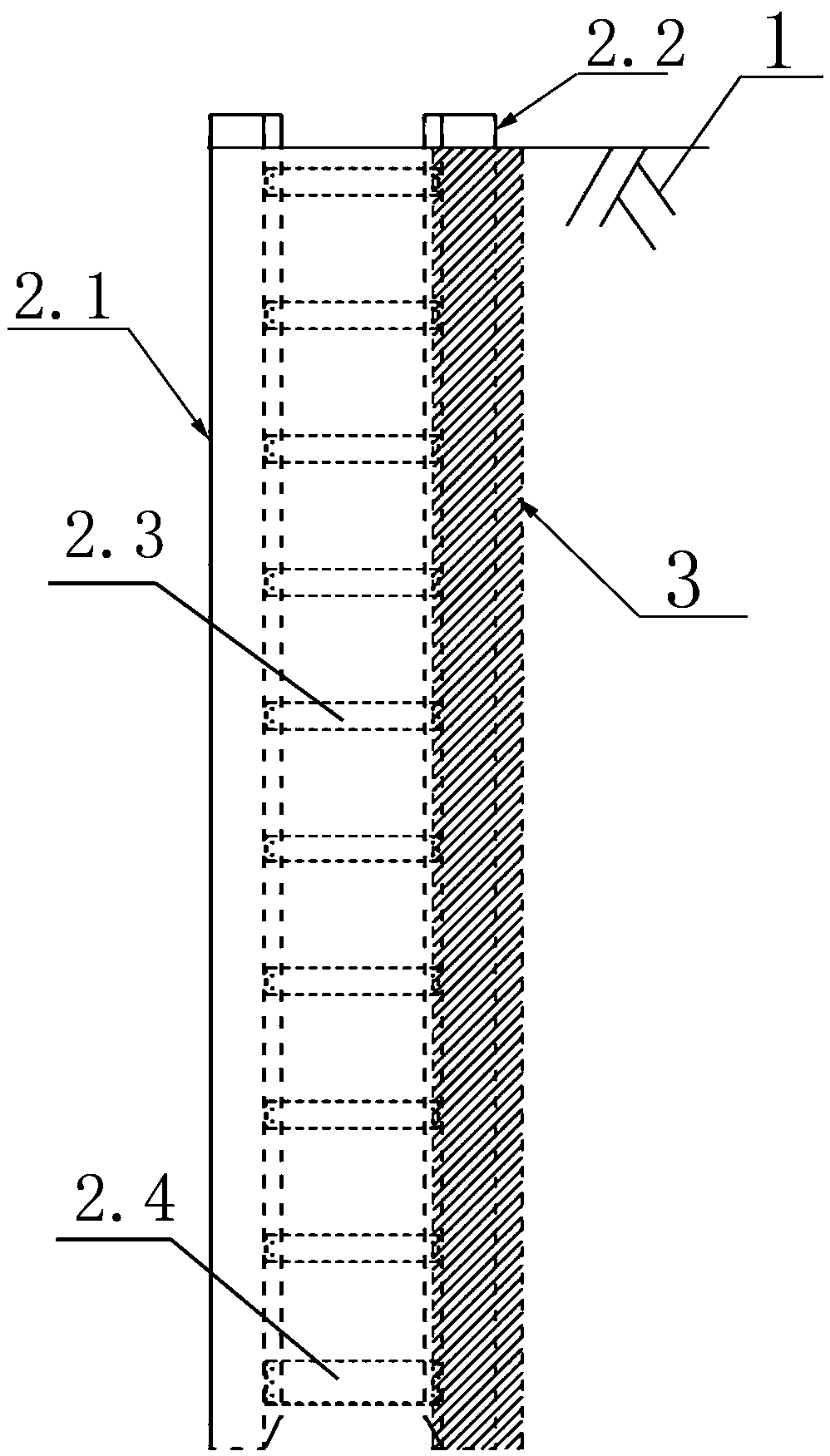

[0035] Such as Figure 1-6As shown, this frame-type double-row pile cement-soil wall foundation pit enclosure structure is arranged in the soil body 1 around the foundation pit; it includes a frame-type double-row pile unit 2 and a cement-soil mixing pile water-stop curtain 3; The water-stop curtain 3 of the cement-soil mixing pile is arranged along the edge of the foundation pit, and a distance is left from the edge of the foundation pit; the water-stop curtain 3 of the cement-soil mixing pile is composed of a group of cement-soil mixing piles 3.1, and the adjacent cement-soil mixing pile The mixing piles 3.1 are interlocked and arranged; the frame-type double-row pile units 2 have a group and are arranged in parallel and at intervals along the edge of the foundation pit; wherein, each frame-type double-row pile unit 2 is a frame structure with high bearing capacity and rigidity Large, the frame-type double-row pile unit 2 includes a front-row single-arm steel pipe pile 2.1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com