Variable rigidity buckling-restrained brace containing lead core materials

A buckling constraint, core material technology, applied in building components, building types, earthquake resistance, etc., can solve problems such as low lateral stiffness, and achieve the effects of improving lateral stiffness, low material cost, and clear design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

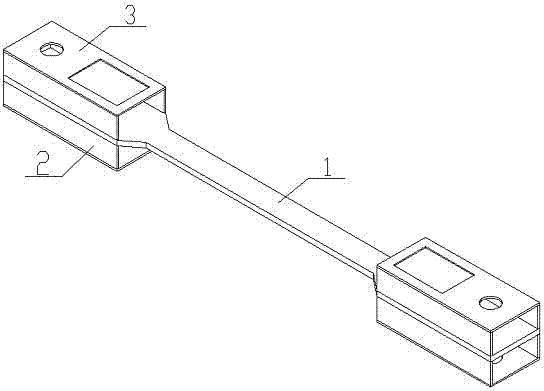

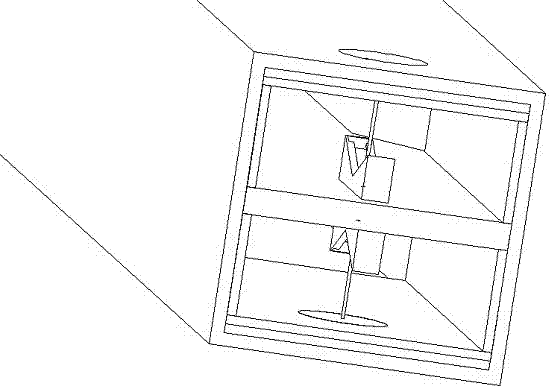

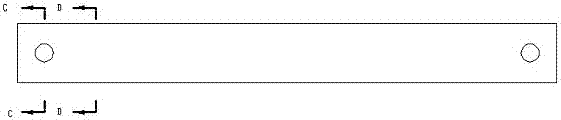

[0026] Such as Figure 1 to Figure 14 As shown, a variable stiffness buckling-constrained support with lead core material, including core plate 1, stiffener 2, stiffener plate 3, filling material 4, steel plate with groove 5, external restraint member 6, lead core material 7 , jacking device, described core plate 1 periphery is provided with external constraint member 6, and filler material 4 is arranged between core plate 1 and external constraint member 6, is coated with non-adhesive material between filler material 4 and core plate 1, makes filler material There is no bonding to the core board. The two ends of the core plate 1 are provided with stiffening ribs 2 on the upper and lower sides, and the upper part of the stiffening ribs 2 is fixed with the stiffening ribs 3, and the grooved steel plate 5 is fixed inside the external restraint me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com