Fabricated concrete beam column sliding self-resetting joint connecting structure and splicing method

A technology of node connections and reinforced concrete columns, applied to structural elements, building components, building structures, etc., can solve problems such as brittle failure at the grouting place, poor energy consumption, etc., to avoid damage and damage, prevent excessive concentration of structural deformation, and operate Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

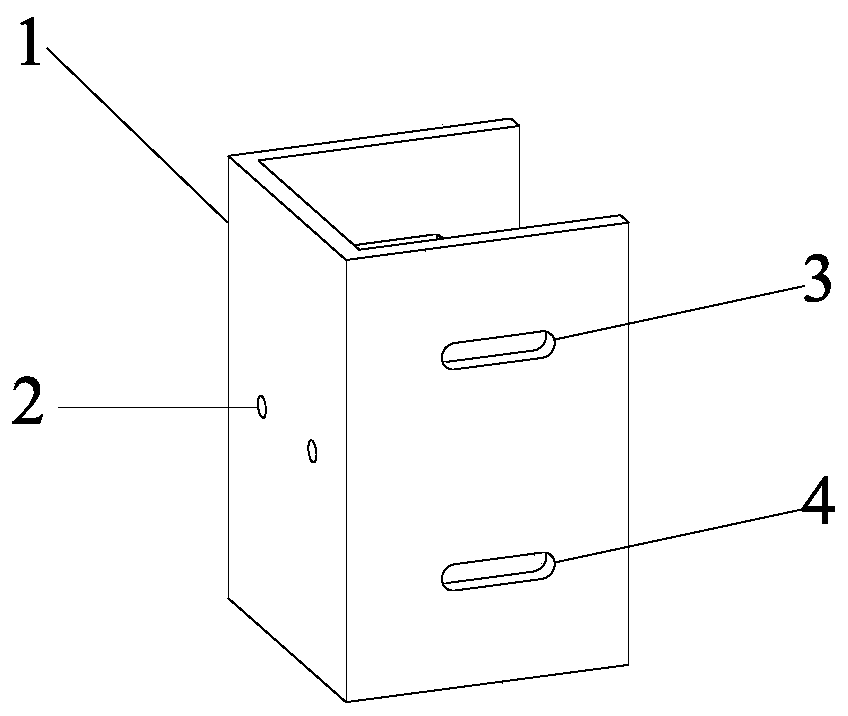

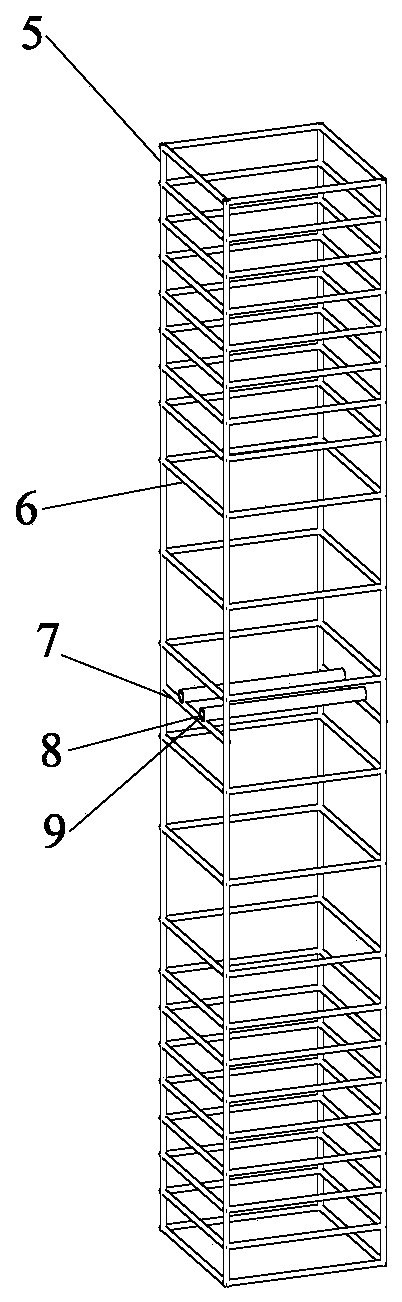

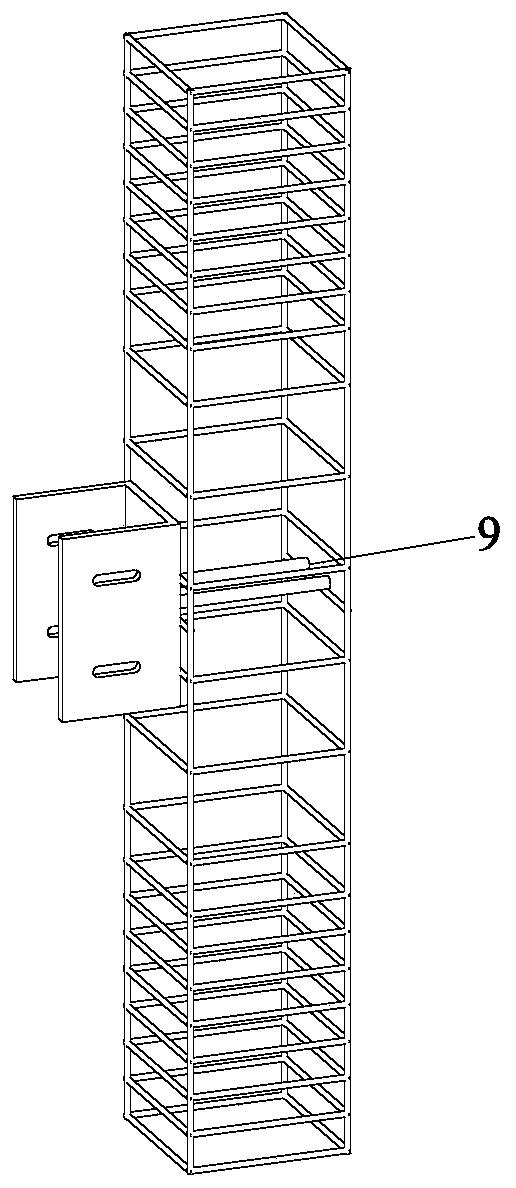

[0046] Specific implementation mode one: see Figure 1-Figure 19 This embodiment will be described. The prefabricated concrete beam-column sliding self-resetting node connection structure described in this embodiment includes U-shaped steel plate embedded parts, prefabricated reinforced concrete columns, prefabricated reinforced concrete beams, mountain-shaped steel plate embedded parts, sliding positioning bolt groups, If prestressed tendons 25 and several prestressed tendon anchors 26, U-shaped steel plate embedded parts are positioned and installed on the prefabricated reinforced concrete column, and mountain-shaped steel plate embedded parts are positioned and installed on the prefabricated reinforced concrete beam. The prefabricated reinforced concrete beams and prefabricated reinforced concrete columns are vertically connected with the U-shaped steel plate embedded parts and the mountain-shaped steel plate embedded parts. The bolt groups are matched and connected to ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com