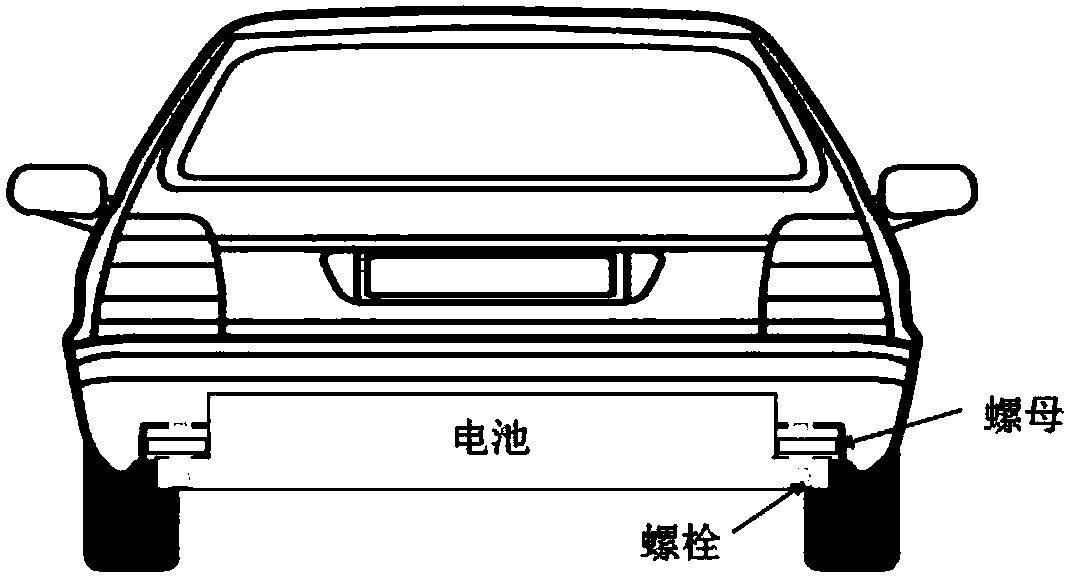

Method and device for detecting connection state between battery and vehicle body, controller and medium

A connection status and detection method technology, which is applied in electrical connection testing, battery/fuel cell control devices, electrical devices, etc., can solve problems such as long charging time and inconvenient use, achieve reliable detection results, prevent battery drop, The effect of safe driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

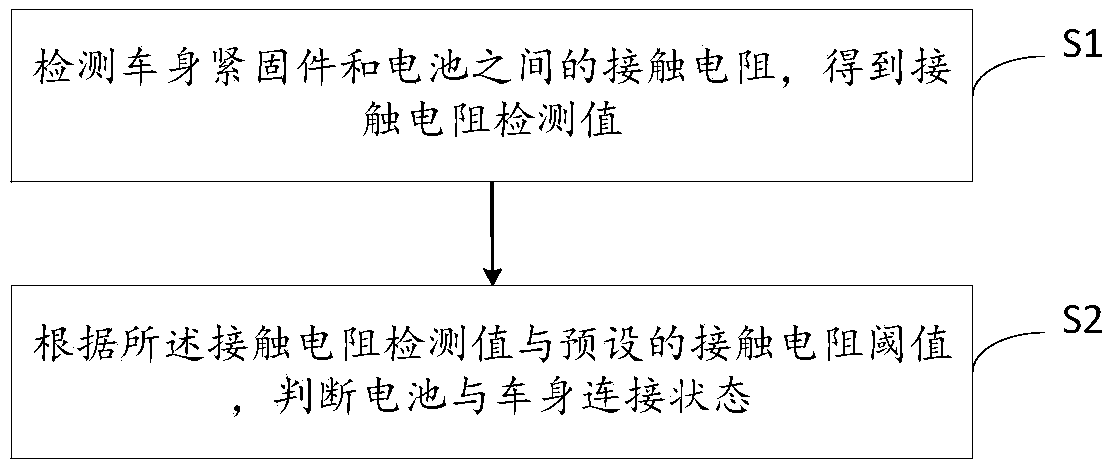

[0082] Step S11 , detecting the contact resistance between each vehicle body fastener and the battery one by one, and obtaining the contact resistance detection value between each vehicle body fastener and the battery.

[0083] Step S11 includes:

[0084] Step S111, connecting a detection circuit between each vehicle body detection point and the corresponding battery detection point to form a detection loop;

[0085] Step S112, obtain the contact resistance value between each vehicle body detection point and the corresponding battery detection point through the detection circuit,

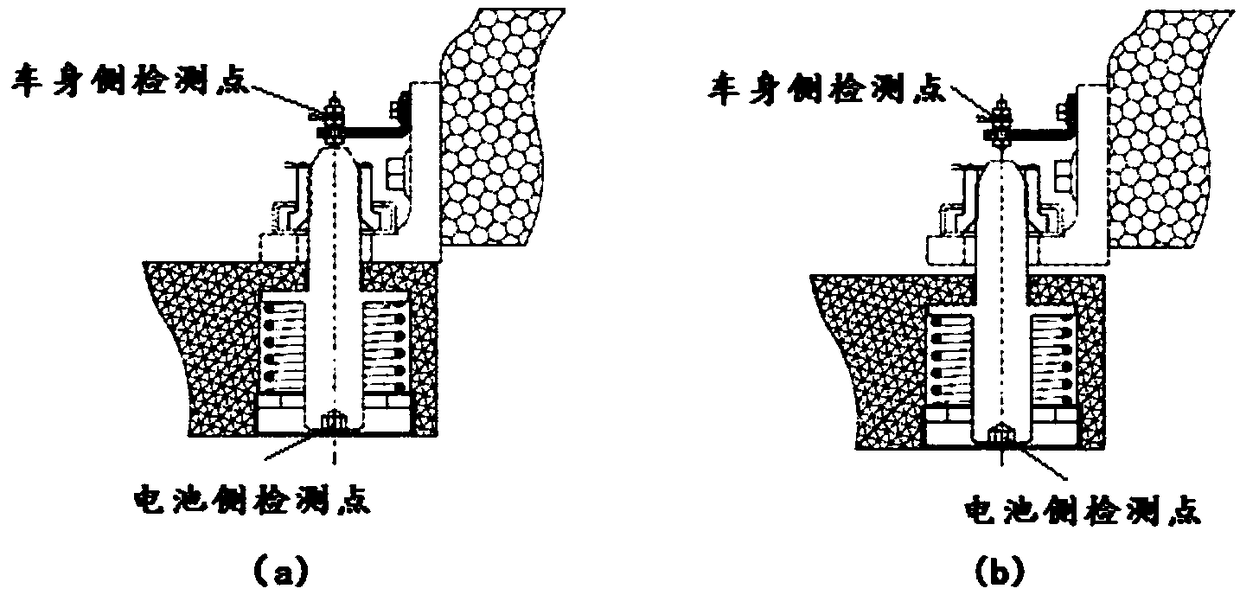

[0086] Wherein, one body detection point is set on each body fastener, all the battery detection points are located on the battery side, and each body detection point corresponds to a battery detection point. Such as image 3 As shown in , respectively show the state of fastening and loosening of the connection, as well as the location of the detection points on the body side and battery side.

...

Embodiment 2

[0091] In the actual detection process, since the method of detecting a single contact resistance described in Embodiment 1 is directly used, a detection circuit needs to be established between the vehicle body and the battery, and the detection process is relatively difficult, so the following process can be used for detection:

[0092] Step S12, assuming that there are M body fasteners in total on the electric vehicle, wherein M is an integer greater than or equal to 2,

[0093] Divide M body fasteners into N groups, where N is an integer greater than or equal to 1, each group includes P body fasteners, where 2≤P≤M, and N groups of fasteners include each body fasteners;

[0094] It should be noted that there are many ways of grouping, which can be set according to specific testing requirements, for example, testing can be done in pairs, that is, two-two testing, or a group of three, a group of four, and so on. The number of body fasteners included in each group can be the s...

Embodiment 3

[0124] The detection circuit 1 is also used to connect each vehicle body detection point and the corresponding battery detection point, detect the contact resistance between each body fastener and the battery one by one, and obtain the contact resistance detection value between each body fastener and the battery .

[0125] Wherein, the vehicle body detection point is located on the body fastener on the side of the vehicle body, the battery detection point is located on the battery side, and each vehicle body detection point corresponds to a battery detection point. Such as image 3 As shown in , respectively show the state of fastening and loosening of the connection, as well as the location of the detection points on the body side and battery side.

[0126] The judgment module 2 is used for:

[0127] Comparing the contact resistance detection value between each body fastener and the battery with the contact resistance threshold value between the corresponding body fastener ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com