Orthodontic pliers

An orthodontic and forceps arm technology, applied in the field of orthodontic forceps, can solve the problems of increased purchase cost, waste of resources, discarding of orthodontic forceps, etc., and achieve the effects of saving resources, improving equipment utilization, and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

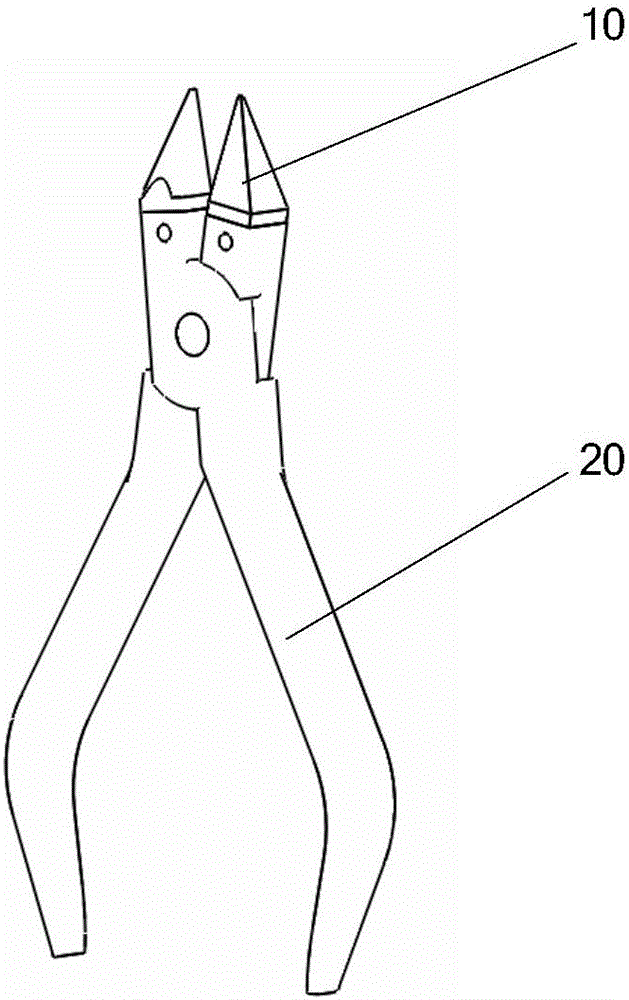

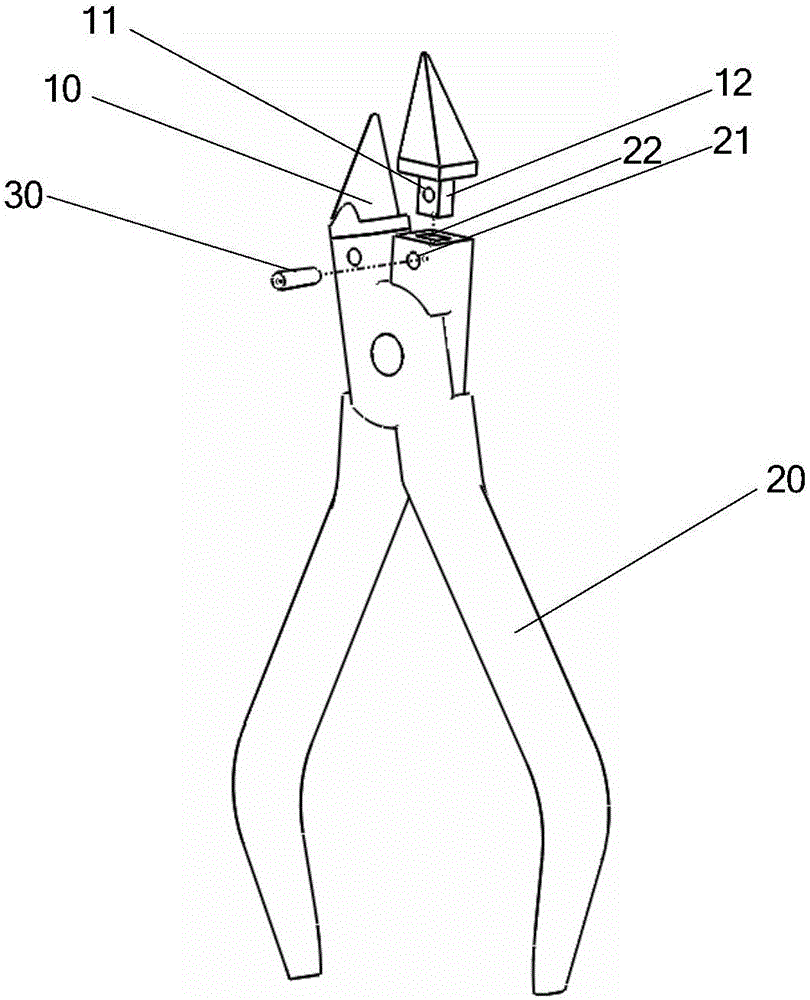

[0019] Such as figure 1 , figure 2 As shown, the orthodontic pliers of the present application, an embodiment thereof, includes a pliers head 10, a pliers arm 20 and a fastener 30, the pliers head 10 is provided with a first mounting hole 11, and the pliers arm 20 is provided with a second mounting hole 21. Fasteners 30 are passed through the first installation hole 11 and the second installation hole 21, the fasteners 30 are interference fit with the first installation hole 11 and the second installation hole 21 respectively, and the pliers head 10 passes through the fasteners 30 is detachably installed on the pliers arm 20. The first installation hole 11 of the present application may include a tapered hole, and the second installation hole 21 may also include a tapered hole. The fastener 30 may include a pin, specifically a tapered pin.

[0020] In one embodiment, the pliers head 10 is provided with a boss 12, the first installation hole 11 is arranged on the boss 12, t...

Embodiment 2

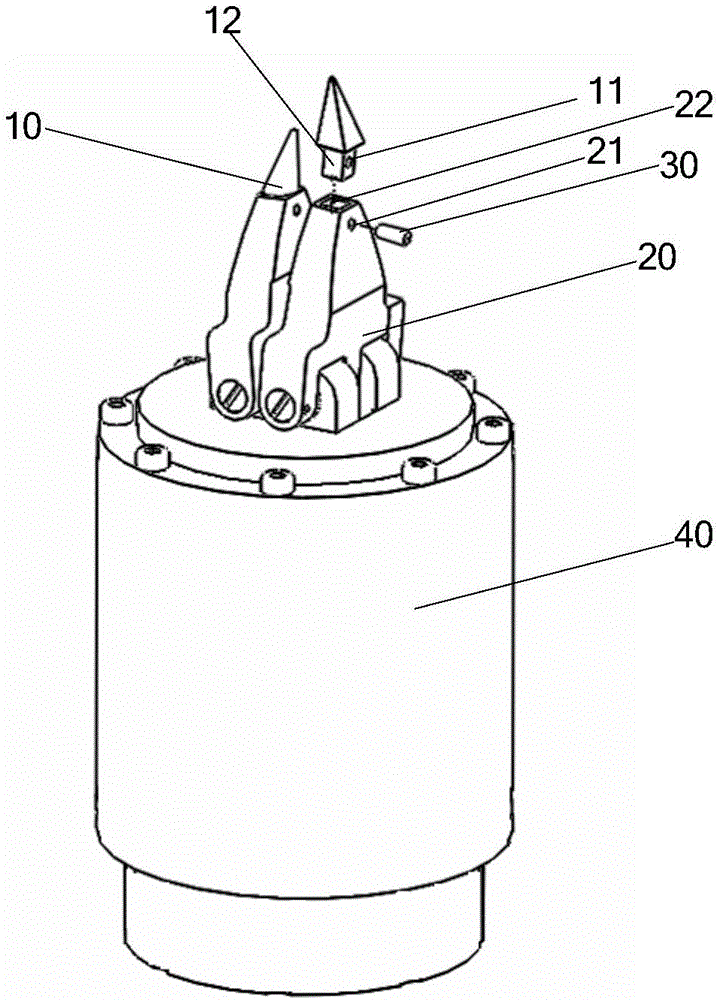

[0025] Such as image 3 As shown, this embodiment is a robotic orthodontic forceps. The difference between this embodiment and Embodiment 1 is that it also includes a mechanical arm 40 on which the forceps arm 20 is arranged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com