Inflection point prefabricated column connecting node and assembling method thereof

A technology for connecting nodes and assembling methods, applied in the directions of columns, piers, pillars, etc., can solve the problems of joint safety, integral discount, affecting the overall safety of the structure, affecting the construction period, etc., and achieving enhanced ductility and lateral stiffness. , The effect of low cost and simplified construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art may make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

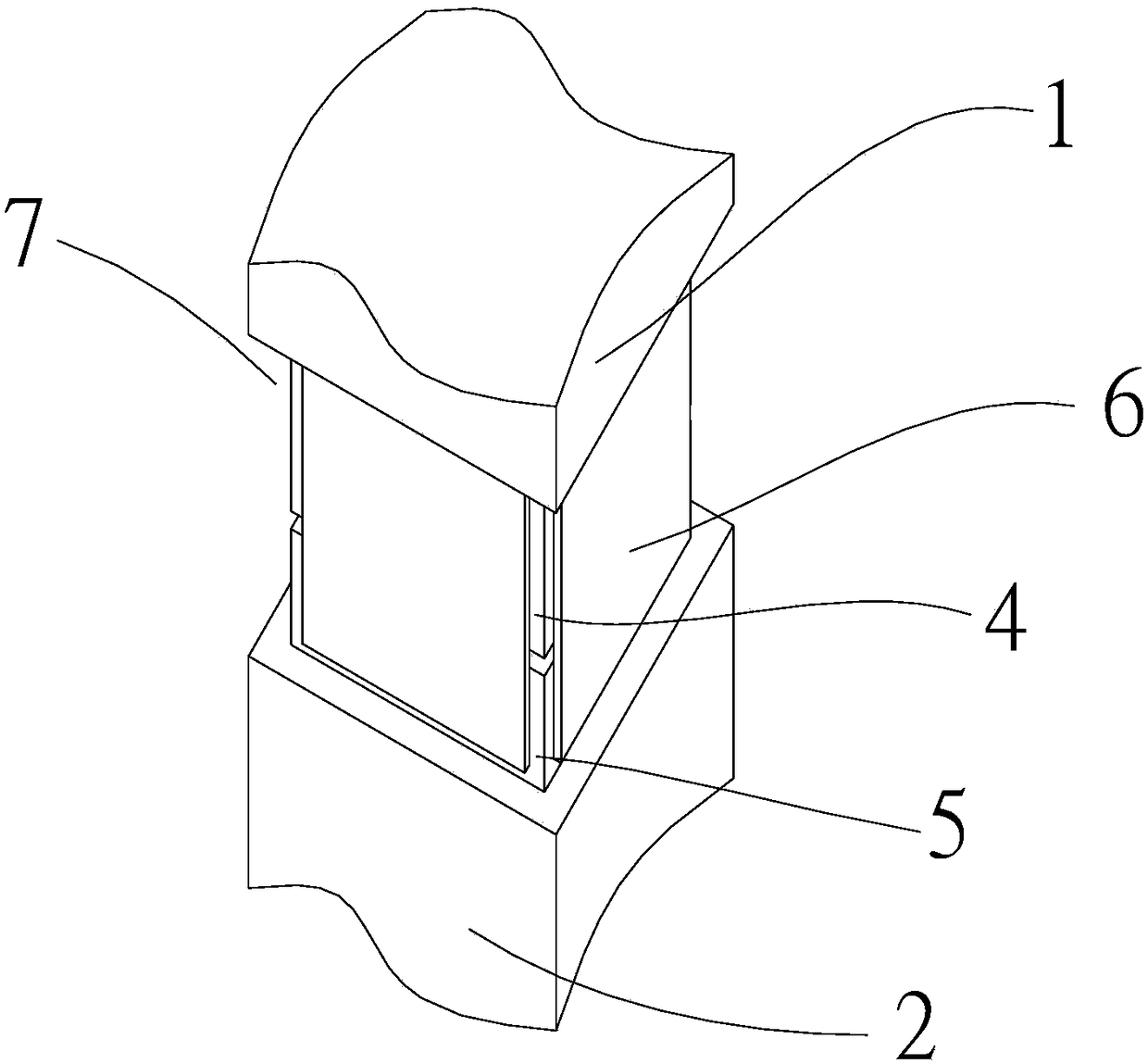

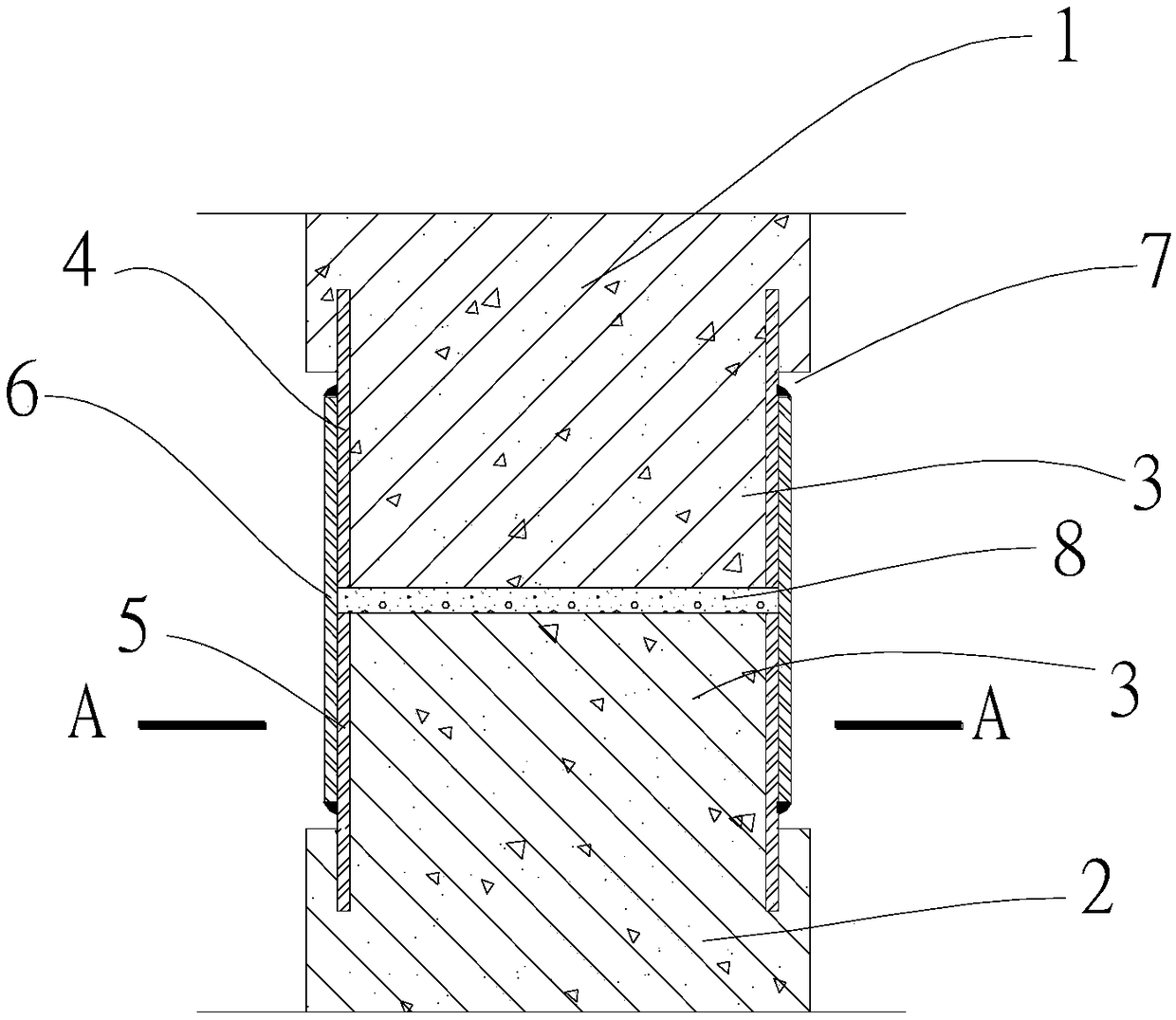

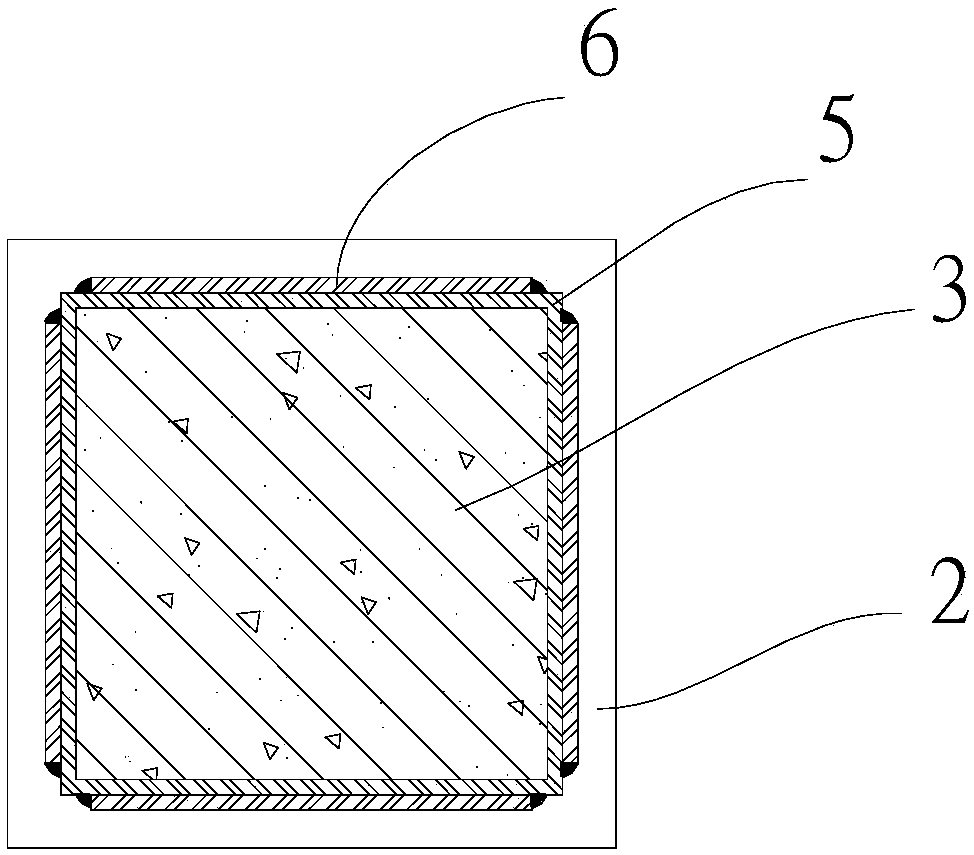

[0037] Embodiments of the present invention are as follows, with reference to Figure 1~3 , a connection node of inflection point prefabricated columns, including an upper precast column 1 and a lower precast column 2 arranged up and down, the splicing ends of the upper precast column 1 and the lower precast column 2 are provided with protrusions 3, and the upper prefabricated column The protruding heads 3 of the column 1 and the lower prefabricated column 2 are respectively sleeved with a first hoop 4 and a second hoop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com