High-voltage lithium-ion battery electrolyte

A lithium-ion battery and electrolyte technology, which is applied in the field of high-voltage lithium-ion battery electrolyte, can solve problems such as film thickness, poor low-temperature discharge performance, and large irreversible capacity, and achieve improved cycle performance, wettability, and high battery capacity. The effect of chemical reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

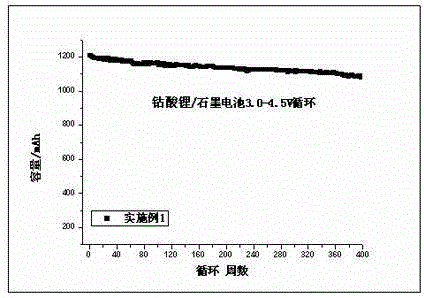

Embodiment 1

[0053] In a glove box filled with argon (moisture 2 HCF 2 CH 2 OCF 2 CF 2 H, the amount added accounts for 0.5%, 5.0%, 1.0%, and 5.0% of the total mass of the electrolyte respectively; finally, lithium hexafluorophosphate accounting for 12.5% of the total mass of the electrolyte is slowly added to the mixed solution, and the lithium ion of Example 1 is obtained after stirring evenly. battery electrolyte.

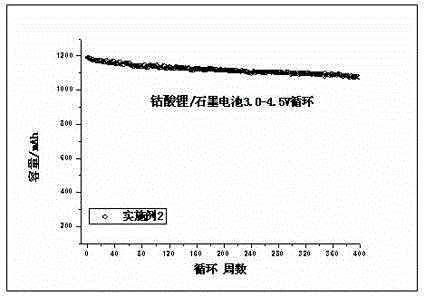

Embodiment 2

[0055] In a glove box filled with argon (moisture 2 HCF 2 CH 2 OCF 2 CF 2 H, the amount added accounts for 1.0%, 5.0%, 1.5%, and 7.0% of the total mass of the electrolyte; finally, lithium hexafluorophosphate, which accounts for 13.0% of the total mass of the electrolyte, is slowly added to the mixed solution, and the lithium ion of Example 2 is obtained after stirring evenly. battery electrolyte.

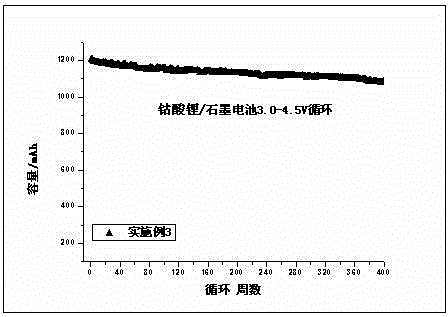

Embodiment 3

[0057] In a glove box filled with argon (moisture 2 HCF 2 OCH 2 CF 3 , the added amount accounts for 1.5%, 5.5%, 2.0%, and 5.0% of the total mass of the electrolyte; finally, slowly add 1.0% of the total mass of the electrolyte to the mixed solution of lithium difluorooxalate borate and 12% of lithium hexafluorophosphate, and stir evenly Obtain the lithium ion battery electrolyte of embodiment 3 afterward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com