Graphene-loaded vanadium pentoxide composite material, preparation method thereof and application of graphene-loaded vanadium pentoxide composite material in aqueous zinc ion battery

A technology of vanadium pentoxide and vanadium pentoxide nanometer, applied in the field of new energy batteries, can solve the problems of low conductivity, poor cycle stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1.V 2 o 5 Preparation of the @graphene complex:

[0045] Measure 25mL of N,N-dimethylformamide (DMF) in a beaker, then weigh 50mg of graphene into it, and ultrasonically disperse it for 60min to obtain a uniform graphene dispersion, and then weigh 3mmol VCl 3 Add in the graphene dispersion liquid, stir to obtain homogeneous solution, be recorded as solution A; Then take by weighing 3mmol of terephthalic acid (H 2 BDC) was dissolved in 25mL of DMF, stirred evenly to obtain a homogeneous solution, which was recorded as solution B; under the state of magnetic stirring, solution B was added dropwise to solution A, and then the mixed solution was transferred to 100mL of polysulfide after stirring continuously for 60min. In the high-pressure reaction kettle lined with vinyl fluoride, seal the high-pressure reaction kettle and put it into a program-controlled blast drying oven. The heating rate is set at 2°C / min, heated to 180°C, and kept for 12 hours. The cooling rate per...

Embodiment 2

[0052] Embodiment 2 (comparative example)

[0053] The difference between embodiment 2 and embodiment 1 is: take the VCl of 3mmol 3 Dissolve in 25 mL of DMF, ie without graphene addition.

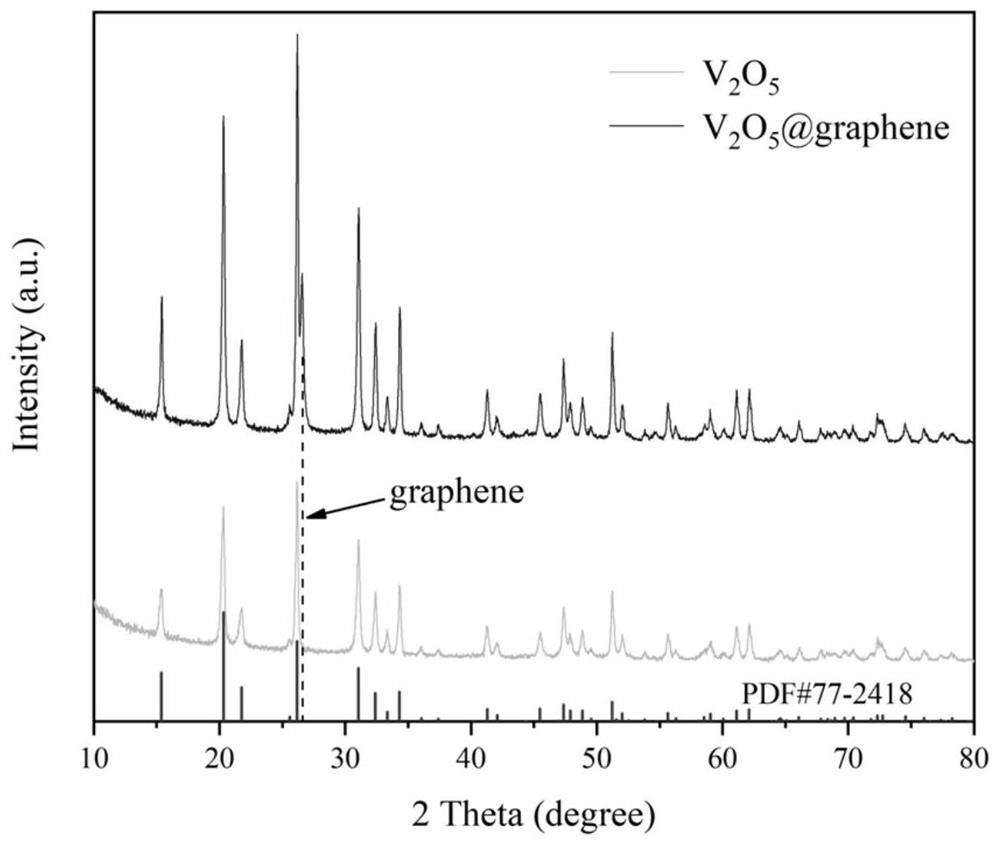

[0054] figure 1 It can be seen from the comparison of the XRD spectra in the figure that the derived V 2 o 5 The position of the diffraction peak can completely correspond to the orthorhombic vanadium pentoxide (PDF#77-2418), V 2 o 5 In addition to the diffraction peak of graphene at 2θ=26.5° in the @graphene composite material, other diffraction peak positions can also correspond to it, which proves the successful synthesis of the material.

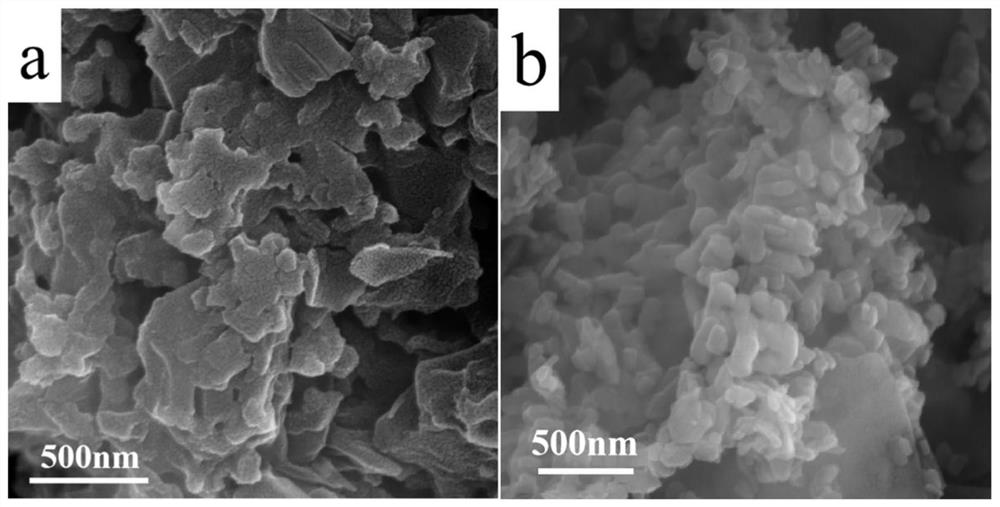

[0055] figure 2 aDisplay V 2 o 5 It is a nanosheet structure with neat and uniform morphology, and the size of the nanosheet is 400-500nm; it can be seen from 2b that V 2 o 5 V in the @graphene complex 2 o 5 The nanosheets are evenly distributed on the two-dimensional graphene to form a two-dimensional hierarchical composite structure, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com