Patents

Literature

175 results about "Density reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

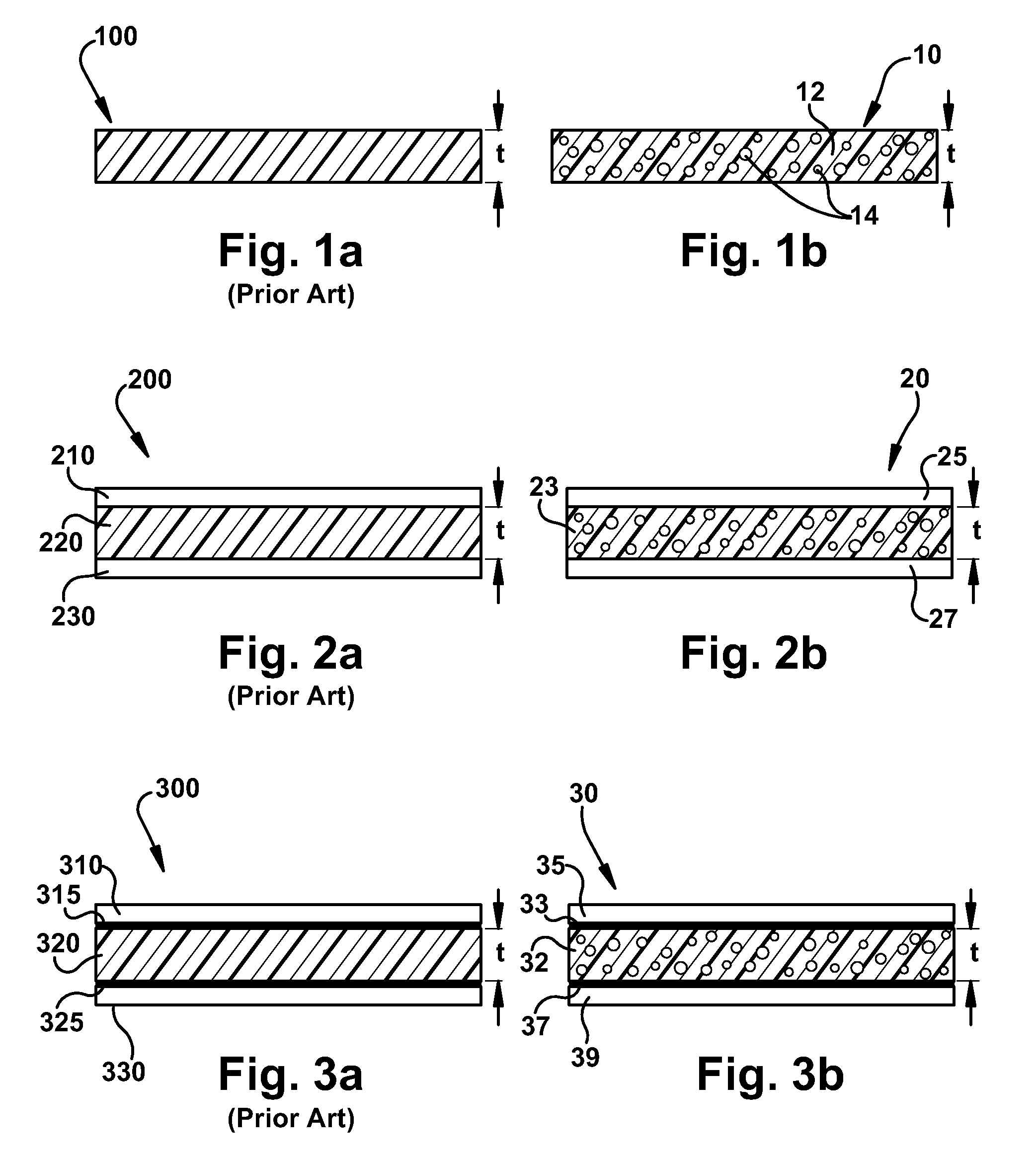

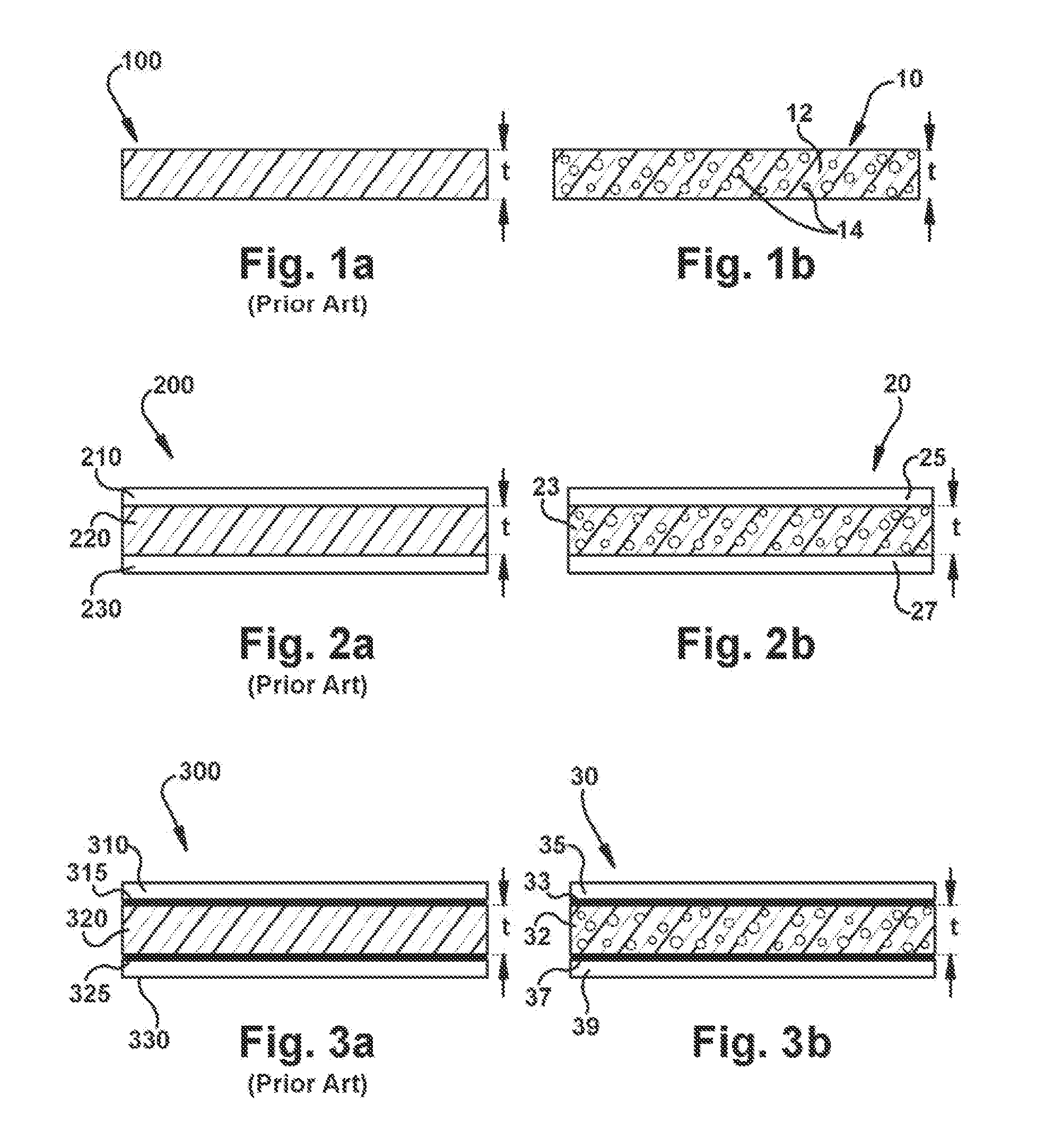

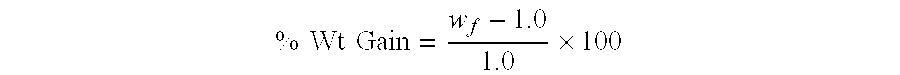

The reduction in density is primarily based on the displacement of polyurethane with a less dense material. Furthermore, with the incorporation of microspheres, RIM parts can be processed with a lower resin specific gravity, i.e., can increase the gas loading without negatively affecting the part quality.

Reduced density article

InactiveUS10087556B2Additive manufacturing apparatusIncreasing energy efficiencyMicro structurePolymer science

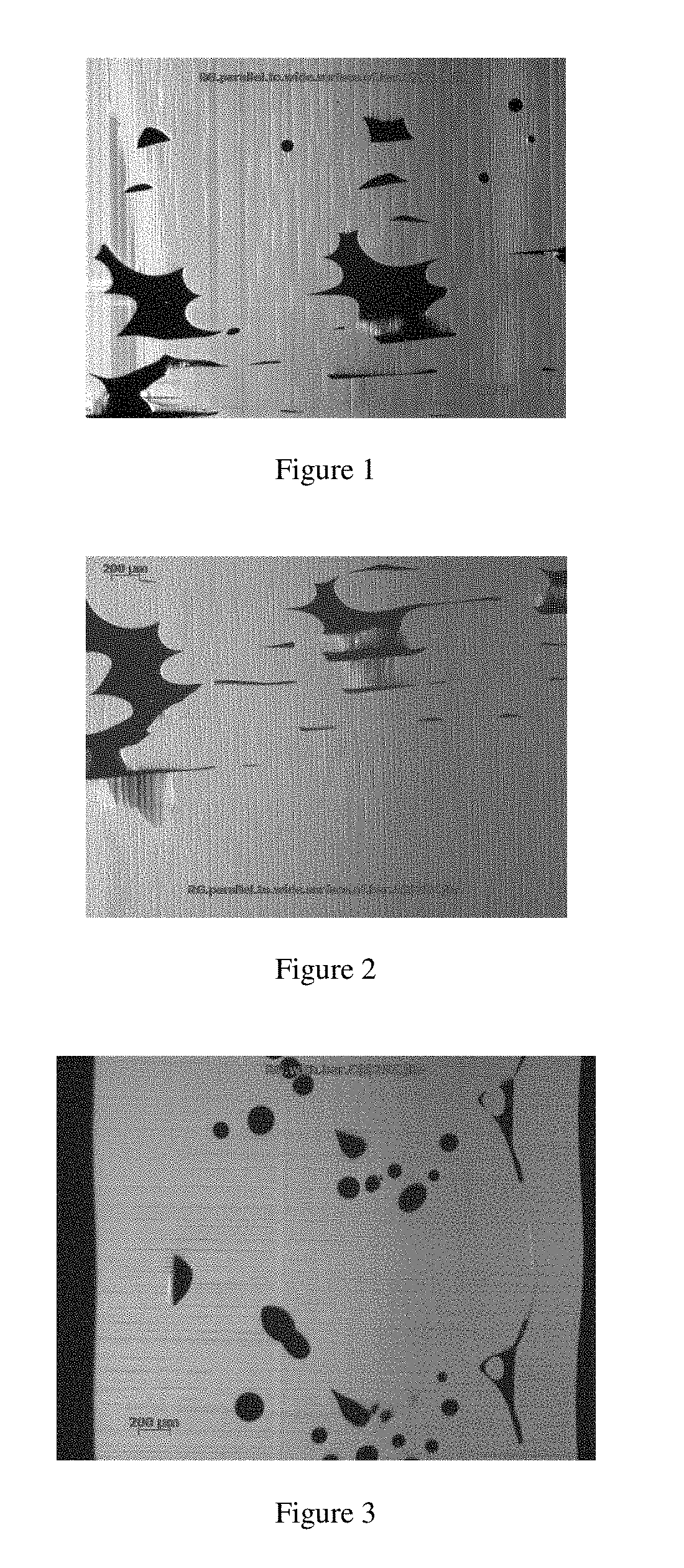

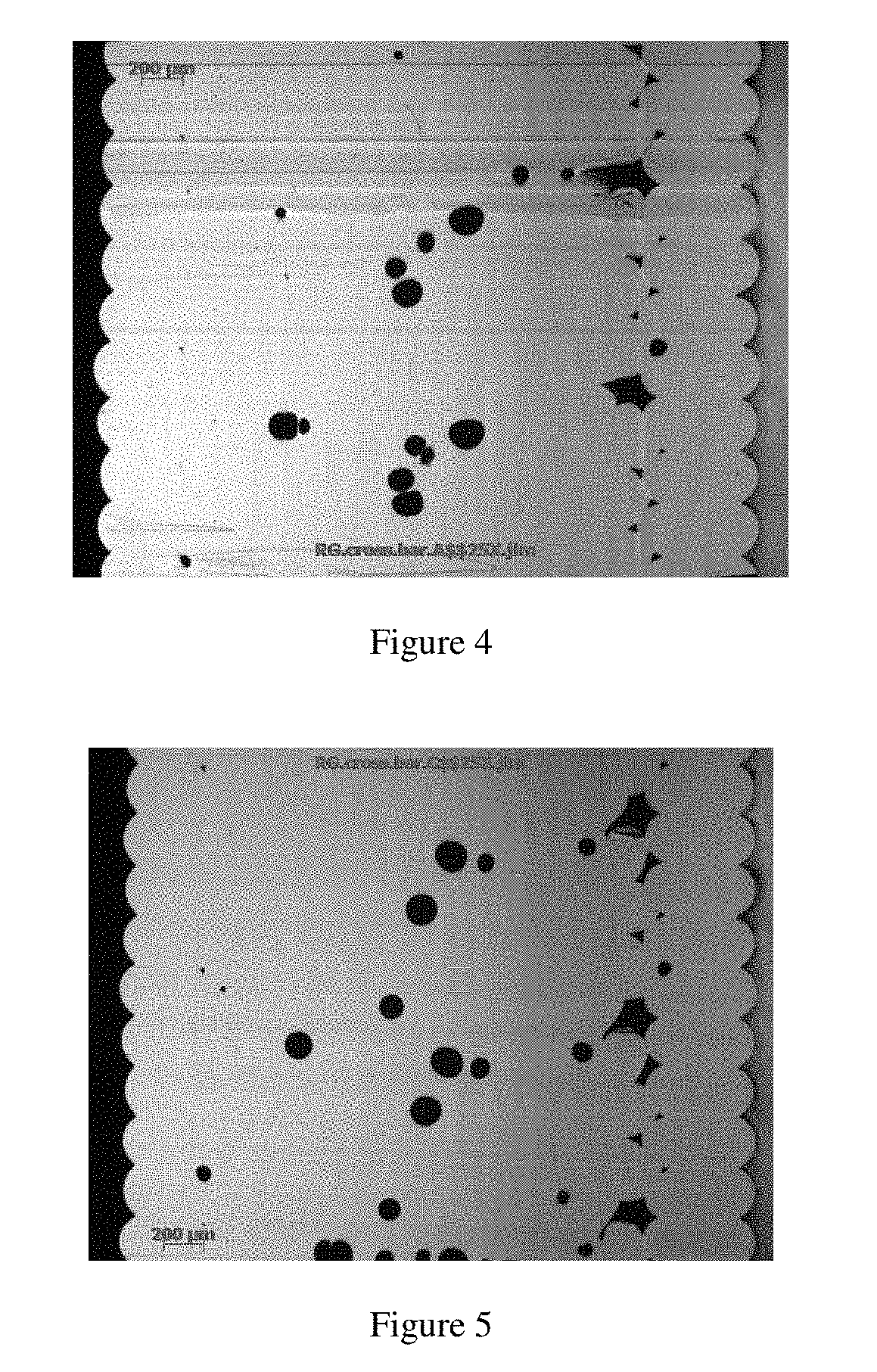

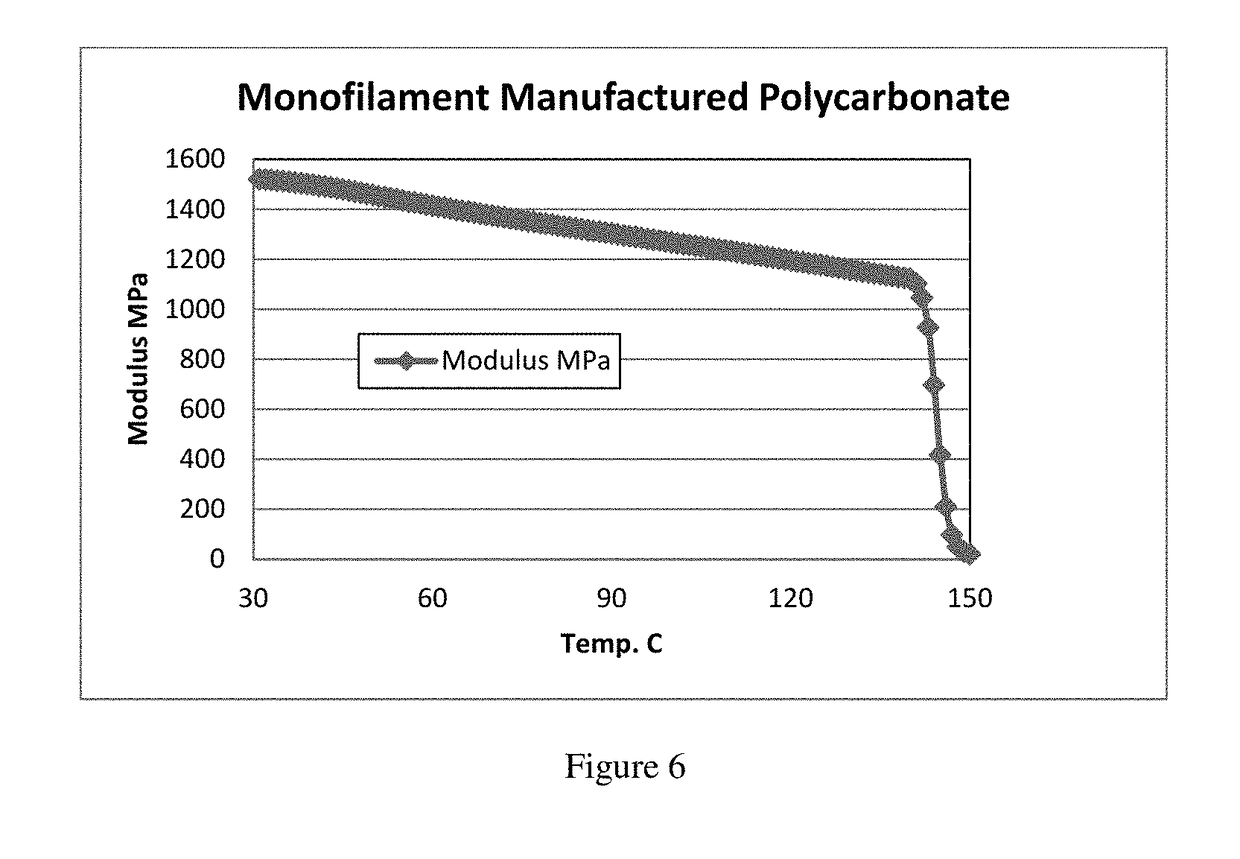

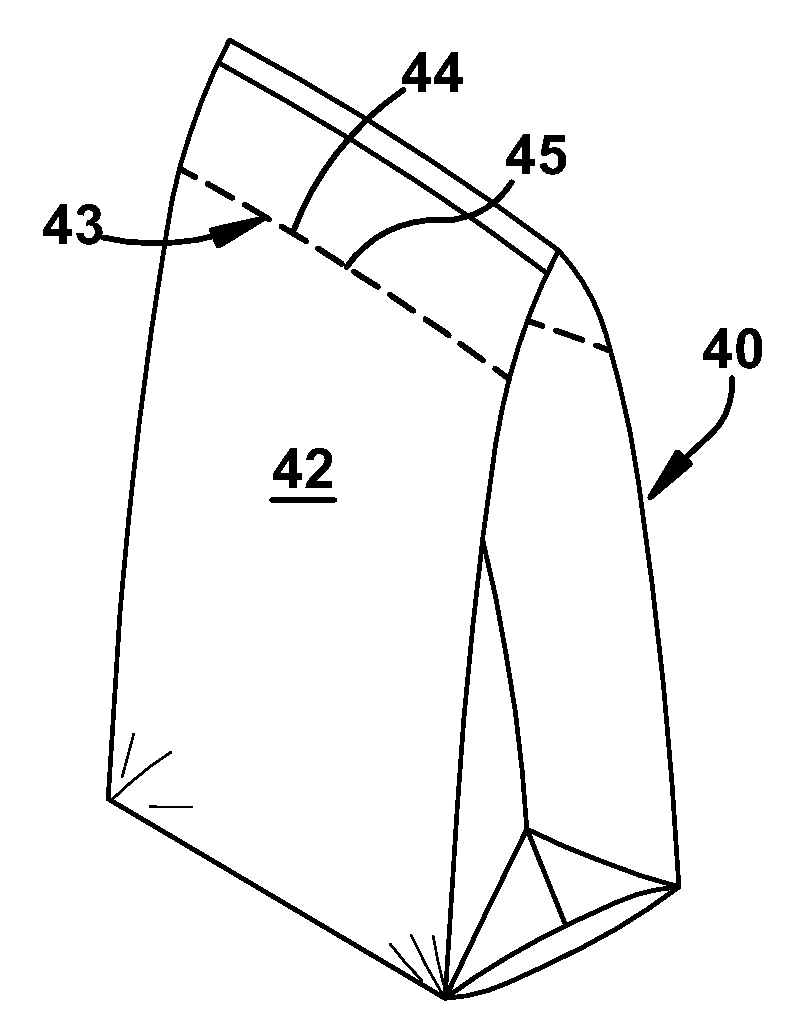

A reduced density article of manufacture, and process for making same, made from a thermoplastic polycarbonate composition. The reduced density article of manufacture has (1) a certain density and (2) a certain micro structure containing from 1% to 20% by volume of voids wherein at least 80% of the voids are high aspect voids and less than 20% of the voids are spherical voids with a diameter of 10 to 100 microns. The polycarbonate thermoplastic composition comprises at least 50 mole % of a certain bisphenol A. The reduced density article of manufacture is made by a monofilament additive manufacturing technique.

Owner:SHPP GLOBAL TECH BV

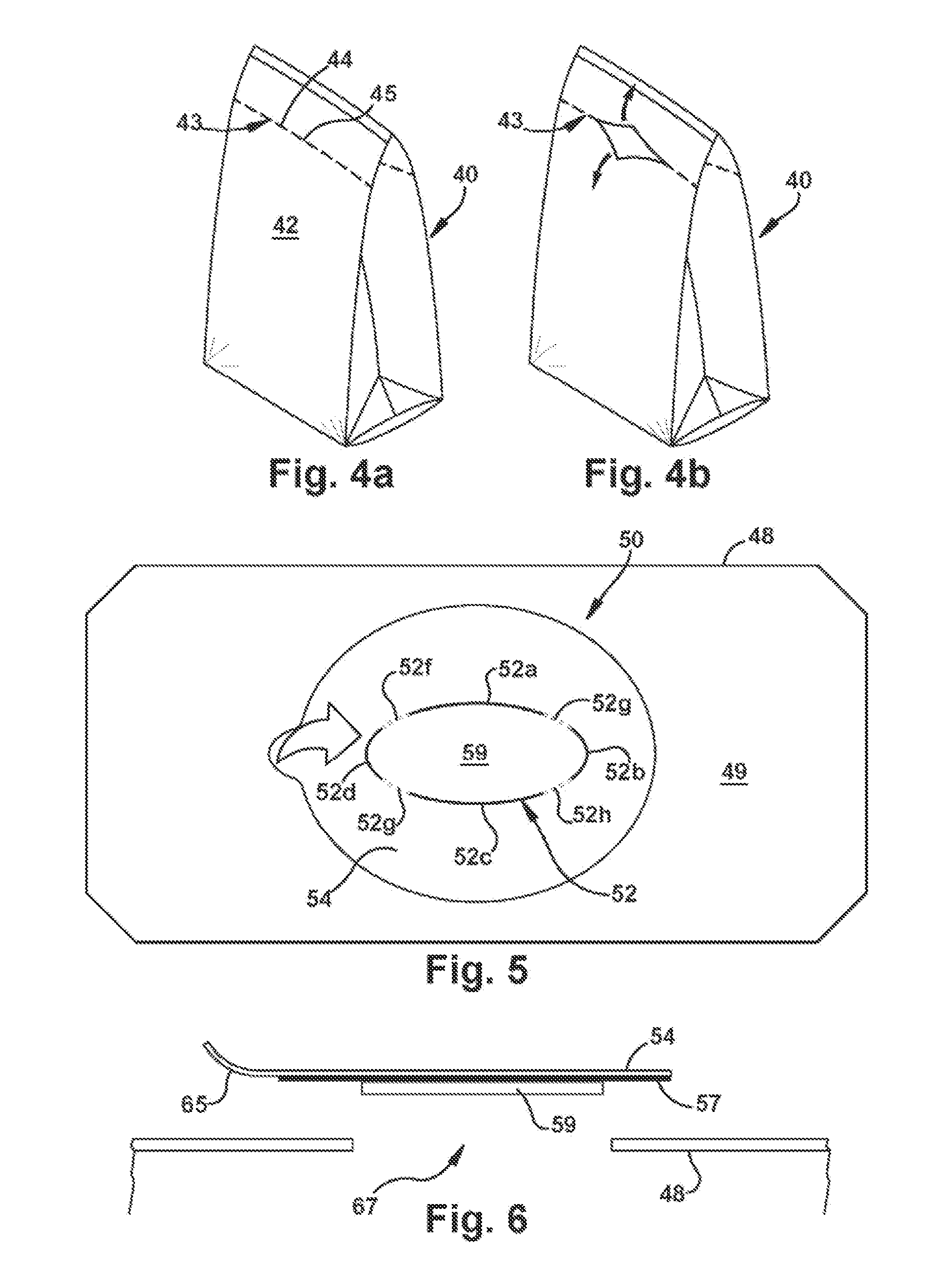

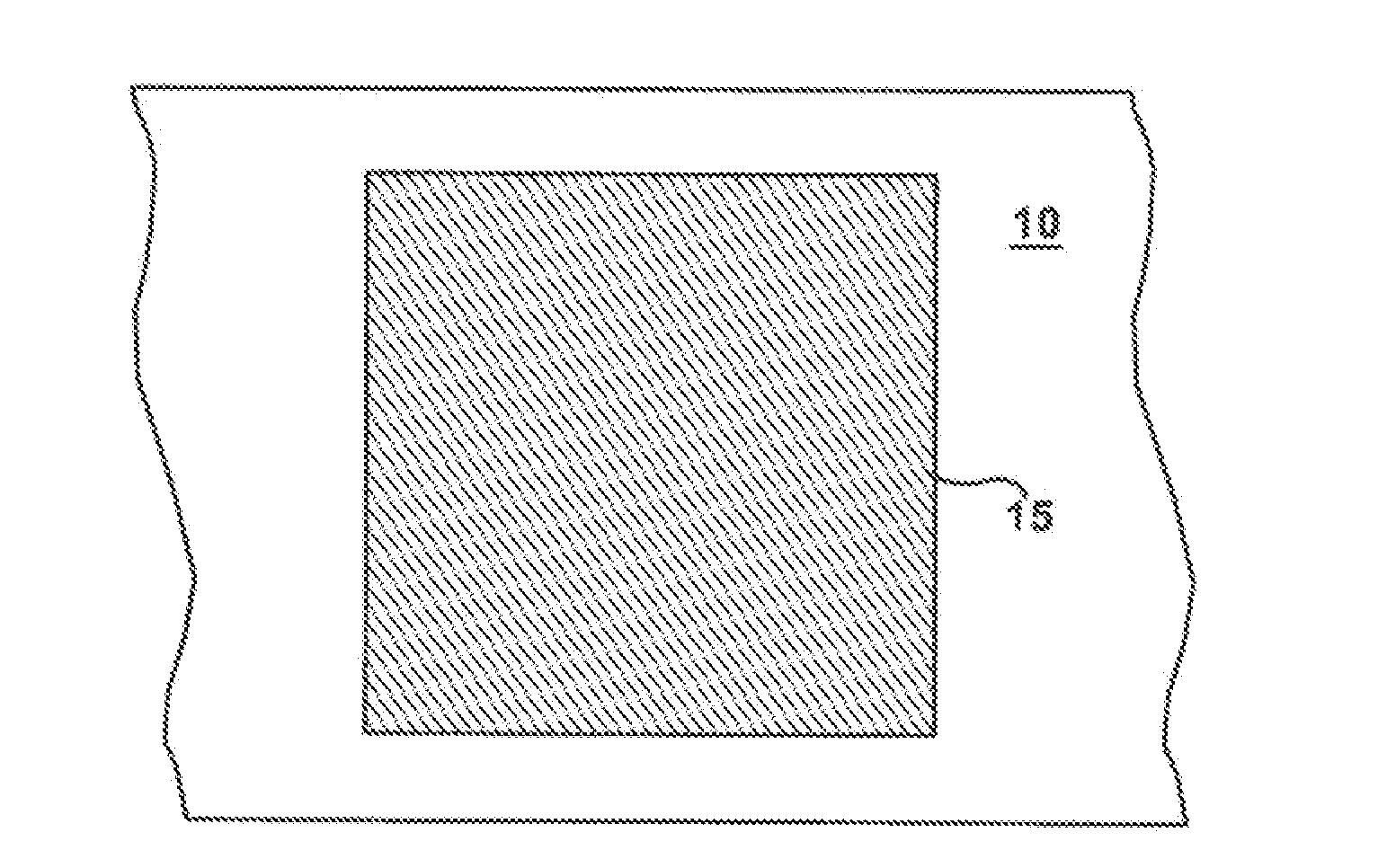

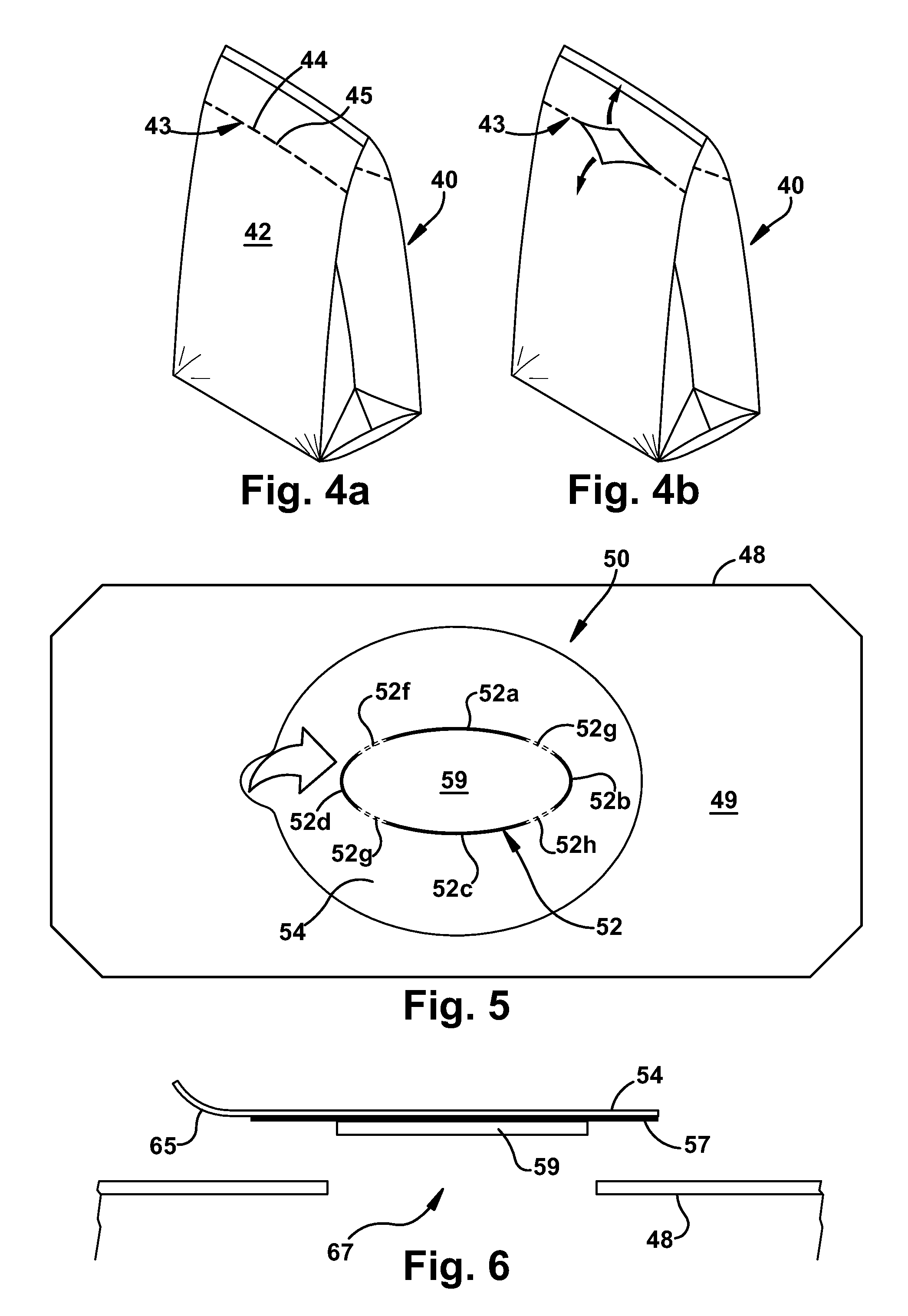

Foamed film package

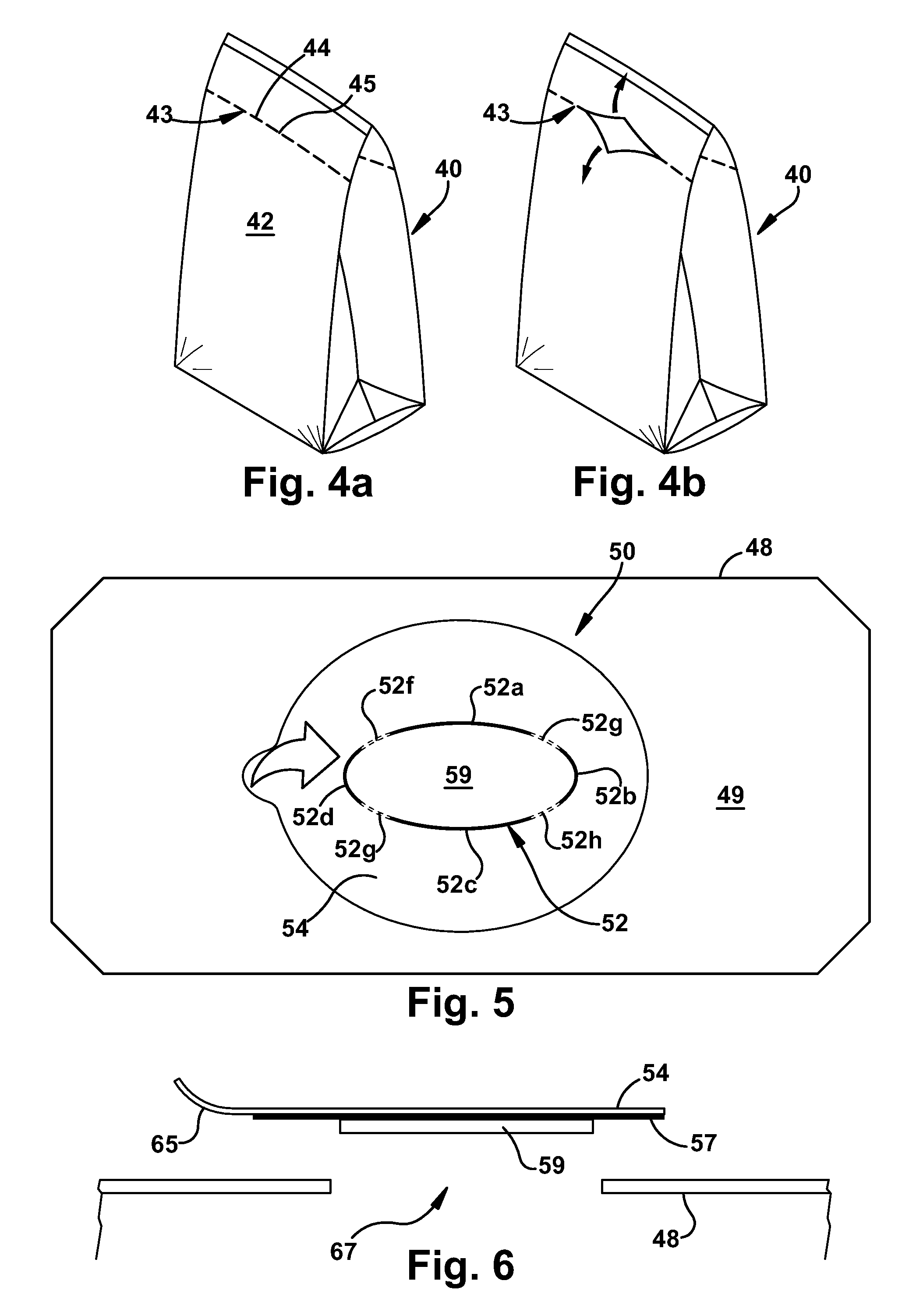

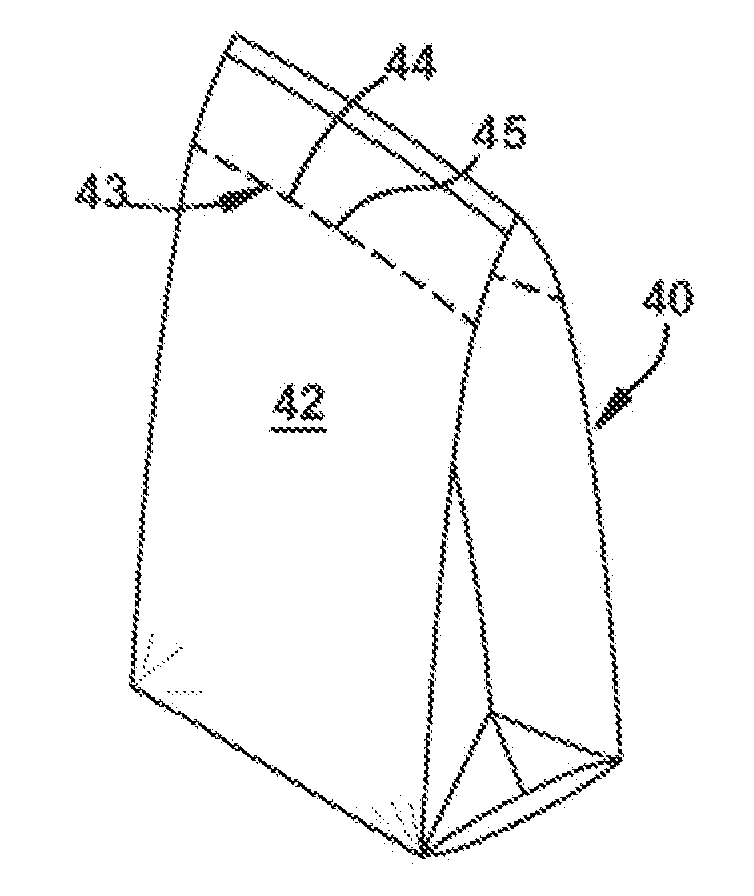

A package includes at least one layer of foamed thin film and an opening feature formed in the layer of foamed thin film. The foamed thin film has a caliper of from about 10 microns to about 250 microns thick. The foamed thin film comprises from about 5% to about 50% density reduction as compared to a non-foamed thin film of substantially the same caliper and substantially the same composition. The package may include foamed thin film made of a plastic resin and a whitening additive that is added to plastic resin. The whitening additive is selected to produce a foamed thin film having an opacity value of from about 35% to about 99%. The whitening agent is of substantially the same composition and is present in substantially the same amount as would be selected to produce substantially the same light reflectivity in a non-foamed thin film of substantially the same caliper and substantially the same composition.

Owner:THE PROCTER & GAMBLE COMPANY

Foamed Film Packaging

A package includes at least one layer of foamed thin film having gaseous bubbles, void volumes, or cells. The foamed thin film includes a bio-based content of between about 10% and about 100%, a caliper of between about 10 and 250 microns, and a density reduction of between about a 5% to 50%, as compared to a non-foamed thin film of substantially the same caliper that does not comprise gaseous bubbles, void volumes, or cells.

Owner:THE PROCTER & GAMBLE COMPANY

Printed Foamed Film Packaging

InactiveUS20140377512A1Decorative surface effectsDuplicating/marking methodsDensity reductionInk printer

A method of constructing a package having printed indicia of acceptable quality includes providing at least one layer of foamed thin film and printing the indicia on the printed surface by applying ink to a printer surface and contacting the printed surface with the inked printer surface to coat the printed surface with ink. The layer of foamed thin film comprises a bio-based content of between about 10% and about 100%, a caliper of between 10 and 250 microns, and between 5% to 50% density reduction as compared to a non-foamed thin film of substantially the same caliper and composition, wherein a first surface of the at least one layer of foamed thin film is the printed surface of the package.

Owner:THE PROCTER & GAMBLE COMPANY

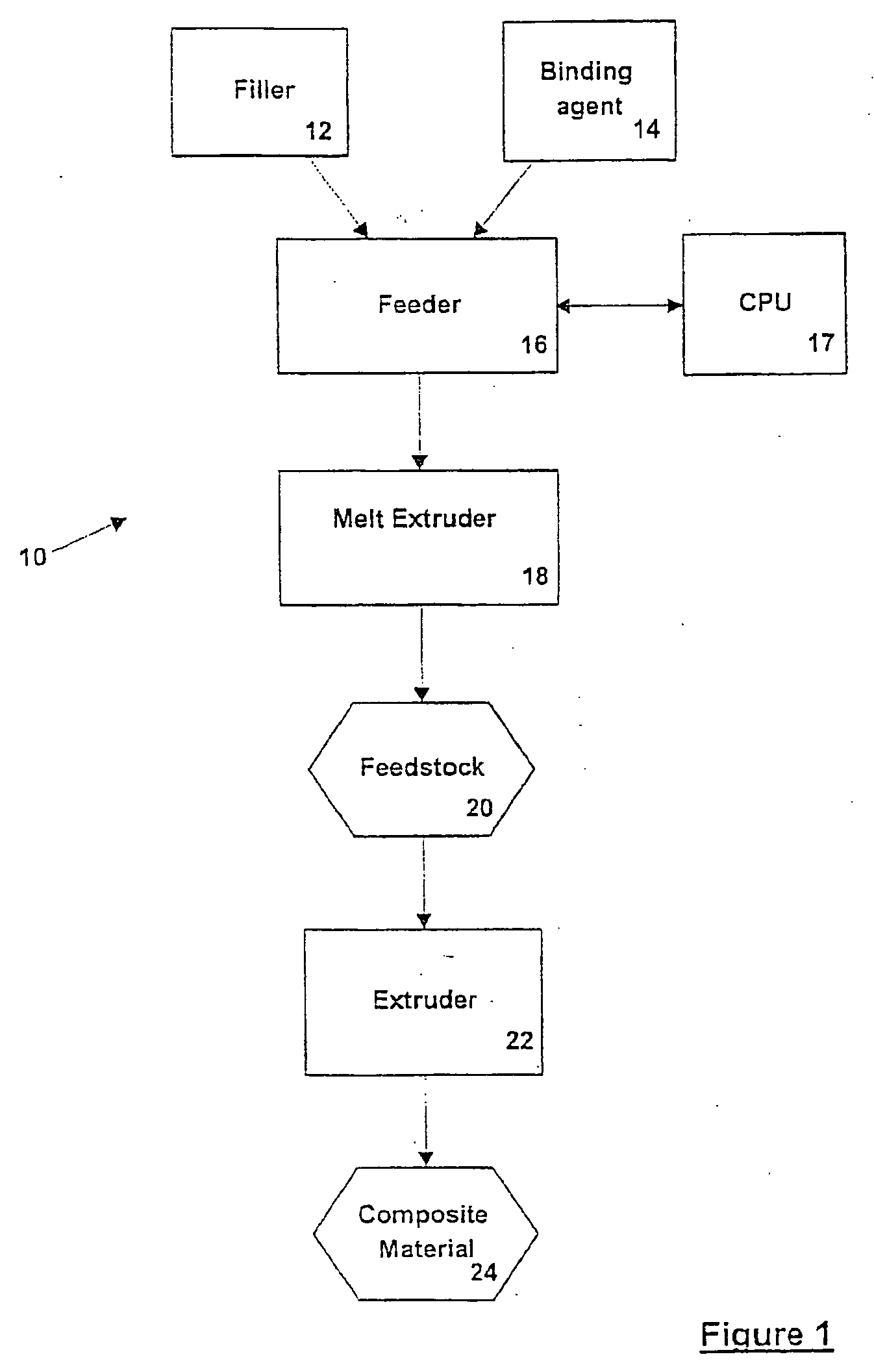

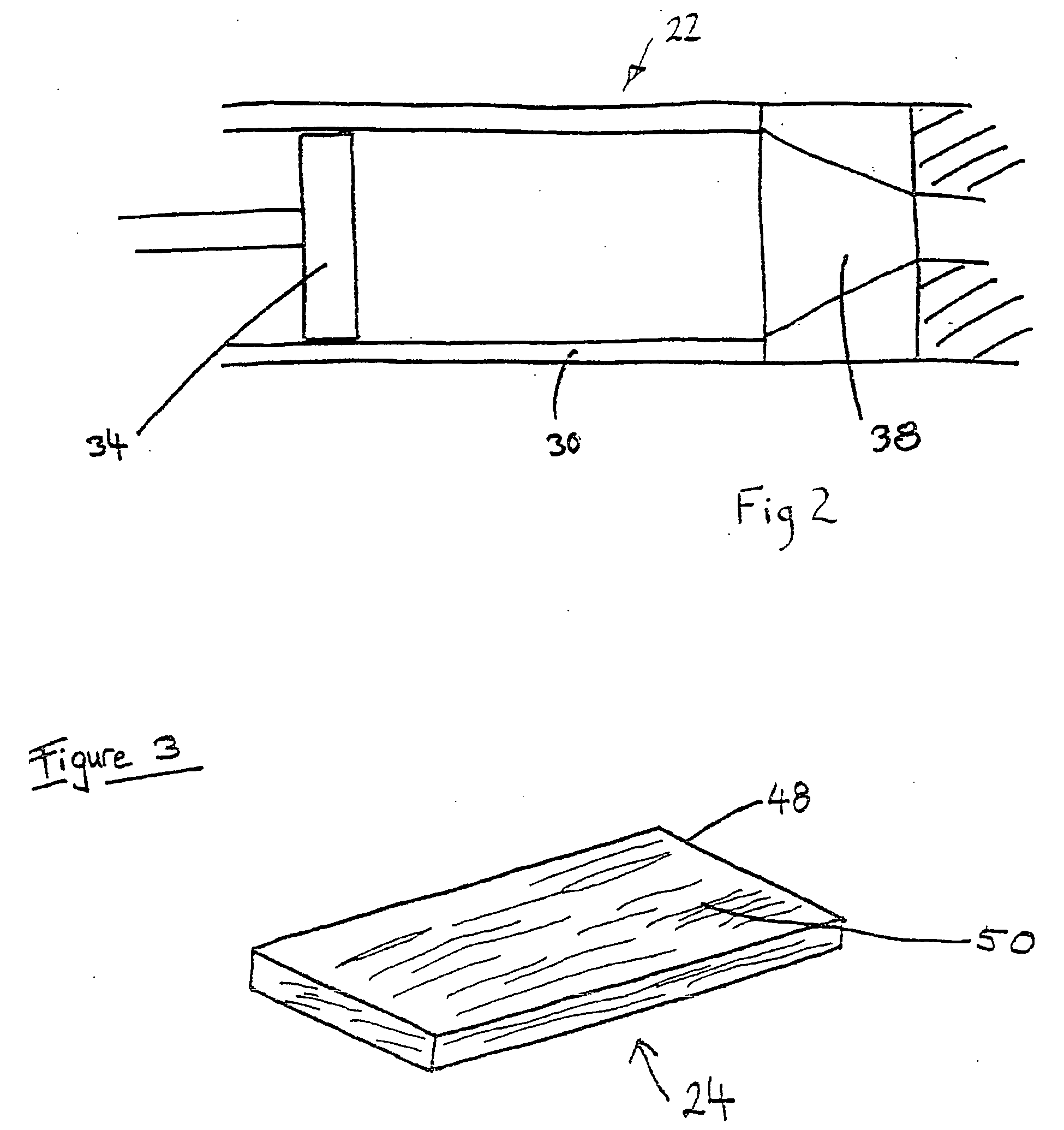

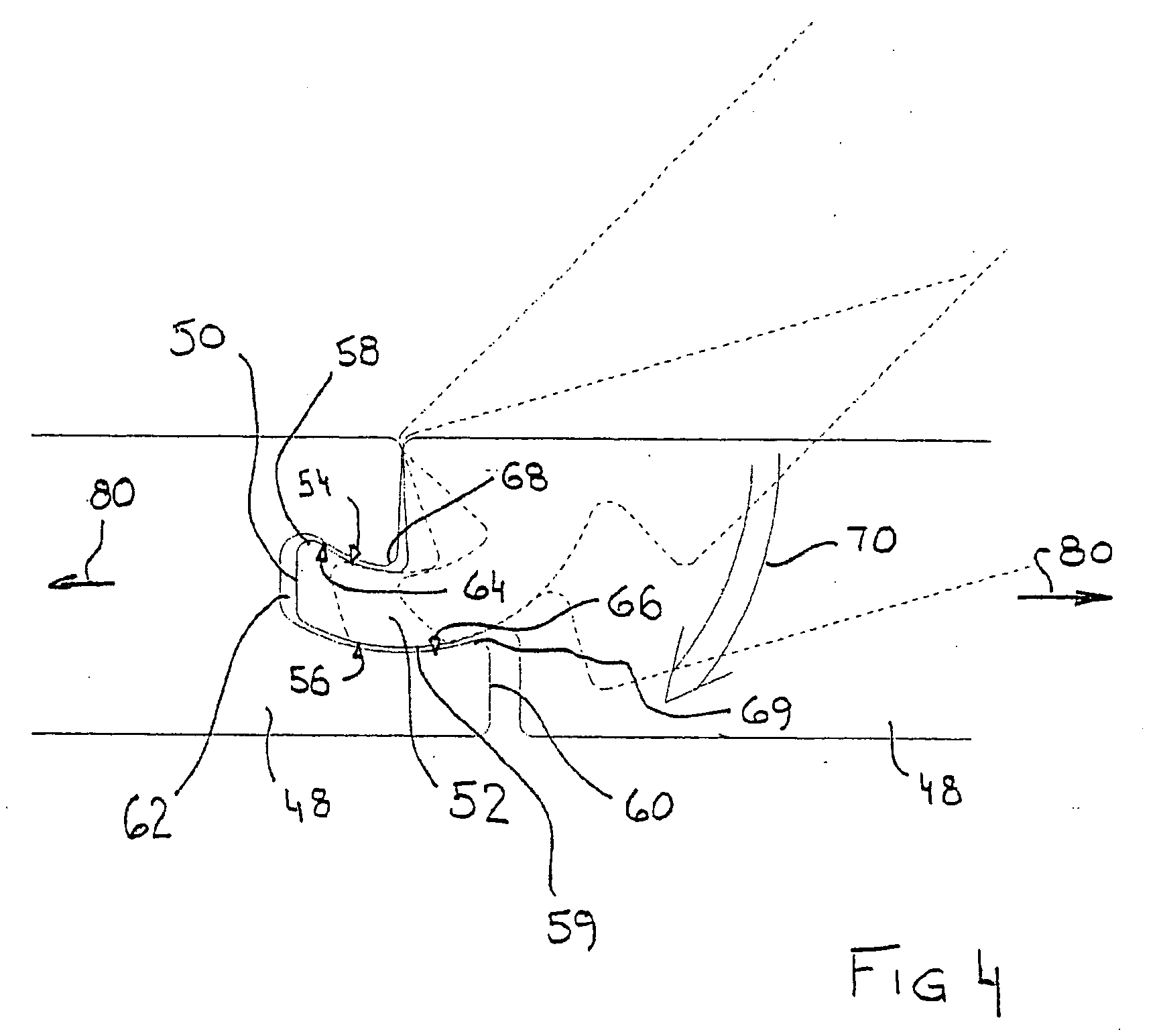

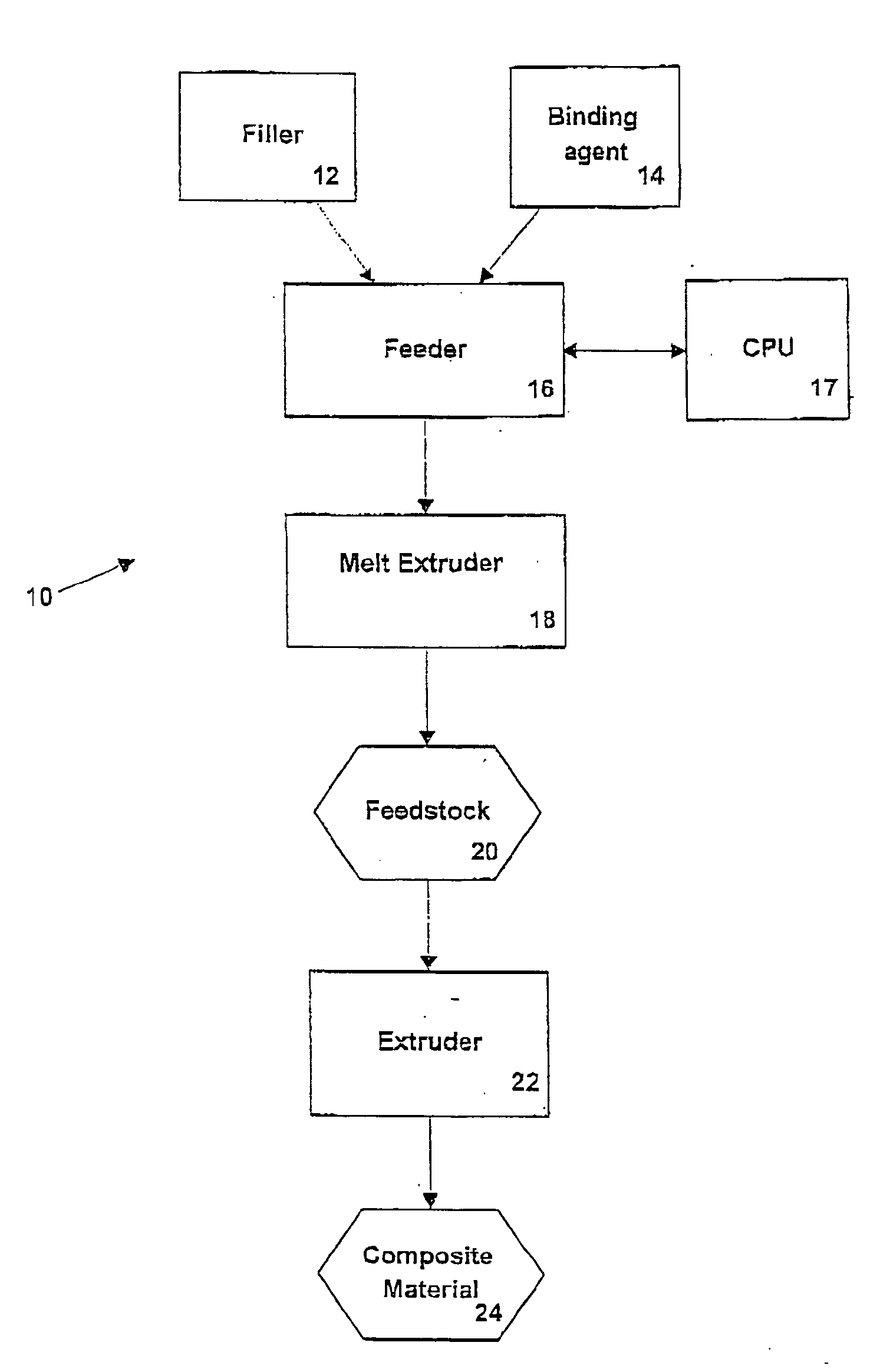

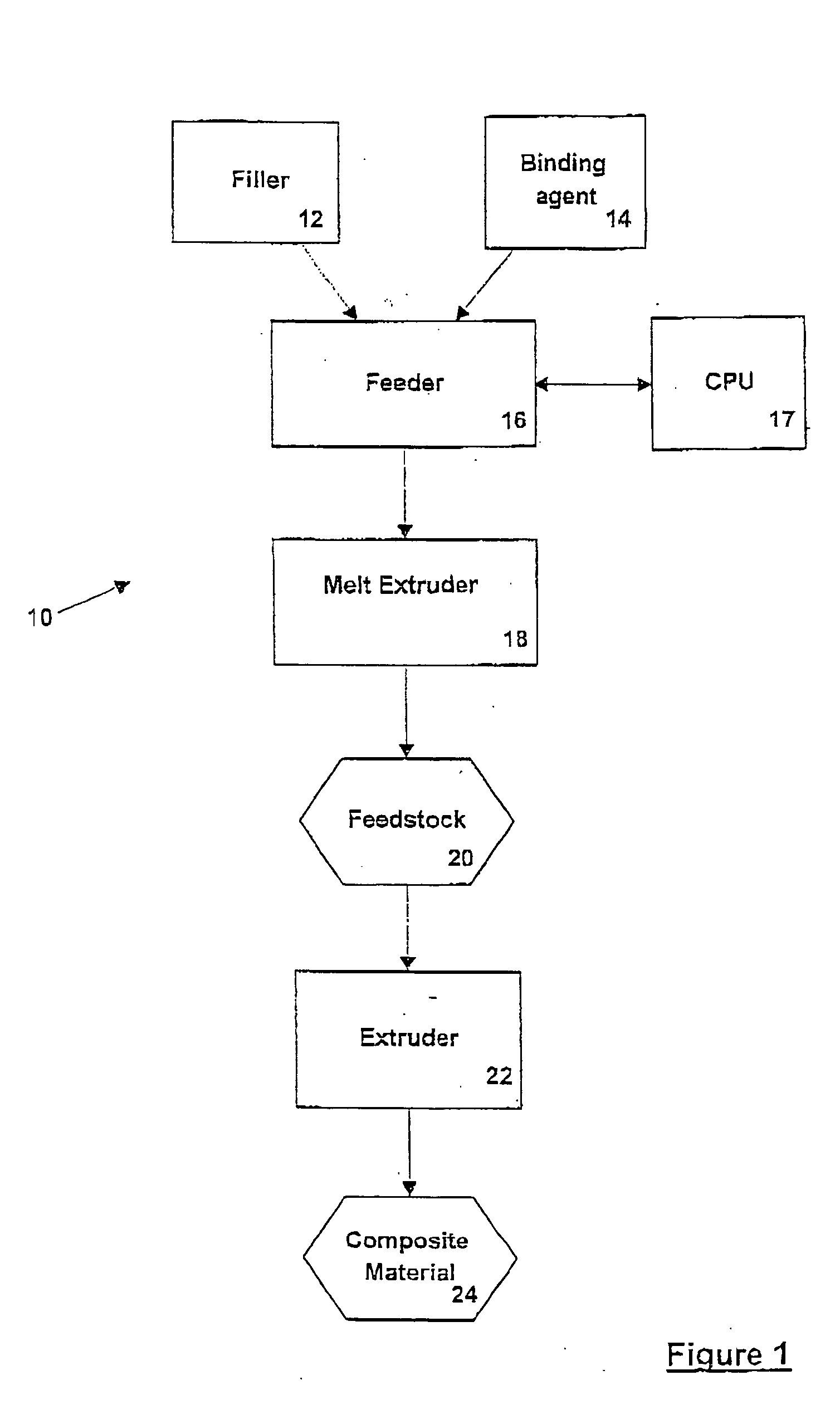

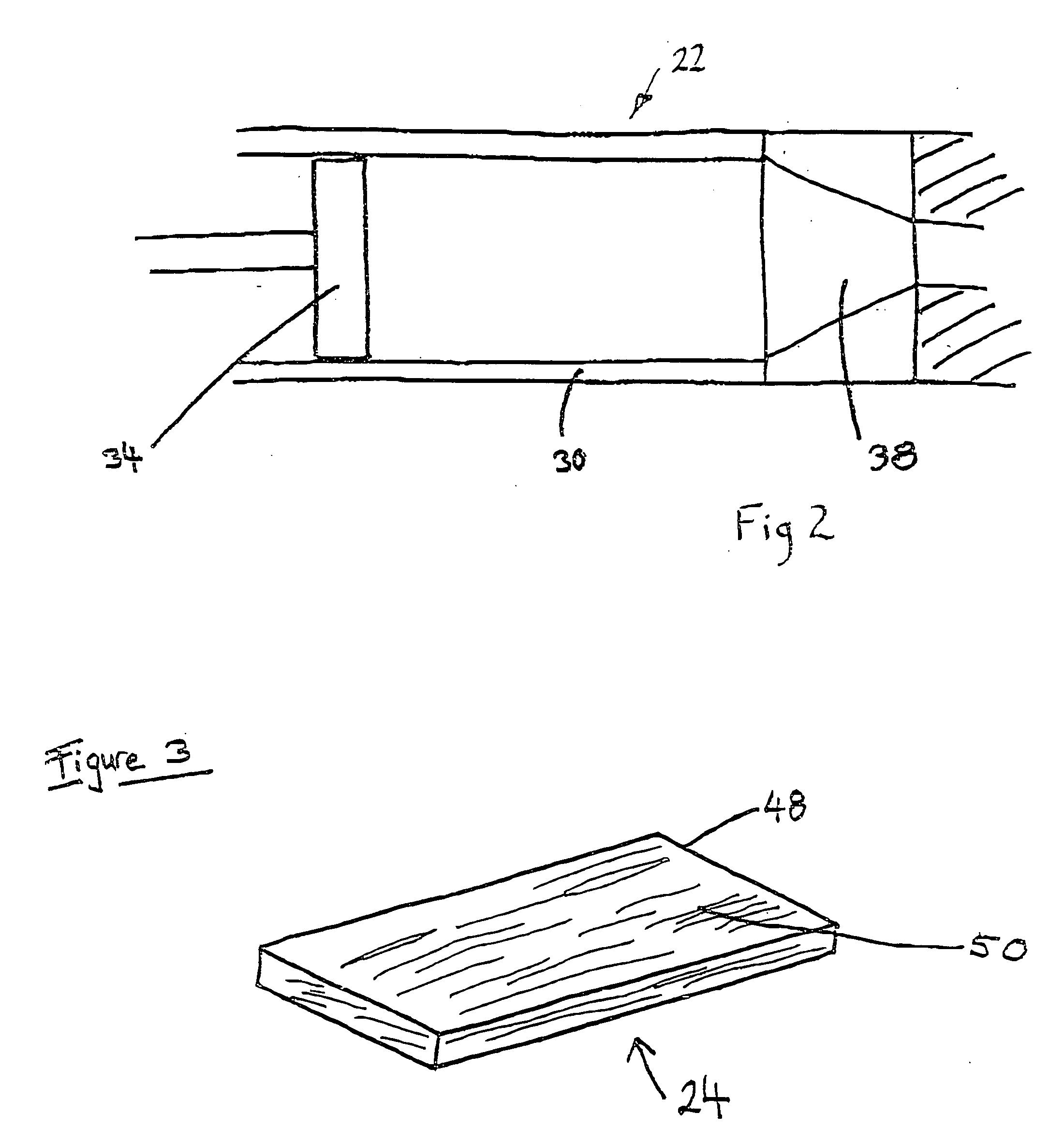

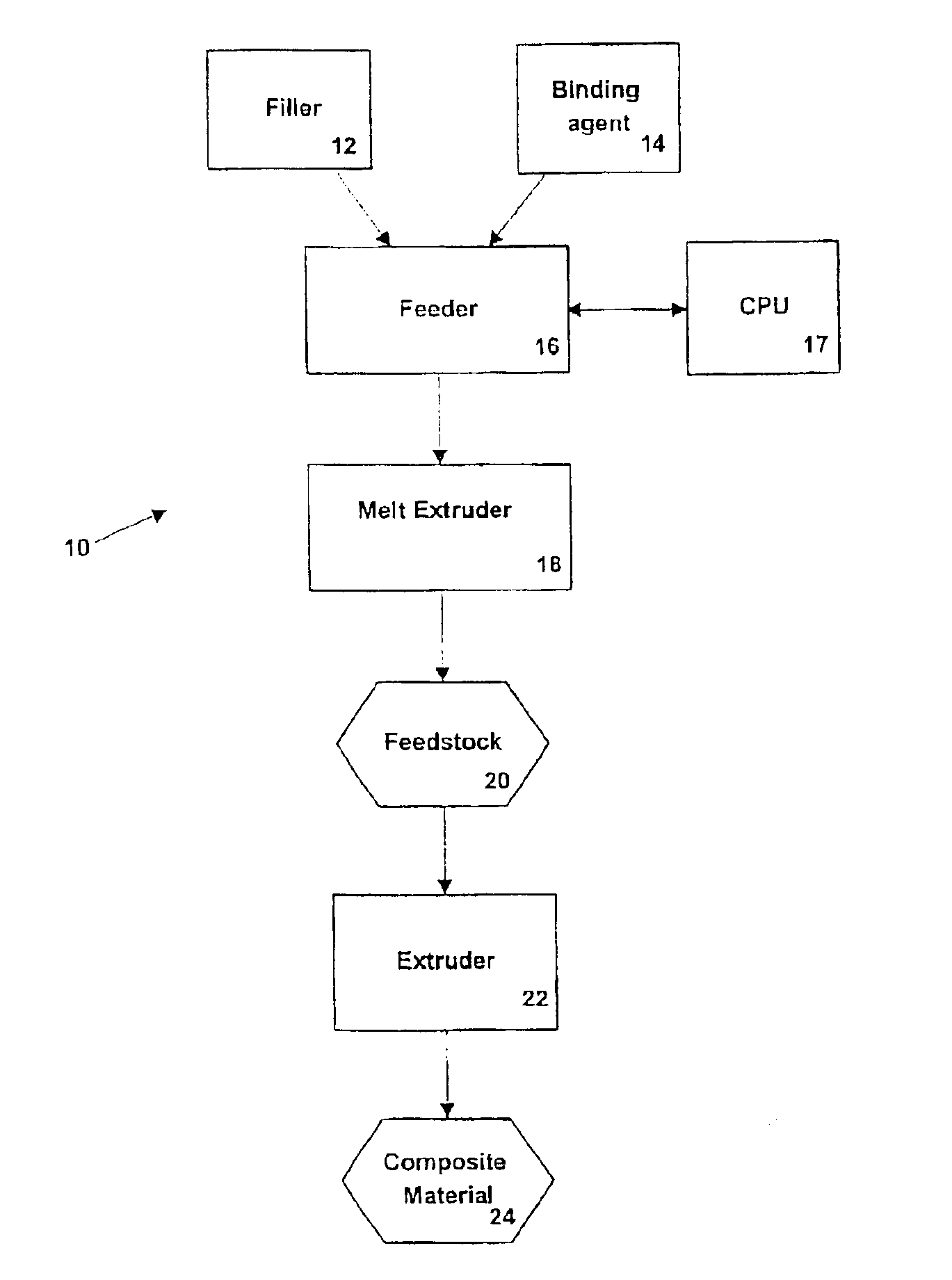

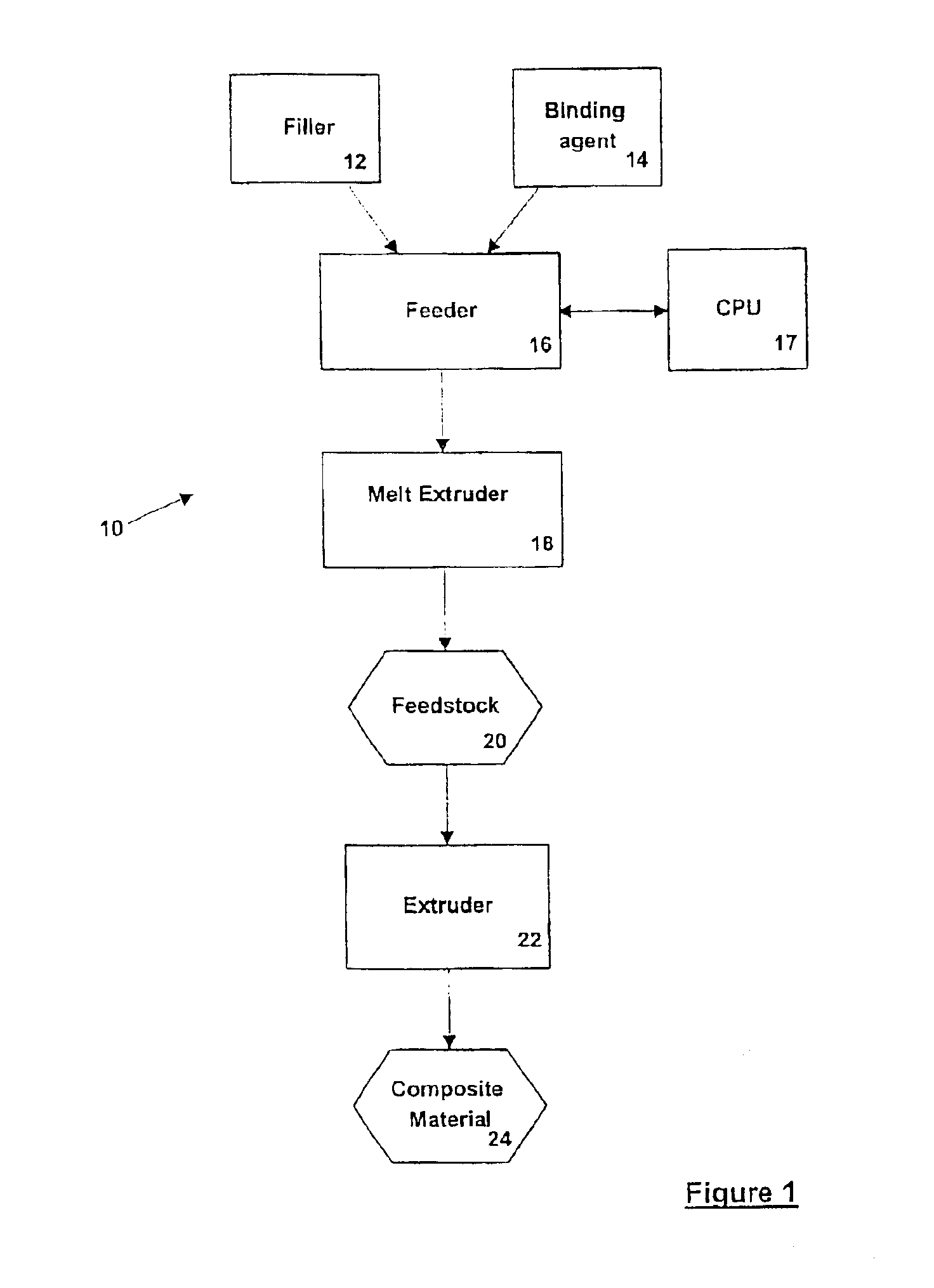

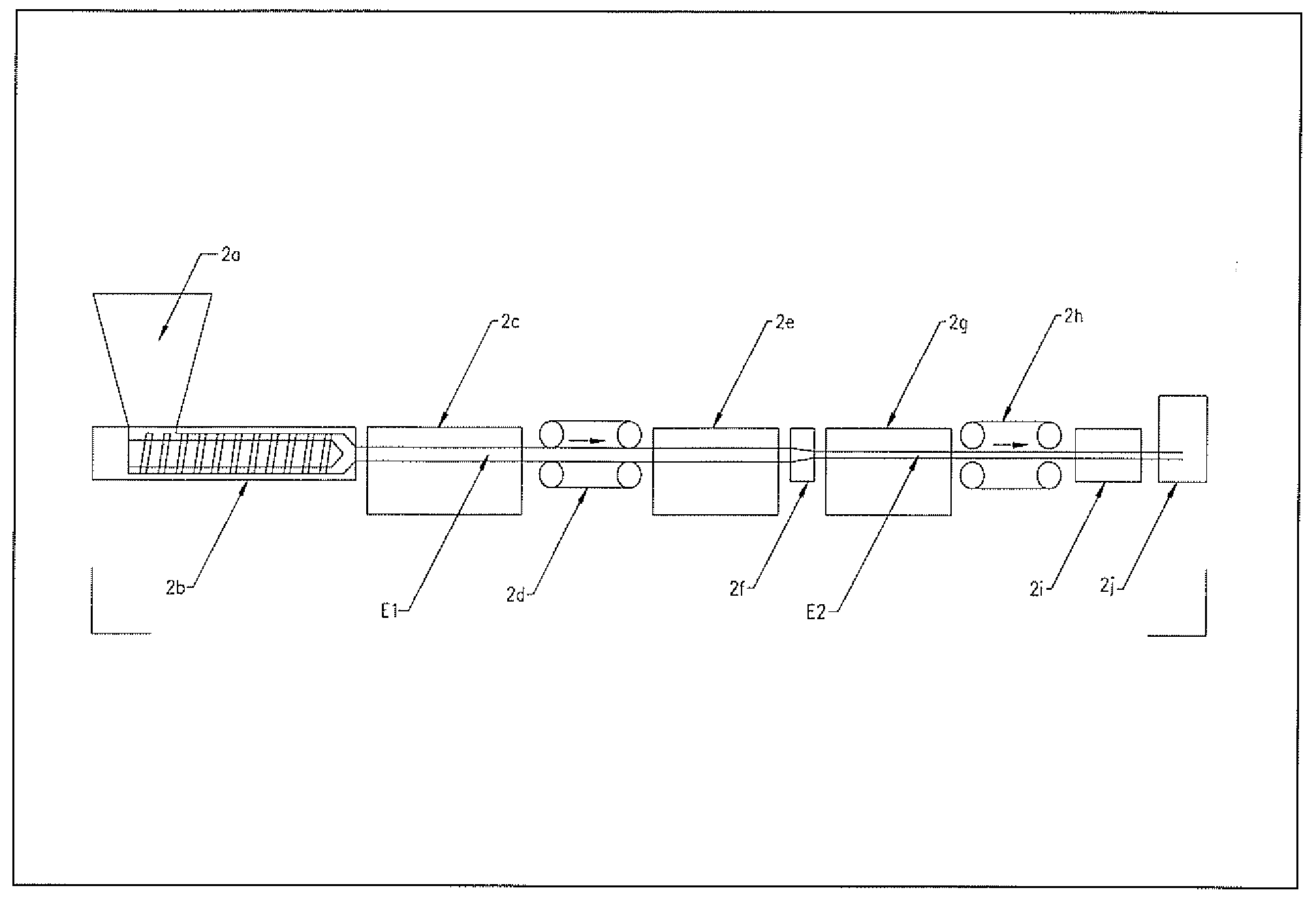

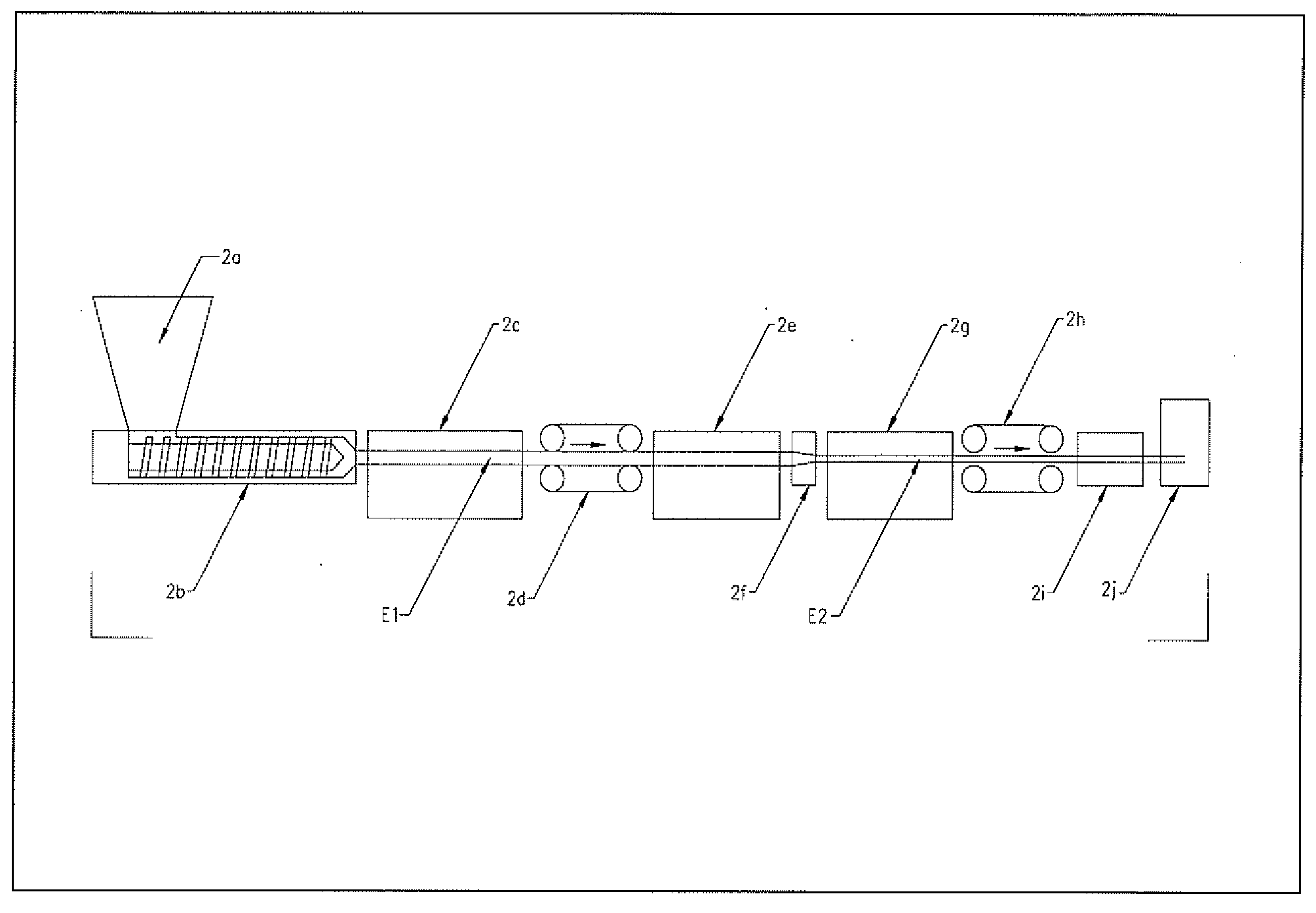

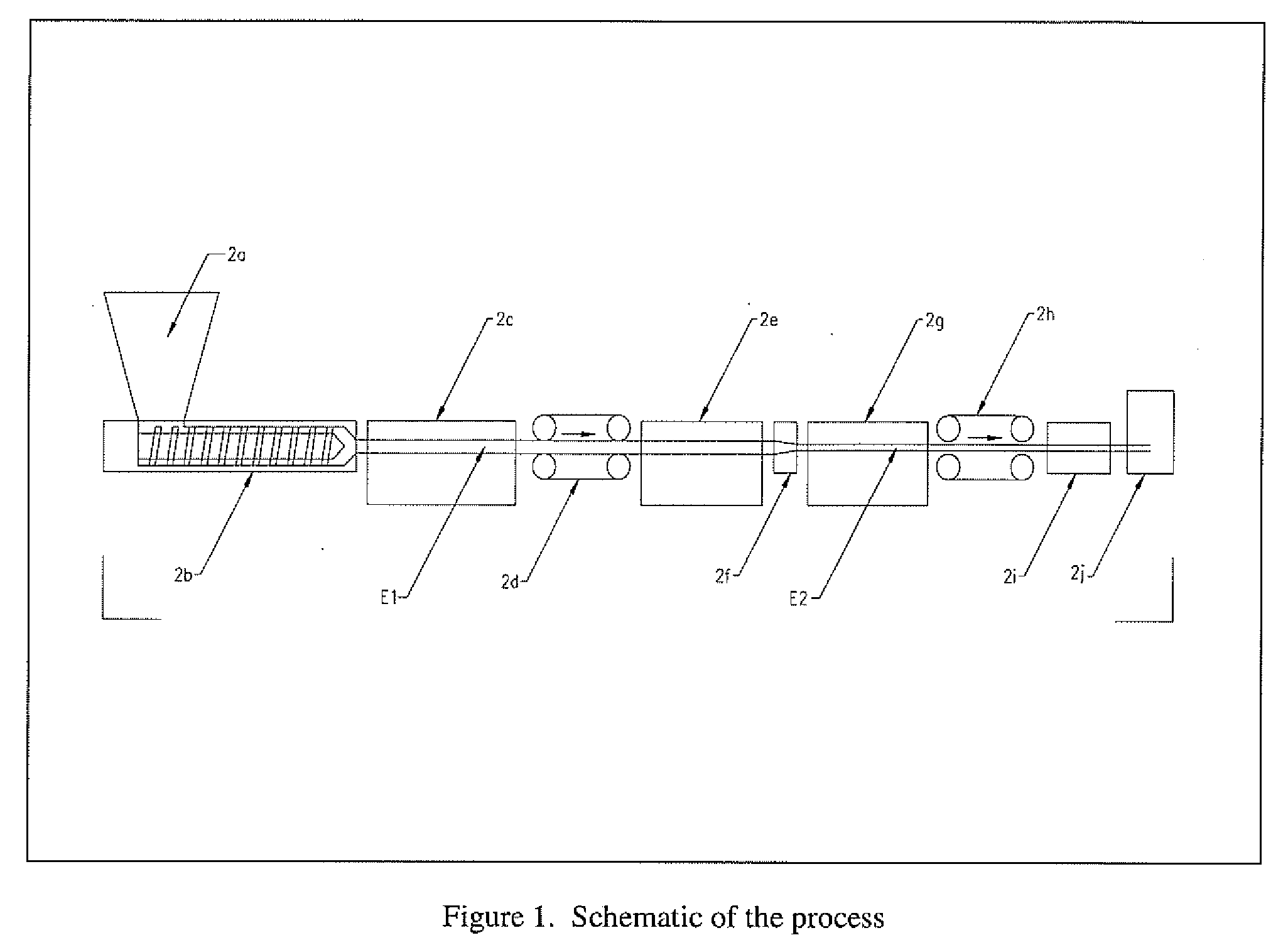

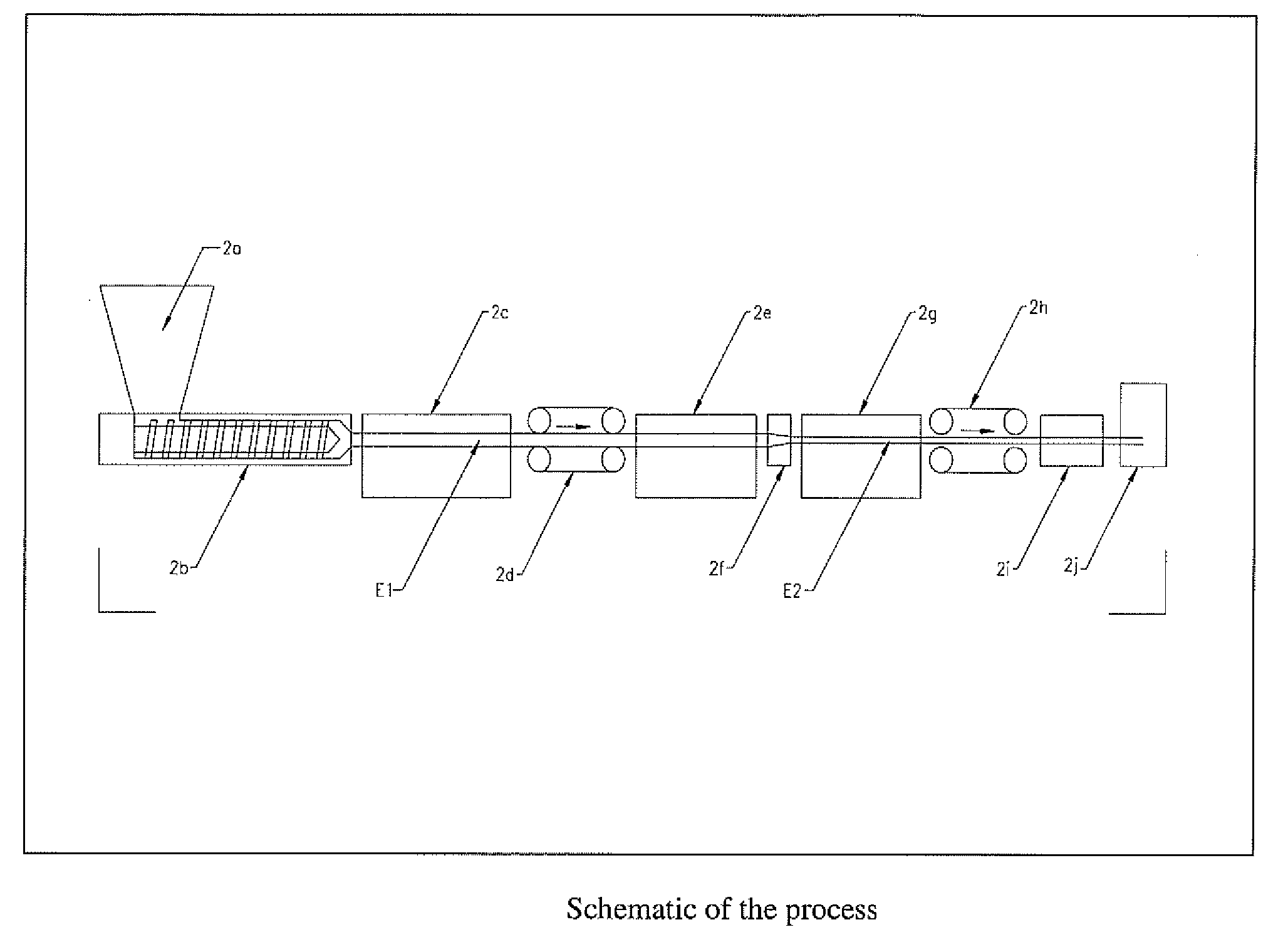

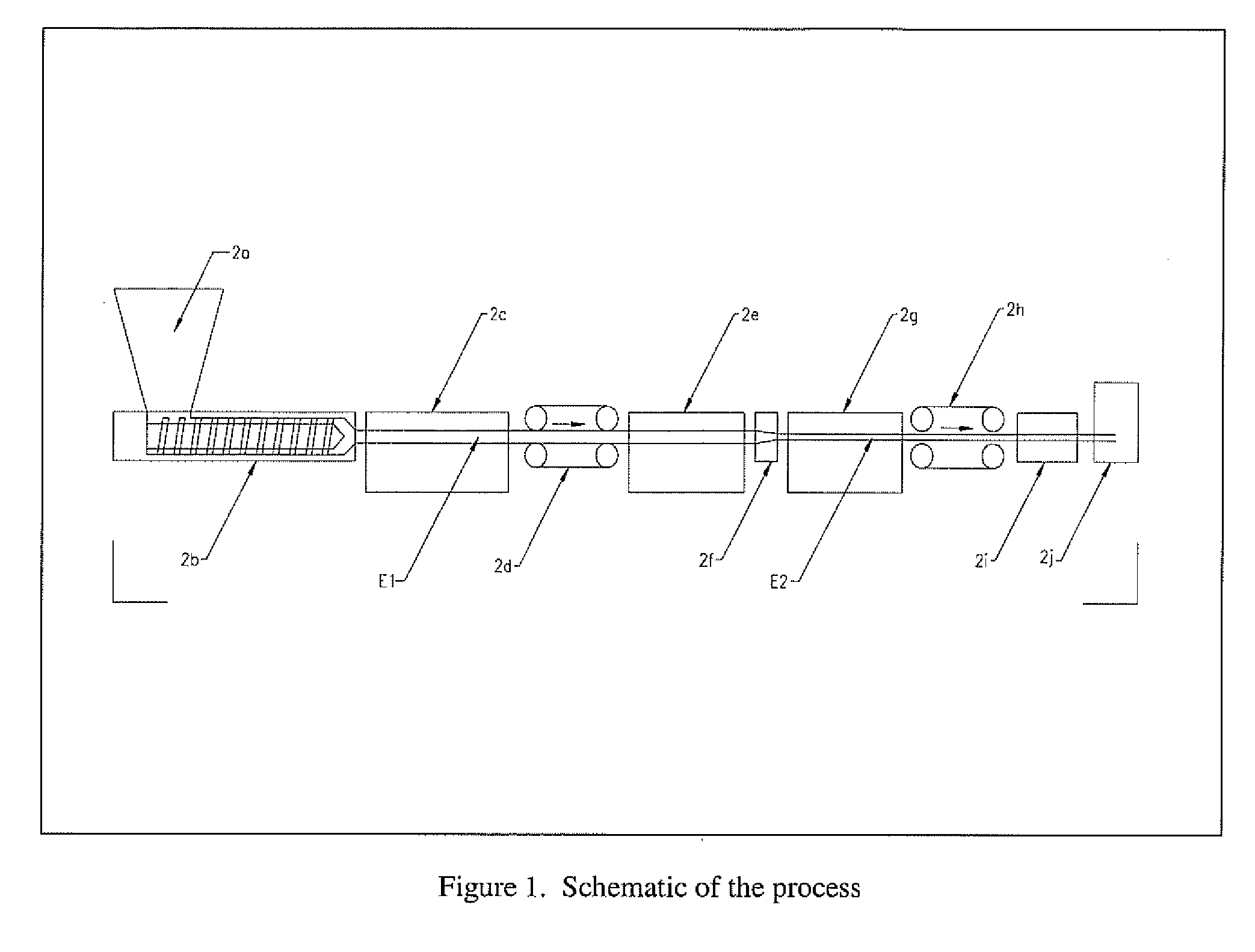

Method and apparatus for forming composite material and composite material therefrom

InactiveUS20050171246A1Good physical propertiesCosmetic preparationsToilet preparationsDensity reductionFilling materials

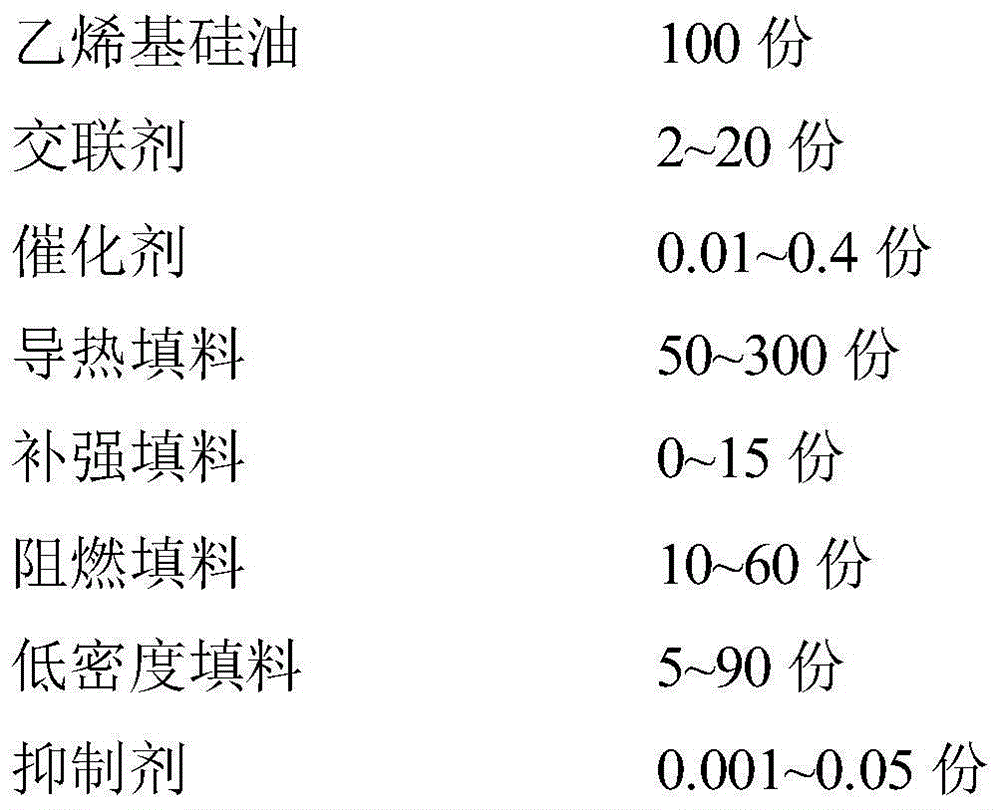

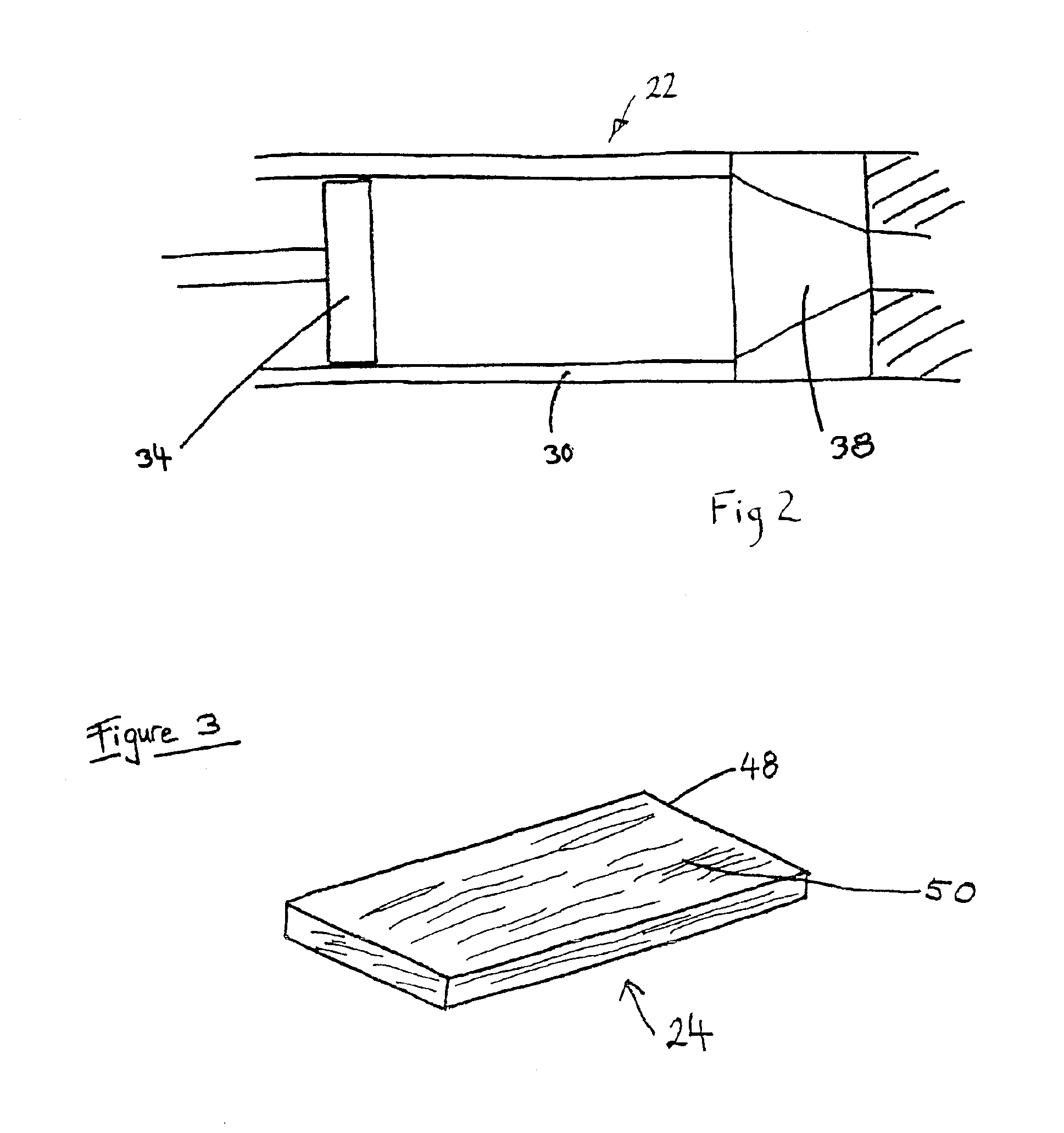

A system and method for extruding composite material and the composite material therefrom. The composite material consists of a filler mixed with a binding agent. The composite material is extruded as billets with enhanced physical properties, such as colour, texture, electrical conductivity and fire retardancy, and contains a dispersion pattern of the filler material. A system and method are also provided for drawing the composite material through a die and a composite material produced thereby. The drawn composite material exhibits a density reduction over the density of the starting material and enhanced physical properties. A particularly useful tongue and groove arrangement are also provided for joining adjacent strips of a composite material made according to the extrusion process.

Owner:PSI INT

Method and apparatus for extruding composite material and composite material therefrom

A system and method for extruding composite material and the composite material therefrom. The composite material consists of a filler mixed with a binding agent. The composite material is extruded as billets with enhanced physical properties, such as colour, texture, electrical conductivity and fire retardancy, and contains a dispersion pattern of the filler material. A system and method are also provided for drawing the composite material through a die and a composite material produced thereby. The drawn composite material exhibits a density reduction over the density of the starting material and enhanced physical properties.

Owner:PSA COMPOSITES

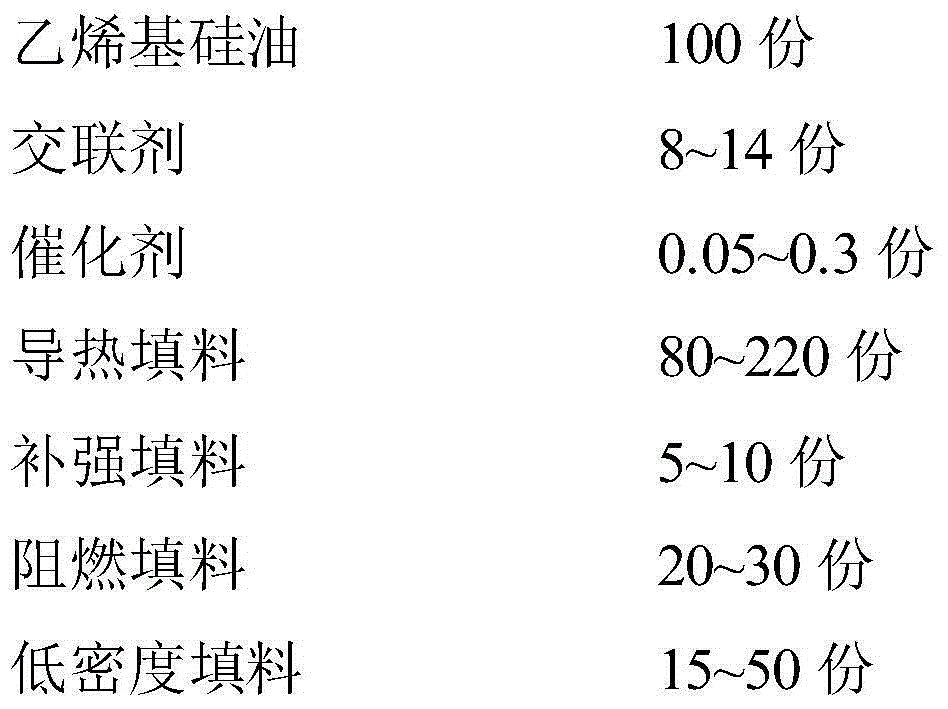

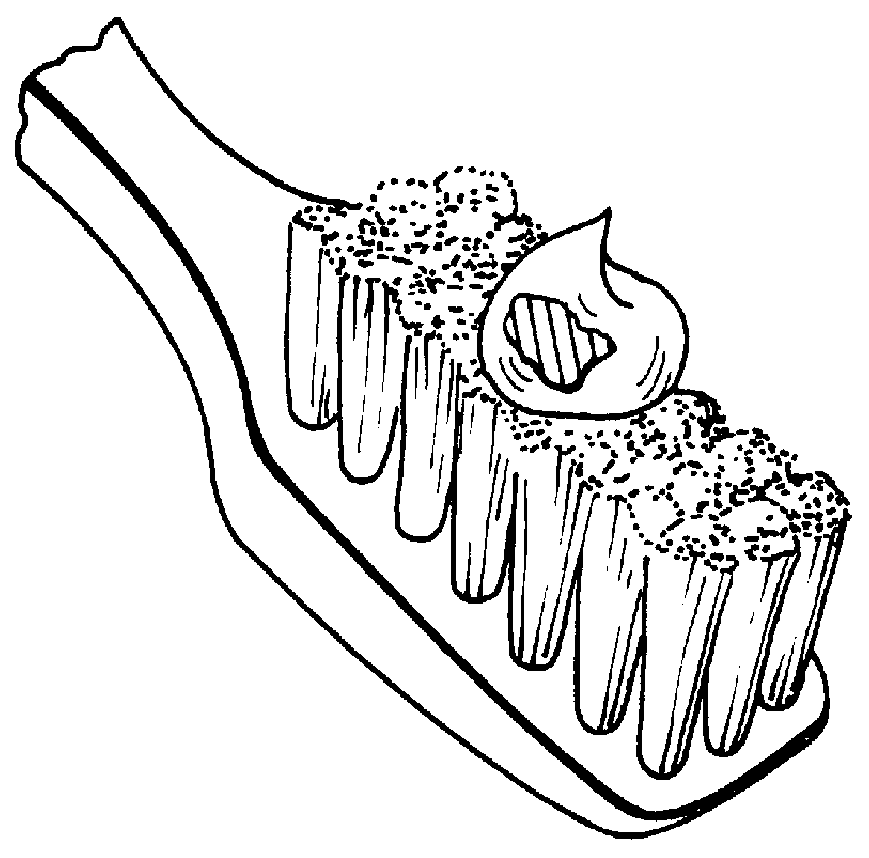

Low density heat conduction pouring sealant and preparation method thereof

InactiveCN104861661ALow densityImprove flame retardant performanceDensity reductionMaterials preparation

The invention discloses a low density heat conduction pouring sealant which comprises 100 parts of vinyl silicone oil, 2-20 parts of cross-linking agent, 0.01-0.4 parts of catalyst, 50-300 parts of heat conduction filler, 0-15 parts of reinforcing filler, 10-60 parts of inflaming retarding filler, 5-90 parts of low density filler and 0.001-0.05 part of inhibitor. The sealant has good heat conduction performance, excellent inflaming retarding performance and dynamic performance and low density. Compared with common heat conduction pouring sealant, the sealant achieves the effect that the density is reduced by about 40%, and has wide application prospect in the field of electronic devices, electric automobiles and the like. A preparation method of the low density heat conduction pouring sealant is further provided. The method includes three steps of base material preparation, preparation of a component A and a component B and preparation of the low-density heat conduction pouring sealant. The preparation method is simple in process, short in production period, low in workload and very suitable for industrial large-scale production. The equipment is conventional equipment.

Owner:浙江中天东方氟硅材料股份有限公司

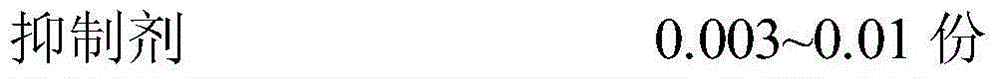

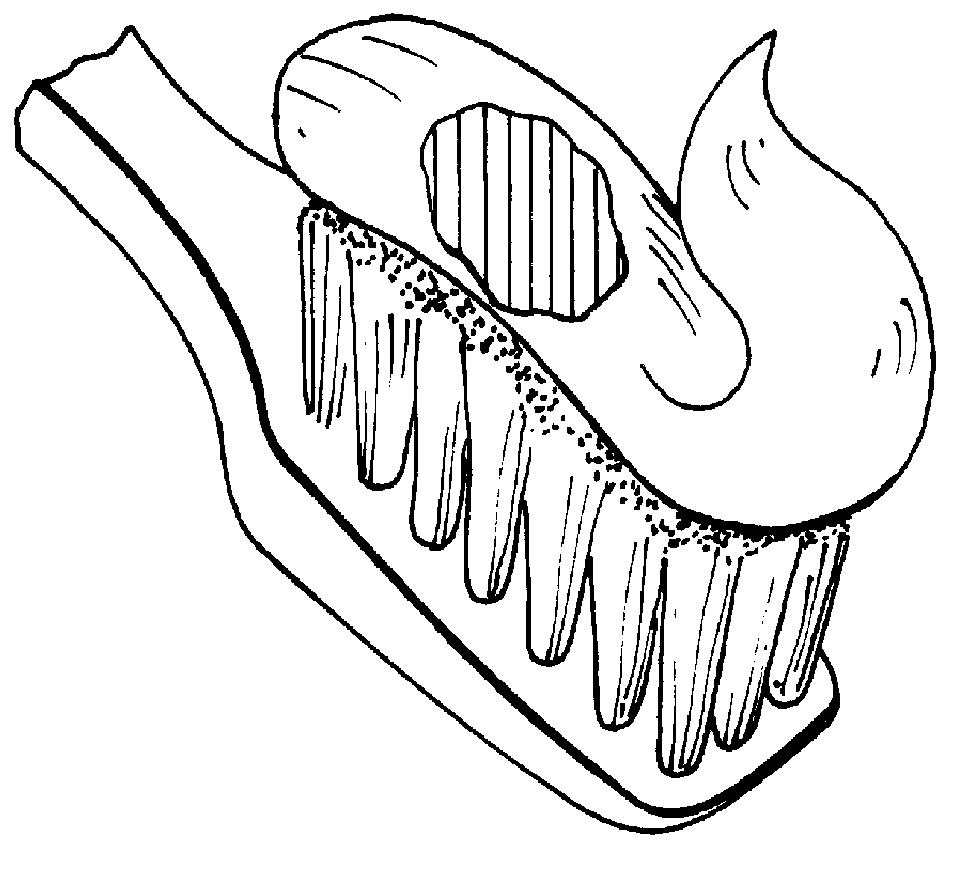

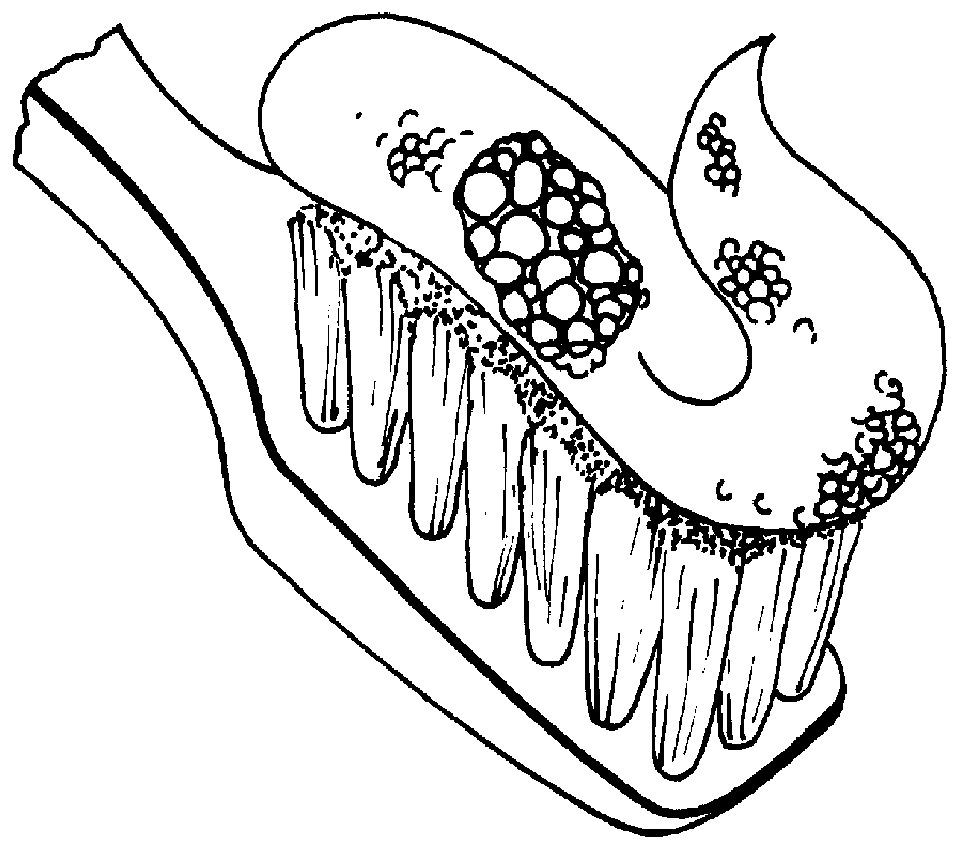

Compositions and methods for reducing the quantity but not the concentration of active ingredients delivered by a dentifrice

InactiveUS6010683AGood dispersionReduce the total massCosmetic preparationsToilet preparationsAir entrainmentToothpaste

Toothpaste and other dentifrices formulated to include a volume increasing agent (density reducing agent) in order to significantly increase the volume of the toothpaste at the time it is dispensed onto a toothbrush. The inventive dental compositions preferably include a substantial quantity of entrained air or other gas in order to reduce the density, and hence the weight, of toothpaste actually placed within a person's mouth. The result is a reduction in the amount of active ingredients introduced into a person's mouth that might be ingested. The entrained air or other gas can also increase the availability of the active ingredient since the foamed composition increases the dispersibility of the active ingredients within saliva. The net effect is that a person decreases the actual amount of toothpaste without decreasing the volume, or visual amount, of toothpaste dispensed on the toothbrush. The density-reduction effect can be augmented using a low density filler in addition to, or instead of, entrained gas. The inventive dentifrices might be pre-foamed with a storage container or formulated to foam in situ when dispensed from the storage container.

Owner:ULTRADENT PROD INC

Method and apparatus for forming composite material and composite material therefrom

InactiveUS6939496B2Good physical propertiesWood working apparatusCeramic shaping apparatusDensity reductionTongue and groove

A system and method for extruding composite material and the composite material therefrom. The composite material consists of a filler mixed with a binding agent. The composite material is extruded as billets with enhanced physical properties, such as color, texture, electrical conductivity and fire retardancy, and contains a dispersion pattern of the filler material. A system and method are also provided for drawing the composite material through a die and a composite material produced thereby. The drawn composite material exhibits a density reduction over the density of the starting material and enhanced physical properties. A particularly useful tongue and groove arrangement are also provided for joining adjacent strips of a composite material made according to the extrusion process.

Owner:POLYMER SHEET APPL +3

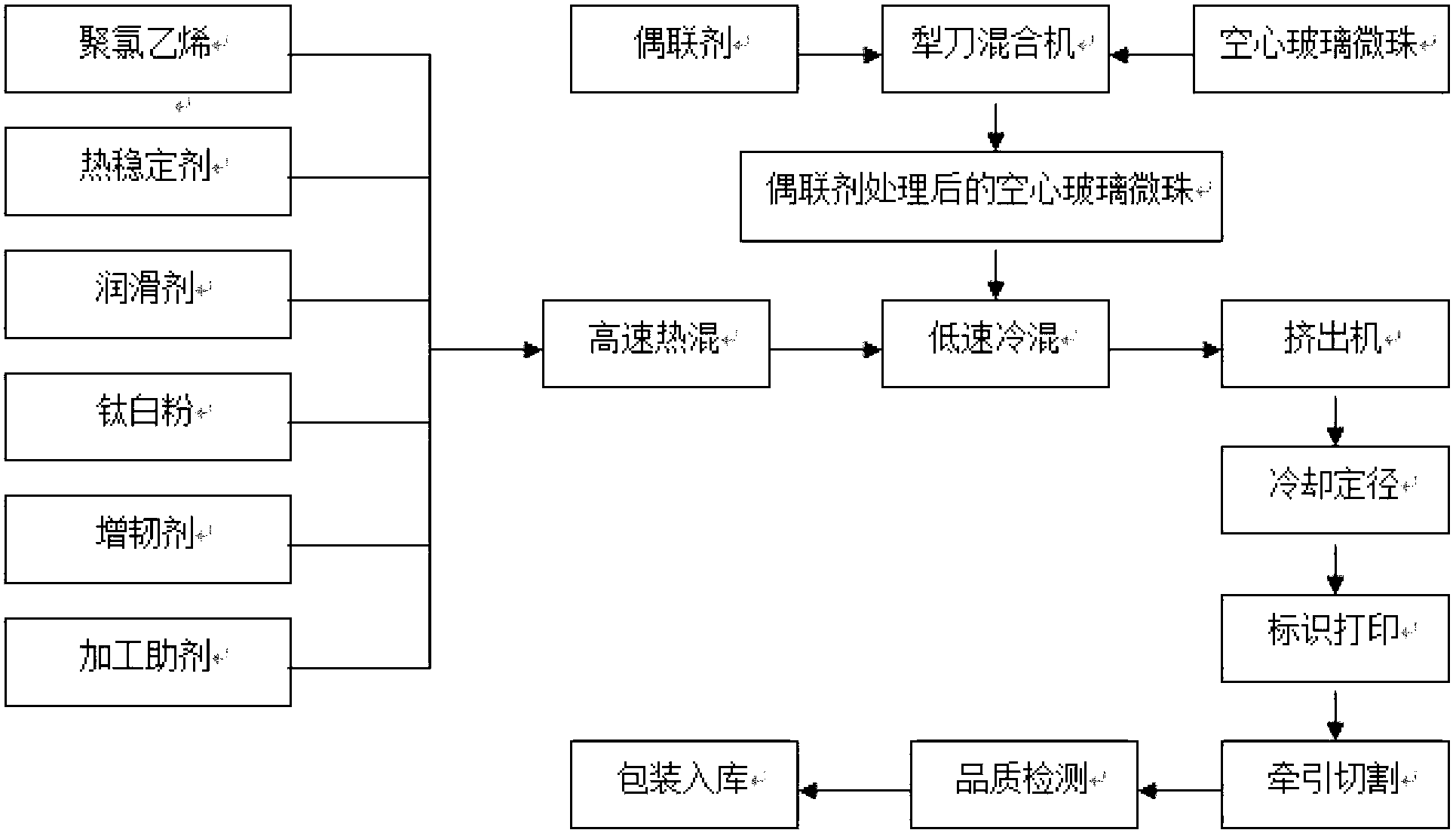

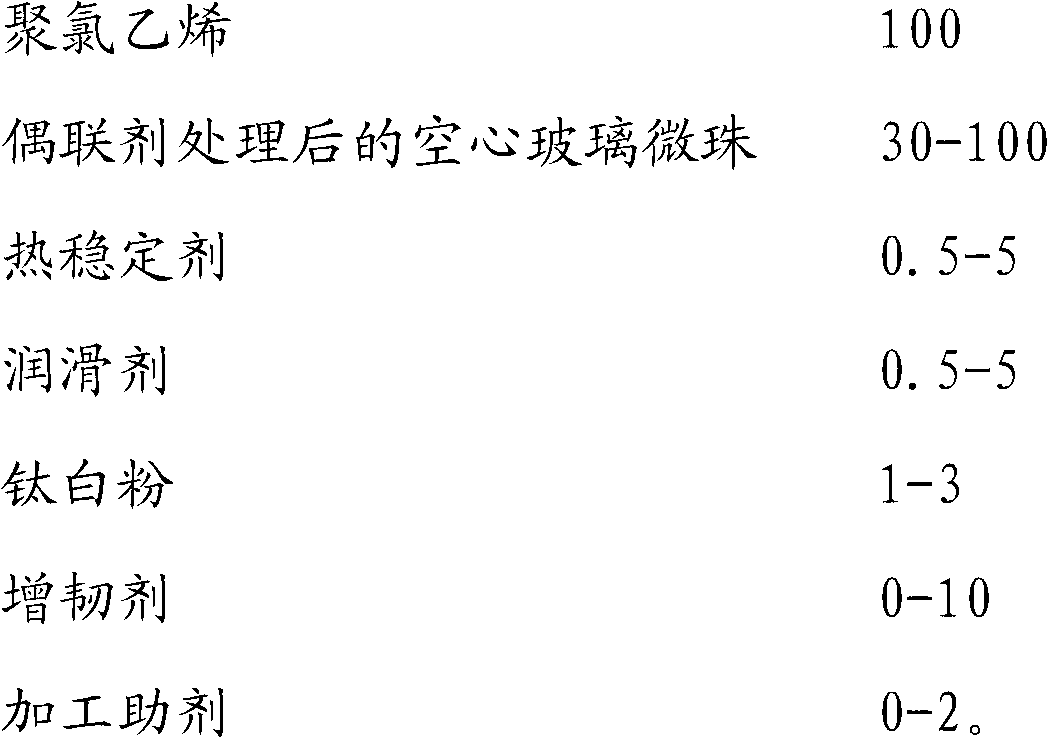

Polyvinyl chloride drain pipe and preparation method thereof

The invention discloses a polyvinyl chloride drain pipe and a preparation method thereof. The polyvinyl chloride drain pipe comprises the following raw materials in part by weight: 100 parts of polyvinyl chloride, 30 to 100 parts of hollow glass microsphere processed by coupling agent, 0.5 to 5 parts of thermal stabilizer, 0.5 to 5 parts of lubricating agent, 1 to 3 parts of titanium dioxide, 0 to 10 parts of flexibilizer and 0 to 2 parts of processing agent. The method adopts the mode of plastic modifying, creatively introduces the hollow glass microsphere for filling, effectively improves the product toughness on the basis that the product rigidity is guaranteed, simultaneously effectively reducing noises through a hollow structure, greatly reduces the product density, reduces the product weight, and can also reduce the product cost.

Owner:RIFENG ENTERPRISE FOSHAN CO LTD +1

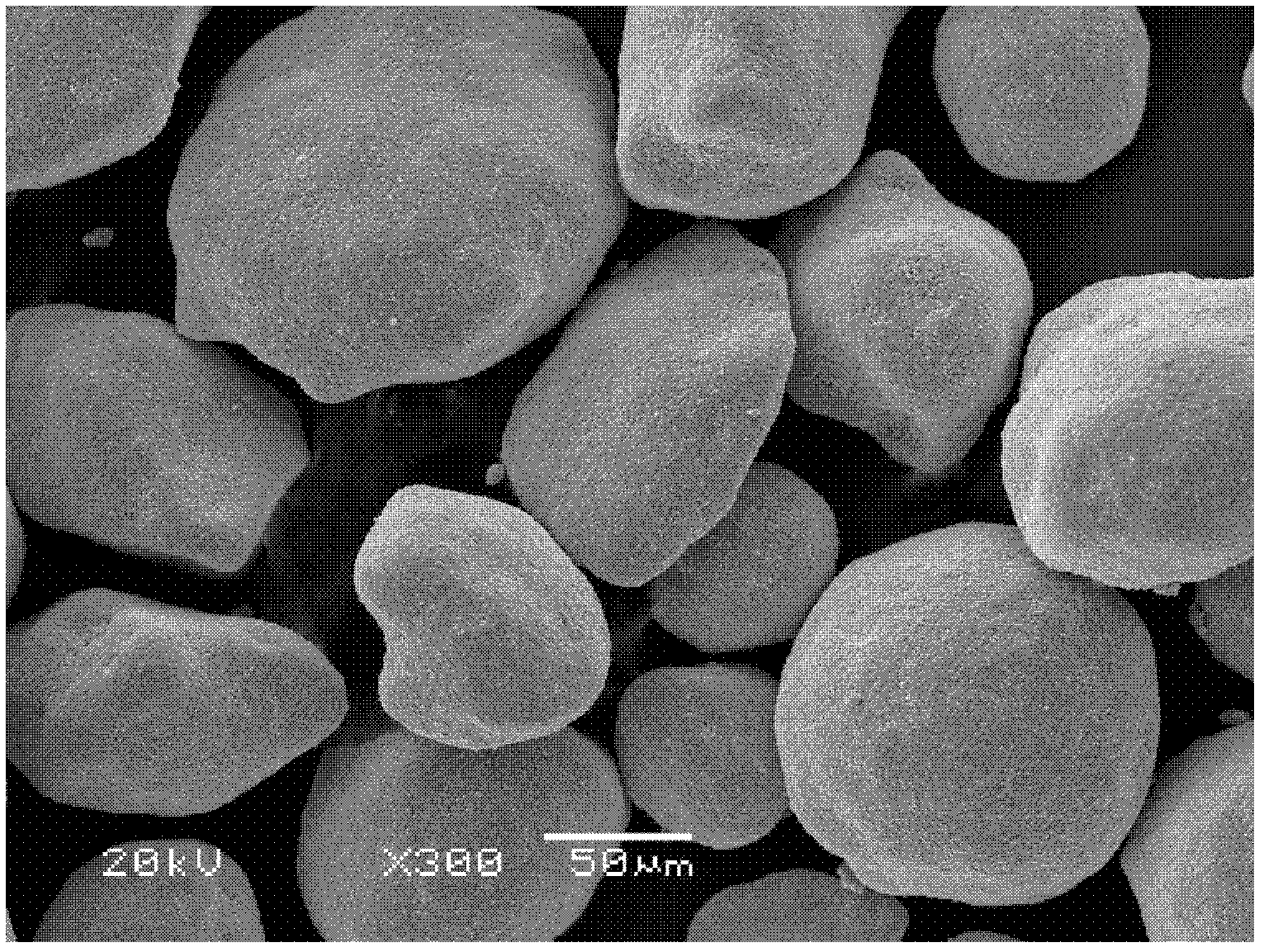

Drilling fluid containing microspheres and use thereof

InactiveUS20050124499A1Low densityReduce pressure requirementsDrilling compositionBorehole/well accessoriesWater basedOcean bottom

The present invention provides a drilling fluid composition and a method of drilling comprising a drilling fluid, which may be oil- or water-based, and a composite microsphere component. The invention drilling fluid composition advantageously reduces the density of a conventional fluid, reduces costs associated with pumping and overcomes problems associated with conventional gas-injection processes. The invention uses conventional drilling and pumping equipment, requires no sea-floor based pumps and may be easily pressure-controlled to maintain the pressure of the fluid.

Owner:3M INNOVATIVE PROPERTIES CO

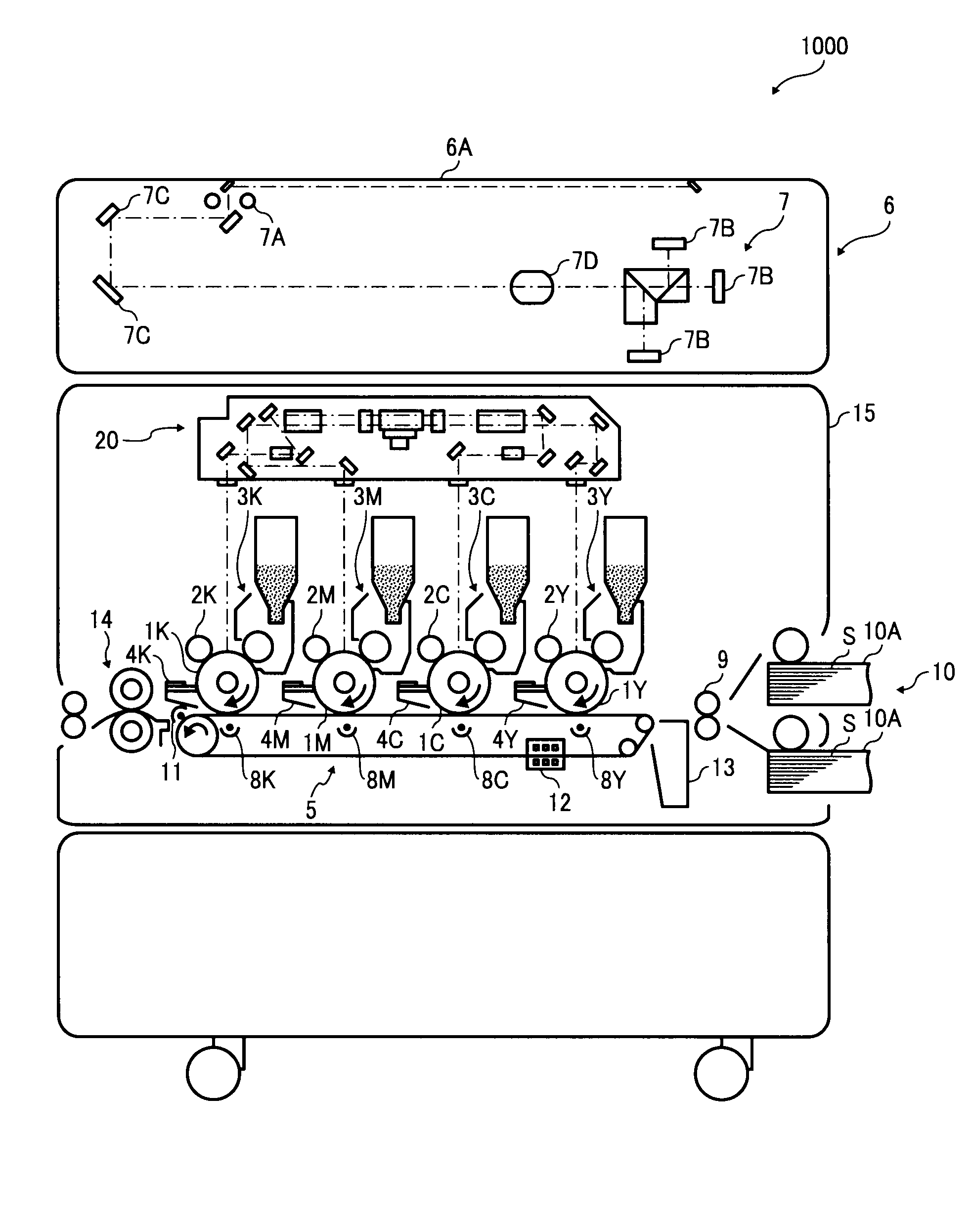

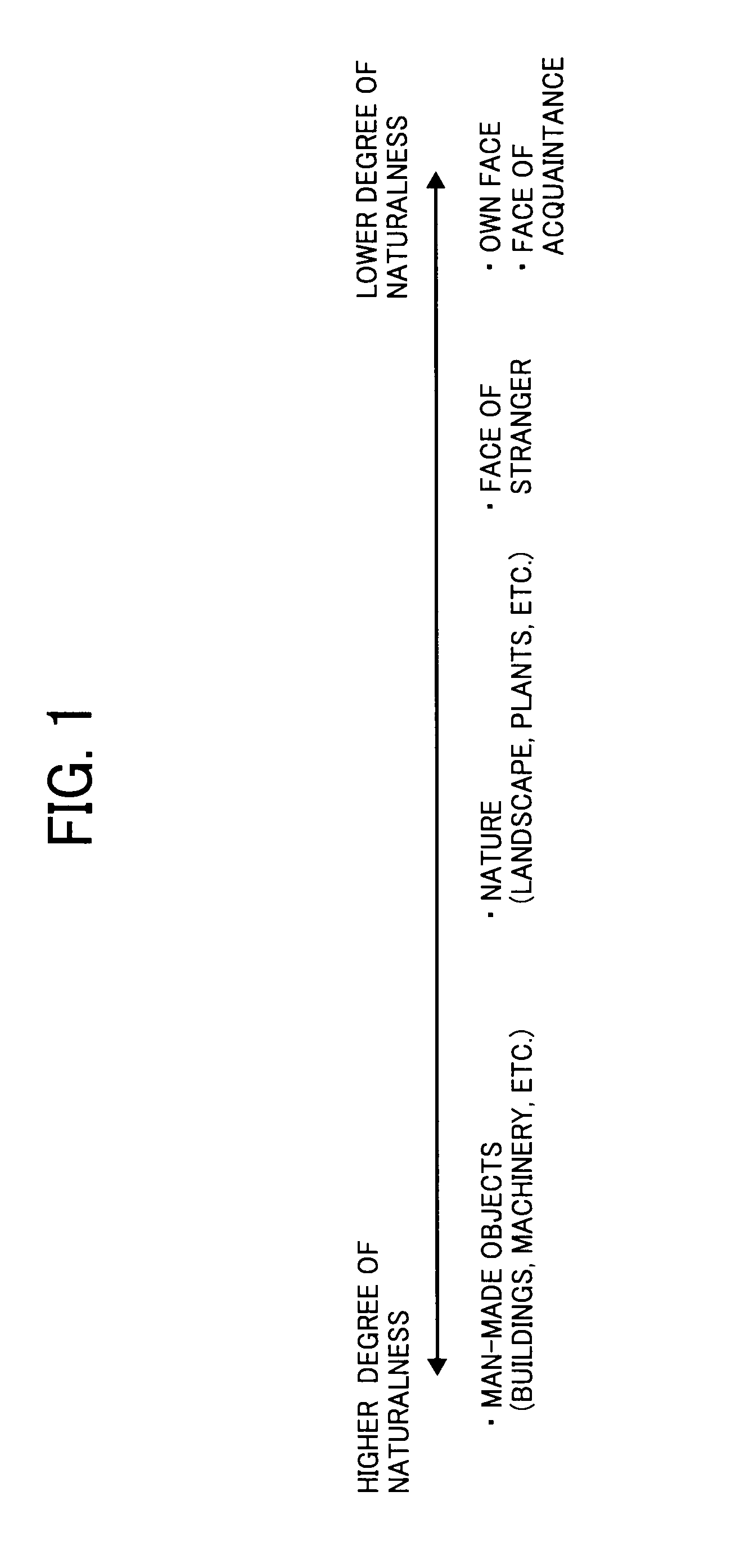

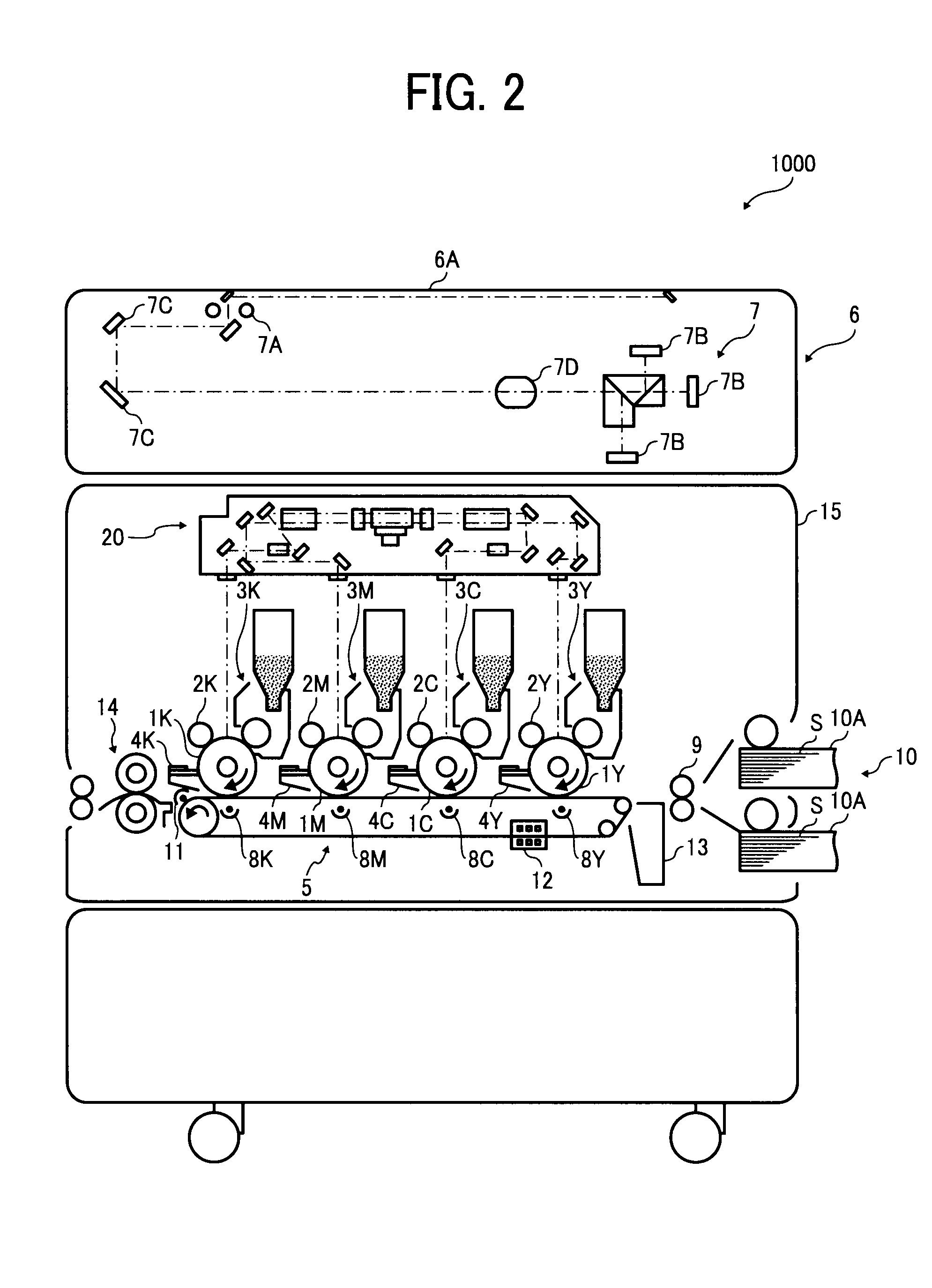

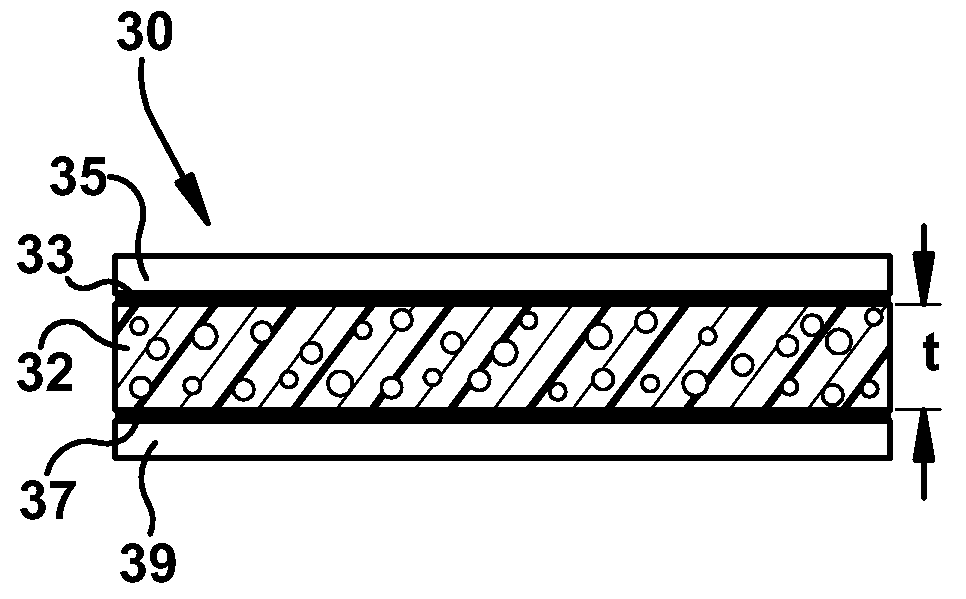

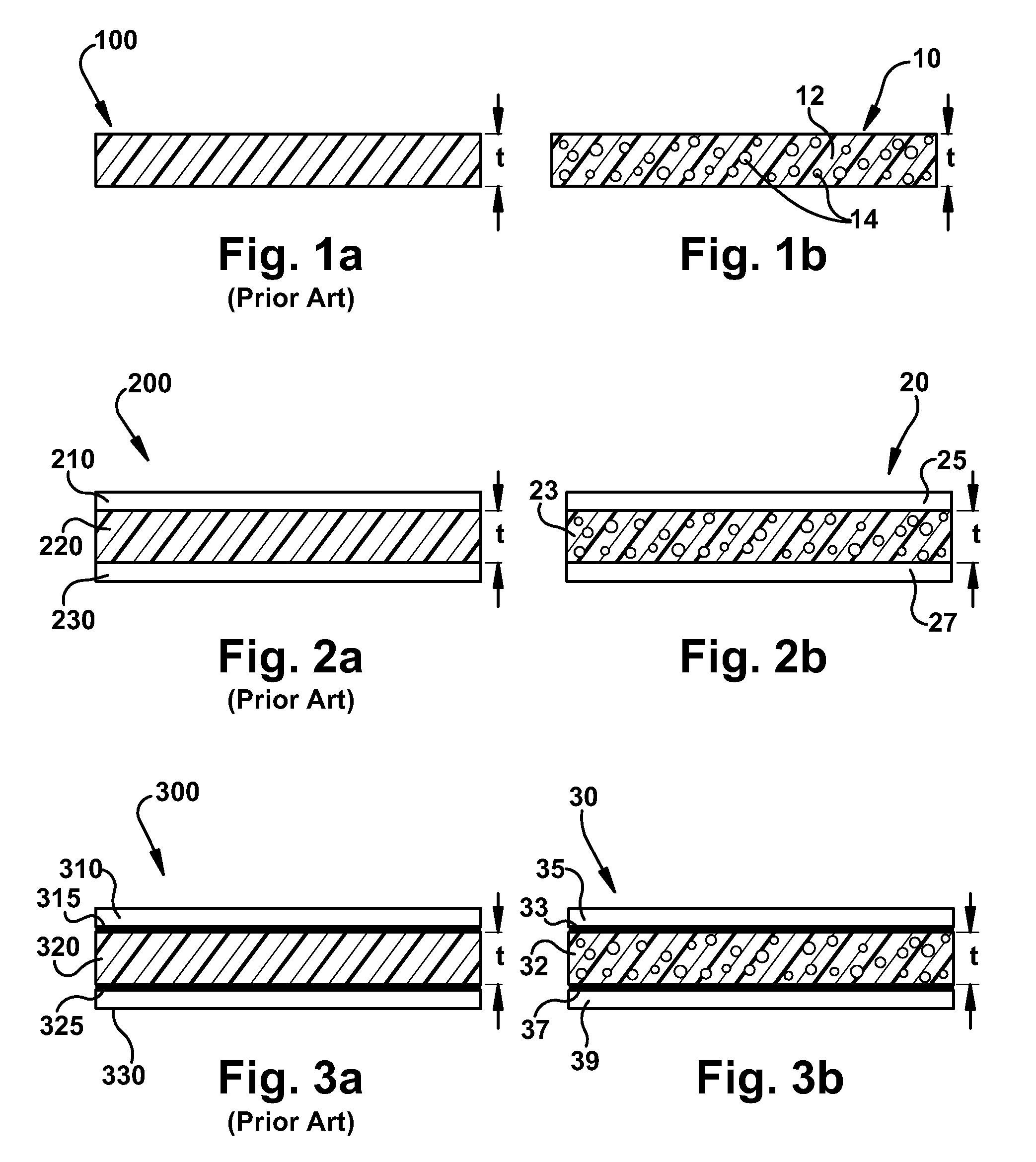

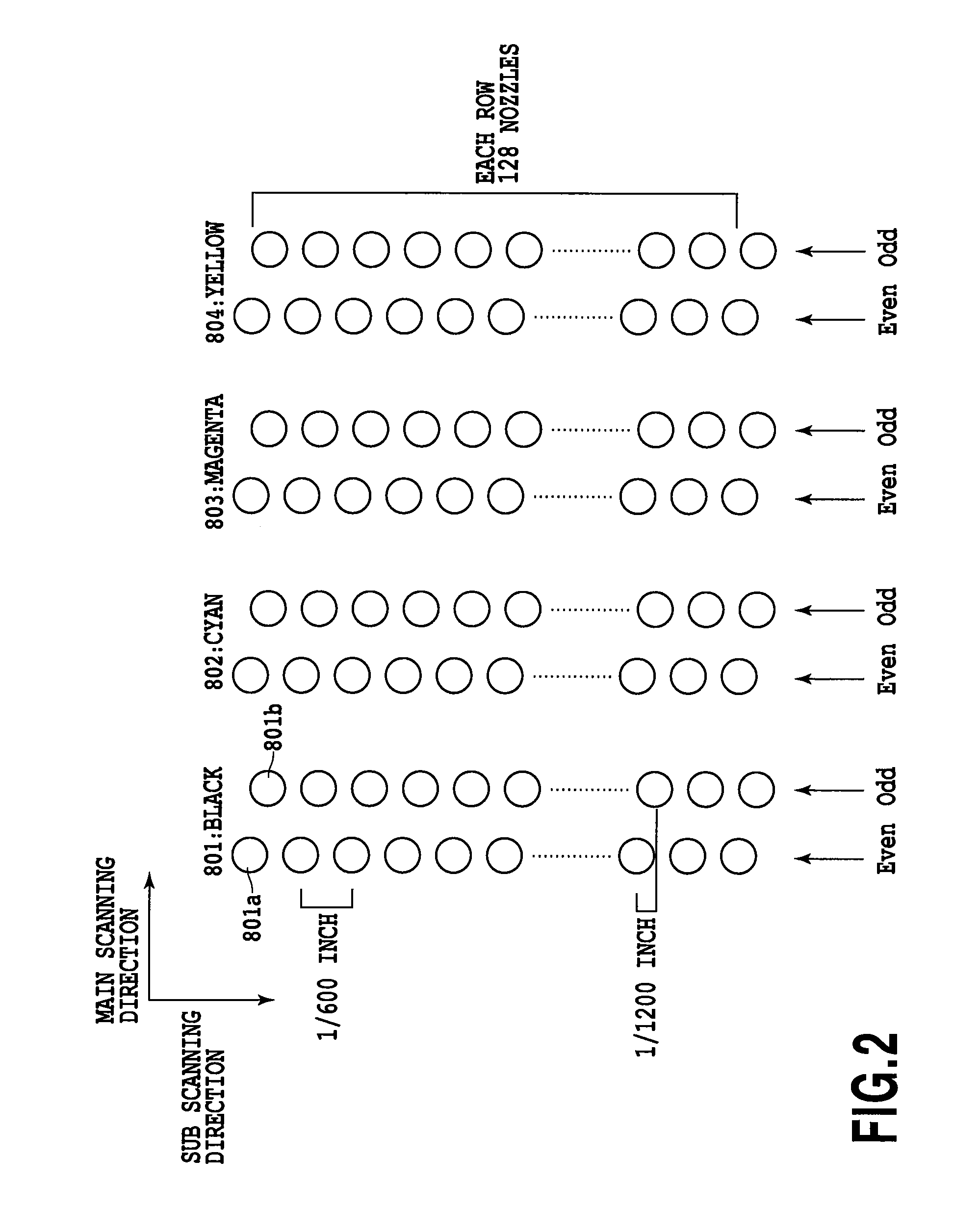

Image processing device, image forming apparatus including same, image processing method, and image processing program

InactiveUS20090034002A1Reducing unnatural and odd partImprove legibilityImage enhancementDigitally marking record carriersDensity reductionImaging processing

An image processing device including an image signal reception unit configured to receive an image signal of an image to be processed; a density reduction area detector configured to detect a density reduction area satisfying predetermined image density reduction requirements in the image to be processed based on the image signal; a specific image area detector configured to detect a specific image area satisfying predetermined specific image requirements different from the predetermined image density reduction requirements in the image to be processed based on the image signal; and a density controller configured to reduce density of the density reduction area detected by the density reduction area detector in a non-specific image area other than the specific image area detected by the specific image area detector, and to not reduce density of the density reduction area in the specific image area.

Owner:RICOH KK

Foamed film package

A package includes at least one layer of foamed thin film and an opening feature formed in the layer of foamed thin film. The foamed thin film has a caliper of from about 10 microns to about 250 microns thick. The foamed thin film comprises from about 5% to about 50% density reduction as compared to a non-foamed thin film of substantially the same caliper and substantially the same composition. The package may include foamed thin film made of a plastic resin and a whitening additive that is added to plastic resin. The whitening additive is selected to produce a foamed thin film having an opacity value of from about 35% to about 99%. The whitening agent is of substantially the same composition and is present in substantially the same amount as would be selected to produce substantially the same light reflectivity in a non-foamed thin film of substantially the same caliper and substantially the same composition.

Owner:THE PROCTER & GAMBLE COMPANY

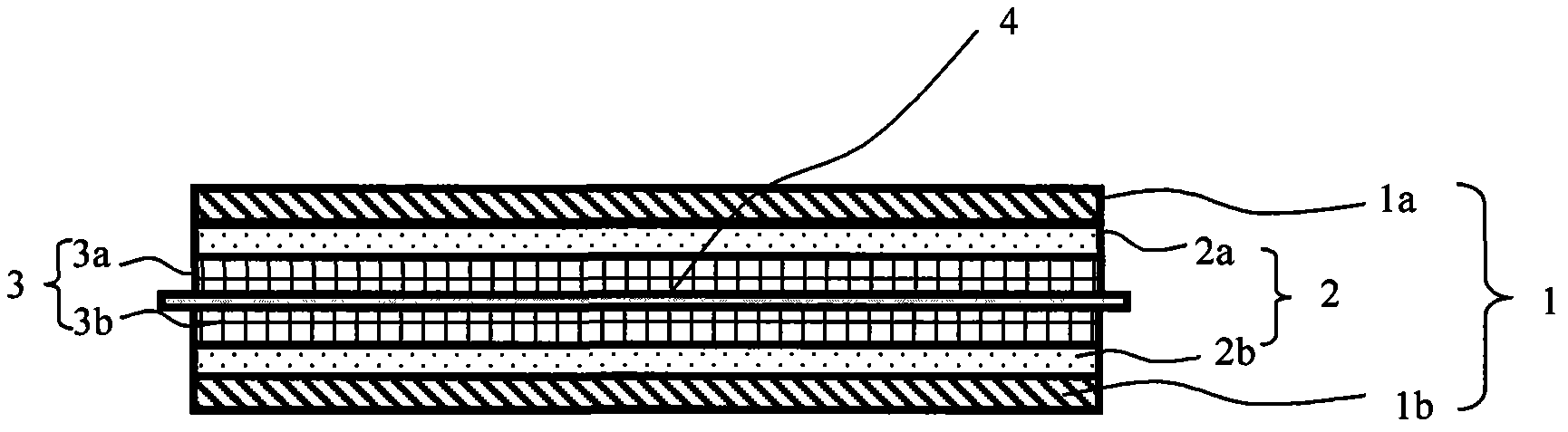

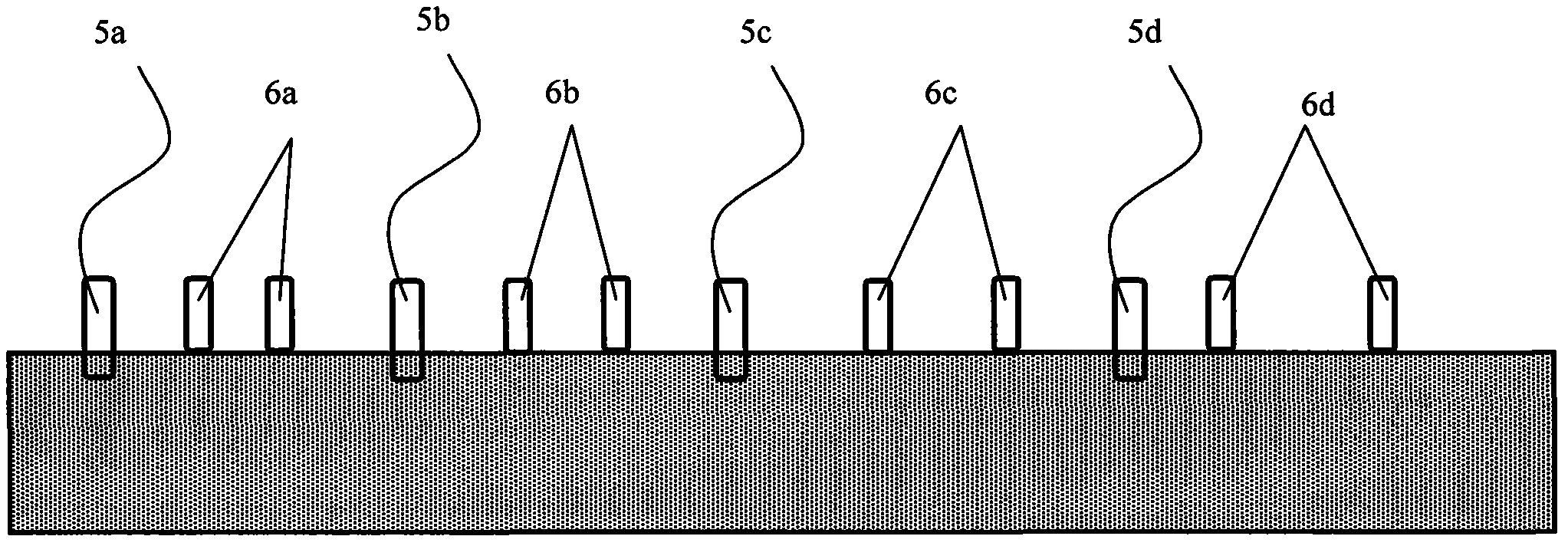

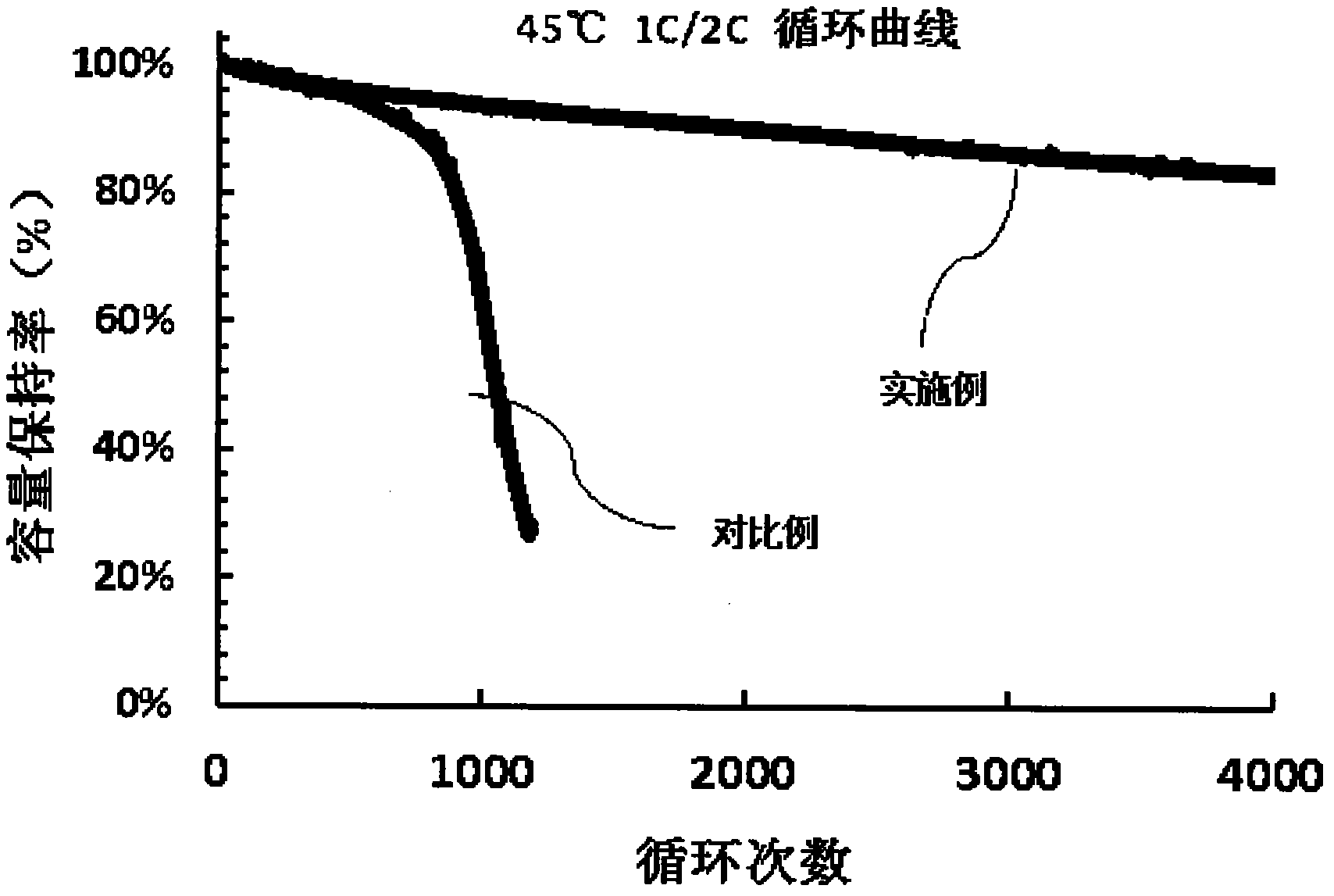

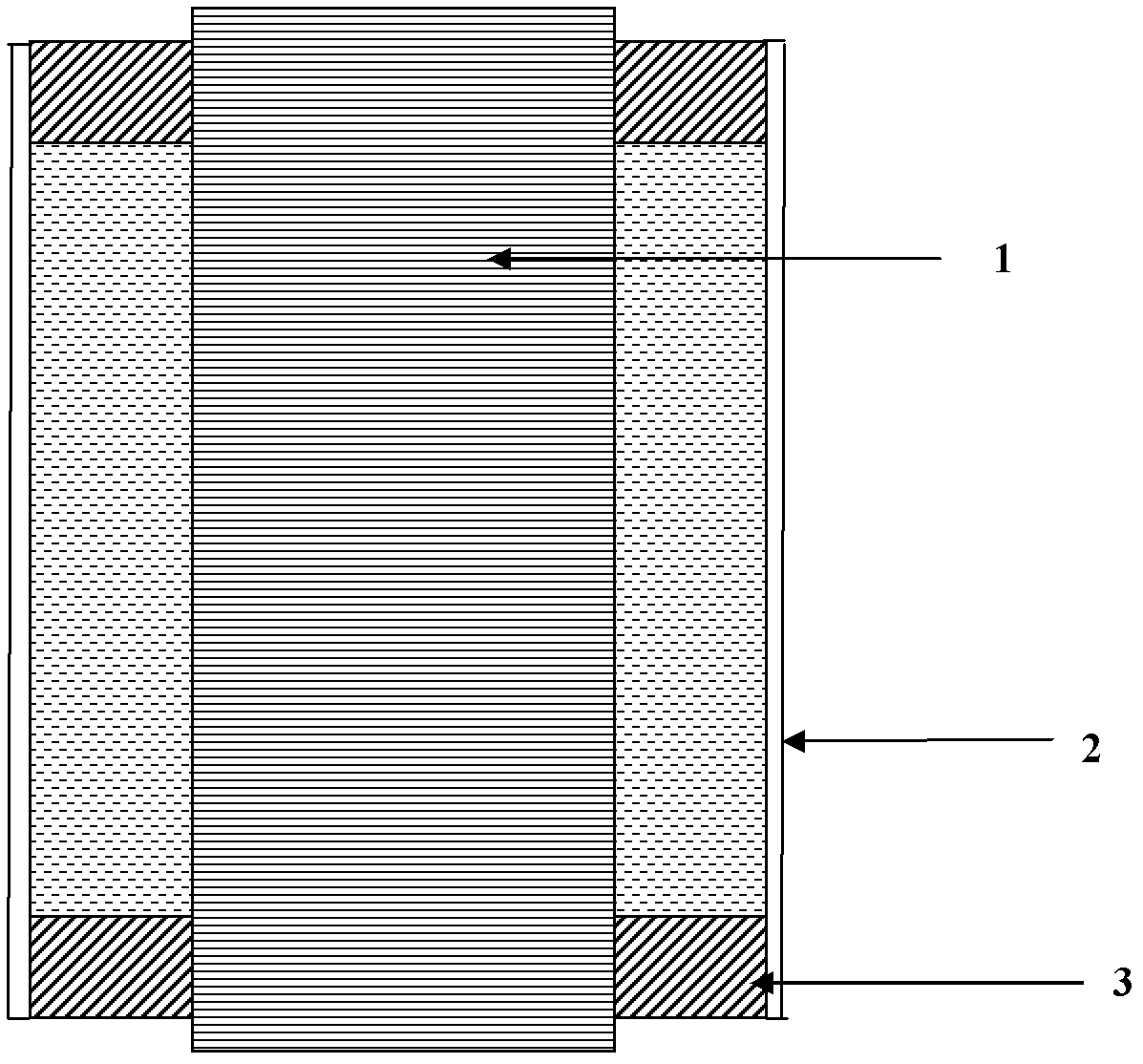

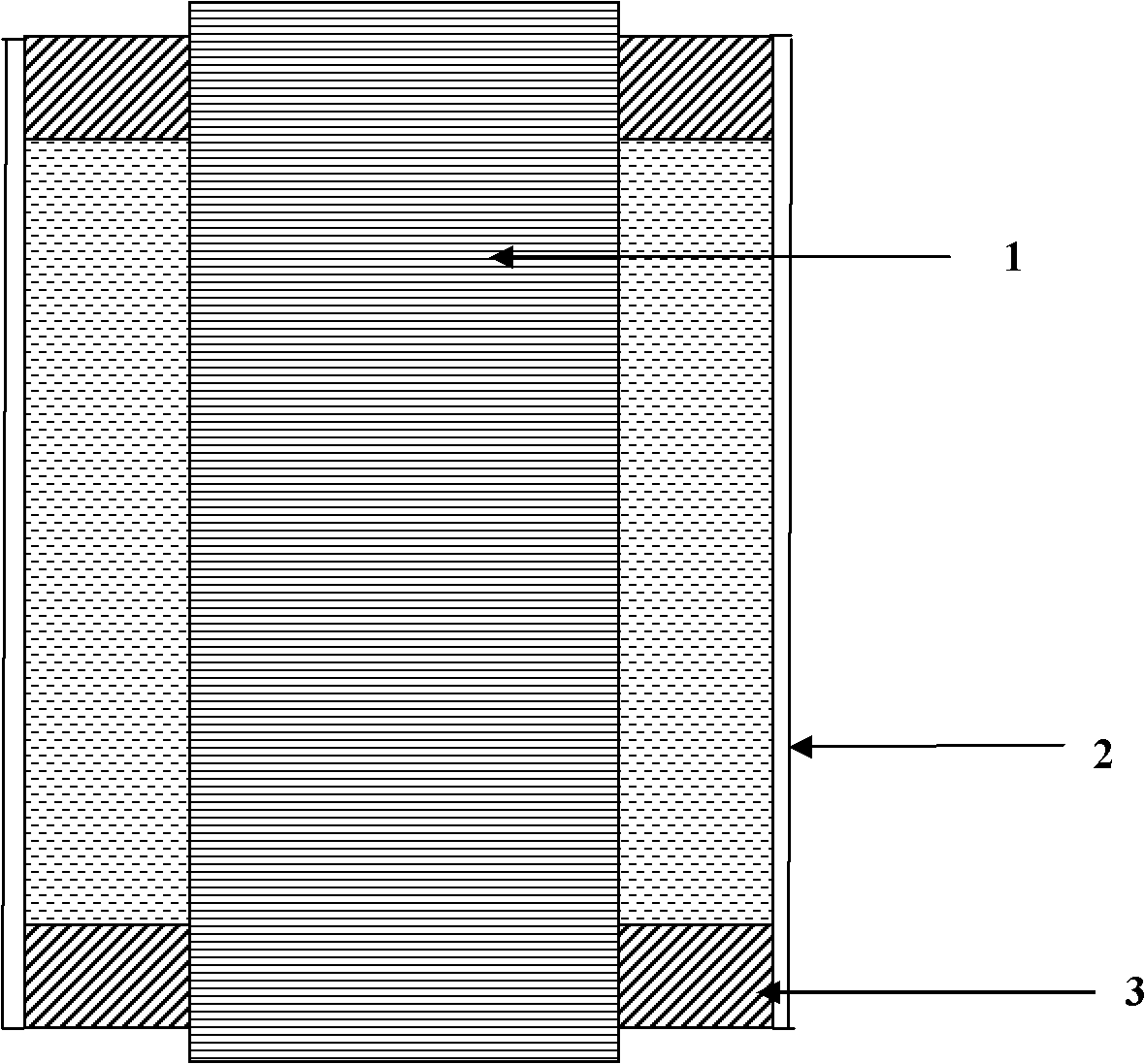

Total temperature-range lithium ion battery

ActiveCN103325991AImprove breathabilityImprove high temperature resistanceCell seperators/membranes/diaphragms/spacersSecondary cellsComposite electrolyteInternal resistance

The invention provides a total temperature-range lithium ion battery. The total temperature-range lithium ion battery comprises a multi-tab anode piece having a compound multi-layer coating structure, a multi-tab cathode piece having a compound multi-layer coating structure, a high temperature-resistant diaphragm and a high / low temperature composite electrolyte. Each one of two sides of a part 4 on positive and negative current collectors is orderly coated with a rapid charging / discharging layer 1 (1a, 1b), a transition layer 2 (2a, 2b) and a slow charging / discharging layer 3 (3a, 3b). Through the structure, the total temperature-range lithium ion battery has rapid charging / discharging performances without battery energy density reduction. Through the multi-tab structure, the high temperature-resistant diaphragm and the high / low temperature composite electrolyte, battery ohmic resistance and electrochemical interface impedance are reduced and battery safety is improved. The total temperature-range lithium ion battery can realize normal charging and discharging at a temperature of -40 to 75 DEG C and has excellent low-temperature high-magnification characteristics and high-temperature and long-life performances.

Owner:余玉英 +1

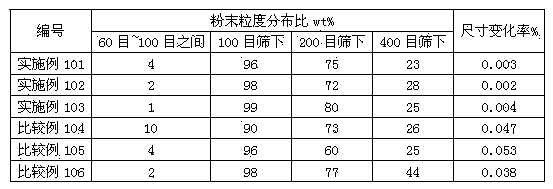

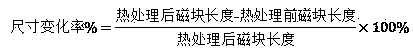

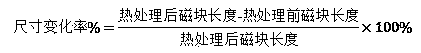

Mixed soft magnetic powder for metal magnetic powder core

InactiveCN103745790AInhibition of volume expansionLow densityInorganic material magnetismDensity reductionMetal powder

The invention discloses mixed soft magnetic powder for a metal magnetic powder core. The mixed soft magnetic powder for the metal magnetic powder core is characterized in that the surface of soft magnetic metal powder is provided with powder with a surface insulating layer and a molding lubricant; relative to total mass of the mixed powder, mass of the mixed powder with particle size below 100 meshes accounts for more than 95%, mass of the mixed power with the particle size below 200 meshes accounts for more than 70%, and mass of the mixed power with the particle size below 400 meshes accounts for less than 30%. The mixed soft magnetic powder for the metal magnetic powder core has the advantages that by reasonable control on particle size distribution of the soft magnetic metal powder with the insulating layer and the mixed soft magnetic metal powder containing the lubricant, gas generated after the lubricant is subjected to heat treatment in the magnetic powder core an be smoothly discharged from the inside of the magnetic powder core, volume expansion of the magnetic powder core after heat treatment can be effectively restrained, density of the magnetic power core is prevented from decreasing due to heat treatment, dimensional accuracy of the magnetic power core is improved, and magnetic property is inhibited from deteriorating.

Owner:CHINA JILIANG UNIV

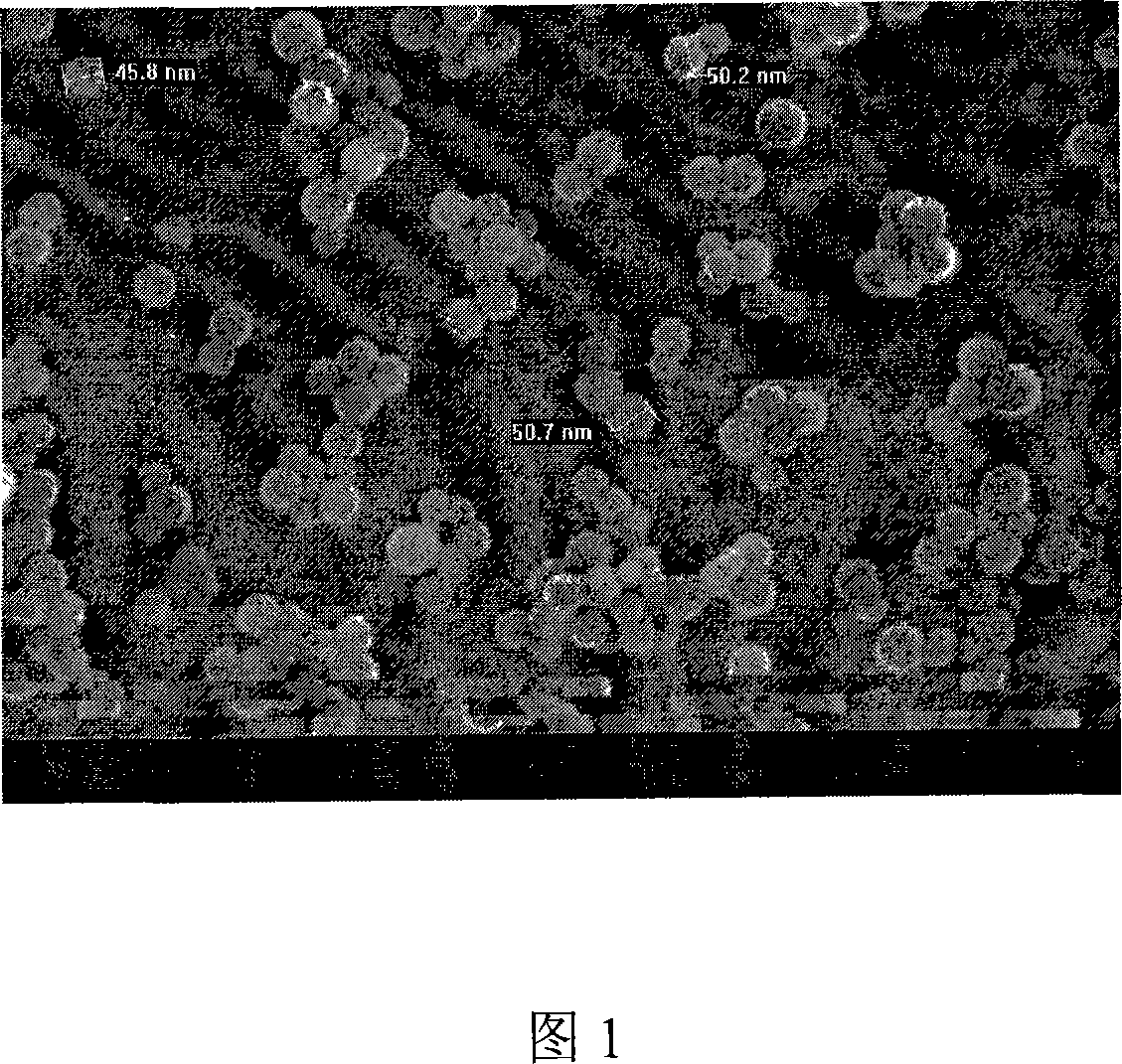

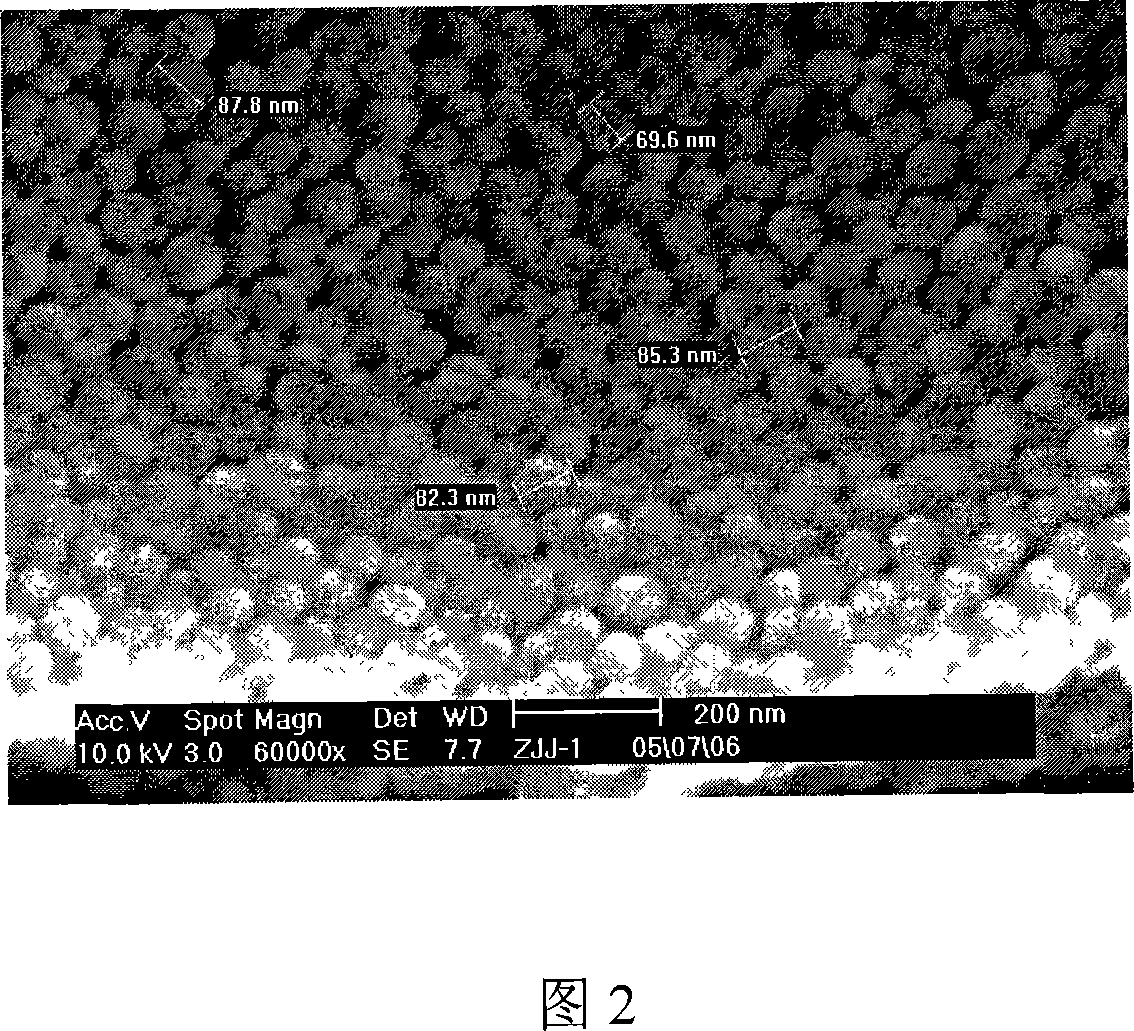

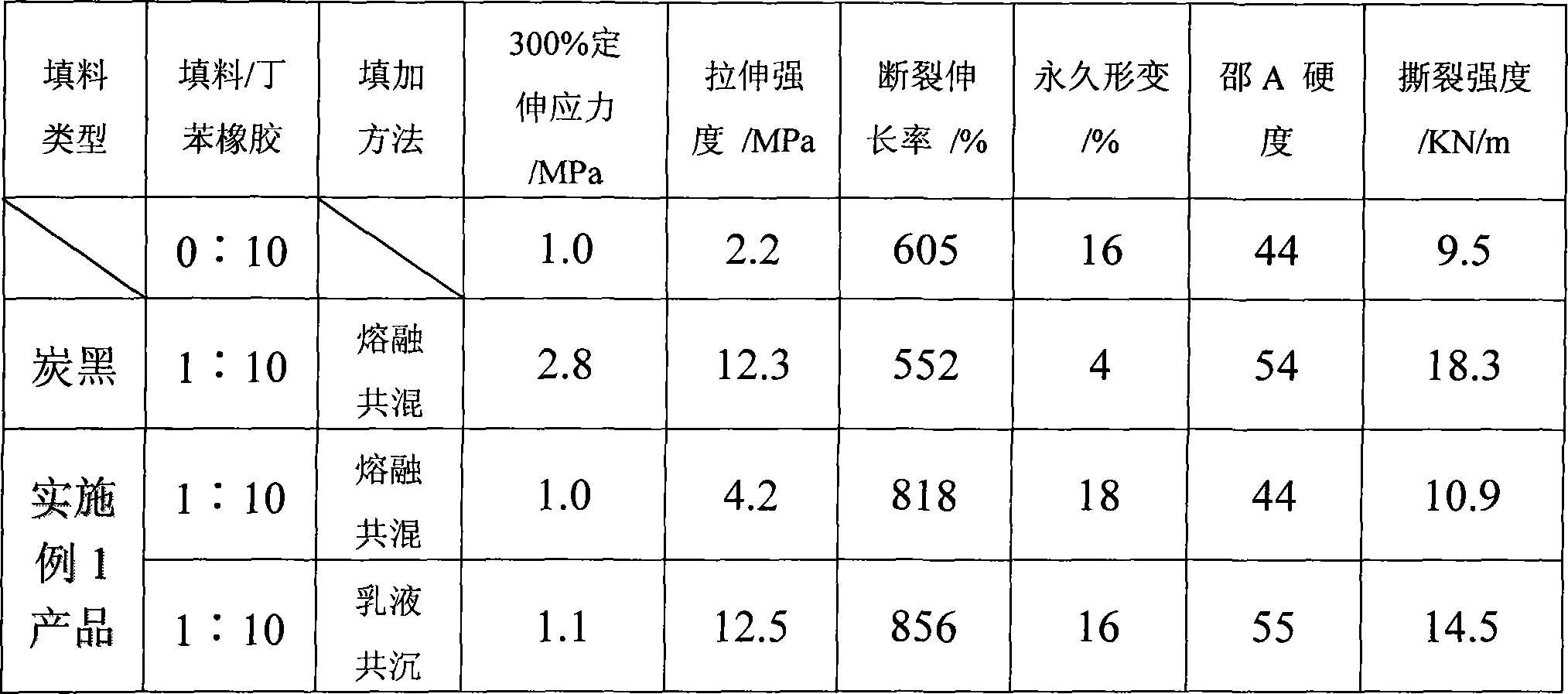

Core-shell type emulsion particle emulsion for enhancing rubber and preparation method thereof

InactiveCN101033267AGood compatibilityImprove mechanical propertiesDensity reductionStress concentration

A kind of core-shell rubber latex particles emulsion for increasing rubber and its preparation is through emulsion polymerization obtaining monodisperse latex particles, then using seed emulsion polymerization to get the core-shell rubber particles emulsion. The core-shell latex particles has spherical inspection and nano-scale, ensures reinforcement capability, and at the same time, makes rubber reduced density, good mobility, small high-stress concentration, and uniform stress distribution, and because of good interface, it can improve the mechanical properties effectively.

Owner:BEIJING UNIV OF CHEM TECH

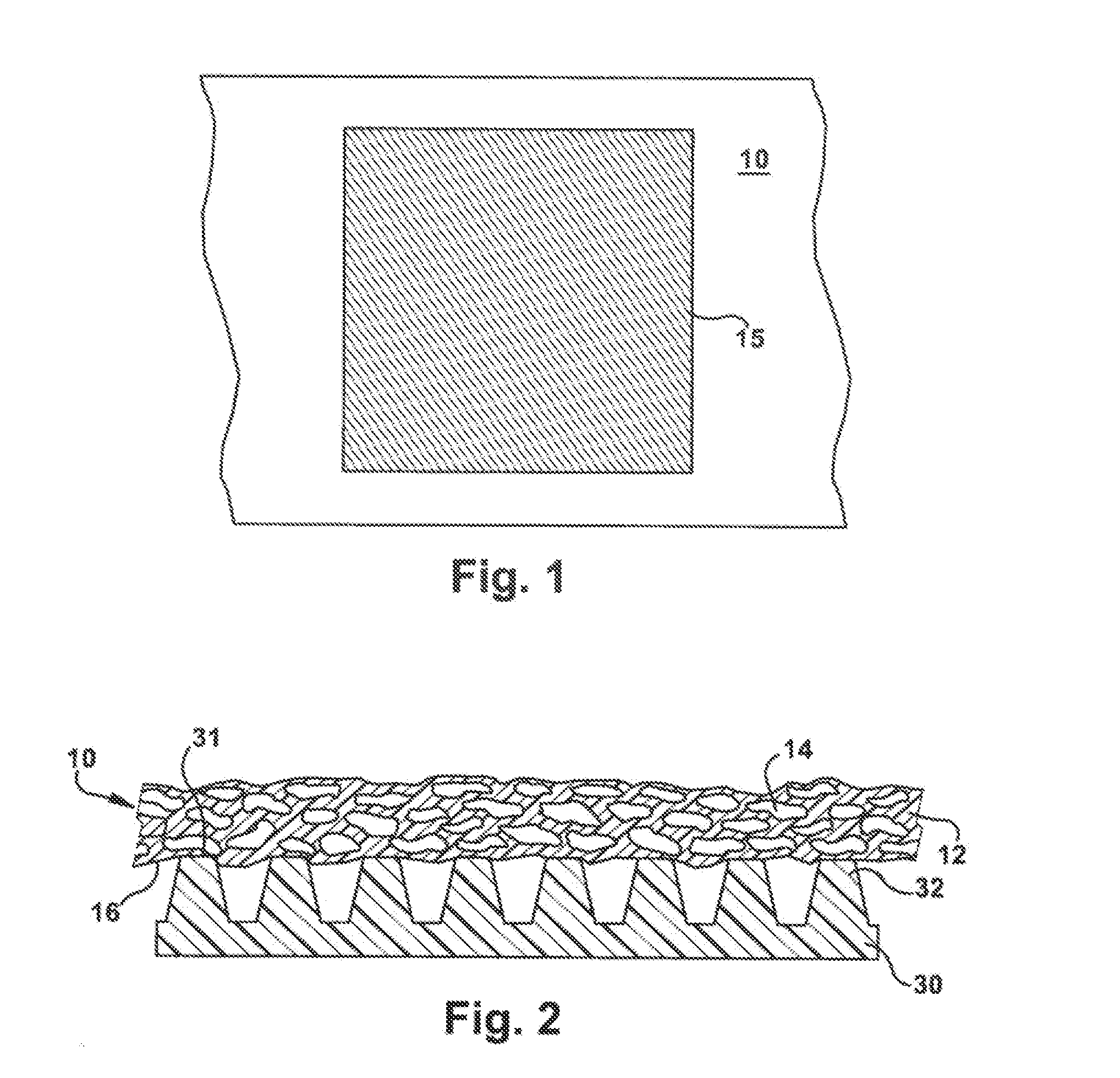

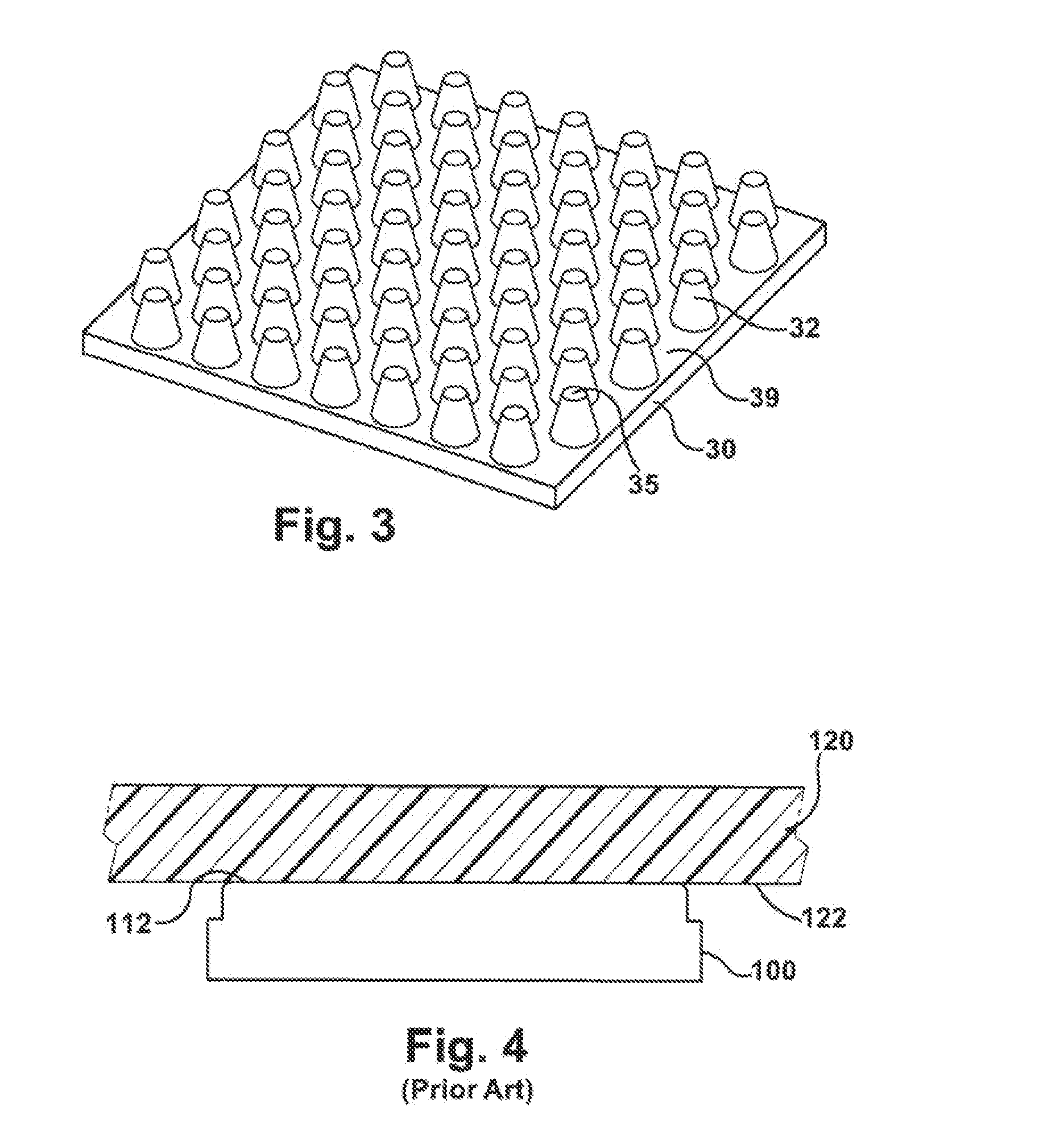

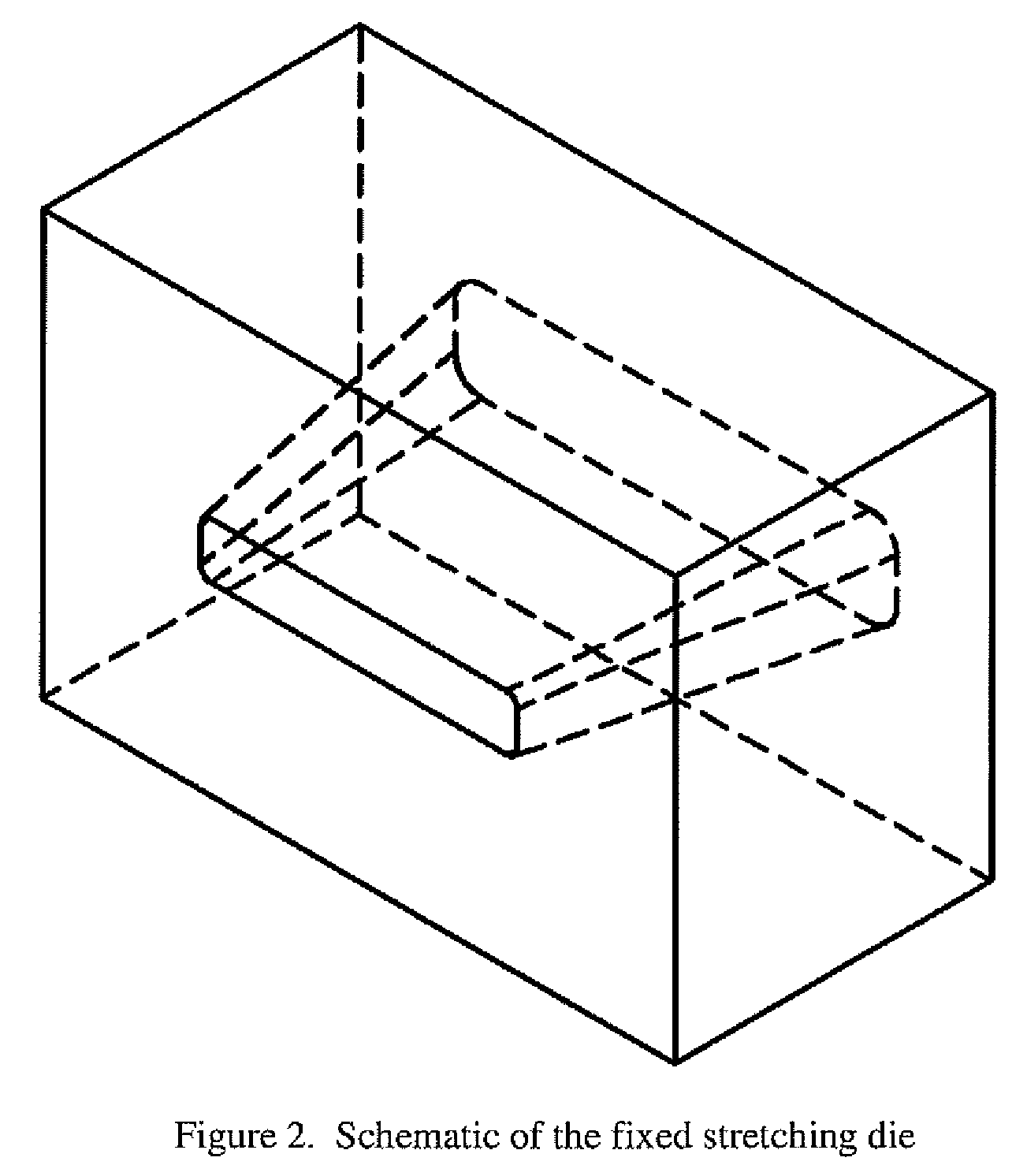

Method for the production of low density oriented polymer composite with durable surface

InactiveUS20090001635A1Flat articlesElectric/magnetic/electromagnetic heatingDensity reductionPolymer science

A process and material therefrom is described where a material comprised of a continuous orientable polymer matrix with one or more discontinuous or continuous second phases is stretched in the solid state using more than one device to apply force to the unoriented material to form a material that consists of a continuous oriented polymer matrix with one or more other phases. At least one of the phases releases from the oriented polymer matrix forming voids during the orientation process, thereby reducing the density to less than that of the original unoriented mixture. One or more of the phases may stay bonded to the continuous oriented polymer phase, acting as a reinforcing agent and forming no voids. Methods for forming such a material allowing for the control of the final shape and affecting the final density independent of the composition are also disclosed.

Owner:WEYERHAEUSER CO

Micropore foaming agent for polypropylene, microcellular foamed polypropylene composite material and methods for preparing micropore foaming agent for polypropylene and microcellular foamed polypropylene composite material

InactiveCN102977458ABreak through the limitationsImprove physical and mechanical propertiesSodium bicarbonatePolypropylene composites

The invention discloses a micropore foaming agent for polypropylene, a microcellular foamed polypropylene composite material and methods for preparing the micropore foaming agent for polypropylene and the microcellular foamed polypropylene composite material. The micropore foaming agent for polypropylene consists of the following components in parts by weight: 9-15 parts of sodium bicarbonate, 21-35 parts of citric acid and 50-70 parts of high polymer material. The microcellular foamed polypropylene composite material consists of the following components in parts by weight: 69-80 parts of polypropylene, 5-10 parts of high density polyethylene, 3-5 parts of nucleating agent, 10-15 parts of inorganic filler, 0.1-1.0 part of heat stabilizer, 0.2-1.5 parts of antioxidant and 0.2-0.8 part of the micropore foaming agent for polypropylene. The preparation methods are simple and low in cost. An economic and environment-friendly foaming system is utilized, the foaming material is an injection molding grade foaming material, so that the limitation of foaming material plates or pipes are broken through; and various physical and mechanical performances of the produced microcellular foamed polypropylene composite material are excellent, and moreover, the density of the material is reduced by 30%.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

Method for producing polytetrafluoroethylene fine powder

To provide a method for producing a PTFE fine powder having a low paste extrusion pressure property by a simple method.The method for producing a PTFE fine power comprises emulsion polymerizing tetrafluoroethylene in the presence of an aqueous medium, a fluorinated surfactant and a radical polymerization initiator, to produce an aqueous PTFE emulsion, and coagulating it in the presence of at least one bulk density-reducing compound selected from the group consisting of ammonia, an ammonium salt and urea in an amount of from 0.4 to 10 parts by mass per 100 parts by mass of PTFE.

Owner:ASAHI GLASS CO LTD

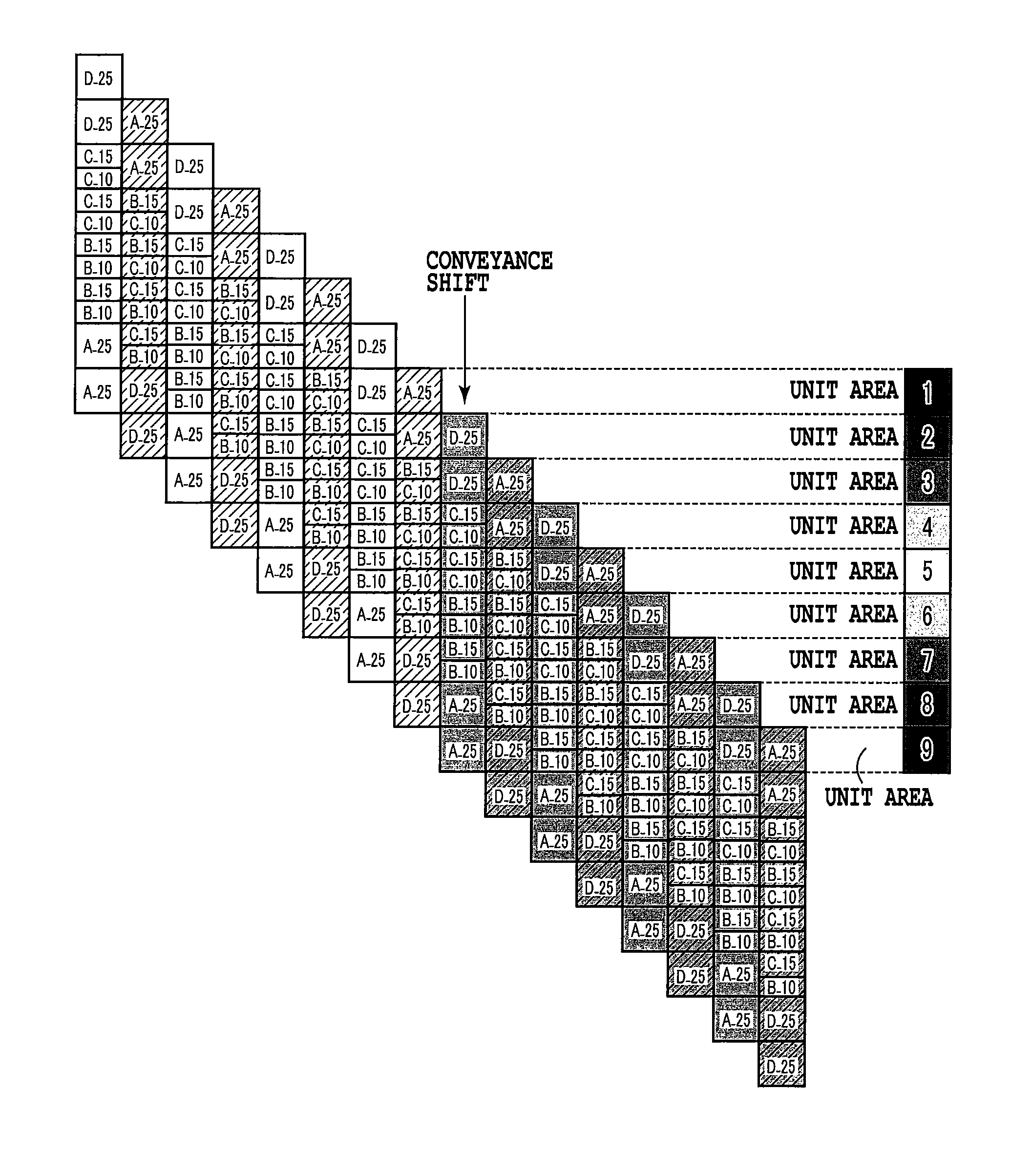

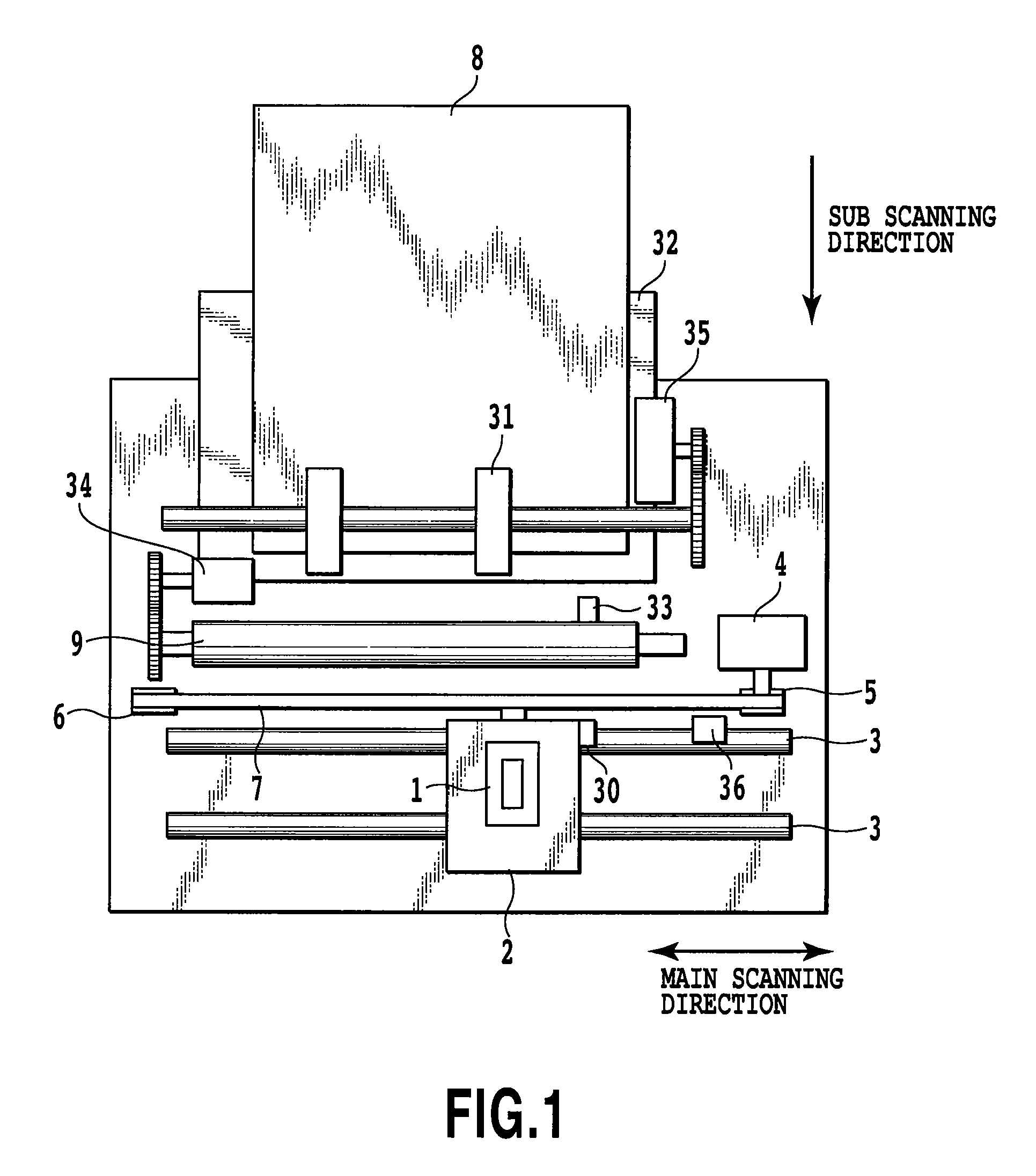

Printing apparatus and printing method

A printing apparatus and a printing method are capable of not permitting a printable ratio of each printing scan to have a deviation and, even if a sudden conveyance shift occurs, outputting a uniform and smooth image in the whole area of the print medium. In order to achieve this, when performing multipass printing of 2M passes, a mask such that a printable area overlapping ratio that relates to straddling between Pass M and Pass M+1 is set higher than the printable area overlapping ratio that relates to straddling between two other consecutive passes is used. By this configuration, even if a complementary relationship of dots collapses due to a sudden conveyance shift or the like and thereby a density reduction is anticipated, by an overlapped dot being separated, increase of the density is accelerated, and it becomes possible to mitigate the above-mentioned density reduction.

Owner:CANON KK

Lightweight high-manganese steel liner plate for ball mill and manufacturing method of liner plate

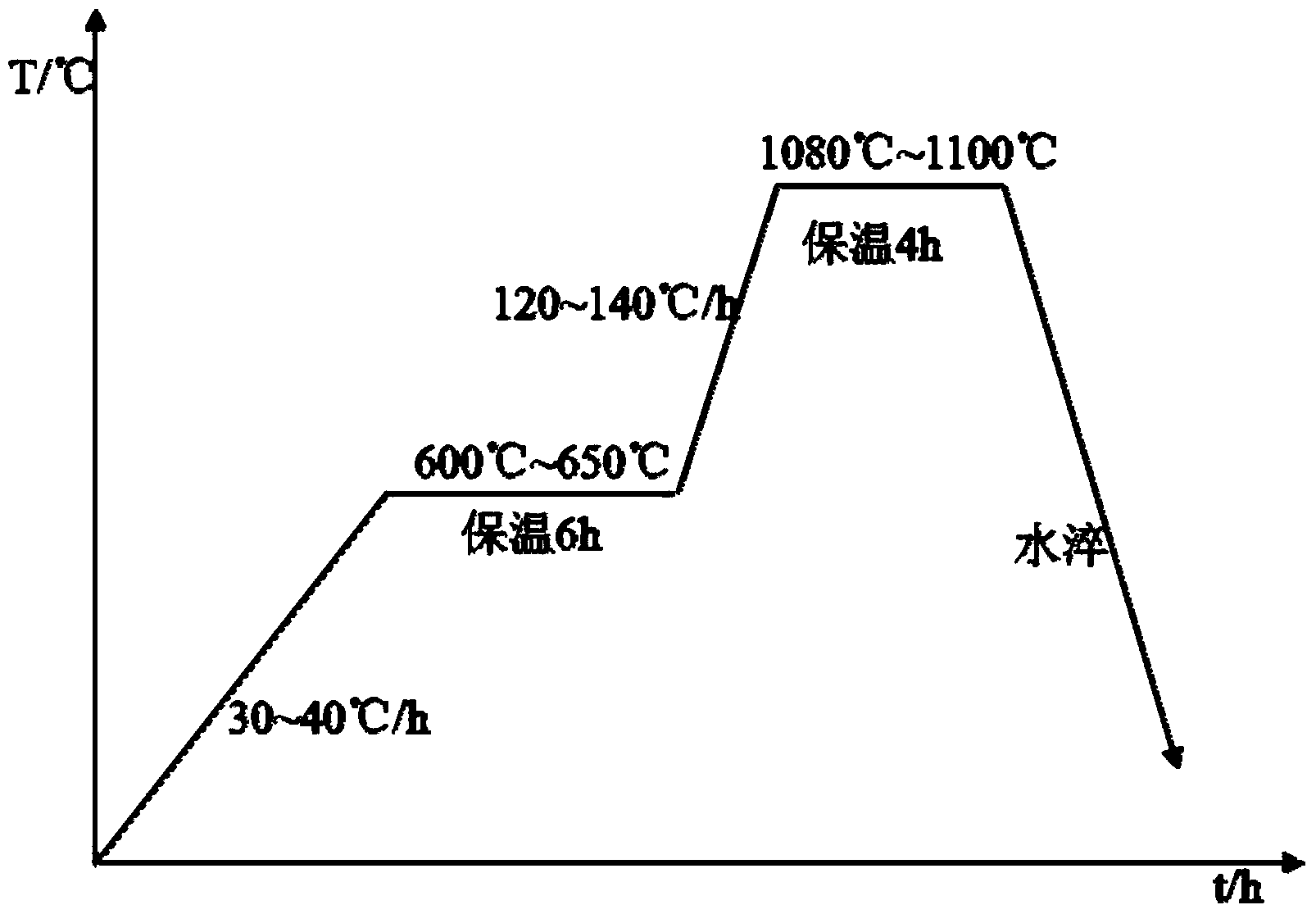

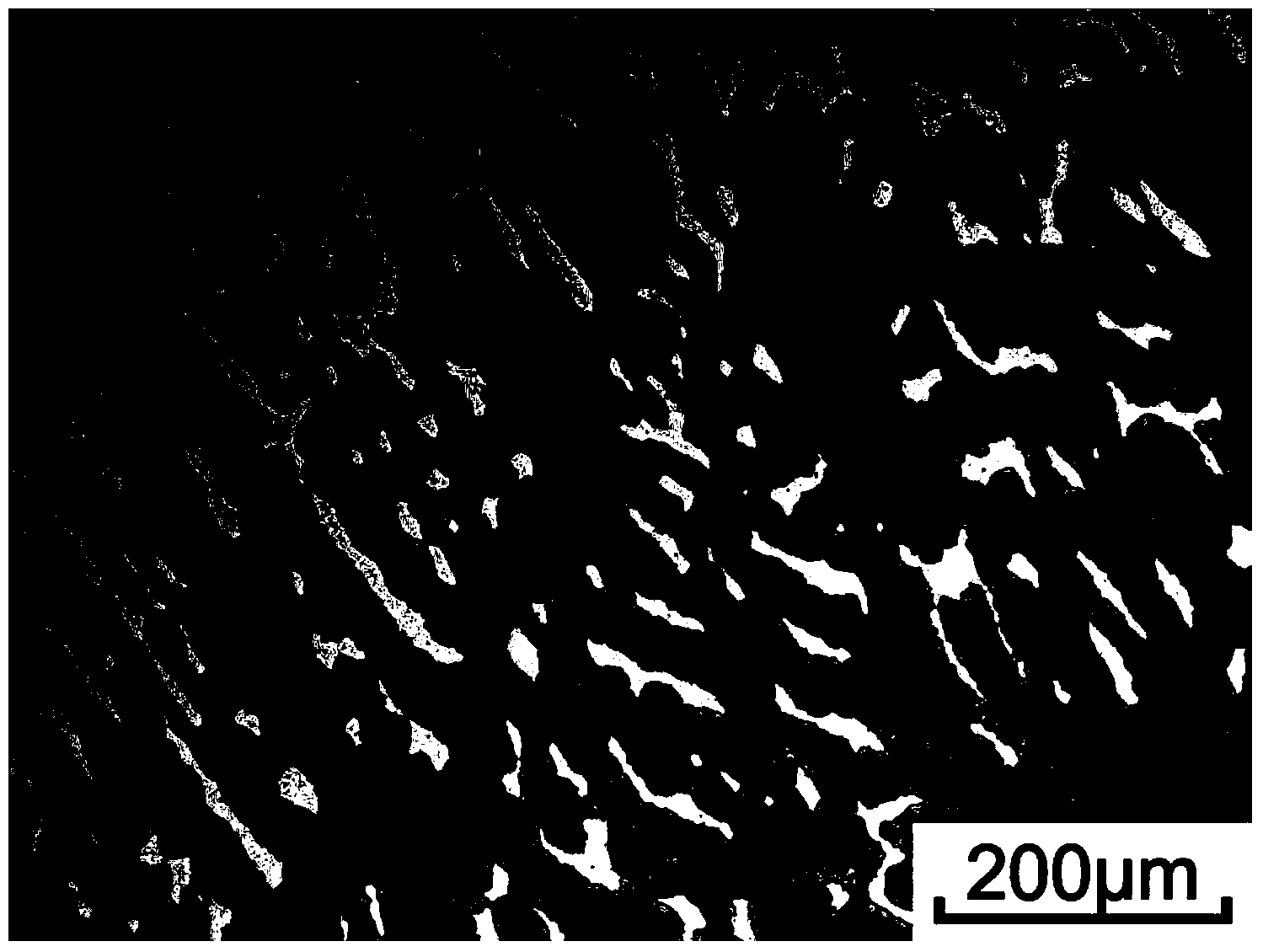

The invention relates to a lightweight high-manganese steel liner plate for a ball mill for use in the fields such as mine, cement and power, and a manufacturing method of the liner plate. The manufacturing method comprises the steps: (1) smelting the raw materials in a medium-frequency induction furnace, adding Al at a temperature ranging from 1500 DEG C to 1650 DEG C, and tapping the molten steel at a temperature ranging from 1530 to 1580 DEG C; (2) pouring the molten steel into a cavity of a metal mold at a temperature ranging from 1400 DEG C to 1450 DEG C; (3) heating to 600 to 650 DEG C from the normal temperature at a heating rate ranging from 30 DEG C / h to 40 DEG C / h, and preserving heat for 6 hours; next, increasing the heating rate to the range from 120 DEG C / h to 140 DEG C / h until the temperature reaches a water quenching temperature in the range from 1080 DEG C to 1100 DEG C, and preserving heat for 4 hours; and carrying out water quenching, controlling the water temperature in the range from 15 DEG C to 30 DEG C, and controlling the water temperature to be below 50 DEG C when quenching is finished. According to the invention, the density of the lightweight high-manganese steel liner plate is reduced by adding Al and Mn properly, and the mechanical properties of the lightweight high-manganese steel liner plate are improved by optimizing the smelting and casting processes; the density of the obtained high-manganese steel liner plate ranges from 6.60g / cm<3>to 7.10g / cm<3>, and is reduced by 9%-15% in contrast with that of an existing high-manganese steel liner plate; the abrasion resistance of the high-manganese steel liner plate can be improved by more than 35% in contrast with that of a common high-manganese steel liner plate. Compared with the liner plate produced by an existing method, the light high-manganese steel liner plate has comparative properties; however, the density and the production cost of the liner plate are obviously reduced.

Owner:UNIV OF SCI & TECH BEIJING

Method for the production of low density oriented polymer composite

A process and material therefrom is described where a material comprised of a continuous orientable polymer matrix with one or more discontinuous or continuous second phases is stretched in the solid state using more than one device to apply force to the unoriented material to form a material that consists of a continuous oriented polymer matrix with one or more other phases. At least one of the phases releases from the oriented polymer matrix forming voids during the orientation process, thereby reducing the density to less than that of the original unoriented mixture. One or more of the phases may stay bonded to the continuous oriented polymer phase, acting as a reinforcing agent and forming no voids. Methods for forming such a material allowing for the control of the final shape and affecting the final density independent of the composition are also disclosed.

Owner:WEYERHAEUSER CO

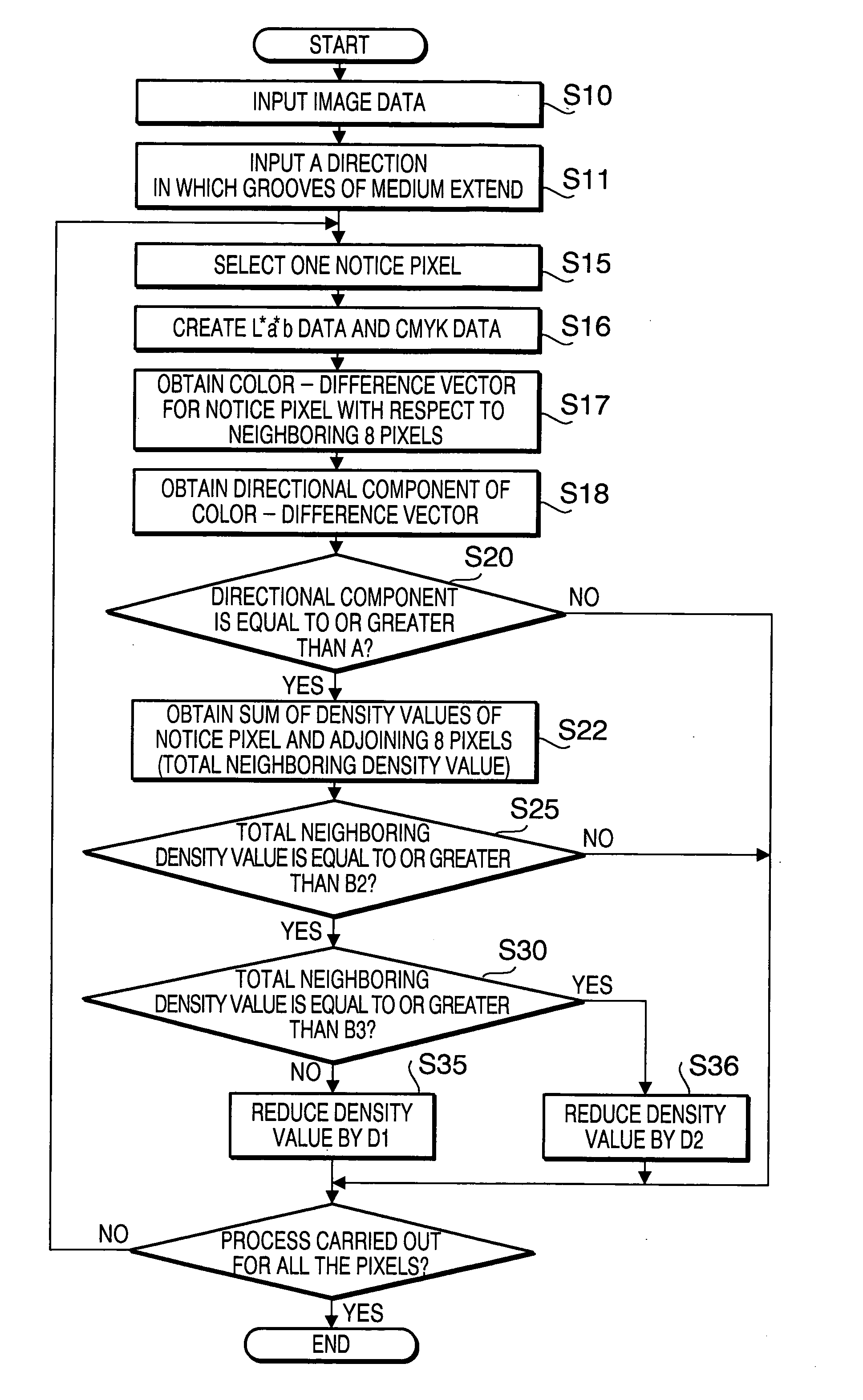

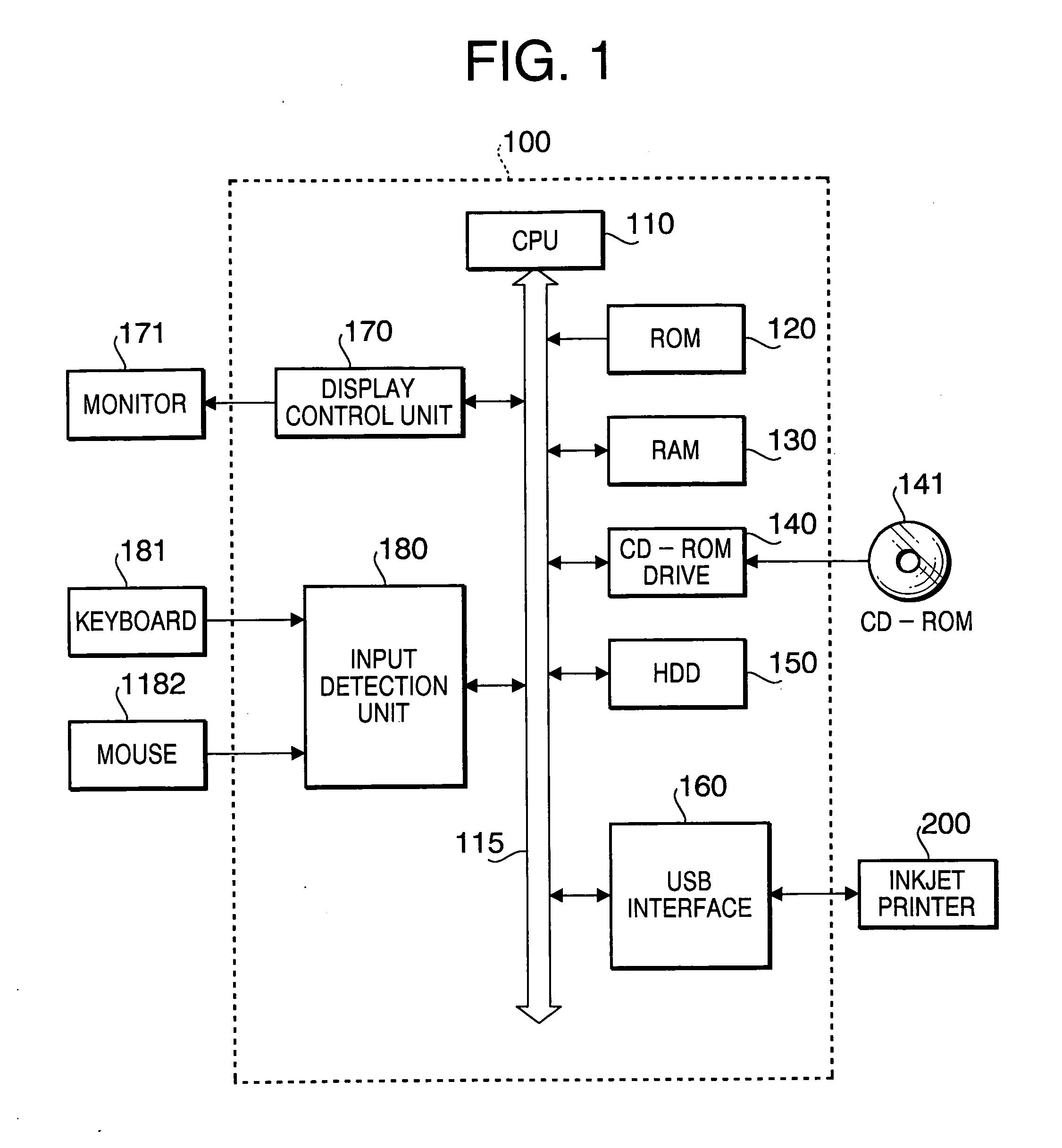

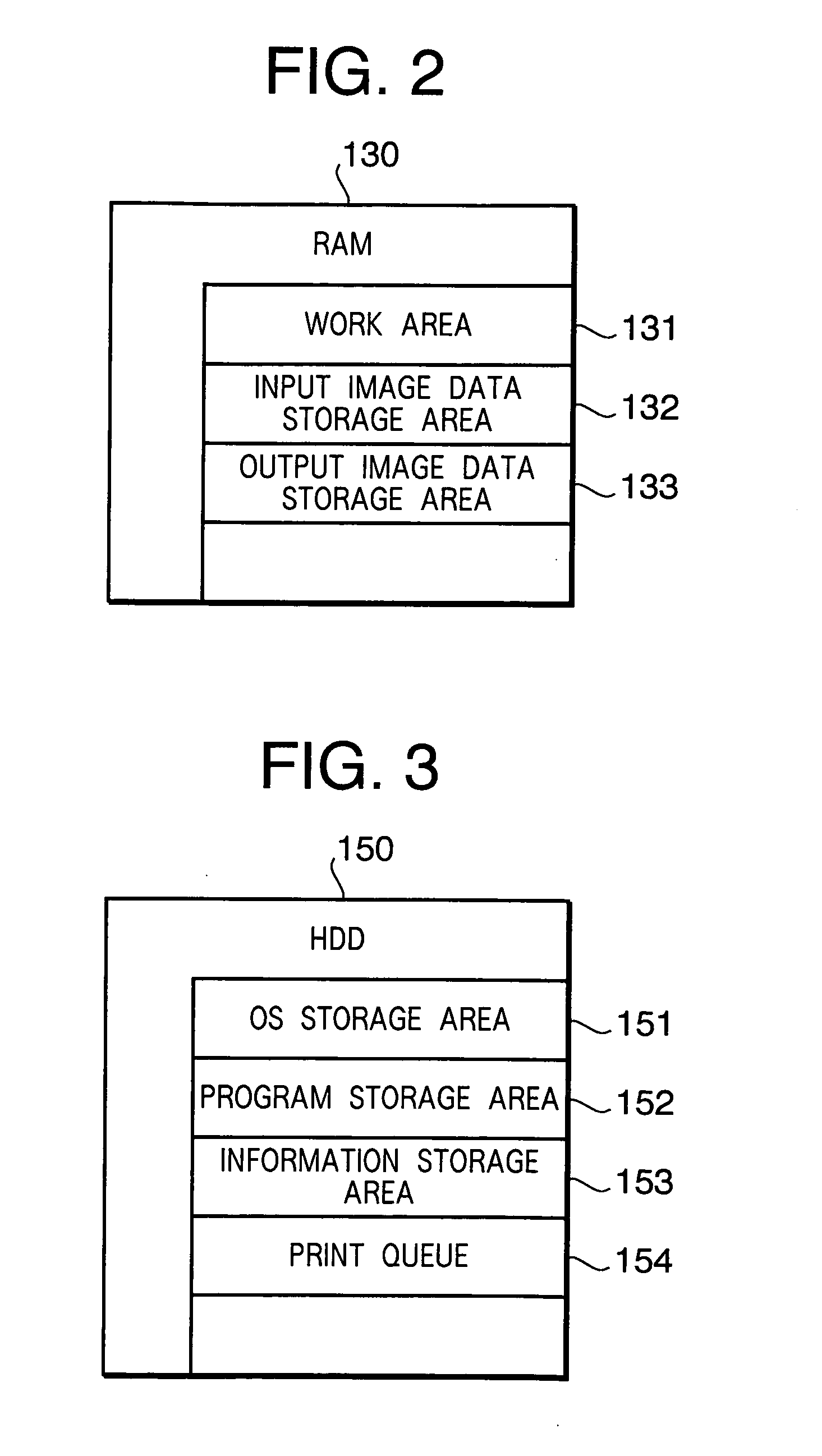

Image data processing system

ActiveUS20050141001A1Suppress bleedingImage enhancementDigitally marking record carriersData processing systemDensity reduction

In an image data processing device, a notice pixel is selected from among a plurality of pixels constituting an image. A specified direction in which ink ejected on a recording medium would bleed by a relatively large amount on the recording medium is obtained. Then, a color-difference vector indicative of the magnitude and direction of a color-difference between the notice pixel and neighboring pixels disposed adjacent thereto is calculated, and a directional component which is a component of the color-difference vector in the specified direction is calculated. Further, a total density value which is a sum of the density value of the notice pixel and density values of the neighboring pixels is calculated, and a density reduction value is determined according to the directional component and the total density value. Then, the density value of the notice pixel is reduced by an amount represented by the density reduction value.

Owner:BROTHER KOGYO KK

Oriented polymer composite template

A process and material therefrom is described where a material comprised of a continuous orientable polymer matrix with one or more discontinuous or continuous second phases is stretched in the solid state using more than one device to apply force to the unoriented material to form a material that consists of a continuous oriented polymer matrix with one or more other phases. At least one of the phases releases from the oriented polymer matrix forming voids during the orientation process, thereby reducing the density to less than that of the original unoriented mixture. One or more of the phases may stay bonded to the continuous oriented polymer phase, acting as a reinforcing agent and forming no voids. Methods for forming such a material allowing for the control of the final shape and affecting the final density independent of the composition are also disclosed.

Owner:WEYERHAEUSER CO

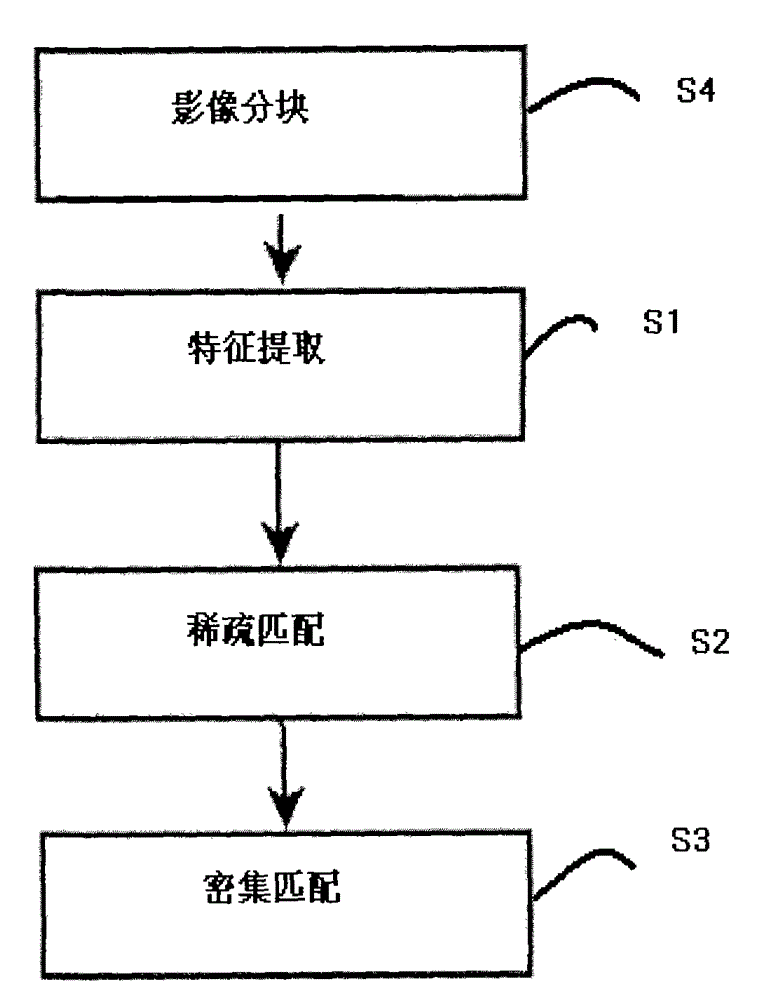

Fast dense matching method based on close-range photogrammetry

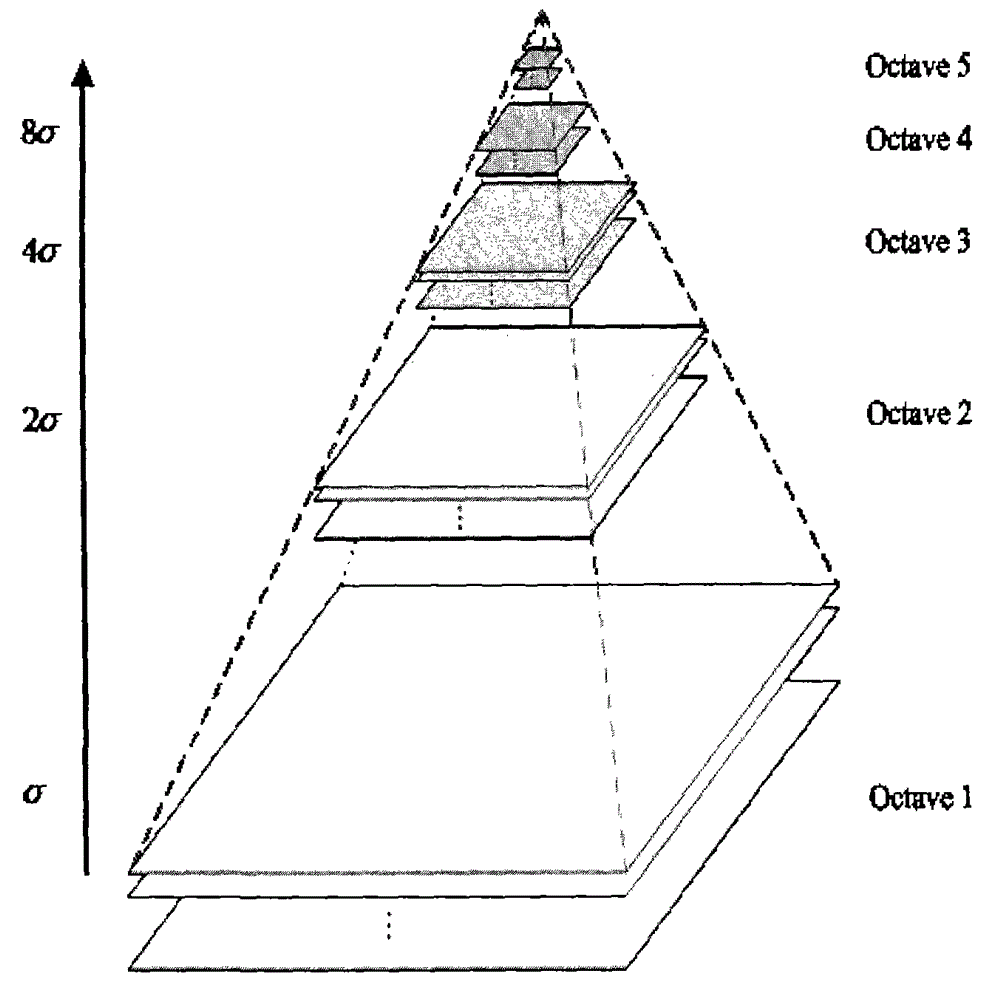

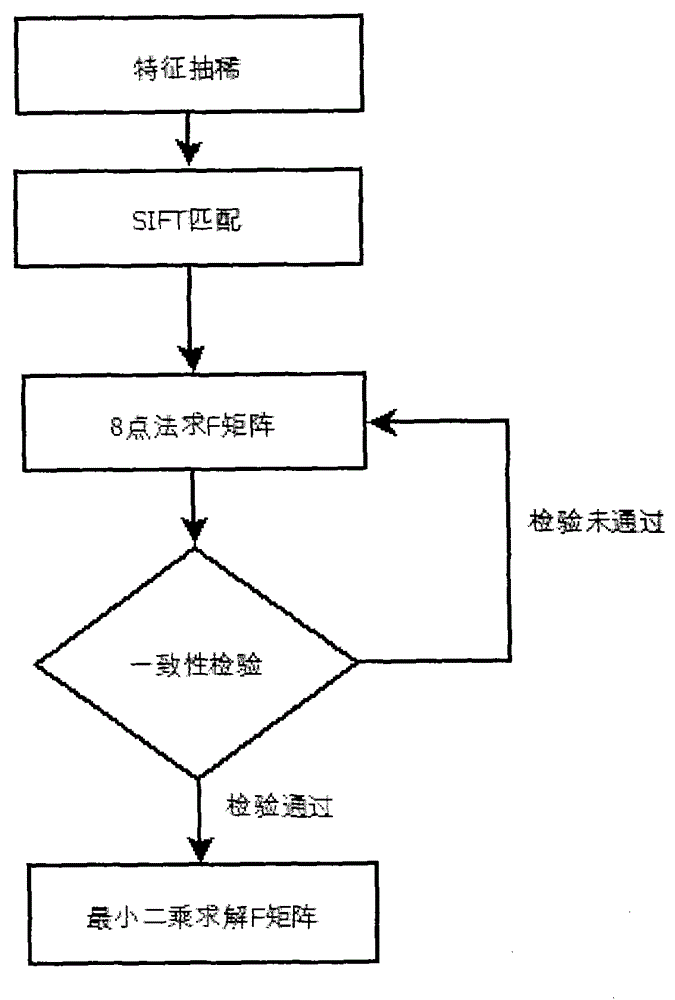

InactiveCN104134203AReduce memory allocationFast extractionImage analysisCharacter and pattern recognitionParallaxDensity reduction

The invention relates to a fast dense matching method based on close-range photogrammetry. The fast dense matching method comprises the following steps of: feature extraction: an image pyramid is built for an original image, an HARRIS corner point response value is calculated for each layer of the image in the image pyramid, and the feature point direction is determined for generating feature point description; sparse matching: density reduction is carried out by aiming at feature points for forming strong feature points, and SIFT matching is carried out on the strong feature points; and dense matching: for consistent points generated by the SIFT matching, an interpolation parallax method on a plane triangular net is adopted for solving initial left and right parallax and left and right image initial matching coordinates, left image feature points are traversed for finding matching points on right images, then, right image feature points are traversed for finding matching points on left images, and the least square template matching is adopted in the matching method. When the fast dense matching method is adopted, the fast, automatic, precise and complete dense matching can be realized.

Owner:SHANGHAI ROCKYSOFT

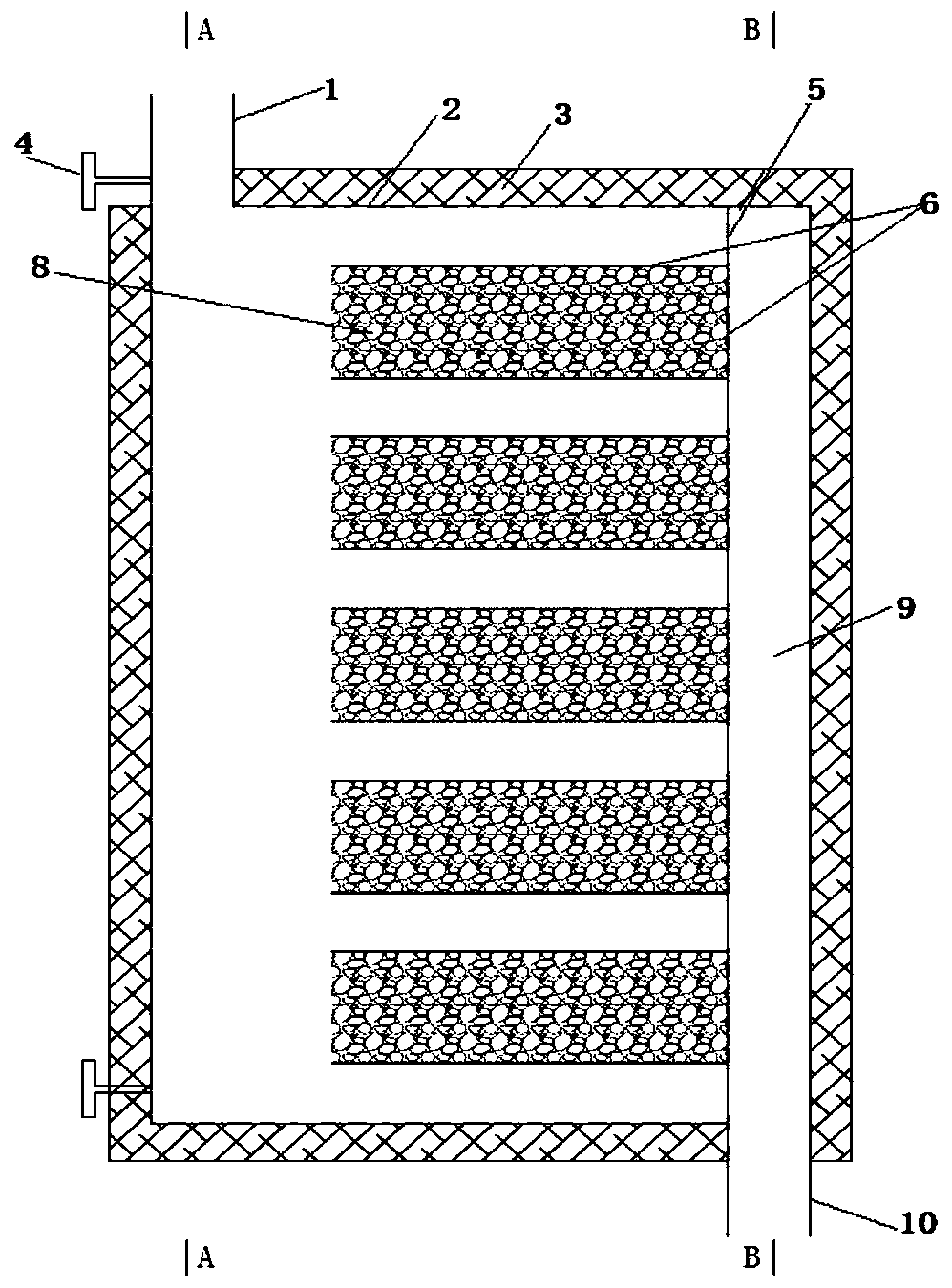

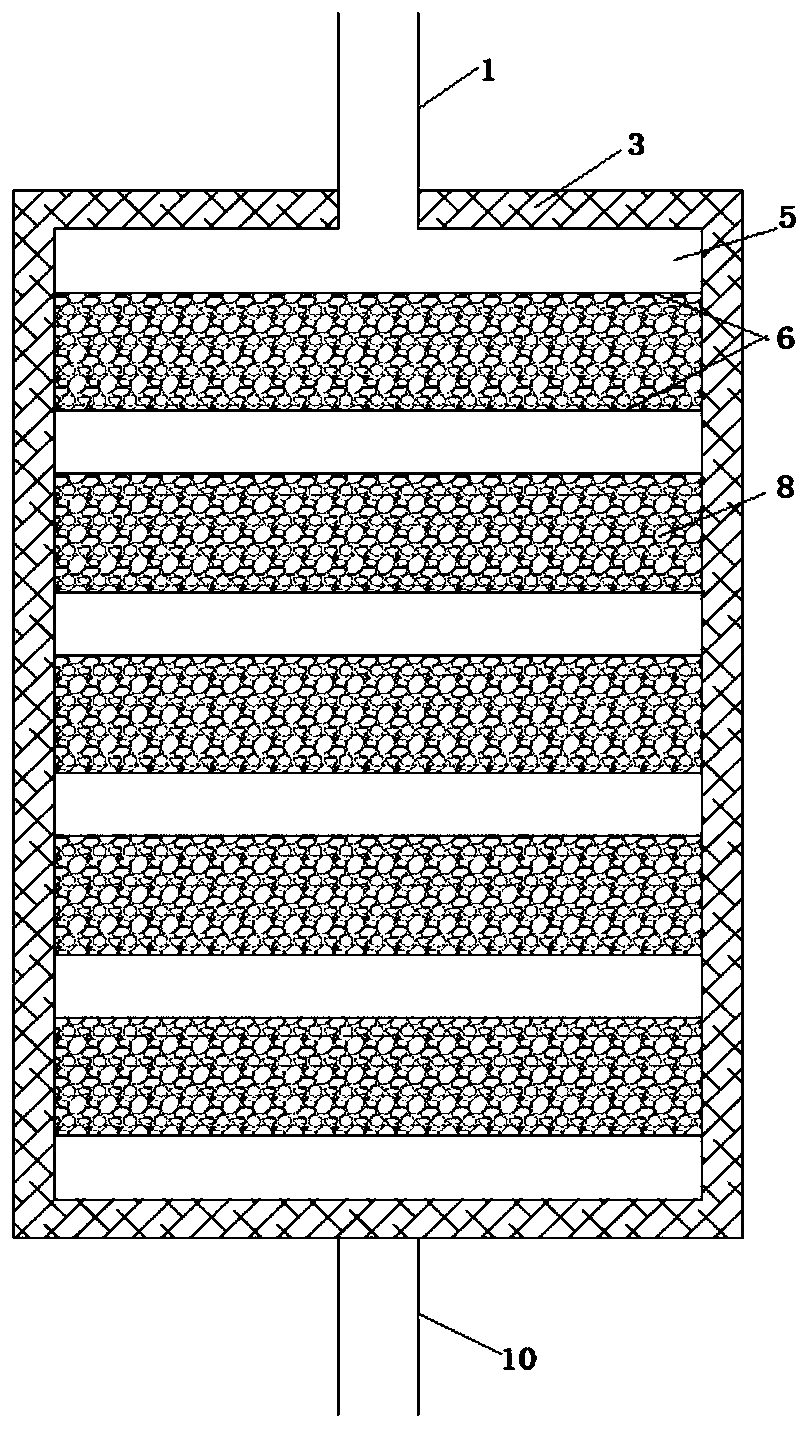

Layered unit type reactor used for hydrated salt heat storage

InactiveCN110193336AAvoid local deliquescenceAvoid cakingHeat storage plantsChemical/physical/physico-chemical stationary reactorsCorrosion reactionParticulates

The invention relates to a layered unit type reactor used for hydrated salt heat storage. The layered unit type reactor is used for desorption / adsorption reaction process heat energy storage and release of hydrated salts or other particular matters; in the reactor, metal sieve screens are adopted as packed beds of a hydrate reactant, the end of each metal sieve screen close to a gas inlet segmentis fixed by a pair of bolts arranged up and down, so that dismounting can be realized, and it is convenient for filling and taking out of reaction particular salts; the periphery and the upper and lower surfaces of the reactors are coated with a thermal insulation material, so that heat loss in reaction process is prevented. The reactor can be used for high efficiency full hydrated salt desorption / adsorption reaction, is not only capable of improving heat and mass transfer effect in reaction process, but also capable of preventing hydrated salt deliquescence because of excess adsorption on moisture; reactor corrosion and heat storage density reduction caused by deliquescence of hydrated salt are avoided, heat storage material circulation operation period is prolonged, and the service lifeis prolonged.

Owner:XI AN JIAOTONG UNIV

Preparation method of zinc oxide-based tubular rotary target material

The invention relates to a preparation method of a zinc oxide-based tubular rotary target material. The preparation method comprises the following steps: taking NH4HCO3 as a precipitant, preparing pure zinc oxide powder and Al-doped zinc oxide powder with an atomic ratio of 1-7at% by a chemical precipitation method, presintering, conglomerating and shaping the powder, filling the powder into a mould, moulding the powder in a cold isostatic pressing manner at 300-340MPa, obtaining a biscuit with a relative density of 70-75%, sintering the biscuit under an oxidizing atmosphere, and processing the sintered biscuit to obtain the rotary target material. Compared with the prior art, the preparation method provided by the invention has the beneficial effects that the density of the biscuit is improved by 10-15%; the volume shrinkage in later stage sintering is reduced; the sintering deformation of the tubular target with a large length-diameter ratio is effectively controlled; and in the process of sintering, the circulating oxygen is served as a control atmosphere to avoid the component changing, large pores on the surface and density reduction caused by the large pores on the surface.

Owner:宁夏中色新材料有限公司

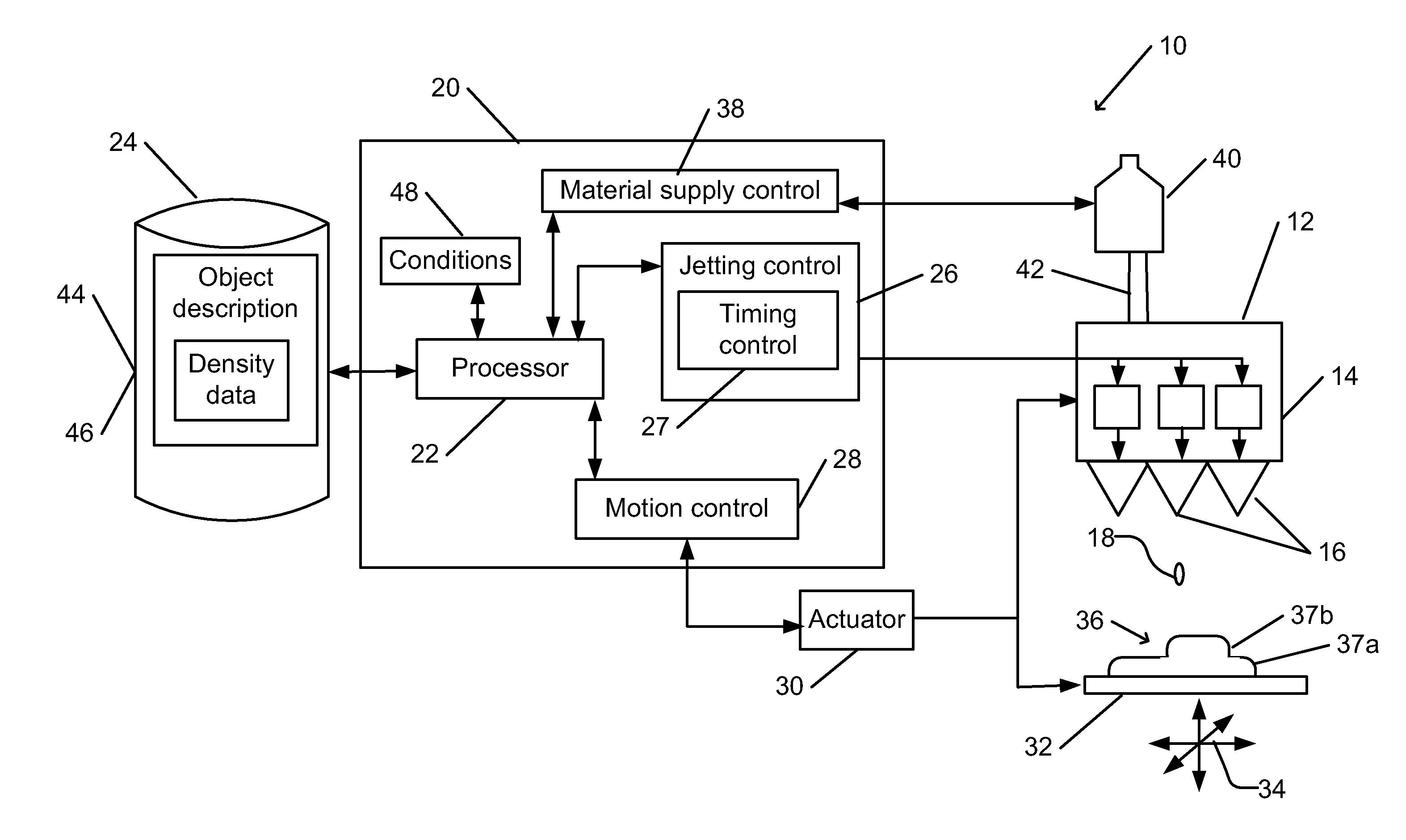

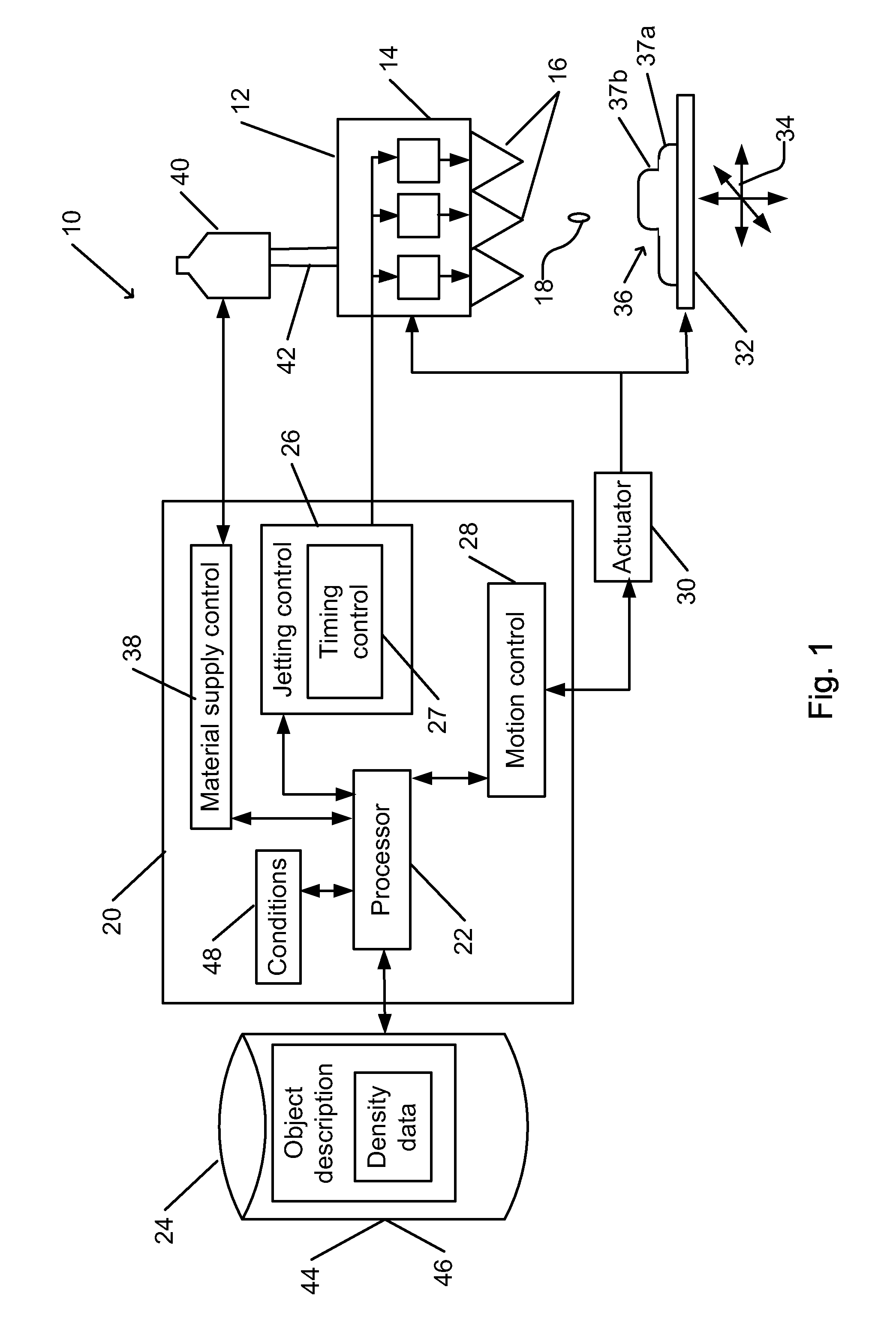

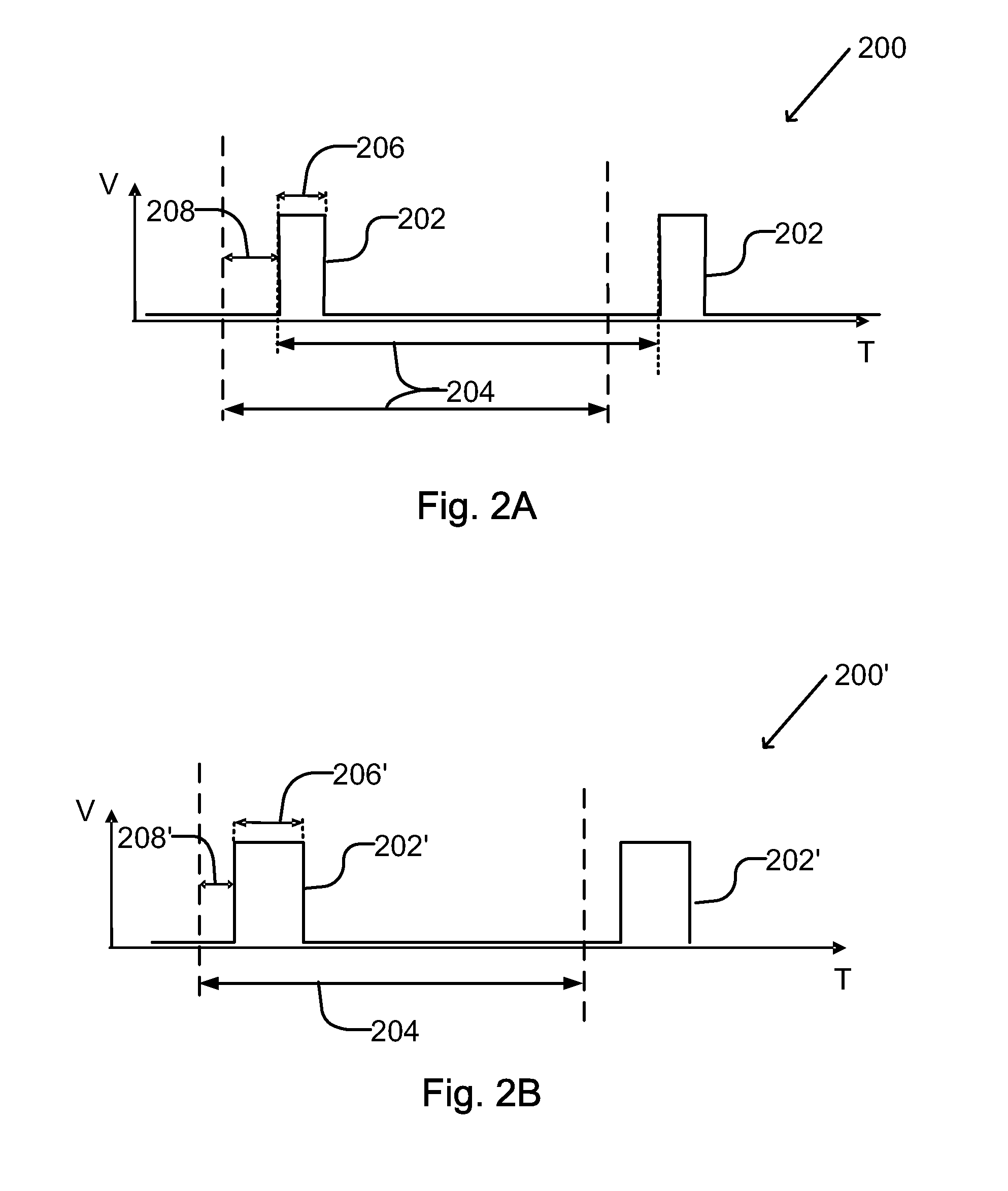

Controlling density of dispensed printing material

A printing method includes controlling timing parameters for application of electrical pulses to a piezoelectric nozzle of an inkjet printing head so as to dispense droplets of a material from the nozzle. The timing parameters are controlled to introduce gas bubbles into the droplets of material so as to reduce the density of the material to a selected density value that is less than a natural density of the material.

Owner:STRATASYS LTD

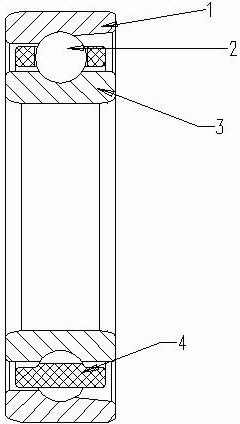

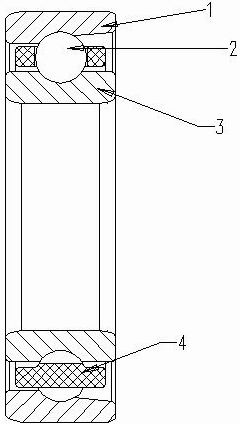

Precise ceramic bearing and machining process thereof

InactiveCN102635635AExtended service lifeReduce coefficient of frictionBearing componentsBall bearingVolumetric Mass Density

The invention relates to a ceramic ball bearing, particularly relates to a precise ceramic bearing and a machining process thereof and belongs to the field of bearings and machining thereof. According to the precise ceramic bearing and the machining process thereof, a rolling body utilizes a silicon nitride ceramic material, the density is reduced, the centrifugal force is reduced by more than 40%, the limited rotating speed is improved by more than 30% and the service life of the bearing is prolonged by more than 50%. Meanwhile, the silicon nitride ceramic material has the advantages of small friction coefficient, strong self-lubricating capability, wear resistance, high-temperature resistance and the like. Furthermore, a sleeve ring machining process adopts cold rolling and the effect of the cold rolling procedure reduces a lathing procedure, shortens the production cycle, improves the production efficiency and reduces the consumption of raw materials. If the precise ceramic bearing is manufactured by a common cutting machining process, the utilization rate of materials is commonly 40-50%, but if the precise ceramic bearing is manufactured by a cold rolling method, the material utilization rate can reach 70-80%.

Owner:李东炬

Drilling fluid containing microspheres and use thereof

InactiveUS20080026956A1Low densityReduce pressure requirementsFluid removalFlushingWater basedOcean bottom

The present invention provides a drilling fluid composition and a method of drilling comprising a drilling fluid, which may be oil- or water-based, and a composite microsphere component. The invention drilling fluid composition advantageously reduces the density of a conventional fluid, reduces costs associated with pumping and overcomes problems associated with conventional gas-injection processes. The invention uses conventional drilling and pumping equipment, requires no sea-floor based pumps and may be easily pressure-controlled to maintain the pressure of the fluid.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com