Polyvinyl chloride drain pipe and preparation method thereof

A drainage pipe material, polyvinyl chloride technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

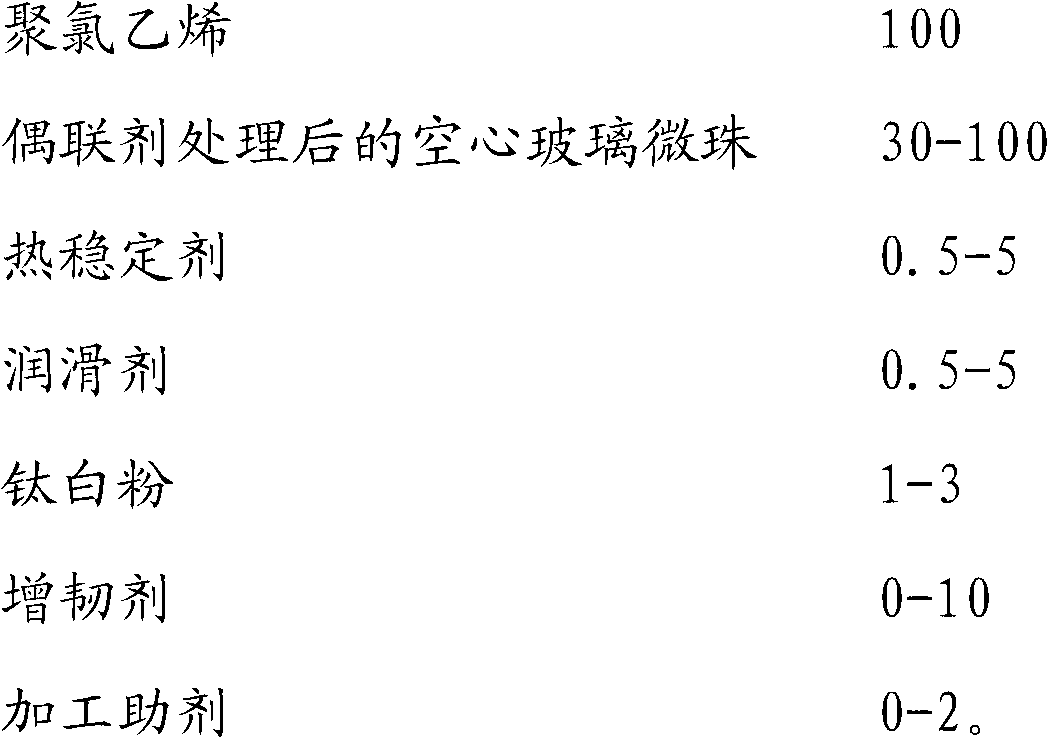

[0041] The raw materials and parts by weight of the lightweight sound-absorbing polyvinyl chloride drainage pipe described in this embodiment are as follows:

[0042] 100 parts of polyvinyl chloride; 30 parts of hollow glass microspheres after coupling agent treatment; 4 parts of heat stabilizer; 1.8 parts of lubricant (stearic acid SA-1840 (trade name) 0.8 part; Maoming Petrochemical No. 58 semi-refined paraffin wax 1.0 parts); titanium dioxide 1 part.

[0043] The particle size of the hollow glass microspheres is 2500 mesh.

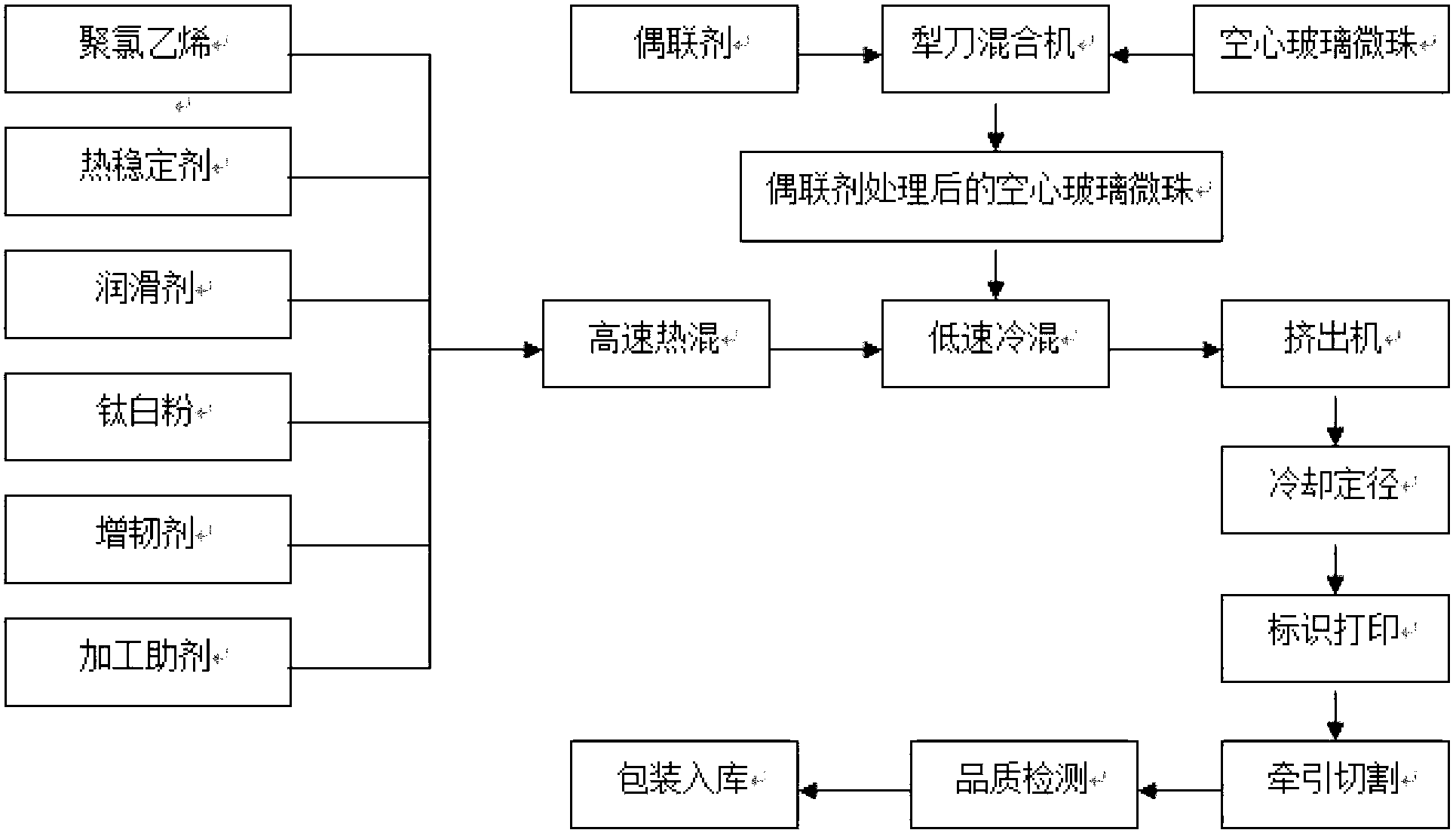

[0044] The preparation method of the polyvinyl chloride drainage pipe of this embodiment is as follows (refer to figure 1 described flow chart):

[0045] (1) The preparation method of hollow glass microspheres after coupling agent treatment, the steps are as follows:

[0046] (a) Weigh 30Kg of glass beads and add them to the coulter type mixing equipment;

[0047] (b) Start the coulter-type mixing equipment at low speed, control the speed at about 2...

Embodiment 2

[0069] The raw materials and parts by weight of the lightweight sound-absorbing polyvinyl chloride drainage pipe described in this embodiment are as follows:

[0070] 100 parts of polyvinyl chloride; 60 parts of hollow glass microspheres after coupling agent treatment; 4 parts of heat stabilizer; 2.6 parts of lubricant (stearic acid SA-1840 (trade name) 1.0, Maoming Petrochemical No. 58 semi-refined paraffin wax (trade name) Name) 1.0, PE wax AC-6A (trade name) 0.6,); 2 parts of titanium dioxide; 4 parts of toughening agent; 1 part of processing aid.

[0071] The particle size of hollow glass microspheres is 2500 mesh.

[0072] The preparation method of the present embodiment polyvinyl chloride drainage pipe is as follows:

[0073] (1) The preparation method of hollow glass microspheres after coupling agent treatment, the steps are as follows:

[0074] (a) Weigh 60Kg of glass beads and add them to the coulter type mixing equipment;

[0075] (b) Start the coulter-type mixing...

Embodiment 3

[0097] The raw materials and parts by weight of the lightweight sound-absorbing polyvinyl chloride drainage pipe described in this embodiment are as follows:

[0098] 100 parts of polyvinyl chloride; 90 parts of hollow glass microspheres after treatment; 4 parts of heat stabilizer; 3.6 parts of lubricant (stearic acid SA-1840 (trade name) 1.3, Maoming Petrochemical No. 58 semi-refined paraffin wax (trade name) 1.5 , PE wax AC-6A (trade name) 0.8); titanium dioxide 2 parts; toughening agent 8 parts.

[0099] The particle size of hollow glass microspheres is 2500 mesh,

[0100] The preparation method of the polyvinyl chloride drainage pipe described in this embodiment is as follows:

[0101] (1) The preparation method of coupling agent-treated hollow glass microspheres, the steps are as follows:

[0102] (a) Weigh 90Kg of glass beads and add them to the coulter type mixing equipment;

[0103] (b) Start the coulter-type mixing equipment at low speed, control the speed at about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com