Printed Foamed Film Packaging

a foamed film and packaging technology, applied in the field of printed foamed film packaging and packages, can solve the problems of voids in ink coverage, difficult printing directly on foamed thin film using flexographic or rotogravure printing, and high cost of plastic film packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

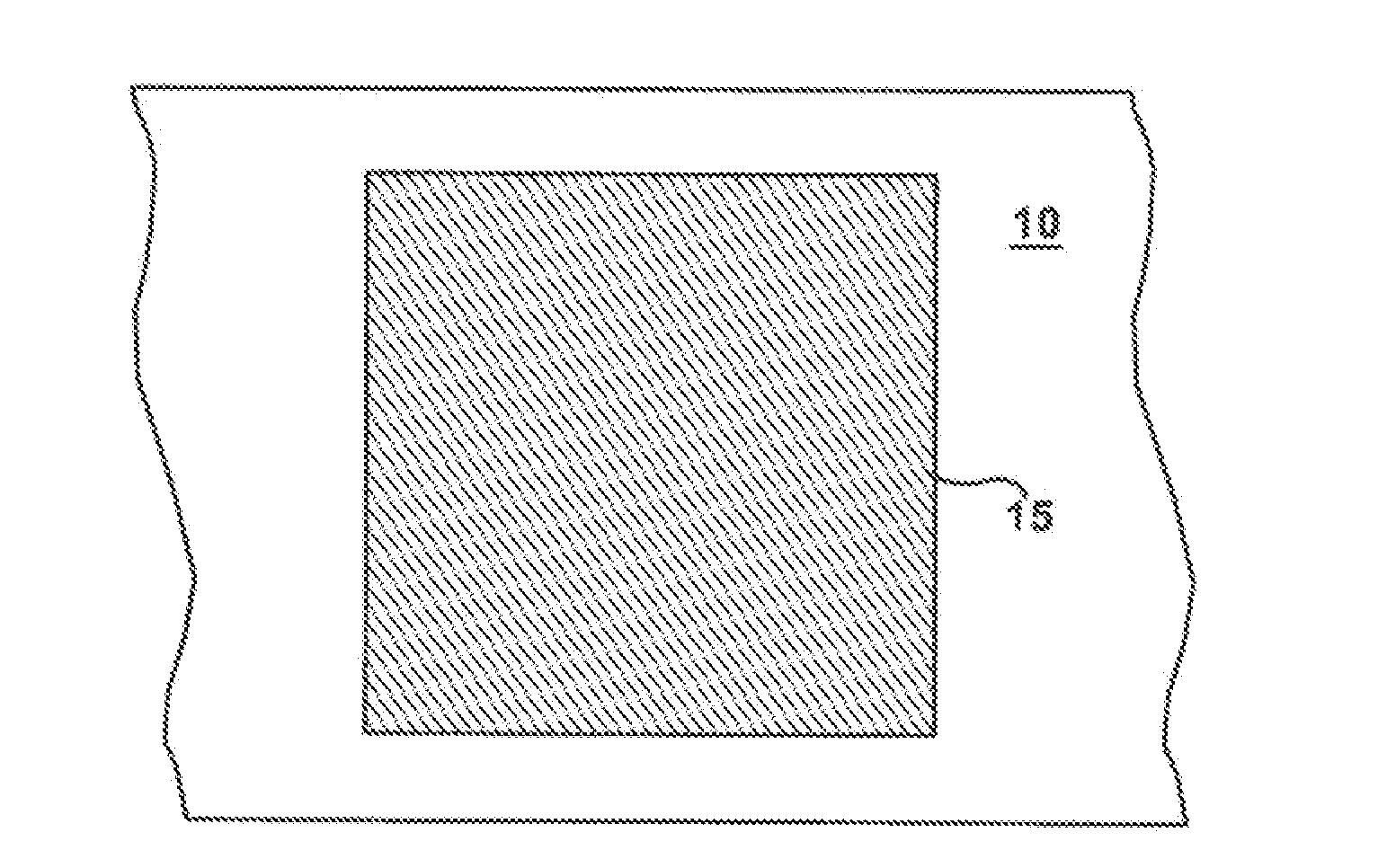

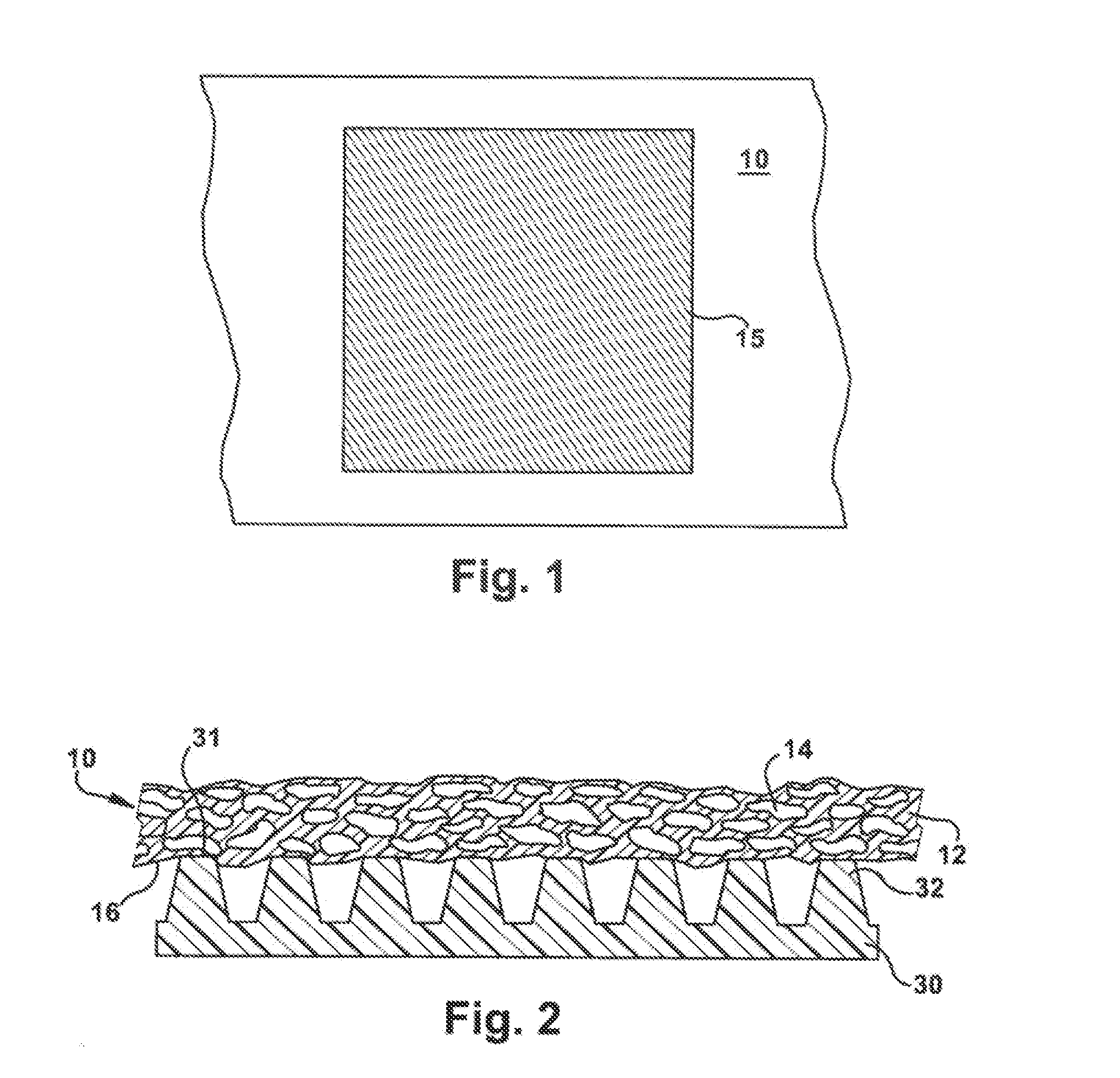

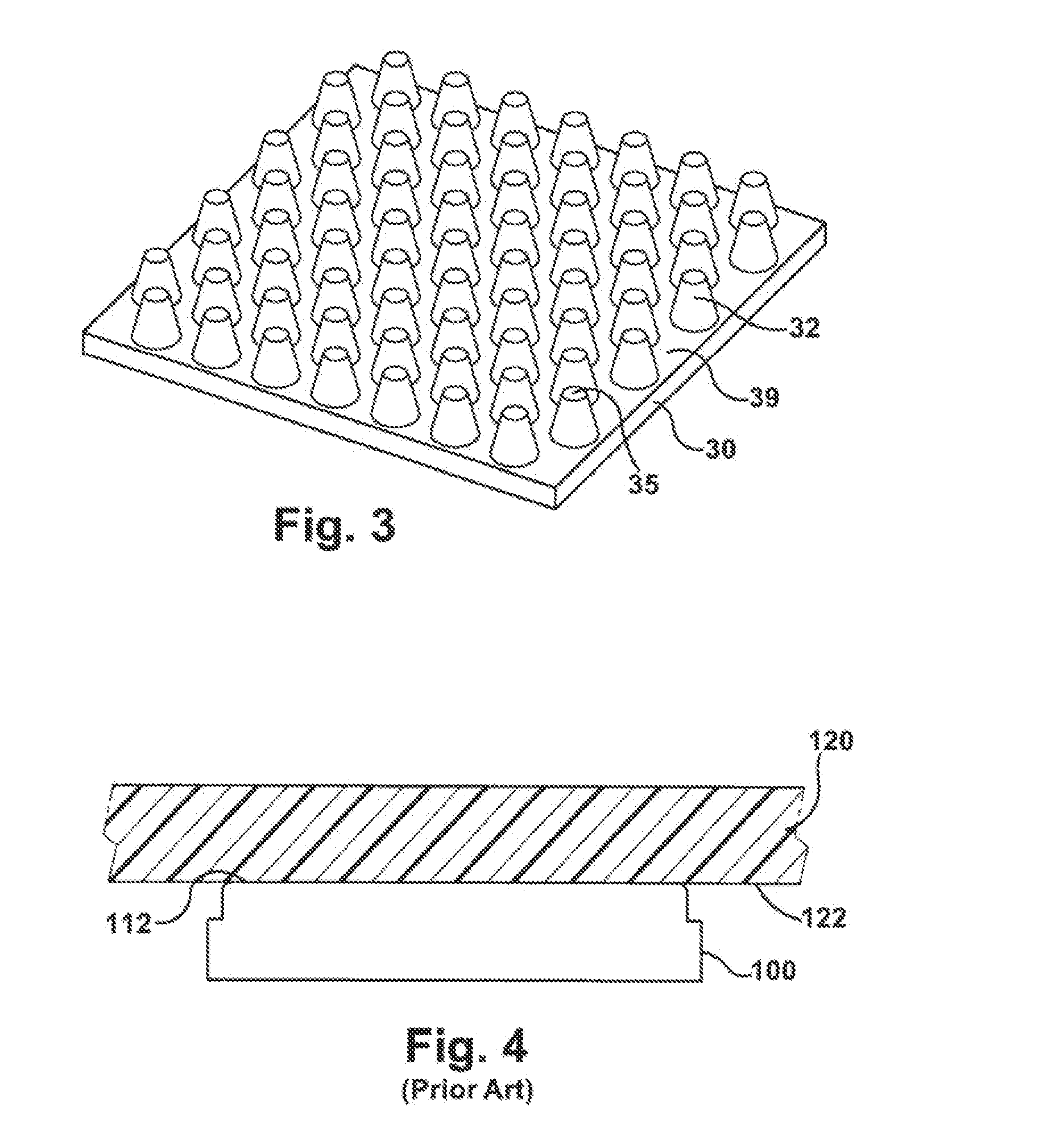

Image

Examples

Embodiment Construction

[0015]As used herein, the following terms have the following meanings:

[0016]“Agricultural product” refers to a renewable resource resulting from the cultivation of land (e.g., a crop) or the husbandry of animals (including fish).

[0017]“Bio-based content” refers to the amount of carbon from a renewable resource in a material as a percent of the mass of the total organic carbon in the material, as determined by ASTM D6866-10, Method B. Note that any carbon from inorganic sources such as calcium carbonate is not included in determining the bio-based content of the material.

[0018]“Biodegradation” refers to a process of chemical dissolution of materials by microorganisms or other biological means.

[0019]“Bio-identical polymer” refers to polymers that are made from monomers where at least one monomer is derived from renewable resources. For instance, a bio-identical polyolefin is made from olefins that are derived from renewable resources, whereas a petro-based polyolefin is made from olef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com