Precise ceramic bearing and machining process thereof

A processing technology and technology of precision ceramics, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of rotational speed, temperature rise, unsatisfactory service life, etc., to shorten the production cycle, reduce the machining process, and reduce the friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

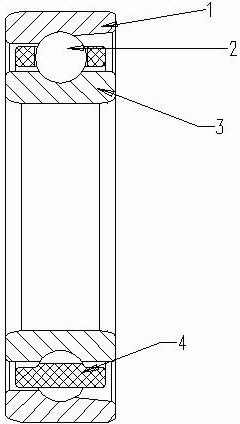

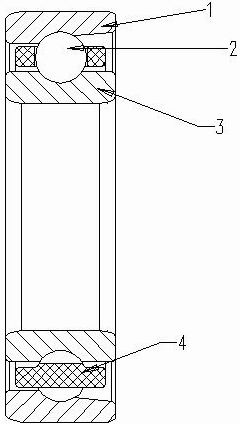

[0019] A precision ceramic bearing and its processing technology. The bearing mainly includes an inner ring, an outer ring, a rolling body and a cage. The rolling body is installed in the pocket of the cage. The inner ring is located inside the rolling body, and the outer side is located at the The outer side forms a whole, which is characterized in that the rolling elements are made of Si 3 N 4 Silicon nitride material with a density of 3.18-3.3 grams per cubic centimeter. The processing steps of precision ceramic bearings are as follows:

[0020] a. Processing procedure of inner ring and outer ring:

[0021] 1) Forming: CNC lathe is used to process the blank into a ring shape;

[0022] 2) Cold rolling: basically process and shape the ferrule;

[0023] 3) Heat treatment and cryogenic treatment: the heat treatment quenching hardness is HRC60-63, and the cryogenic temperature is controlled at minus 60°C to minus 90°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com