Patents

Literature

30results about How to "Large volume shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

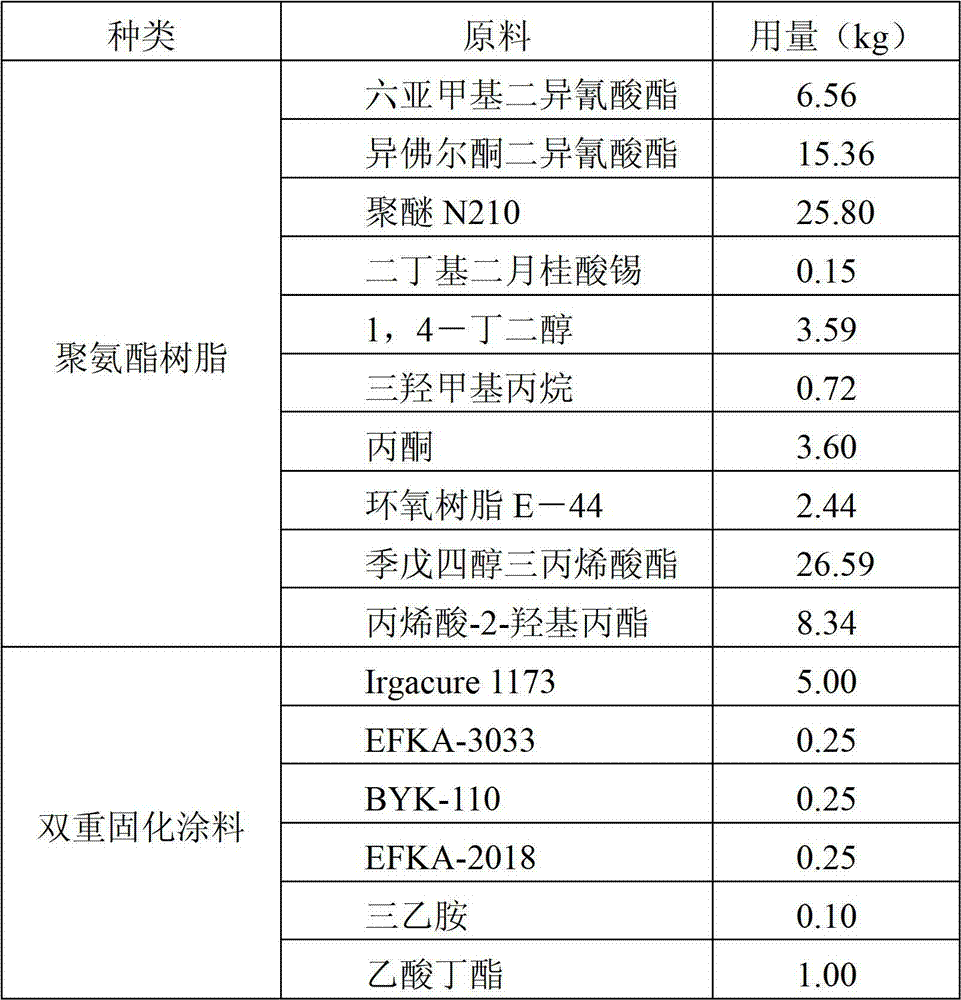

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

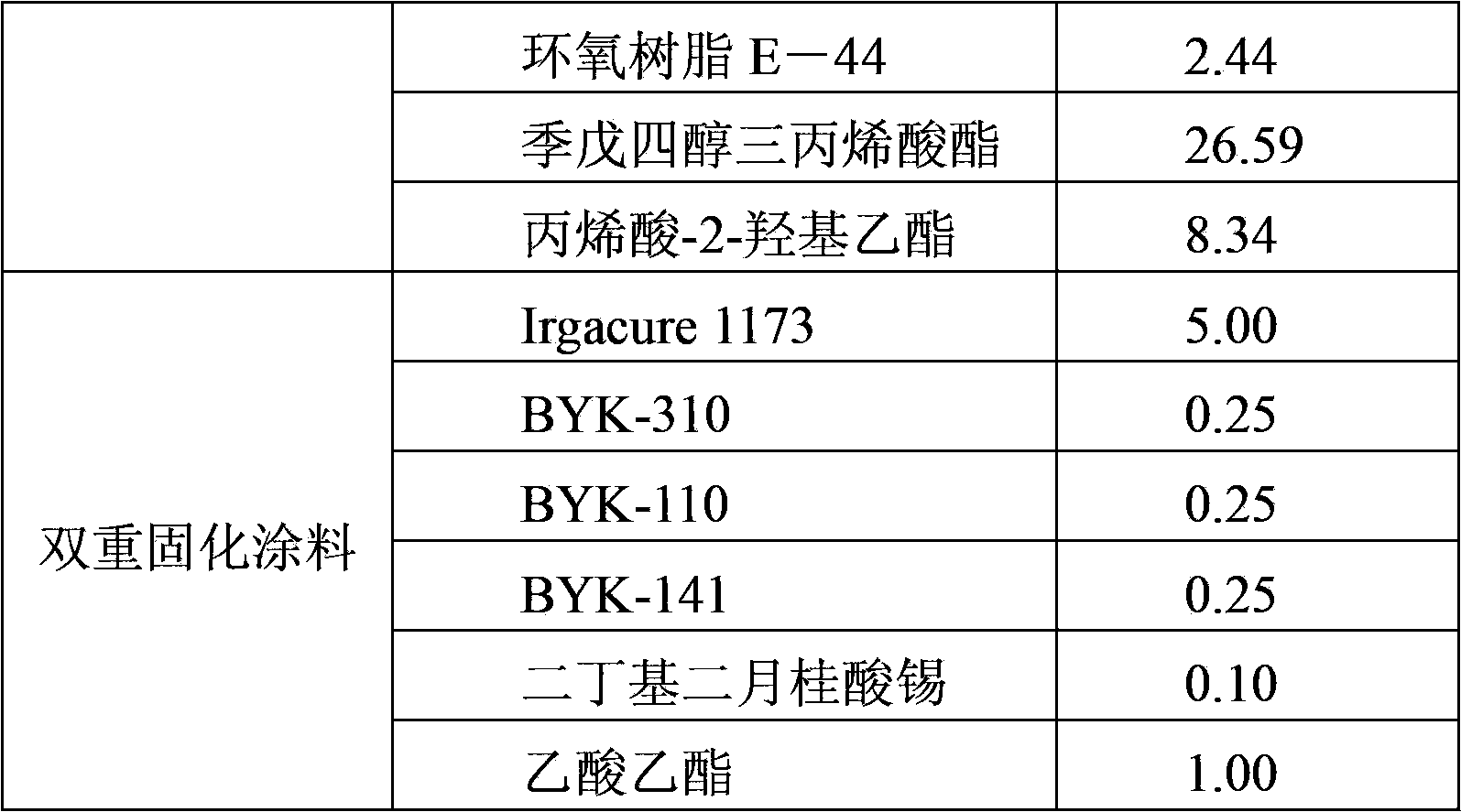

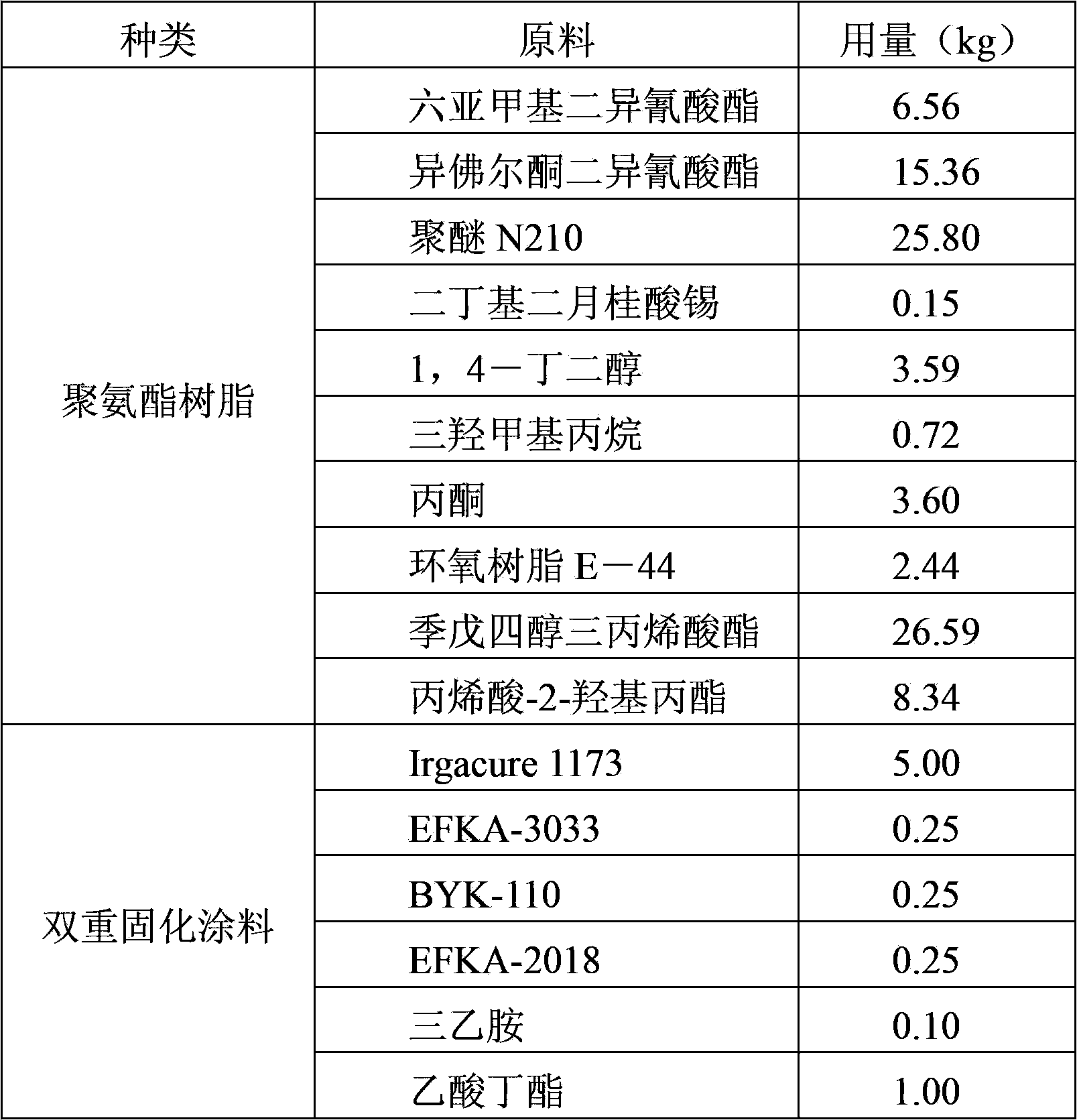

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

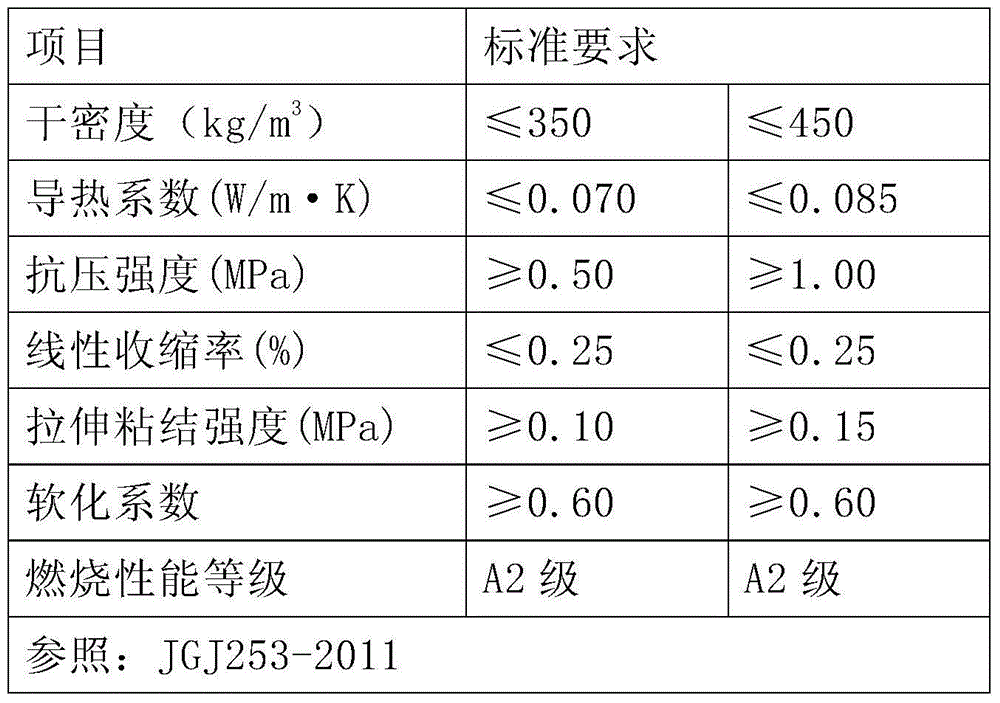

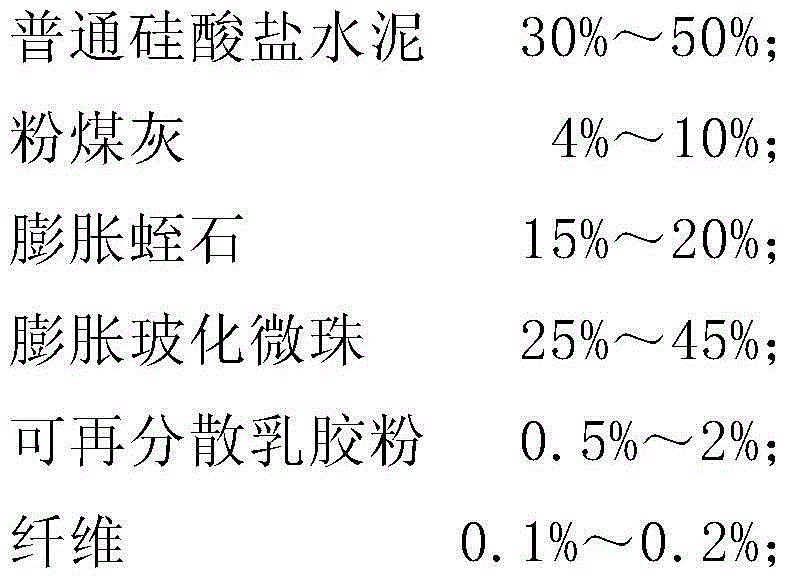

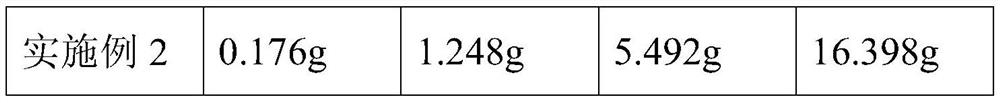

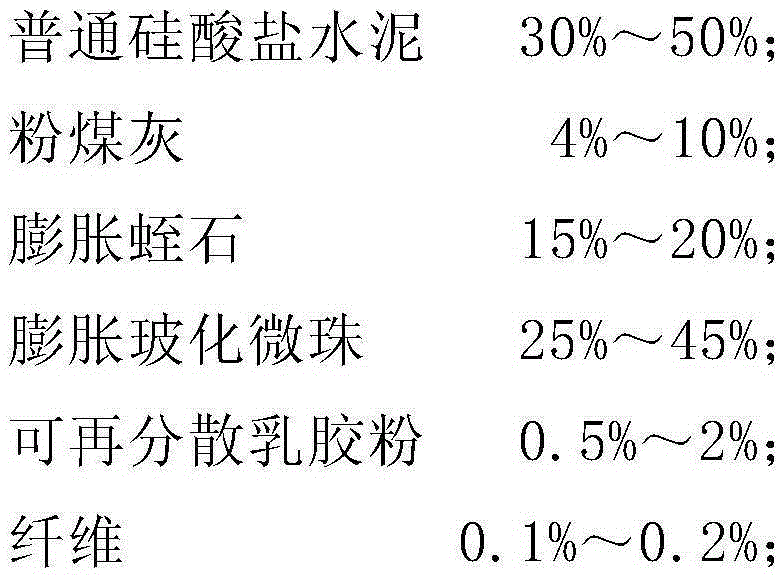

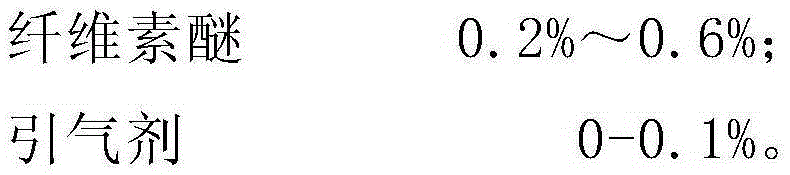

A1-grade fireproof insulation mortar and preparation method thereof

ActiveCN103553480AImprove overall performance and construction performanceSolve easy pulverizationPerliteWeather resistance

The invention discloses an A1-grade fireproof insulation mortar which is prepared from the raw materials of, by weight: common Portland cement, fly ash, expanded vermiculite, expanded glass micro-beads, re-dispersible latex powder, fiber, cellulose ether, and an air-entraining agent. According to the invention, glass micro-beads are adopted as a light aggregate, and the expanded vermiculite with excellent fireproof performance is doped in. Compared with a dry-mix insulation mortar light aggregate with expanded perlite and polystyrene particles, the defects of high water absorption, easy pulverization, high volume shrinkage rate in slurry stirring, and phenomena of product low post-stage strength and hollowing cracking, and the like of expanded perlite are overcome. Also, defects of high inflammability, poor fire retardant performance, harmful gas production under high temperature, low aging resistance, low weather resistance, high resilience during construction, and the like of organic materials such as EPS and XPS are overcome. With the mortar provided by the invention, insulation mortar comprehensive performances and construction performance are improved. On the basis of good safety, energy-saving and comfortableness are realized. With the mortar, building, human, and nature are harmonious and unified.

Owner:宜昌恒达利新材料科技有限公司

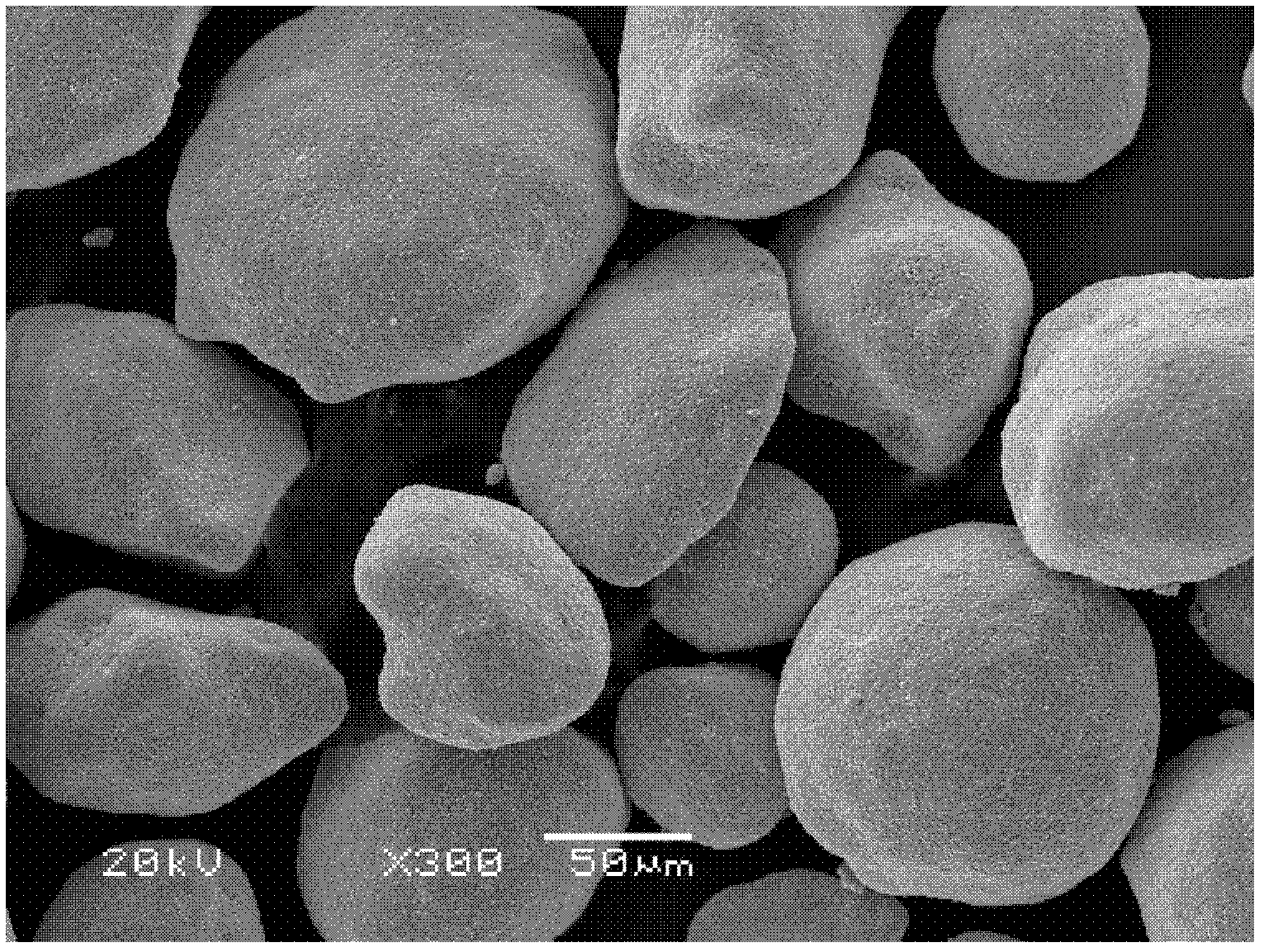

Preparation method of zinc oxide-based tubular rotary target material

The invention relates to a preparation method of a zinc oxide-based tubular rotary target material. The preparation method comprises the following steps: taking NH4HCO3 as a precipitant, preparing pure zinc oxide powder and Al-doped zinc oxide powder with an atomic ratio of 1-7at% by a chemical precipitation method, presintering, conglomerating and shaping the powder, filling the powder into a mould, moulding the powder in a cold isostatic pressing manner at 300-340MPa, obtaining a biscuit with a relative density of 70-75%, sintering the biscuit under an oxidizing atmosphere, and processing the sintered biscuit to obtain the rotary target material. Compared with the prior art, the preparation method provided by the invention has the beneficial effects that the density of the biscuit is improved by 10-15%; the volume shrinkage in later stage sintering is reduced; the sintering deformation of the tubular target with a large length-diameter ratio is effectively controlled; and in the process of sintering, the circulating oxygen is served as a control atmosphere to avoid the component changing, large pores on the surface and density reduction caused by the large pores on the surface.

Owner:宁夏中色新材料有限公司

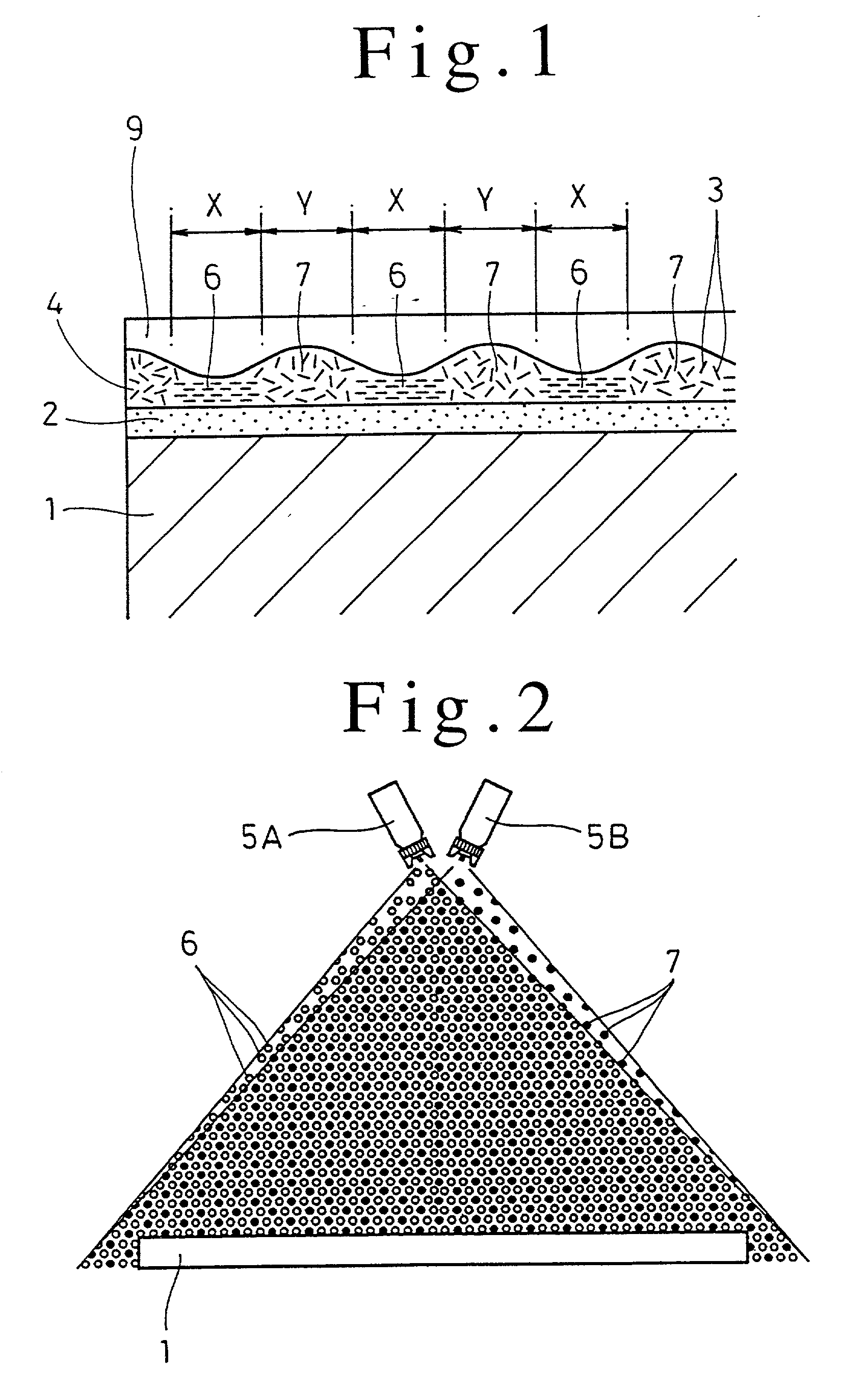

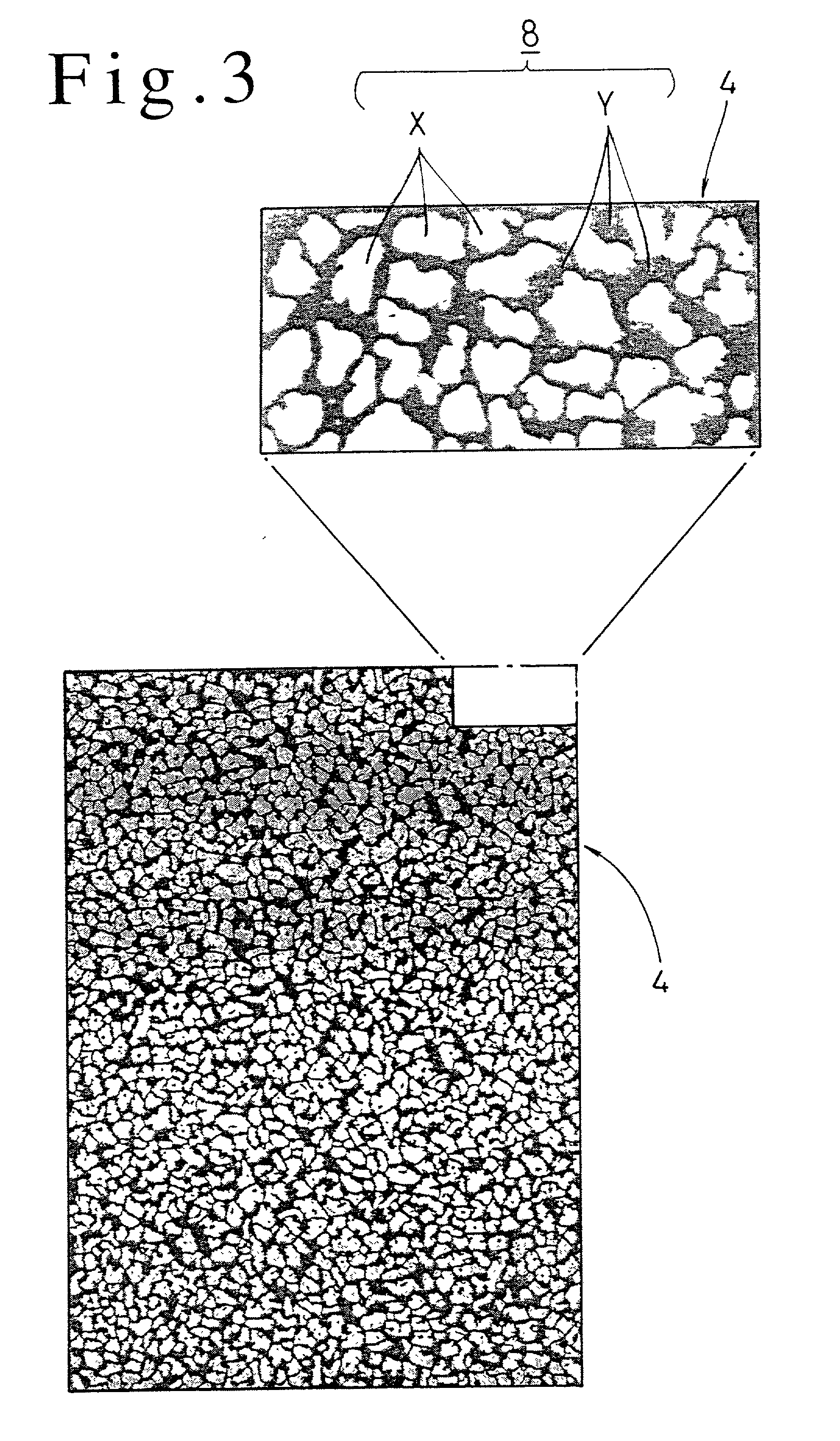

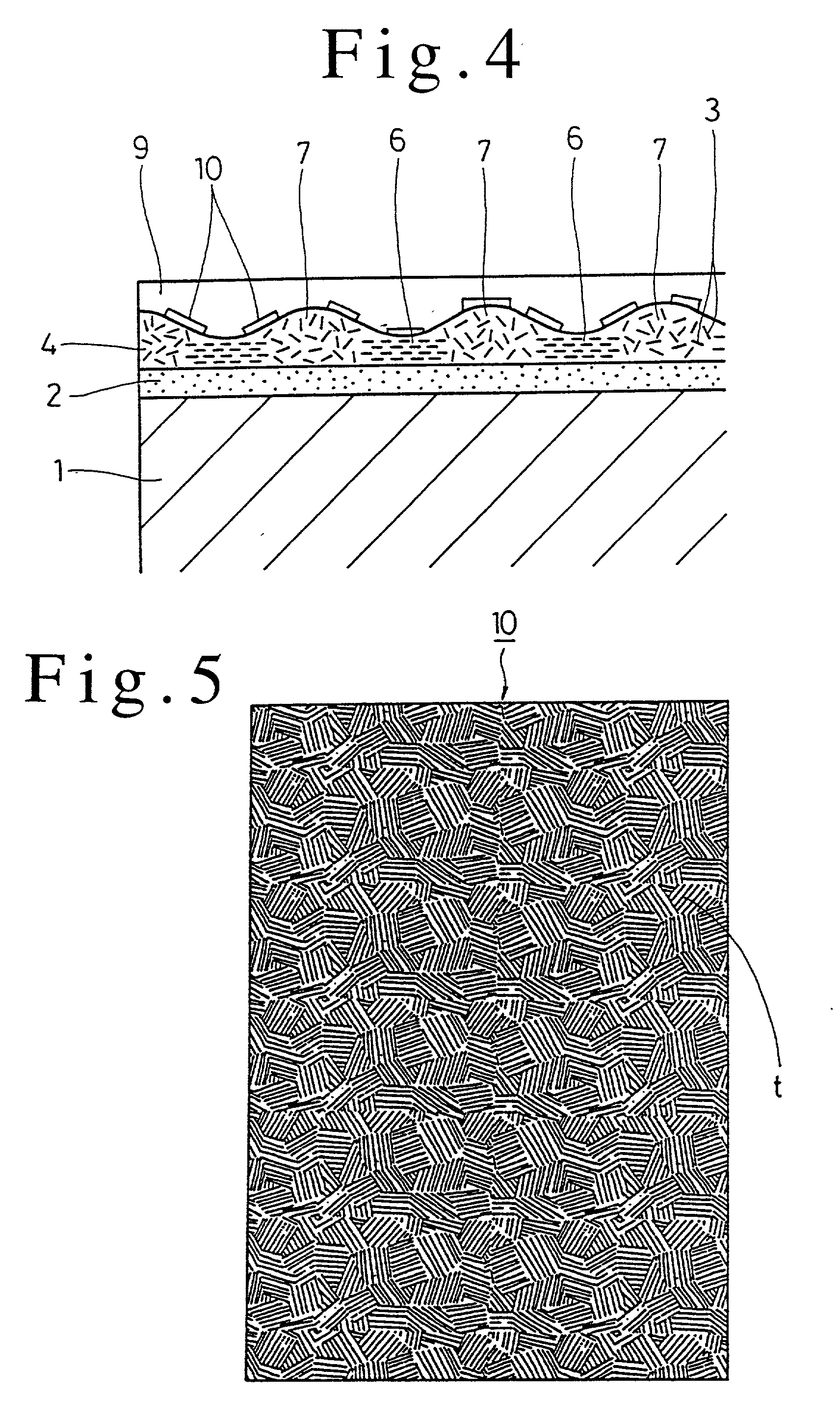

Surface decorated article and decoration method thereof

InactiveUS20010031352A1Improve the sense of qualityHigh viscosityIrregular area designNatural patternsPolymer scienceSolvent

A surface decorated article in which a surface is entirely or partially decorated with a coating membrane of a glitter paint using a flaky glitter material as a pigment, wherein paint particles at a low viscosity with a relatively high solvent dilution ratio formed by coarsely particulating a glitter paint and paint particles at a high viscosity with a relatively low solvent dilution ratio formed by coarsely particulating a glitter paint are coated in a state mixed with each other, to form a coating membrane of a glitter paint comprising areas in which the paint particles at a low viscosity are dried to solidify and areas in which the coated particles at a high viscosity are dried to solidify are mixed together in a spotwise pattern. The surface of articles can be provided with colors or textures exhibiting unique and high quality feelings.

Owner:TRINITY IND CORP

Preparation method of hollow fiber internal pressure composite film

ActiveCN102489176AGood separation performance and mechanical propertiesAvoid filament ruptureSemi-permeable membranesWater soluble polymersWater soluble

The invention discloses a preparation method of a hollow fiber internal pressure composite film, and aims to provide a preparation method of a hollow fiber internal pressure composite film with high supporting property and high pressure resistance. The preparation method comprises the following steps of: uniformly blending an outer layer film forming material, an outer layer film forming diluent and an outer layer film forming additive in a fusing process to obtain a thermally induced phase separation method outer layer film forming system; dissolving and uniformly mixing an inner layer film forming material, an inner layer film forming solvent and an inner layer film pore forming agent to obtain a non-solvent induced phase separation method inner layer film forming system, wherein the inner layer film pore forming agent contains over 70 percent of water-soluble polymer; and extruding and spinning in a composite way by introducing a core liquid into a central pipe, taking the inner layer film forming system as a middle layer and taking the outer layer film forming system as the outside, quickly soaking into a coagulation bath, fully curing an outer layer and an inner layer under the actions of the coagulation bath and the core liquid, and extracting and washing to obtain the hollow fiber internal pressure composite film. The large-inner-diameter hollow fiber internal pressure composite film prepared with the method disclosed by the invention can be used for replacing a tubular film during application.

Owner:TIANJIN MOTIMO MEMBRANE TECH

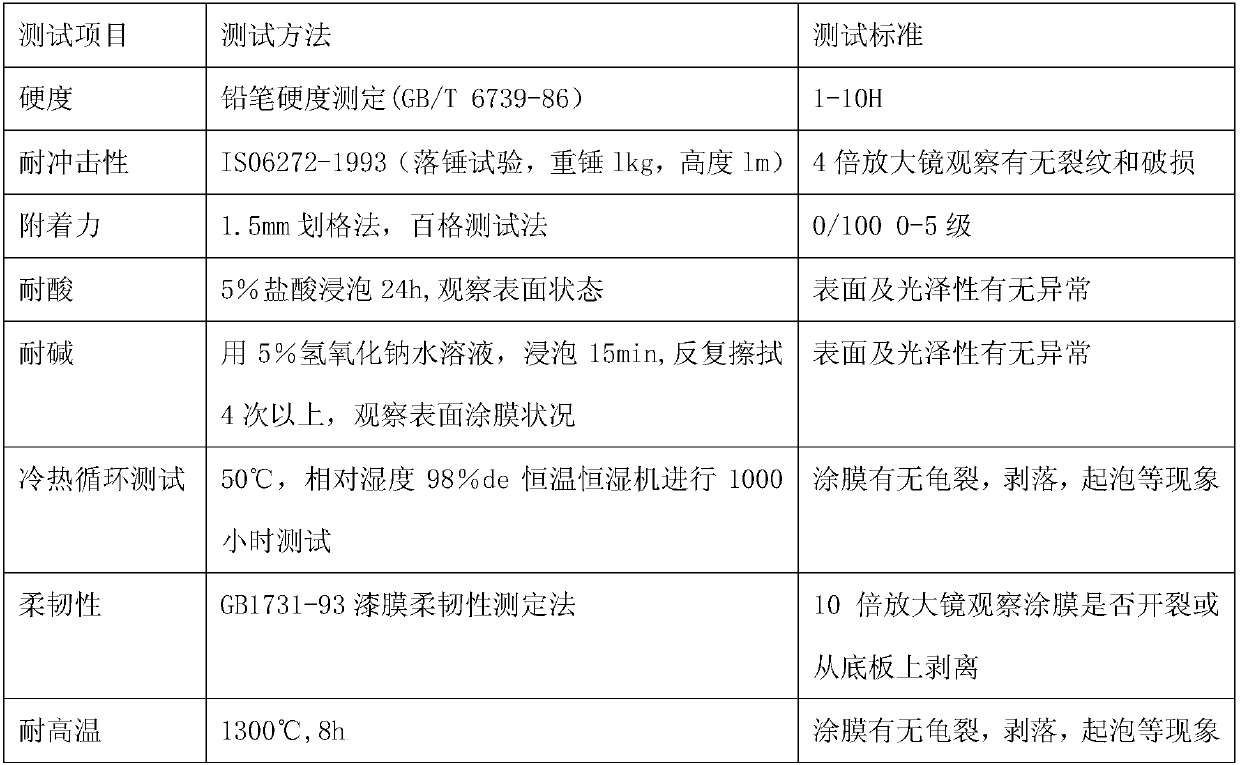

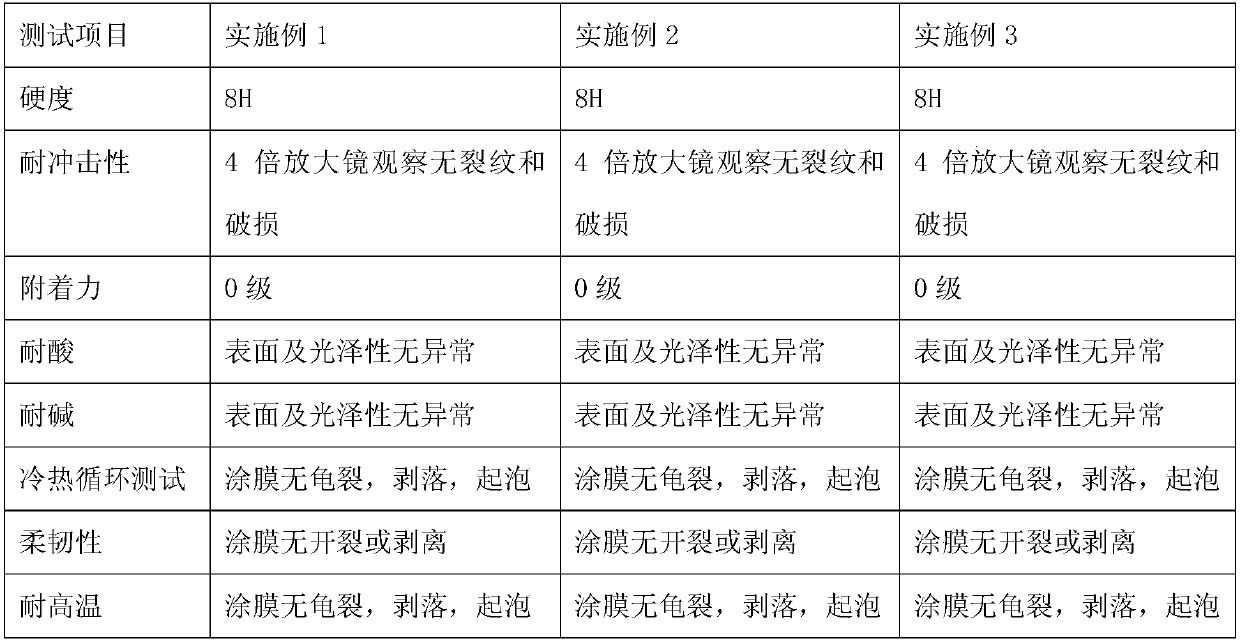

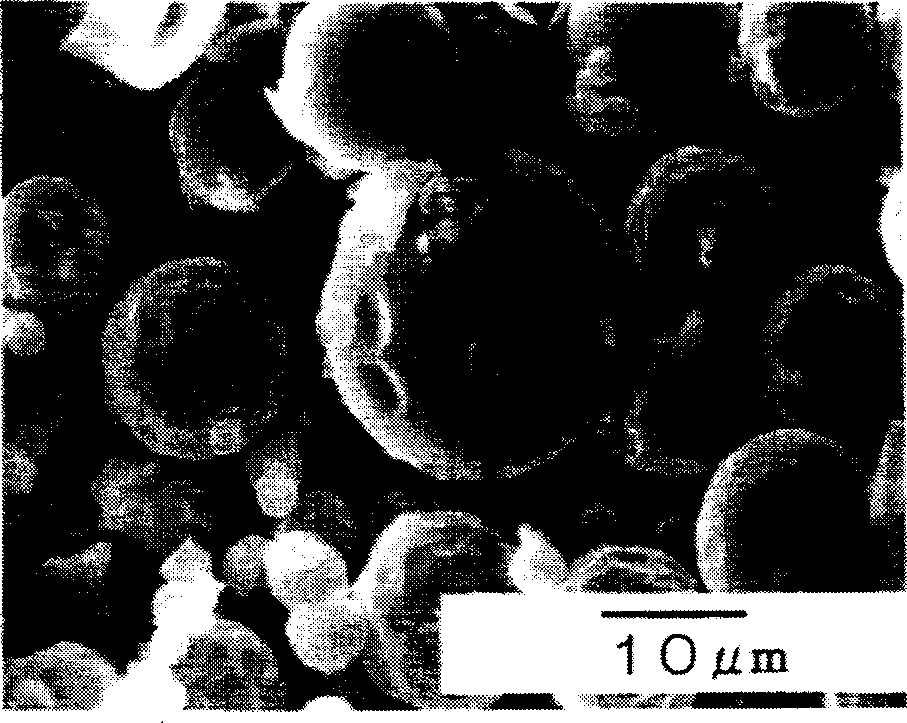

Graphene and vermiculite-based high-temperature-resistant anticorrosive paint and preparation method thereof

ActiveCN107652727AImprove adhesionNon-foamingFireproof paintsAntifouling/underwater paintsSodium BentoniteSodium phosphates

The invention provides a graphene and vermiculite-based high-temperature-resistant anticorrosive paint and a preparation method. The graphene and vermiculite-based high-temperature-resistant anticorrosive paint comprises following components in percentage by mass: 0.05-10% of bentonite, 5-20% of vermiculite, 1-10% of kaolin, 1-20% of graphene, 3-10% of fused alumina powder, 5-15% of magnesium hydrate whiskers, 10-30% of titanium dioxide, 30-40% of an inorganic binder and 3-6% of silicone acrylic emulsion; and the inorganic binder comprises following components in percentage by mass: 5-20% of sodium phosphate, 60-80% of sodium silicate, 5-20% of potassium silicate and 10-30% of hydrophobic modified silica sol. The paint is featured with relatively high adhesion and needs no blasting treatment or corroding and roughening treatment on a metal surface, thereby greatly simplifying the difficulty of construction. Meanwhile, the paint would not be trapped in blistering, crazing and dropping at high temperature and plays roles of preventing water, fire, corrosion and rust, keeping warm, resisting aging, insulating and so on.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

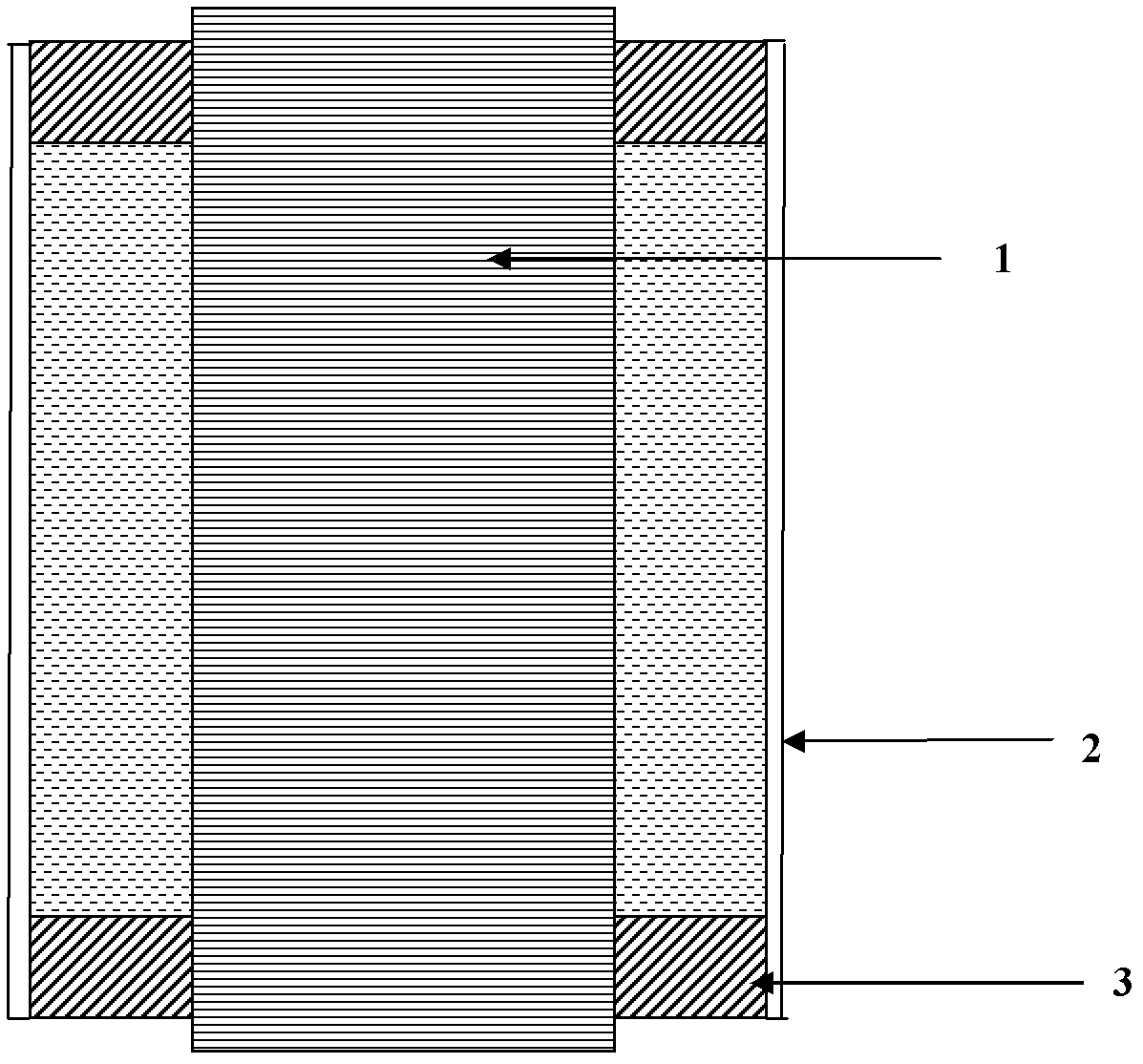

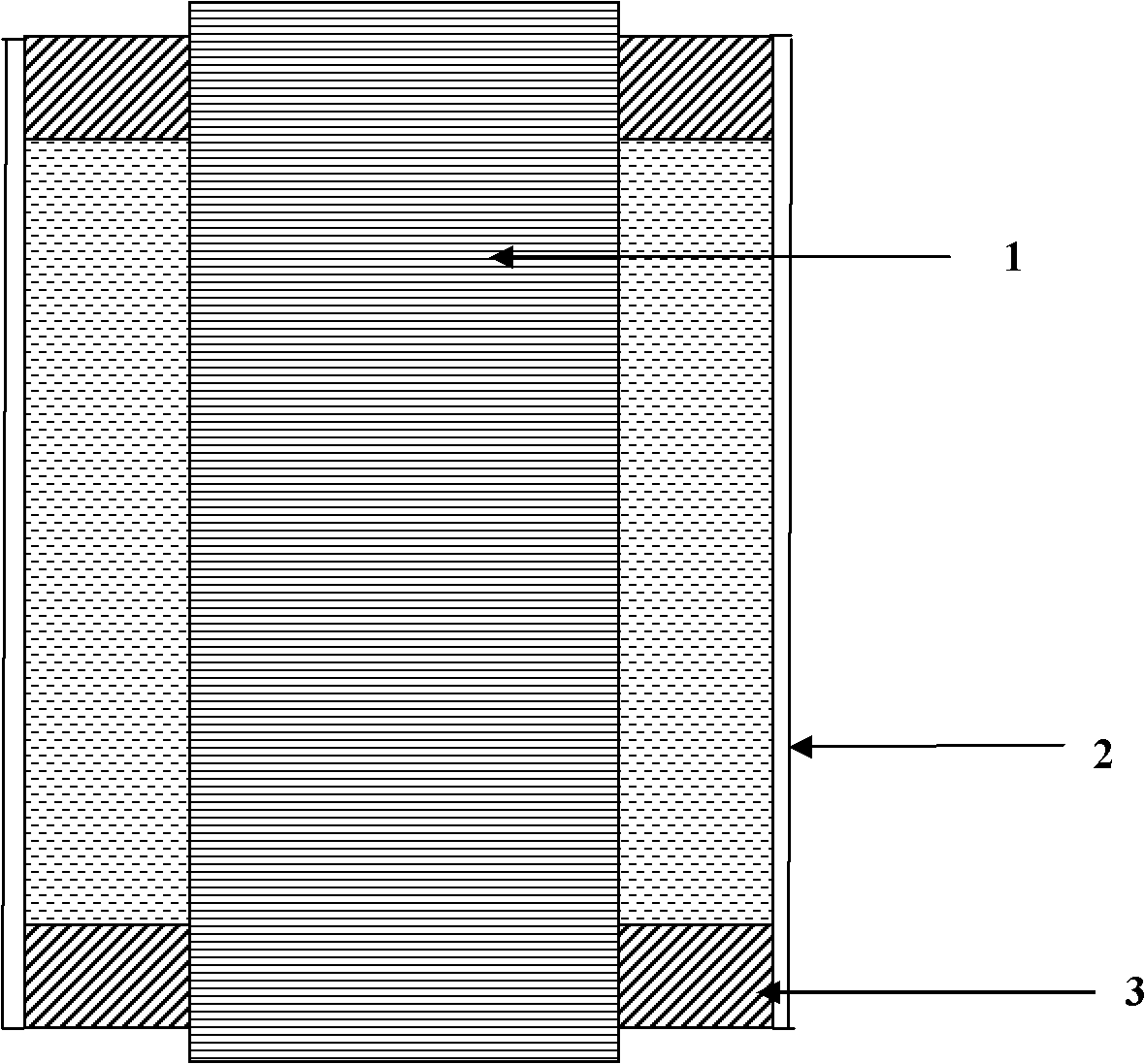

Ceramic flowerpot capable of slowly releasing fertilizers

ActiveCN109279864AControl release speedPracticalAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCross-linkMaterials science

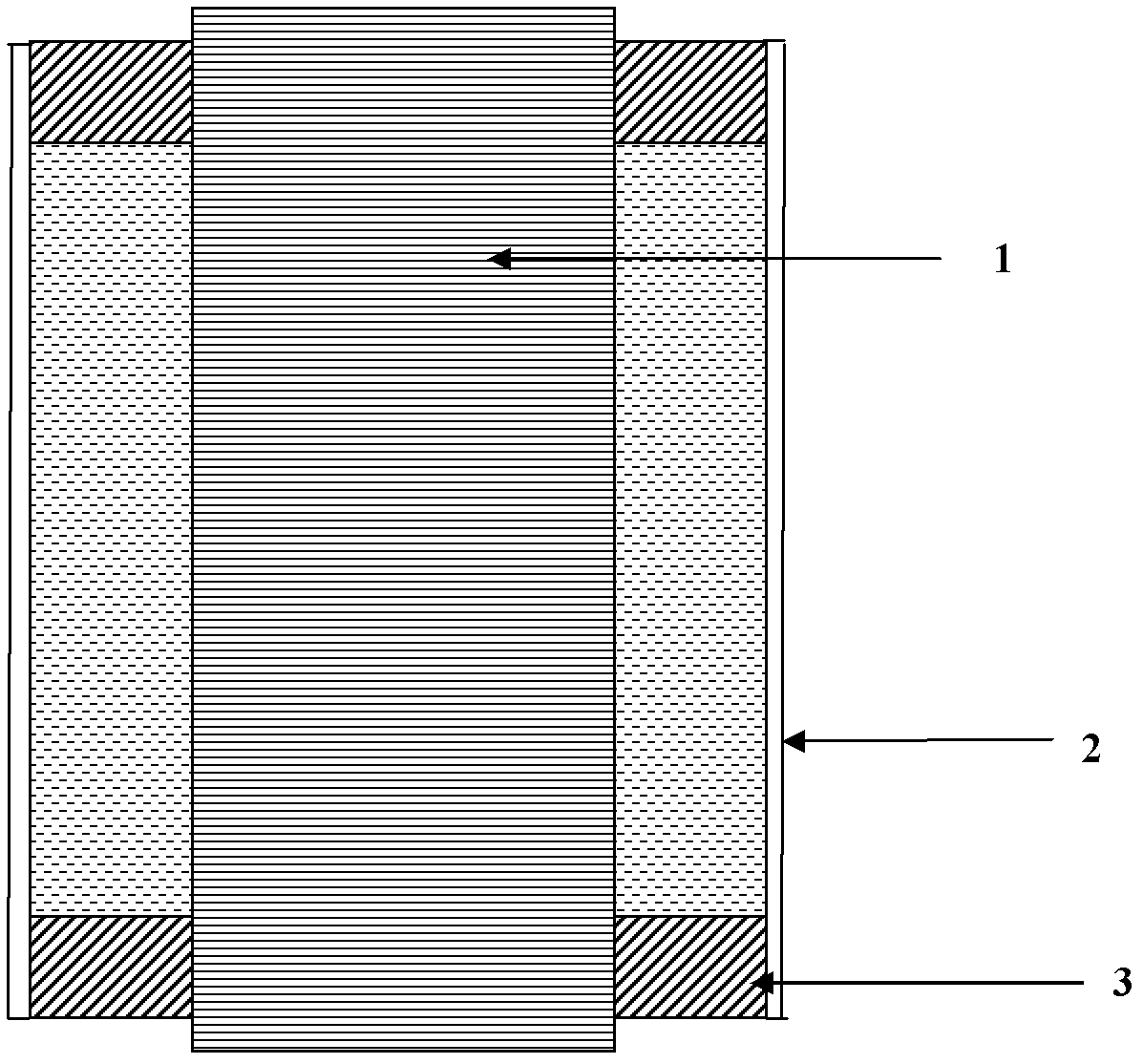

The present invention provides a ceramic flowerpot capable of slowly releasing fertilizers, comprising three parts, namely an outer barrier layer, an inner space layer, and cross-linked fertilizer particles packed in the inner space layer. The interior of the pot wall of the flowerpot is loaded with the fertilizer suitable for flower growth, and the fertilizer is slowly released into soil in the flowerpot for a long time, thereby eliminating a process of fertilizing flowers and plants. In actual production, the total amount of fertilizers in the flowerpot and the rate of fertilizer leaching can be designed according to the daily average amount of fertilizers required for different types of flowers and plants. When the fertilizers inside the flowerpot is completely released, the flowerpot can continue to be used as a common flowerpot.

Owner:宜兴奕安陶瓷有限公司

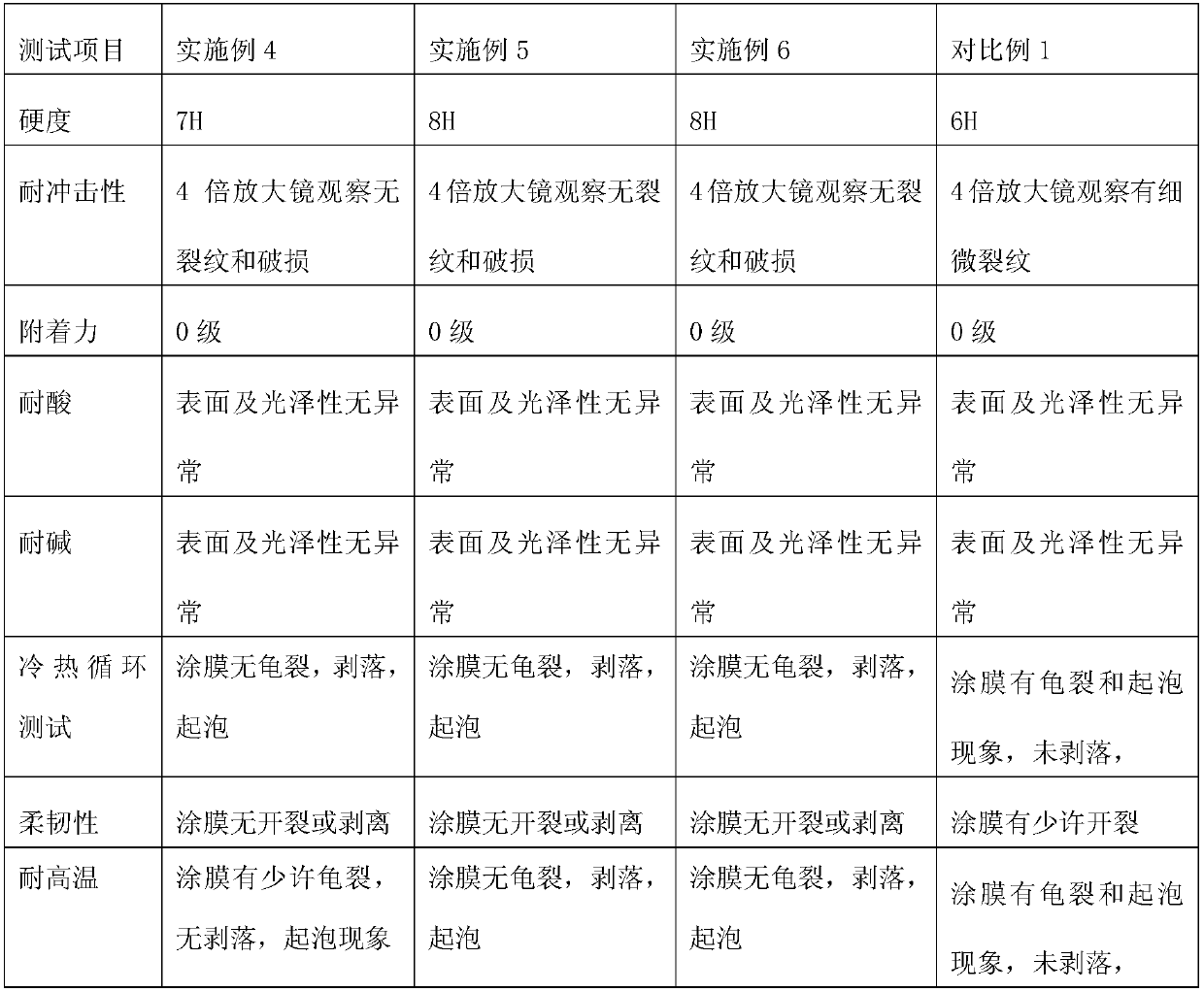

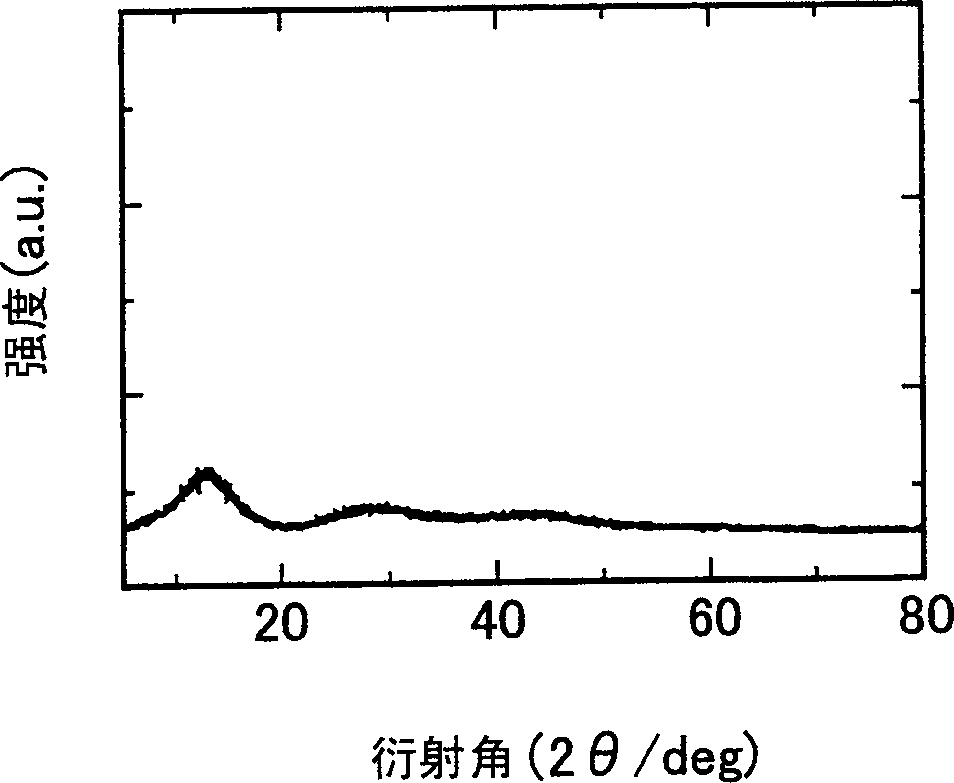

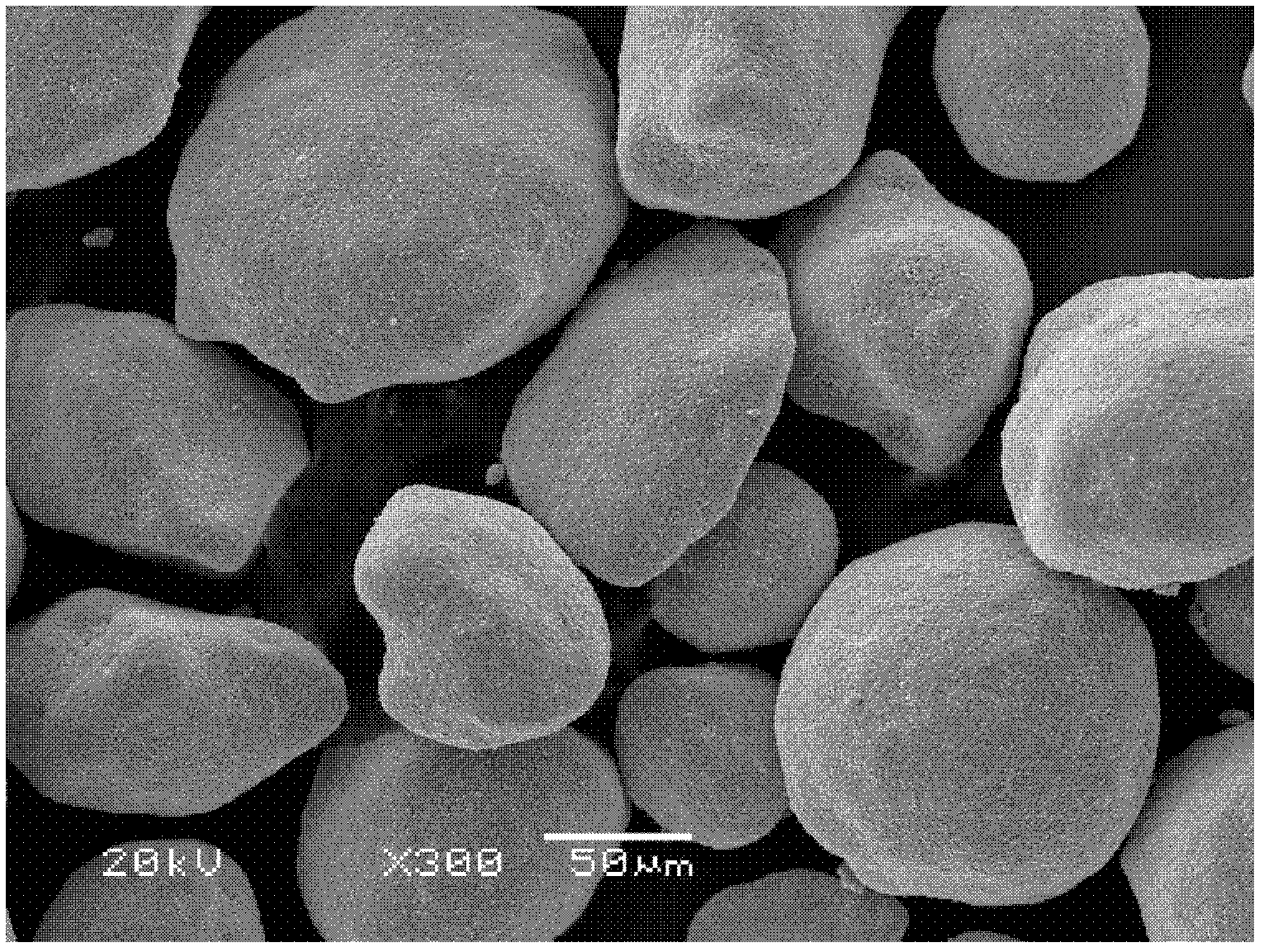

Process for producing fluorescent metal oxide material

A process for producing a metal oxide phosphor includes a step of firing a powder containing an organic metal chelate complex including a plurality of metals constituting the metal oxide at a uniform composition, whereby produced is a metal oxide phosphor having substantially spherical shape with substantially uniform particle size and excellent luminance properties.

Owner:CHUBU KIRESUTO +1

Novel thermal insulation material preparation method

The invention discloses a novel thermal insulation material preparation method. The method comprises the following steps that (1) phosphate, expand perlite, fiber, silicate, a water repellent and a penetrant are put into a blender for mixing and blending evenly, and a first mixture is obtained; (2) the first mixture continues to be blended by the blender for 40-60 min after distilled water is added, and a second mixture is obtained; (3) the second mixture is poured into a mold for compression molding by a compression molding machine, and is subjected to natural caring for 2-3 days; (4) calendaring processing is conducted on the surface of molded material, after a calendaring layer is completely dried, a layer of curing agent is smeared on the surface of the calendaring layer, and a finished product can be obtained after the curing agent layer is dried completely. Thermal insulation material is applicable to the field of architecture, which has the advantages of waterproofing, fireproofing, corrosion resistance, high strength and long service life, the thermal insulation material is large in density, high in compressive strength and low in heat conductivity coefficient in addition, thereby making a good effect on thermal insulation, and moreover, the preparation method is simple and the cost is low, which make the thermal insulation material suitable for industrialized mass production.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Novel composite fire-resistant material and preparation method thereof

The invention provides a novel composite fire-resistant material and a preparation method thereof. The novel composite fire-resistant material is prepared by a fire-resistant base material, silicon carbide, waste tailings slag, partially stabilized zirconia, zirconium carbide particles, acrylated amine, methylene bisacrylamide, ammonium persulfate, an organic solvent, a binding agent and a naturalplasticizer. Compare with a traditional fire-resistant material, the prepared fire-resistant material is low in pore number, high in density, small in expansion rate and linear change on reheating, good in stability, excellent in thermal shock performance and good in wear resistance.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

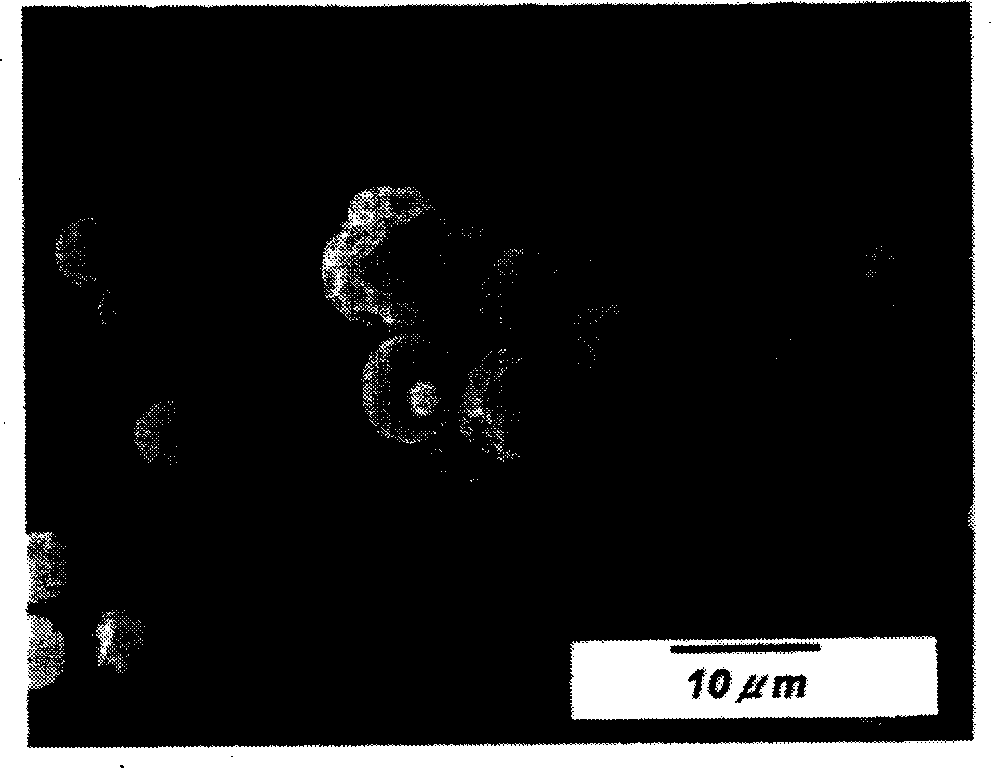

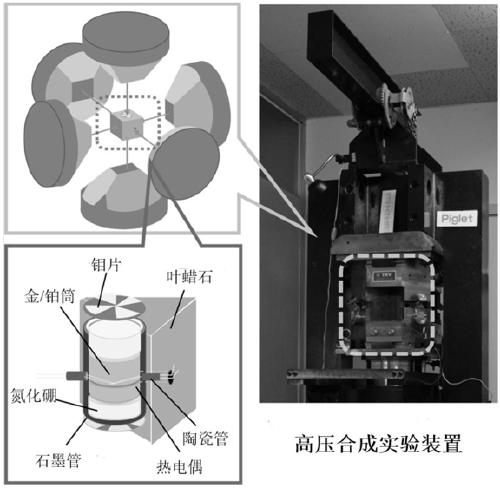

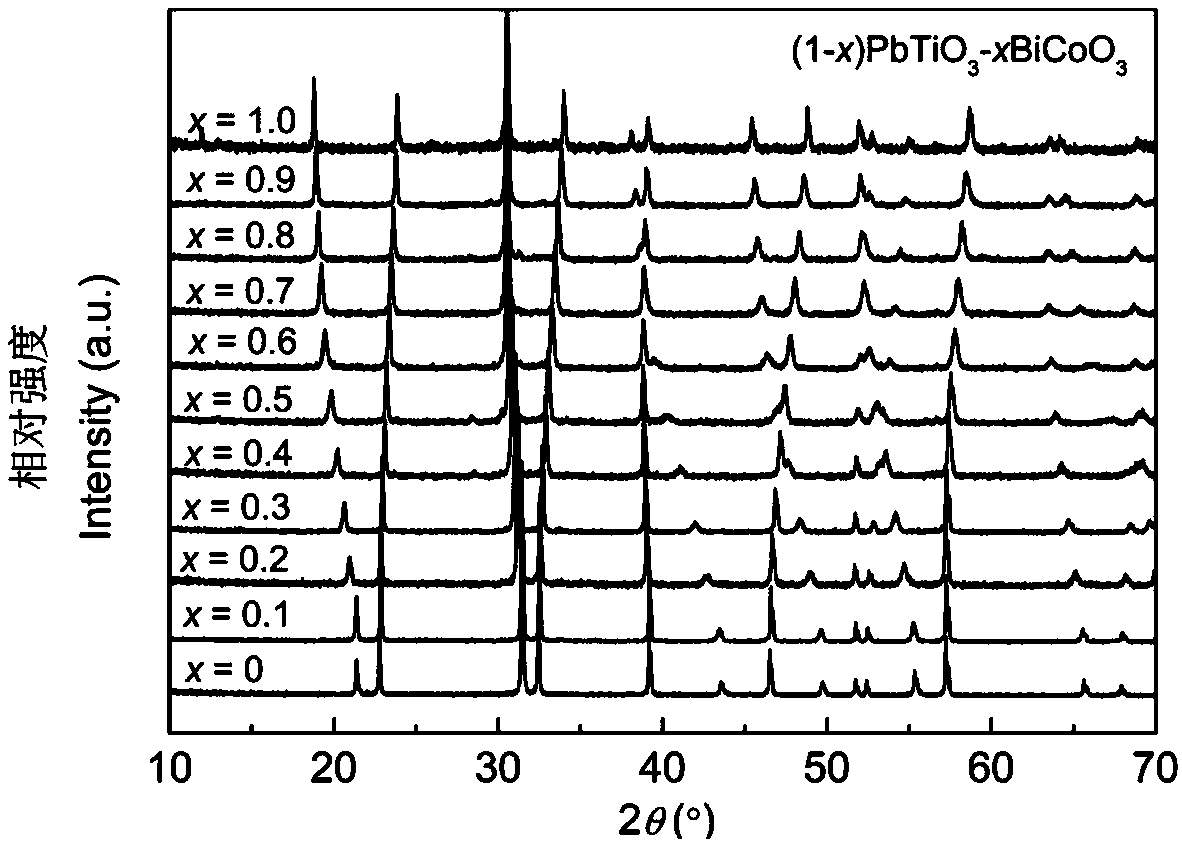

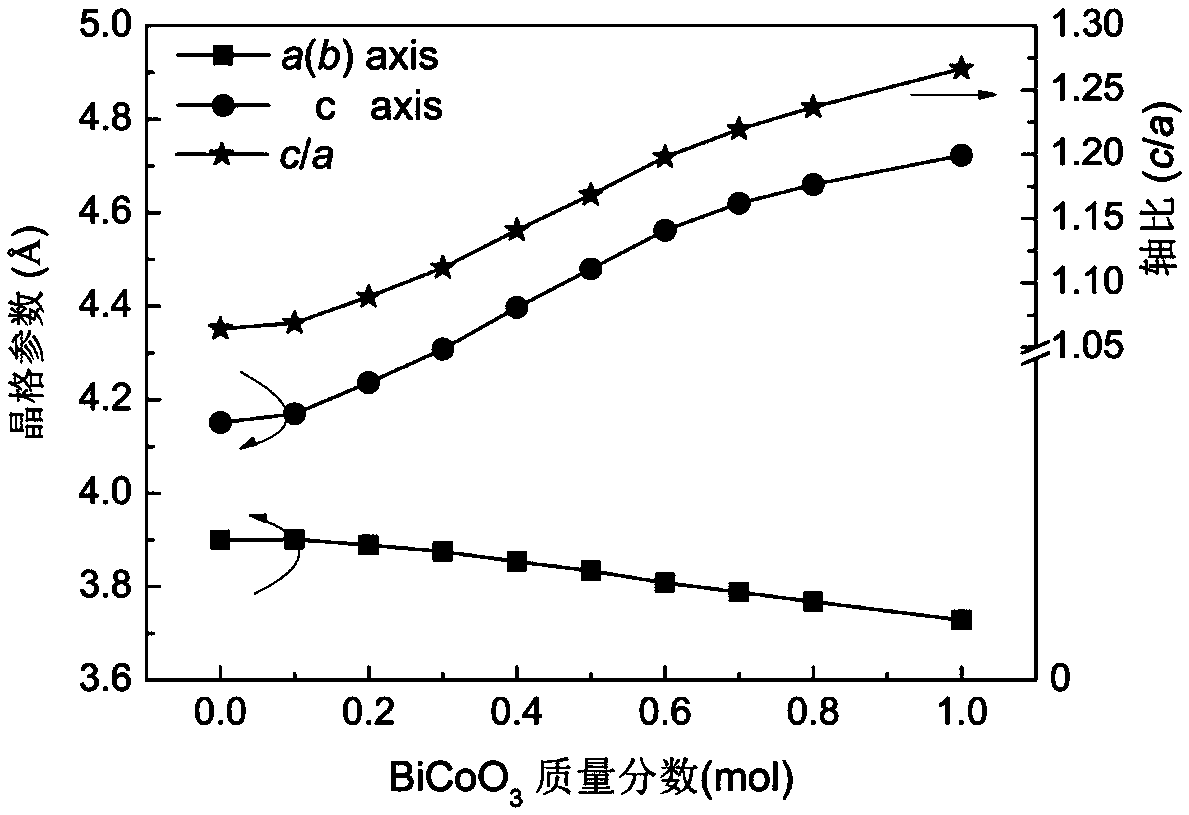

Material with negative thermal expansion performance and preparation method thereof

The invention relates to a material with negative thermal expansion performance and a preparation method thereof. The method is characterized by comprising the steps that 1, PbO, TiO2, Bi2O3 and Co3O4samples are mixed and blended uniformly according to a preset ratio, and pre-processing is conducted; 2, the mixed samples are added to a tube crucible, an antioxidant is added, and the tube cruciblecontaining the mixed samples is placed into a sealed mold; 3, the sealed mold is placed in high-pressure synthesis equipment, temperature and pressure are increased, heat and pressure preserving areconducted, and the temperature and the pressure are reduced to a room temperature and normal pressure; 4, the processed samples are taken out and demolded, the processed samples are washed, the samples are dried, and the novel material (1-x)PbTiO3-xBiCoO3 with the negative thermal expansion performance is obtained, wherein 0.0<=x<=1.0. Compared with a traditional material with the negative thermalexpansion performance, the material, with the negative thermal expansion performance, prepared through the method has high purity, high repeatability, significantly enhanced negative thermal expansion performance and broadened negative expansion temperature zone, and therefore the material has wide scientific researching and practical value.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of high-temperature refractory material

The invention provides a preparation method of a high-temperature refractory material. The preparation method comprises the following preparation steps: a, mixing a carbon-containing material, a refractory substrate and aluminum oxide, guiding the mixture into a ball milling tank to be subjected to ball milling, then adding an organic solvent, and performing stirring to obtain slurry; b, mixing partially stabilized zirconium oxide, zirconium carbide particles, acrylated amines, methylene bisacrylamide and ammonium persulfate, guiding the mixture into a high mixing machine, and performing stirring and ultrasonic oscillation to obtain a material 1; c, adding a catalyst and a binder into the material 1, dissolving the catalyst and the binder by stirring, then guiding the slurry into the material 1, and performing heating and stirring to obtain a billet; and d, drying and pulverizing the billet, performing secondary drying treatment, and then, performing cooling and compression molding. Compared with the traditional refractory material, the refractory material prepared by the preparation method provided by the invention has the advantages of lower pores, higher volume density, smallerexpansion ratio and linear change on reheating, better stability, more superior thermal shock performance and better wear resistance.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

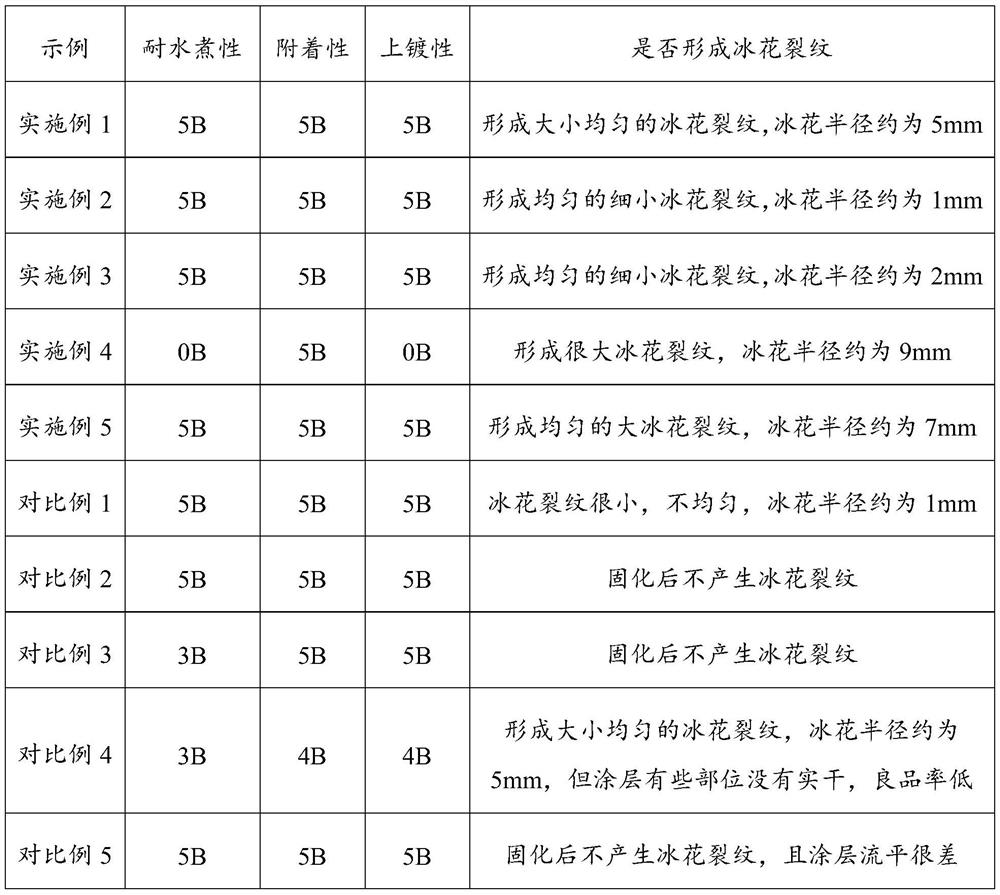

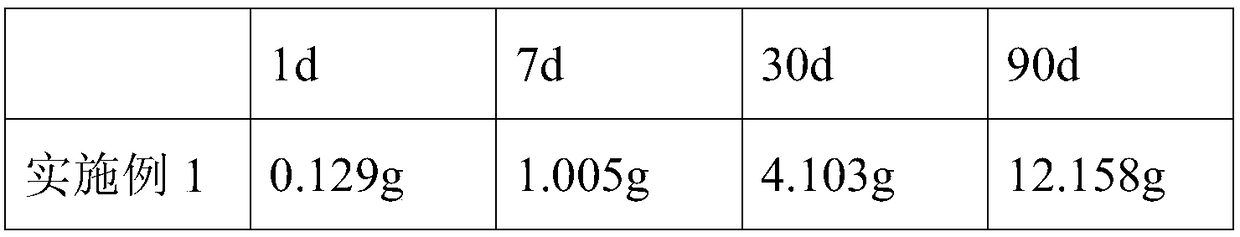

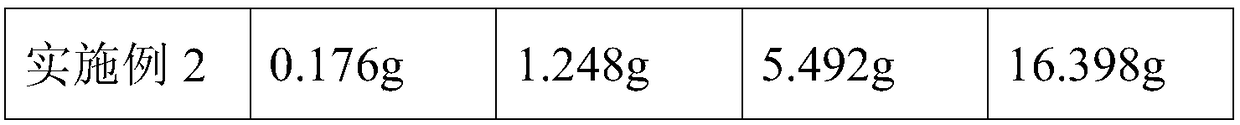

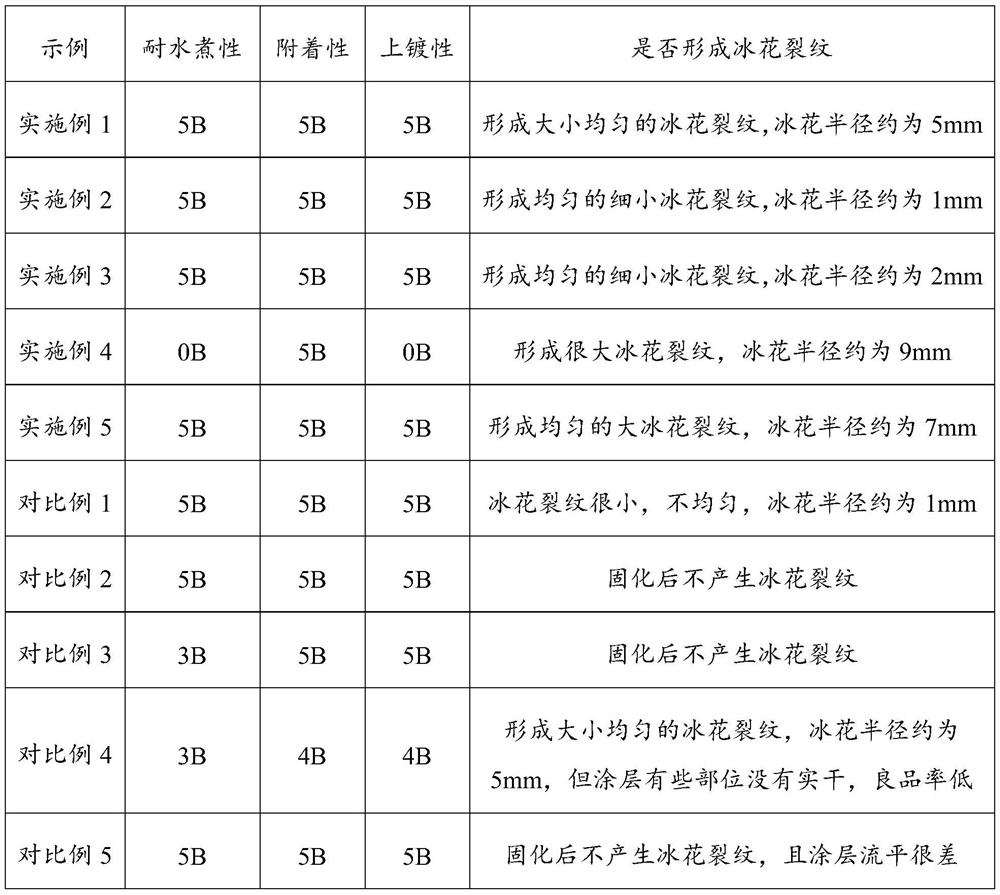

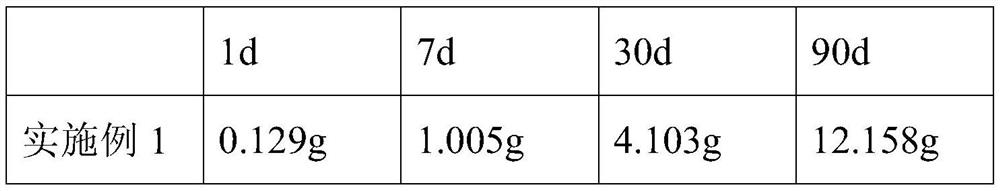

Ice flower crack coating and preparation method and curing method

ActiveCN112980298ASimple curing methodHigh speedPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceUV curing

The invention belongs to the technical field of coating preparation, and particularly relates to an ice flower crack coating and a preparation method and a curing method. The ice flower crack coating is prepared from 5 to 15 parts of six-functionality aromatic polyurethane acrylate, 15 to 30 parts of fatty acid modified epoxy acrylate, 8 to 15 parts of reactive diluent, 6 to 15 parts of benzophenone and 1 to 2 parts of active amine. When the six-functionality aromatic polyurethane acrylate, the fatty acid modified epoxy acrylate, the benzophenone and the active amine are subjected to UV curing, ice flower cracks are generated due to different shrinkage of the surface and the bottom of a coating in the stress release process. By adopting the synergistic effect of the six-functionality aromatic polyurethane acrylate, the fatty acid modified epoxy acrylate, the benzophenone and the active amine in a specific ratio, the coating with good plating property, boiling resistance, high yield and uniform ice flower crack distribution can be obtained.

Owner:上海抚佳精细化工有限公司

Active positive-electrode material for lead-acid battery and preparation method thereof

The formula of active positive-electrode material consists of: lead sulfate 68-75 wt%, sulfuric acid 10-15 wt5, deionized water 6-12 wt%, short fiber 0.04-0.8 wt%, inorganic conducting additive 2-4 wt% and organic additive 1-2.5 wt%. The preparation process of the active positive-electrode material includes reaction sulfuric acid and lead powder to obtain lead sulfate powder, mixing lead sulfate powder with other material to obtain mixture paste. Utilizing lead sulfate, rather than lead powder, as positive electrode material results in high porosity, high active matter utilization, plate homogeneity, no environmental pollution, simple production process and low production cost.

Owner:江苏隆源双登电源有限公司

Preparing method of novel building energy-saving and heat-preserving material

The invention relates to a preparing method of a novel building energy-saving and heat-preserving material. The preparing method includes the following steps that 1, flyash, expanded perlite, fiber, silicate, sulfonated acetone formaldehyde and a silane coupling agent are put into a stirrer, mixed and stirred uniformly to obtain a first mixture; 2, distilled water is added into the first mixture and mixed through the stirrer to obtain a second mixture; 3, the second mixture is poured into a mold and formed in a compression mode through a compression forming device; 4, the surface of the formed material is calendered, after a calendering layer is fully dried, a curing agent is smeared on the surface of the calendering layer, and the finished product can be obtained after the curing agent layer is fully dried. The energy-saving and heat-preserving material is suitable for the wall building field and has the advantages of being waterproof, fireproof, corrosion resistant, high in strength, long in service life, high in density and compressive strength, low in heat conductivity and good in heat preserving effect.

Owner:合肥市旺友门窗有限公司

Ceramic flowerpot capable of slowly releasing EM-bacterium-containing fertilizers

ActiveCN109020606AHigh reactivityGood dispersionCultivating equipmentsReceptacle cultivationFlowerpotBlocking layer

The invention provides a ceramic flowerpot capable of slowly releasing EM-bacterium-containing fertilizers. The ceramic flowerpot comprises three parts which are respectively an outer blocking layer,an inner space layer and crosslinking fertilizer particles filled in the inner space layer. The fertilizers and EM bacteria suitable for flowers and grass to grow are loaded in a pot wall of the flower pot; the fertilizers are is slowly released into soil in the flowerpot in a long time; the fertilization work procedure during the flower and grass planting is avoided; meanwhile, the EM bacteria can better promote the flower and grass growth. In the practical production, the fertilizer total quantity and the EM bacterium content in the flowerpot and the fertilizer and EM bacterium leaching speed can be designed according to the average daily fertilizer quantity required by different kinds of flowers and grass; after all fertilizers and EM bacteria in the flowerpot are released, the flowerpot can be continuously used as an ordinary flowerpot.

Owner:宜兴奕安陶瓷有限公司

A kind of high temperature resistant anticorrosion coating based on graphene and vermiculite and preparation method thereof

ActiveCN107652727BImprove adhesionNon-foamingFireproof paintsAntifouling/underwater paintsSodium BentoniteSodium phosphates

The invention provides a graphene and vermiculite-based high-temperature-resistant anticorrosive paint and a preparation method. The graphene and vermiculite-based high-temperature-resistant anticorrosive paint comprises following components in percentage by mass: 0.05-10% of bentonite, 5-20% of vermiculite, 1-10% of kaolin, 1-20% of graphene, 3-10% of fused alumina powder, 5-15% of magnesium hydrate whiskers, 10-30% of titanium dioxide, 30-40% of an inorganic binder and 3-6% of silicone acrylic emulsion; and the inorganic binder comprises following components in percentage by mass: 5-20% of sodium phosphate, 60-80% of sodium silicate, 5-20% of potassium silicate and 10-30% of hydrophobic modified silica sol. The paint is featured with relatively high adhesion and needs no blasting treatment or corroding and roughening treatment on a metal surface, thereby greatly simplifying the difficulty of construction. Meanwhile, the paint would not be trapped in blistering, crazing and dropping at high temperature and plays roles of preventing water, fire, corrosion and rust, keeping warm, resisting aging, insulating and so on.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

A ceramic plant pot with slow-release fertilizer

ActiveCN109279864BInhibition releaseSufficient gasAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAgricultural engineeringFlowerpot

The present invention provides a ceramic flowerpot capable of slowly releasing fertilizers, comprising three parts, namely an outer barrier layer, an inner space layer, and cross-linked fertilizer particles packed in the inner space layer. The interior of the pot wall of the flowerpot is loaded with the fertilizer suitable for flower growth, and the fertilizer is slowly released into soil in the flowerpot for a long time, thereby eliminating a process of fertilizing flowers and plants. In actual production, the total amount of fertilizers in the flowerpot and the rate of fertilizer leaching can be designed according to the daily average amount of fertilizers required for different types of flowers and plants. When the fertilizers inside the flowerpot is completely released, the flowerpot can continue to be used as a common flowerpot.

Owner:宜兴奕安陶瓷有限公司

High-strength refractory material and preparation method thereof

The invention provides a high-strength refractory material and a preparation method thereof. The high-strength refractory material is prepared from the following components: a base material, a refractory base material, aluminum oxide, partially stabilized zirconia, zirconium carbide particles, acrylamide, methylene bisacrylamide, ammonium persulfate, an organic bonding agent, a catalyst and an organic solvent. The refractory material prepared in the invention also has relatively high fracture toughness; the service life of the refractory material can be prolonged while the using reliability ofthe refractory material can be enhanced; moreover, the preparation method is simple and efficient, and large-scale production can be easily realized on existing equipment.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

Preparation method of fireproof material

The invention provides a preparation method of a fireproof material. The method comprises the following preparation steps: a, mixing a carbon-containing material, a fireproof base material and aluminum oxide; guiding the mixture into a ball milling tank; performing ball milling; then, adding an organic solvent; stirring to obtain slurry; b, mixing partial stable zirconium oxide, zirconium carbideparticles, acrylated amine, methylene bisacrylamide and ammonium persulfate; guiding the materials into a high mixing machine; performing stirring and ultrasonic oscillation to obtain a first material; c, adding a catalyst and a bonding agent into the first material; performing stirring and dissolution; then, guiding the slurry; heating and stirring to obtain a blank; d, drying and crushing the blank; then, performing secondary drying treatment; next, performing cooling and pressing shaping. Compared with a conventional fireproof material, the prepared fireproof material has the advantages that the air porosity is lower; the bulk density is higher; the expansion rate and the linear change on reheating are smaller; the stability is better; the heat shock performance is more excellent; the wear-resistant performance is better.

Owner:湖州南浔研艺斋工艺品有限公司

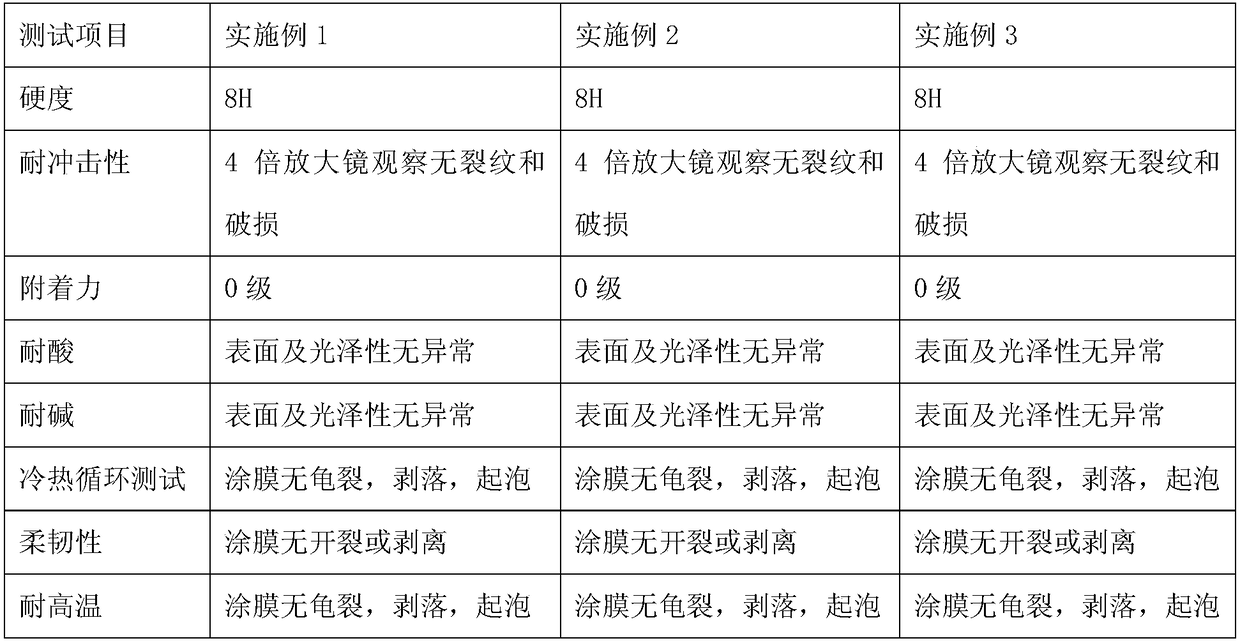

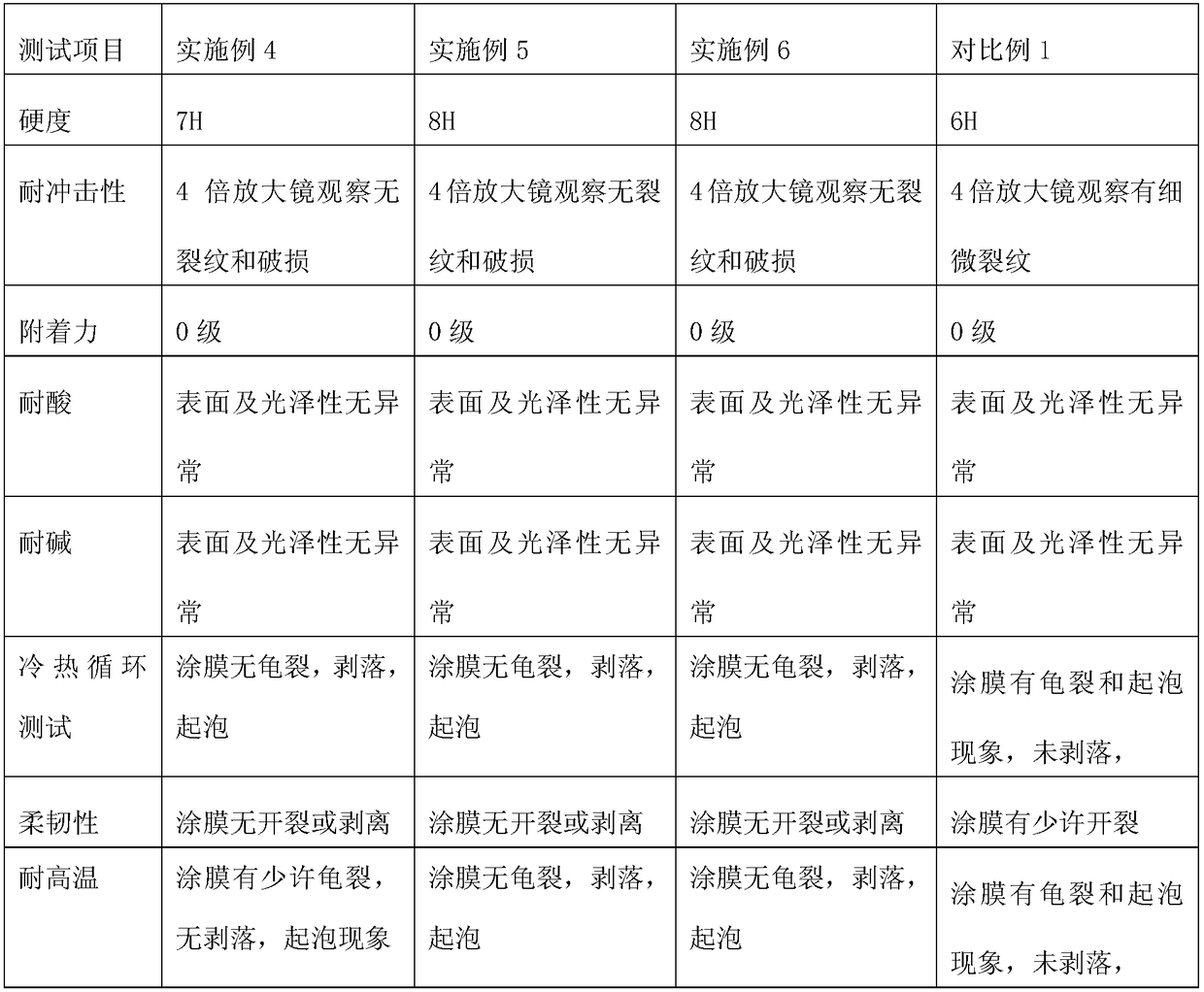

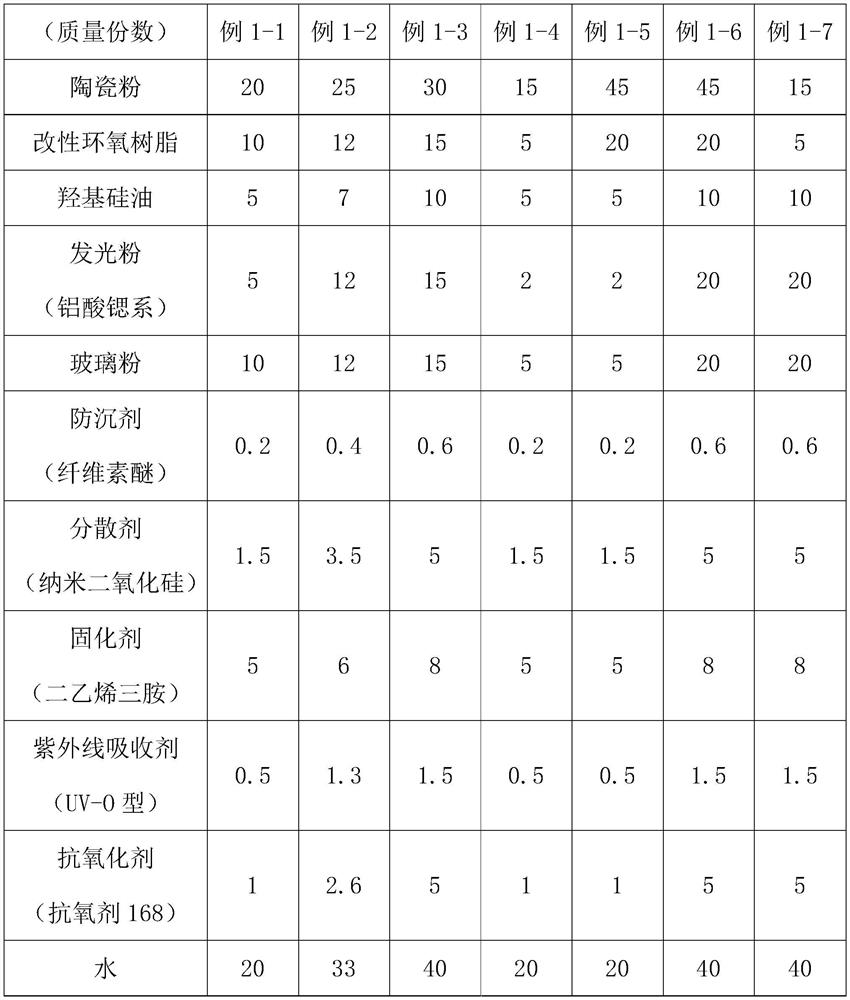

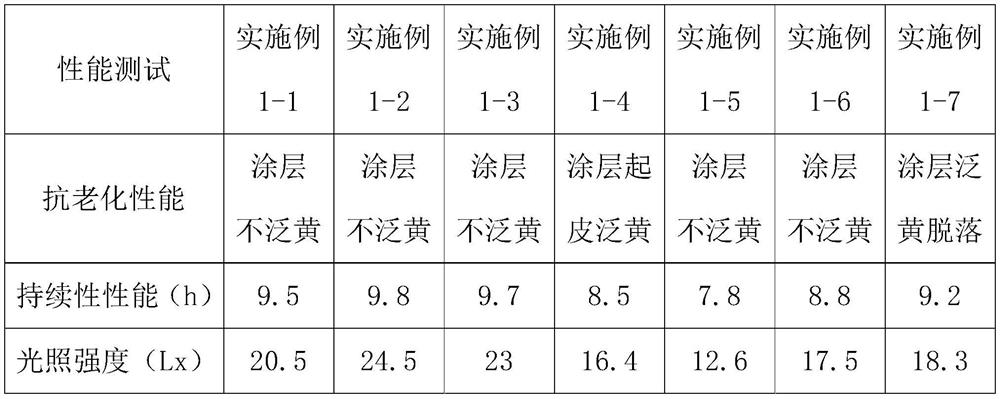

Anti-aging luminescent inorganic coating for building exterior wall and preparation method thereof

The invention discloses an anti-aging luminescent inorganic coating for building exterior walls and a preparation method thereof. According to parts by mass, the anti-aging luminescent inorganic coating for building exterior walls comprises the following raw materials: 20-30 parts of ceramic powder, 10-30 parts of modified epoxy resin 15 parts, 5-10 parts of hydroxyl silicone oil, 5-15 parts of luminescent powder, 10-15 parts of glass powder, 8.2-20.1 parts of mixing aid and 20-40 parts of water; the raw materials of modified epoxy resin include epoxy resin and A polyoxyethylene alkylphenol condensate, and according to the mass ratio, the mixing ratio of the epoxy resin and the polyoxyethylene alkylphenol condensate is (1.5-3):1. The anti-aging luminescent inorganic coating for building exterior walls proposed in this technical solution improves and optimizes the formulation of the luminescent coating, which helps to improve the anti-aging performance of the coating on the premise of ensuring the luminous effect of the coating. Furthermore, a preparation method of an anti-aging luminescent inorganic paint for building exterior walls is proposed, which has simple steps and strong operability, so as to overcome the shortcomings in the prior art.

Owner:广东至道先进土木工程材料技术研究有限公司

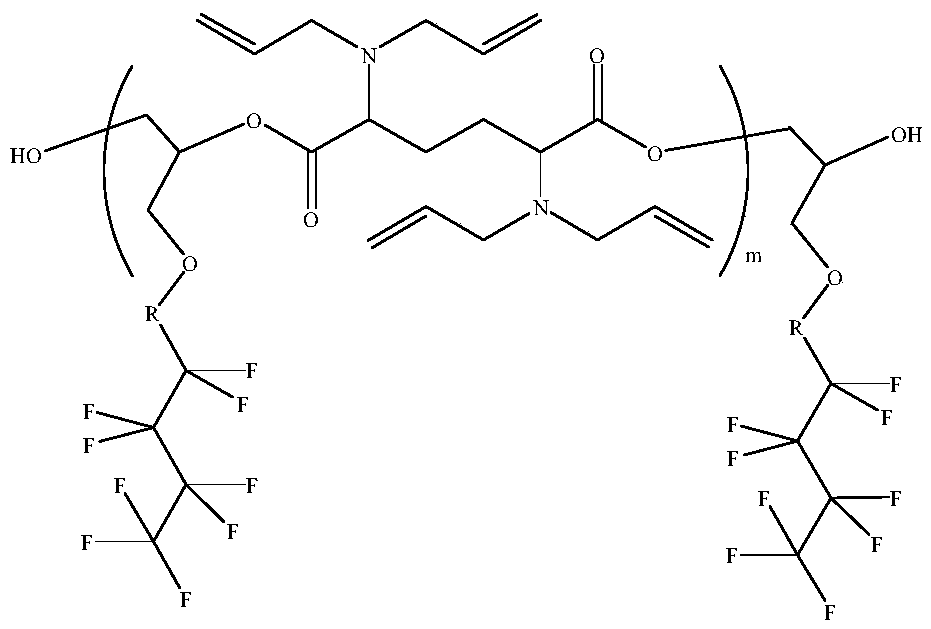

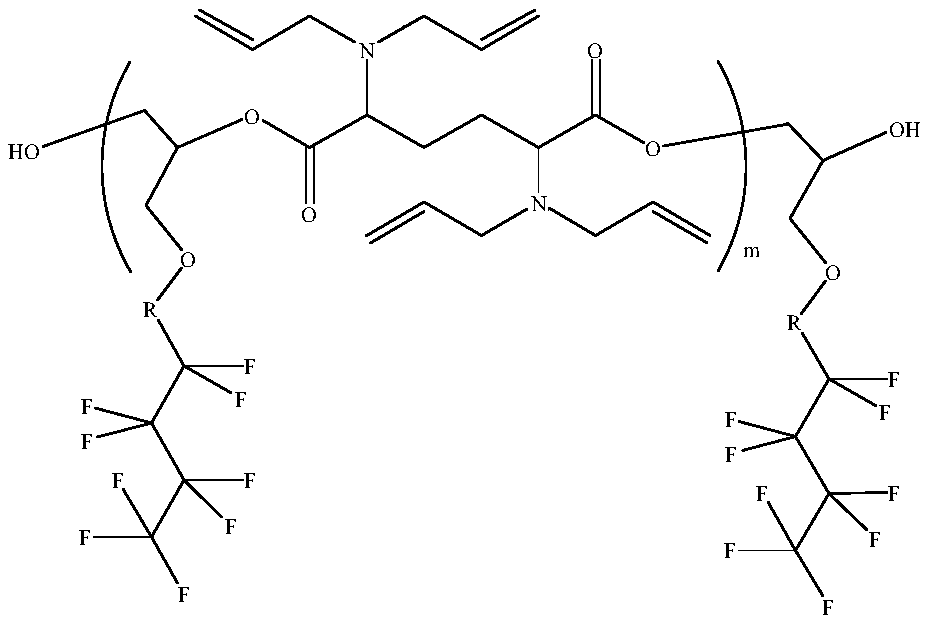

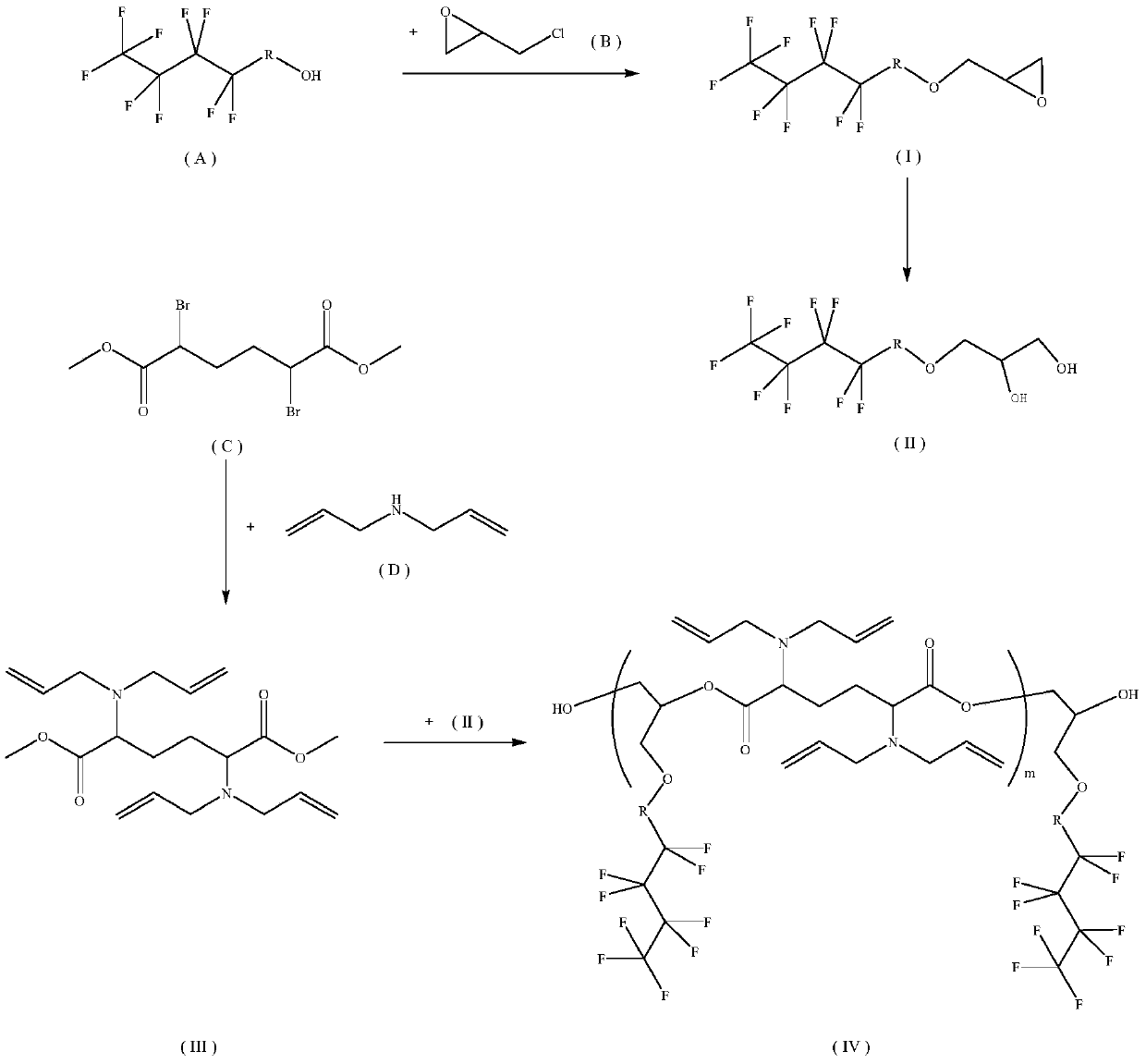

UV orange-peel agent and orange-peel paint

ActiveCN111440475AWide variety of sourcesSolve poor unevennessAntifouling/underwater paintsOrganic compound preparationPolymer scienceAlcohol

The invention belongs to the field of coatings. The invention relates to a UV orange-peel agent and orange-peel paint. The method comprises the steps of: taking fluorine-containing monohydric alcohol(A), epichlorohydrin (B), 2, 4, 6-tetramethyl-1, 3-pentanedione and 2, 3-pentanedione as raw materials to perform ring opening, ring forming, ring opening, coupling, hydrolysis and condensation reaction to obtain a UV orange-peel agent material and prepare the orange-peel paint. The problems that existing orange-peel paint is difficult to construct and poor in orange-peel effect are solved, efficient anti-fouling performance is achieved, foreseeability is achieved, and the material can meet wide market prospects in the field of paint and is particularly suitable for the fields of decorative coatings and the like.

Owner:广东省沙基姆环保新材料有限公司

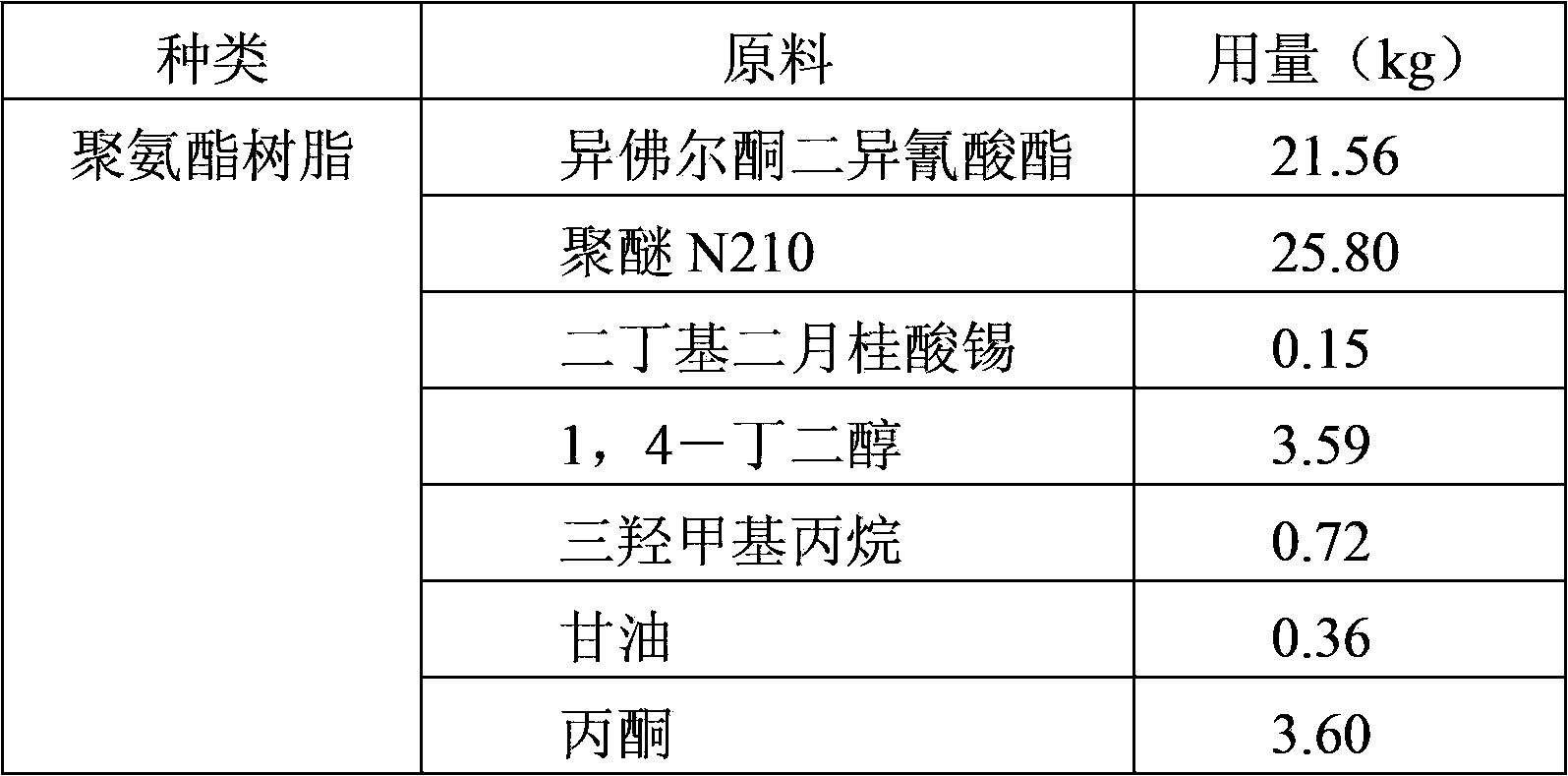

Polyurethane unsaturated polyester resin and photocuring coating containing same

ActiveCN102827343BReduce adhesionImprove adhesionPolyurea/polyurethane coatingsUnsaturated polyesterDibasic acid

Owner:广东百汇达新材料有限公司

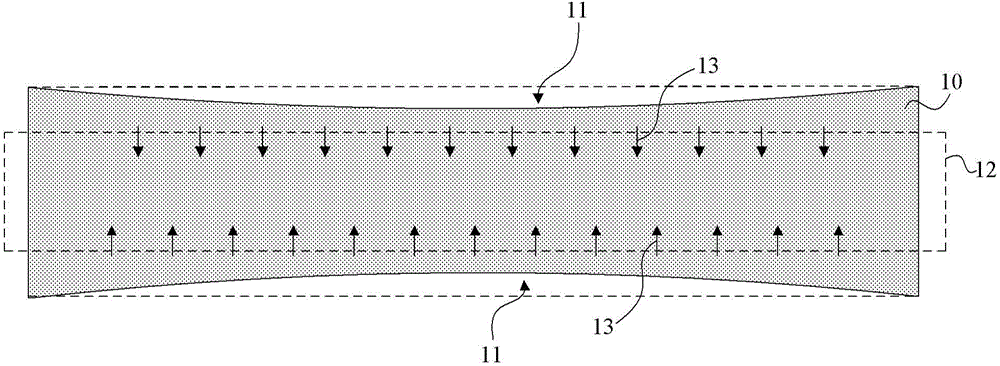

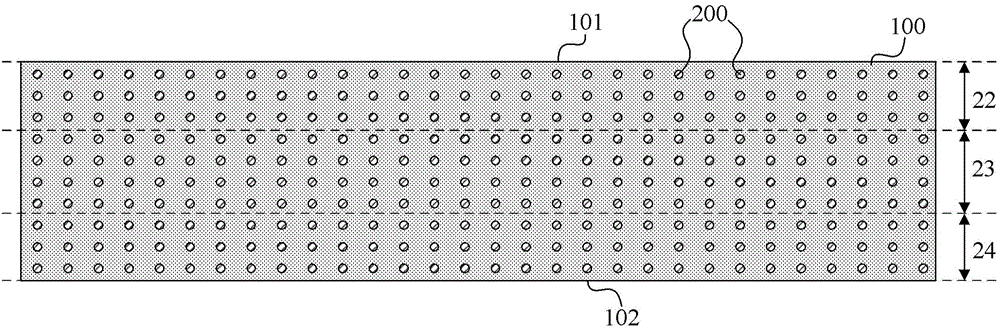

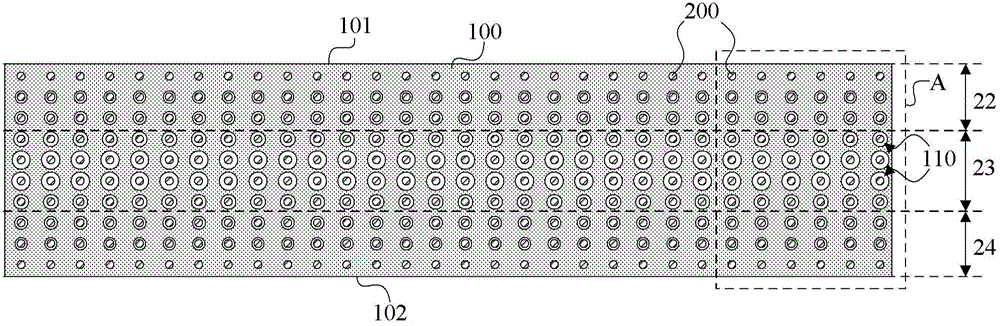

Injection-molded part, forming method thereof, edge covering structure and vehicle window

InactiveCN106142446ASmall volume shrinkageLarge volume shrinkageWindowsWindscreensBiomedical engineeringRaw material

Owner:SAINT-GOBAIN GLASS FRANCE

Preparation method of hollow fiber internal pressure composite film

Owner:TIANJIN MOTIMO MEMBRANE TECH

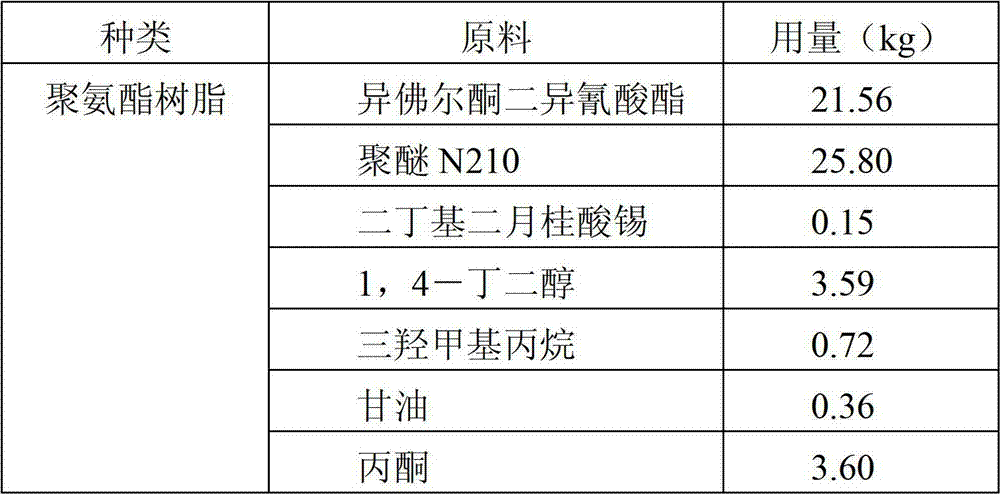

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

Preparation method of zinc oxide-based tubular rotary target material

The invention relates to a preparation method of a zinc oxide-based tubular rotary target material. The preparation method comprises the following steps: taking NH4HCO3 as a precipitant, preparing pure zinc oxide powder and Al-doped zinc oxide powder with an atomic ratio of 1-7at% by a chemical precipitation method, presintering, conglomerating and shaping the powder, filling the powder into a mould, moulding the powder in a cold isostatic pressing manner at 300-340MPa, obtaining a biscuit with a relative density of 70-75%, sintering the biscuit under an oxidizing atmosphere, and processing the sintered biscuit to obtain the rotary target material. Compared with the prior art, the preparation method provided by the invention has the beneficial effects that the density of the biscuit is improved by 10-15%; the volume shrinkage in later stage sintering is reduced; the sintering deformation of the tubular target with a large length-diameter ratio is effectively controlled; and in the process of sintering, the circulating oxygen is served as a control atmosphere to avoid the component changing, large pores on the surface and density reduction caused by the large pores on the surface.

Owner:宁夏中色新材料有限公司

A kind of ice flower crack coating and its preparation method and curing method

ActiveCN112980298BGood plating performanceFast platingPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceCrazing

The invention belongs to the technical field of coating preparation, and in particular relates to an ice crack coating, a preparation method and a curing method. The ice crack paint includes 5-15 parts of six-functional aromatic polyurethane acrylate, 15-30 parts of fatty acid modified epoxy acrylate, 8-15 parts of reactive diluent, 6-15 parts of benzophenone and 1-2 parts active amine. When the hexafunctional aromatic urethane acrylate, fatty acid modified epoxy acrylate, benzophenone and active amine of the present invention are UV cured, ice cracks are generated due to different shrinkage of the surface and bottom of the coating during the stress release process. The invention adopts the synergistic effect between hexafunctional aromatic urethane acrylate, fatty acid modified epoxy acrylate, benzophenone and active amine in a specific ratio, and can obtain good plating performance, water boiling resistance, high yield, Coating with evenly distributed ice cracks.

Owner:上海抚佳精细化工有限公司

A ceramic flower pot that slowly releases fertilizer containing em bacteria

ActiveCN109020606BInhibition releaseSufficient gasCultivating equipmentsOrganic fertilisersAgricultural engineeringFlowerpot

The invention provides a ceramic flowerpot capable of slowly releasing EM-bacterium-containing fertilizers. The ceramic flowerpot comprises three parts which are respectively an outer blocking layer,an inner space layer and crosslinking fertilizer particles filled in the inner space layer. The fertilizers and EM bacteria suitable for flowers and grass to grow are loaded in a pot wall of the flower pot; the fertilizers are is slowly released into soil in the flowerpot in a long time; the fertilization work procedure during the flower and grass planting is avoided; meanwhile, the EM bacteria can better promote the flower and grass growth. In the practical production, the fertilizer total quantity and the EM bacterium content in the flowerpot and the fertilizer and EM bacterium leaching speed can be designed according to the average daily fertilizer quantity required by different kinds of flowers and grass; after all fertilizers and EM bacteria in the flowerpot are released, the flowerpot can be continuously used as an ordinary flowerpot.

Owner:宜兴奕安陶瓷有限公司

A kind of A1 grade fireproof and thermal insulation mortar and preparation method thereof

The invention discloses an A1-grade fireproof insulation mortar which is prepared from the raw materials of, by weight: common Portland cement, fly ash, expanded vermiculite, expanded glass micro-beads, re-dispersible latex powder, fiber, cellulose ether, and an air-entraining agent. According to the invention, glass micro-beads are adopted as a light aggregate, and the expanded vermiculite with excellent fireproof performance is doped in. Compared with a dry-mix insulation mortar light aggregate with expanded perlite and polystyrene particles, the defects of high water absorption, easy pulverization, high volume shrinkage rate in slurry stirring, and phenomena of product low post-stage strength and hollowing cracking, and the like of expanded perlite are overcome. Also, defects of high inflammability, poor fire retardant performance, harmful gas production under high temperature, low aging resistance, low weather resistance, high resilience during construction, and the like of organic materials such as EPS and XPS are overcome. With the mortar provided by the invention, insulation mortar comprehensive performances and construction performance are improved. On the basis of good safety, energy-saving and comfortableness are realized. With the mortar, building, human, and nature are harmonious and unified.

Owner:宜昌恒达利新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com