A kind of ice flower crack coating and its preparation method and curing method

A crack coating, ice flower technology, applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high energy consumption, uneven ice cracks, and harsh curing conditions of ice crack coatings, and achieve fast speed. , The effect of uniform ice cracks and good plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

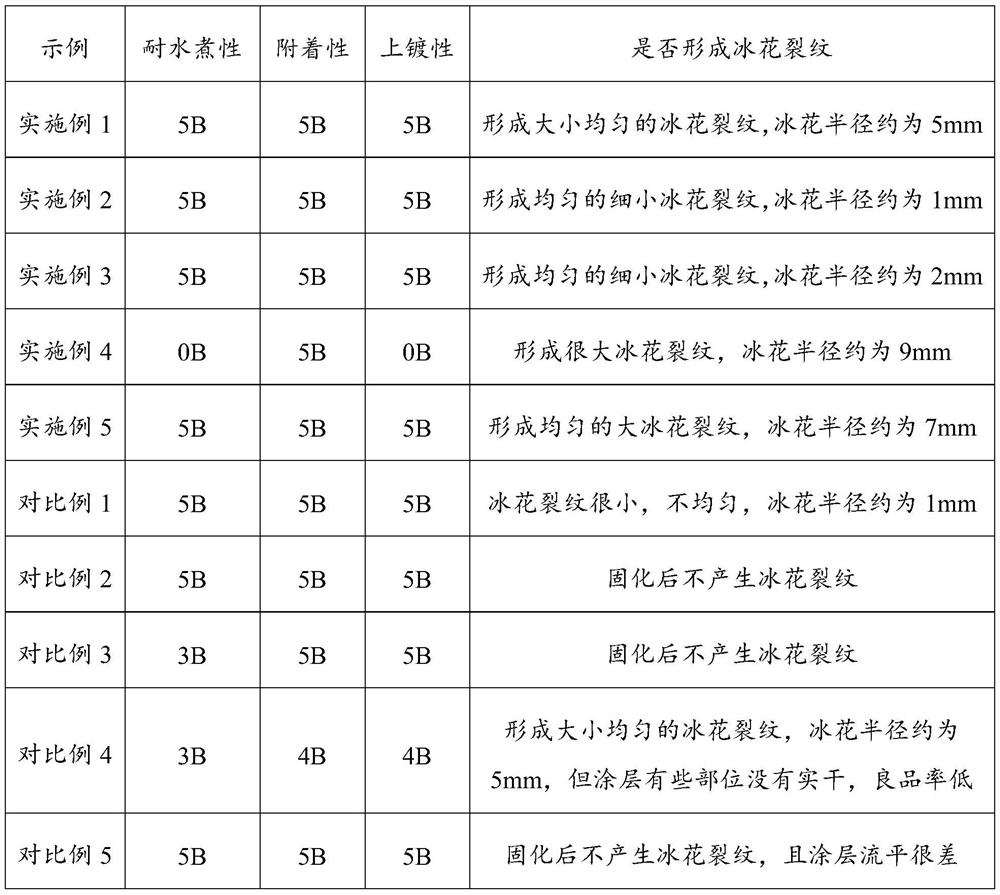

Examples

Embodiment 1

[0032] The present embodiment provides a coating crack Ice, 10kg including hexafunctional aromatic urethane acrylate (CN975), 22kg fatty acid modified epoxy acrylate (EB3701), 7kgHDDA, 3kgTPMTA, 10kg benzophenone, 1kg active amine 50kg and a mixed solvent (a mixed solvent comprises a mass ratio of 1: 1 ethyl acetate and butyl acetate).

[0033] Method for preparing the coating material comprises the steps of,

[0034] According to the above respective raw materials weighed mass, uniformly mixed to obtain a coating Ice cracks.

Embodiment 2

[0036] The present embodiment provides a coating crack Ice, 9kg including hexafunctional aromatic urethane acrylate (CN975), 24kg fatty acid modified epoxy acrylate (EB3701), 7kgHDDA, 3kgTPMTA, 10kg benzophenone, 1kg active amine 50kg and a mixed solvent (a mixed solvent comprises a mass ratio of 1: 1 ethyl acetate and butyl acetate).

[0037] Method for preparing the coating material comprises the steps of,

[0038] According to the above respective raw materials weighed mass, uniformly mixed to obtain a coating Ice cracks.

Embodiment 3

[0040] The present embodiment provides a coating crack Ice, 15kg including hexafunctional aromatic urethane acrylate, 30kg fatty acid modified epoxy acrylate, 8kgHDDA, 8kg benzophenone, 1kg and 50kg toluene active amine.

[0041] Method for preparing the coating material comprises the steps of,

[0042] According to the above respective raw materials weighed mass, uniformly mixed to obtain a coating Ice cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com