High-performance vacuum electroplating UV (Ultraviolet) coating and preparation method thereof

A vacuum electroplating, high-performance technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problem of difficulty in adapting to the high-performance requirements of mobile phone manufacturers, poor performance of vacuum electroplating UV coatings, vibration and wear resistance of mobile phone casings Achieve high construction yield, excellent performance effect, and good coloring effect without any problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

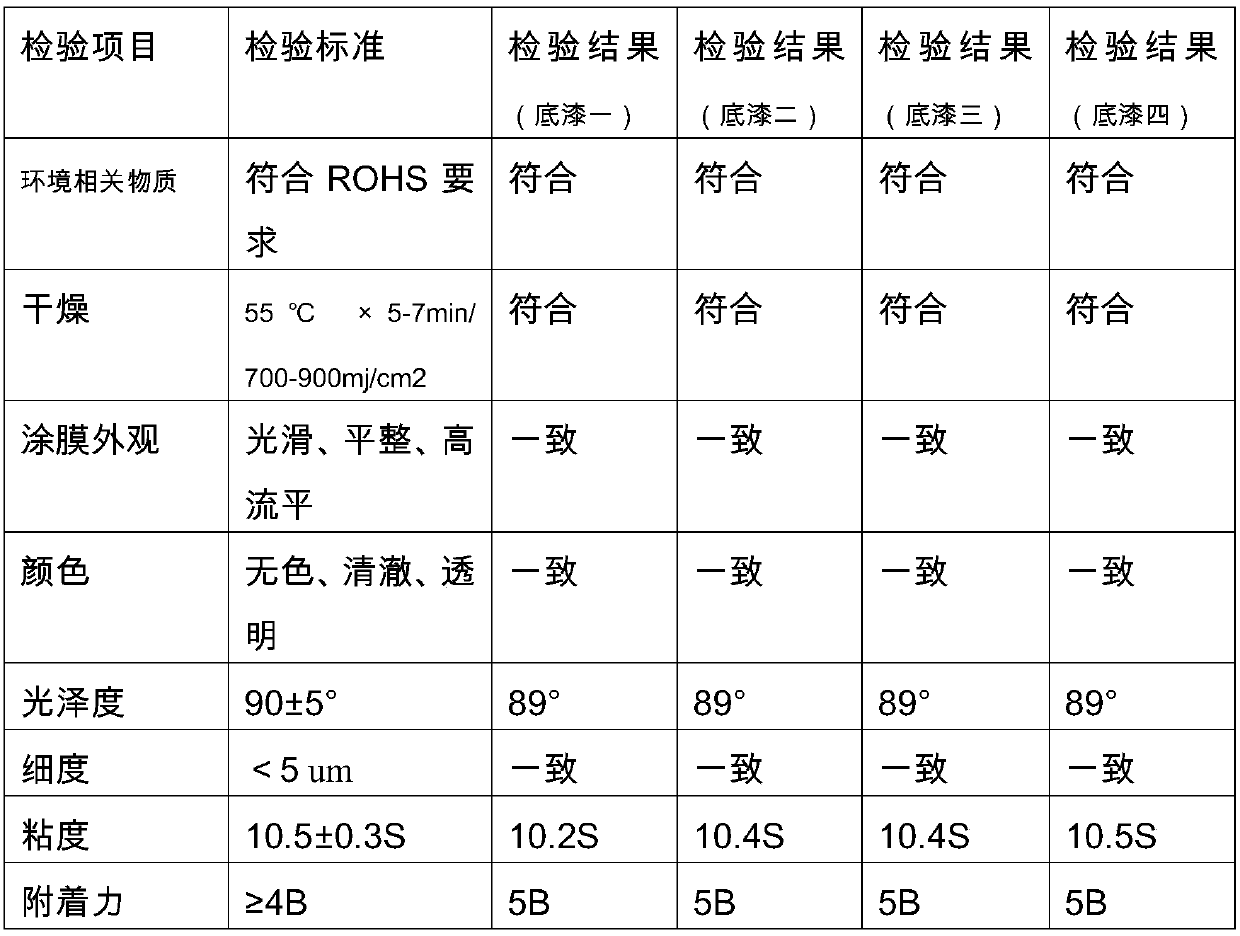

[0065] For the primer in the UV coating, its preparation method is as follows: in a certain volume of stirring dispersion tank, according to the weight ratio, add aliphatic polycarbonate type polyurethane acrylate resin (trade name Boxing B-221) 30 parts, (3) 5 parts of ethoxylated trimethylolpropane triacrylate, start stirring, and add 1.5 parts of photoinitiator 184 while dispersing at a low speed, and 0.2 parts of leveling agent acrylate (trade name BYK-358N) , and then add 24 parts of butyl ester in the mixed solvent, and disperse for 30 minutes at a speed of 1000±50 rpm, so that the material is completely dispersed; then add 13 parts of ethyl ester in the mixed solvent, methyl isobutyl ketone 18 parts, after stirring for 5-8 minutes at a speed of 600±50 rpm, stop the dispersion, check the viscosity and other items of the primer coating, filter it with an 800-mesh filter bag and pack it after passing the test.

Embodiment 2

[0067] For the primer in the UV coating, its preparation method is as follows: in a certain volume of stirring dispersion tank, according to the weight ratio, add aliphatic polycarbonate type polyurethane acrylate resin (trade name Boxing B-221) 35 parts, (3) 8 parts of ethoxylated trimethylolpropane triacrylate, start stirring, and add 1.5 parts of photoinitiator 184 while dispersing at a low speed, and 0.3 parts of leveling agent acrylate (trade name BYK-358N) , and then add 24 parts of butyl ester in the mixed solvent, the speed is 1000±50 rpm, disperse for 30 minutes, so that the material is completely dispersed; then add 15 parts of ethyl ester and 18 parts of methyl isobutyl ketone in the solvent After stirring for 5-8 minutes at a speed of 600±50 rpm, stop the dispersion, check the viscosity and other items of the primer coating, filter it with an 800-mesh filter bag and pack it after passing the test.

Embodiment 3

[0069] For the primer in the UV coating, its preparation method is as follows: in a certain volume of stirring dispersion tank, according to the weight ratio, add aliphatic polycarbonate type polyurethane acrylate resin (trade name Boxing B-221) 40 parts, (3) 8 parts of ethoxylated trimethylolpropane triacrylate, start stirring, and add 2 parts of photoinitiator 184 while dispersing at a low speed, 0.2 part of leveling agent acrylate (trade name BYK-358N) , and then add 28 parts of butyl ester in the mixed solvent, and disperse for 30 minutes at a speed of 1000±50 rpm, so that the material is completely dispersed; then add 16 parts of ethyl ester and 21 parts of methyl isobutyl ketone in the solvent After stirring for 5-8 minutes at a speed of 600±50 rpm, stop the dispersion, check the viscosity and other items of the primer coating, filter it with an 800-mesh filter bag and pack it after passing the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com