Patents

Literature

85results about How to "Fast plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

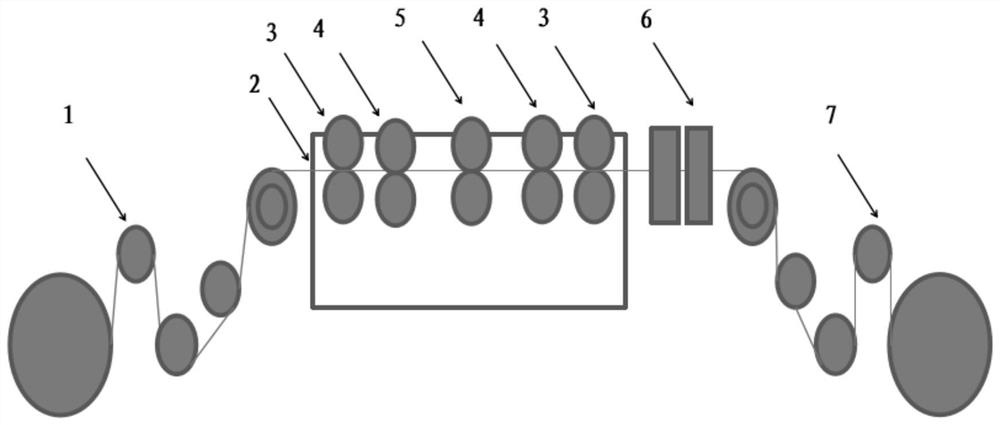

Method for preparing solar array electrode by electro-brush plating

ActiveCN101789468AImprove conversion efficiencyImprove collection effectFinal product manufactureSemiconductor devicesElectrical resistance and conductanceSilicon solar cell

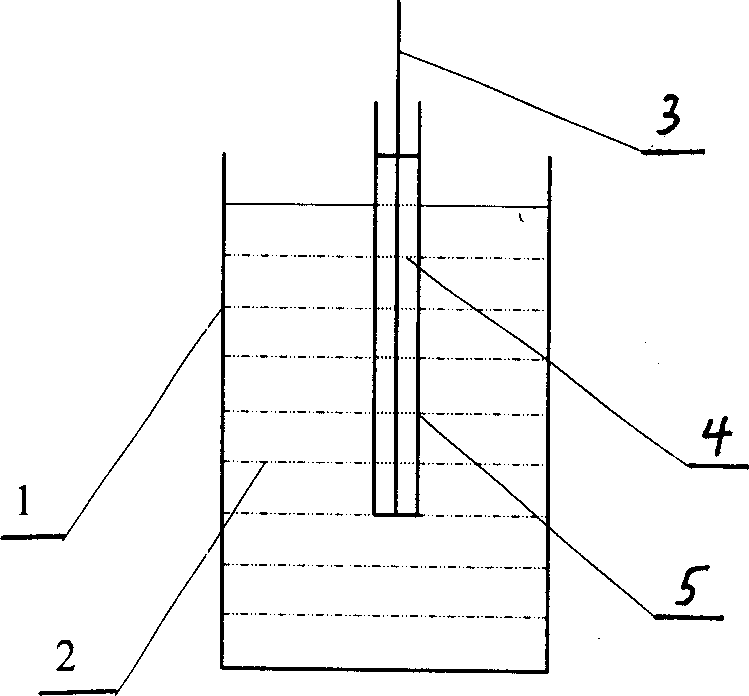

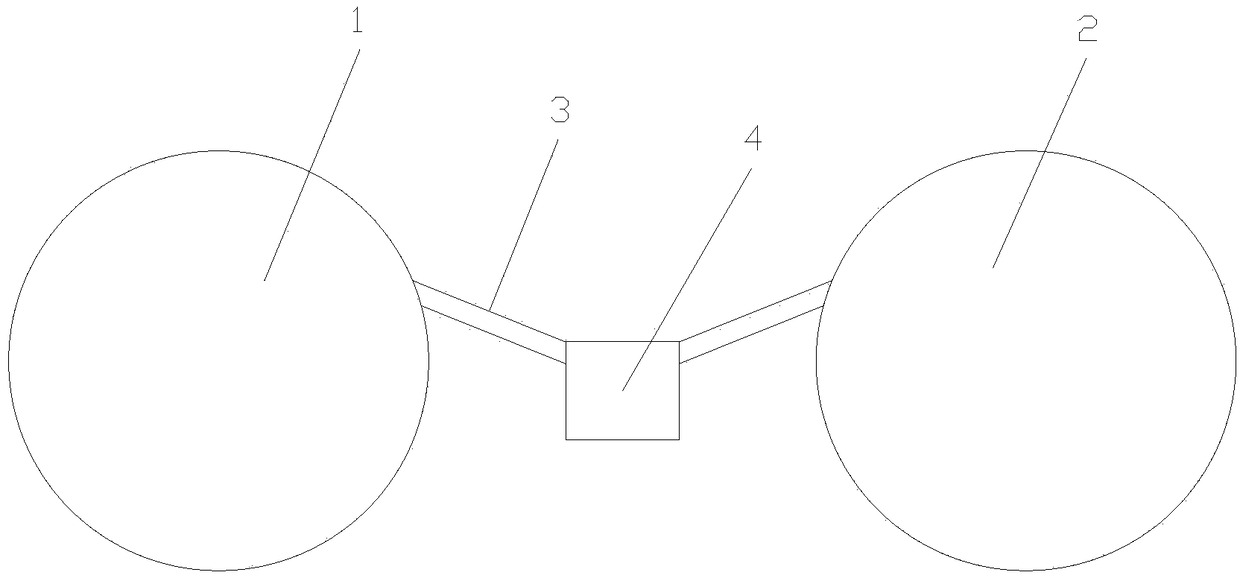

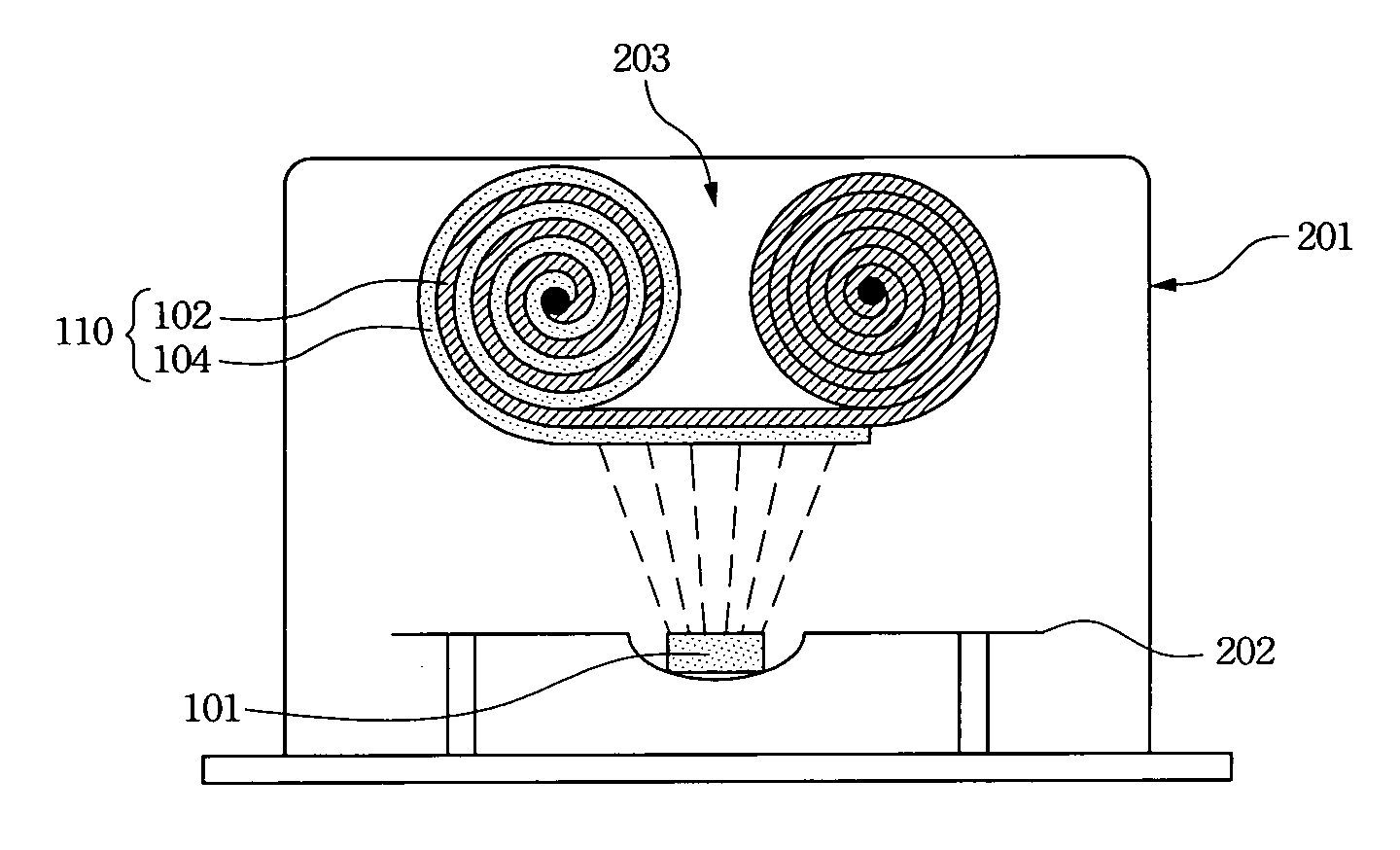

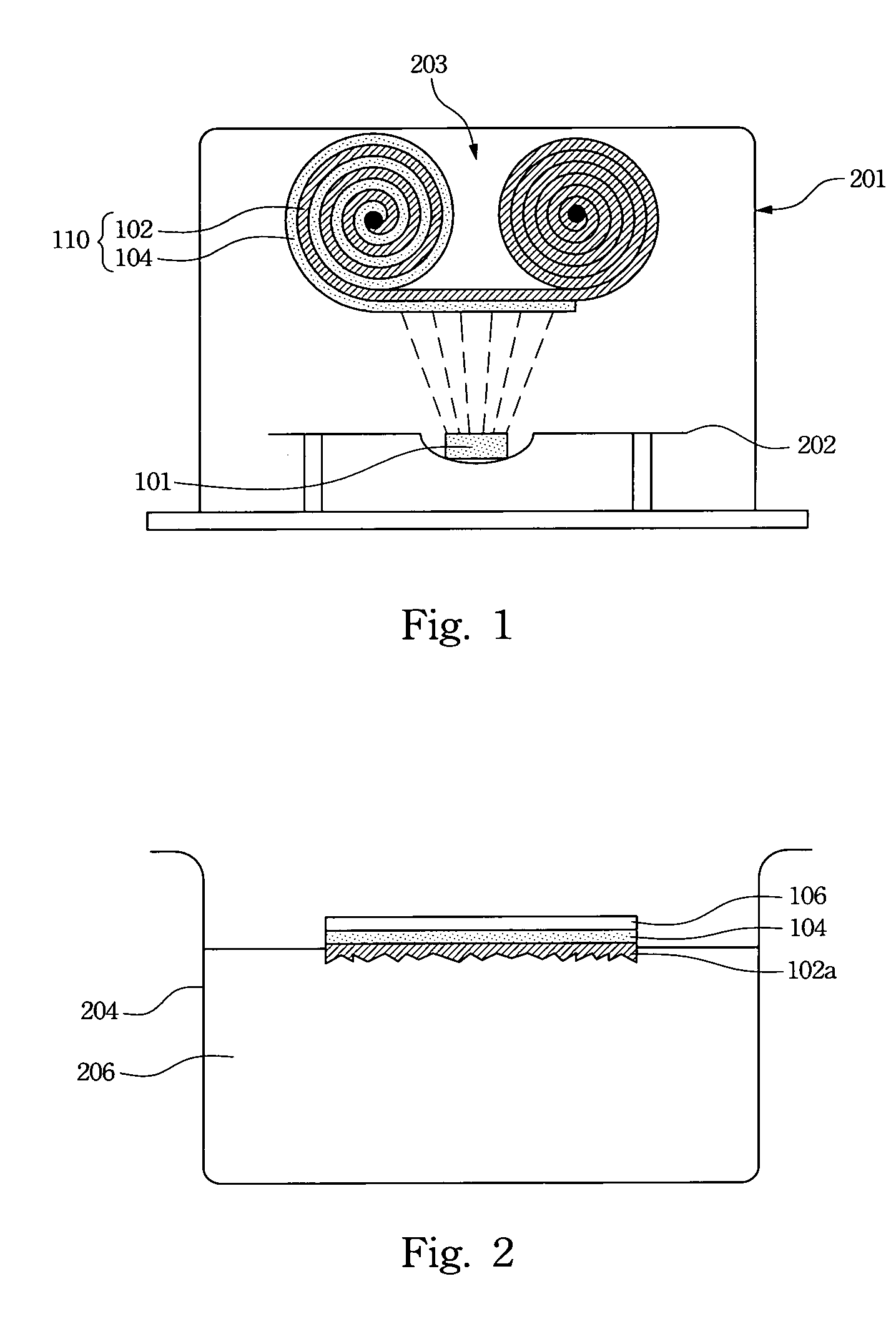

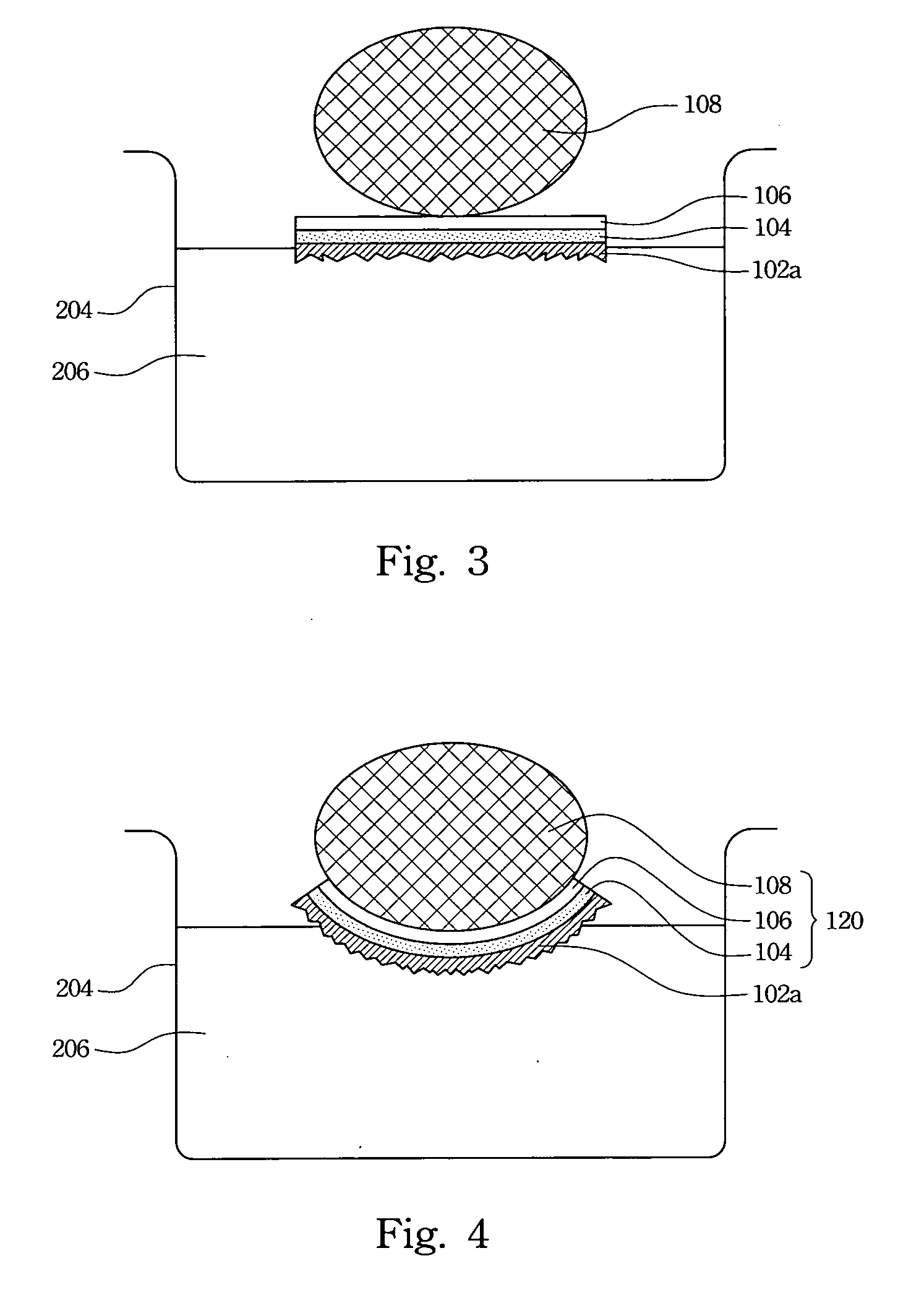

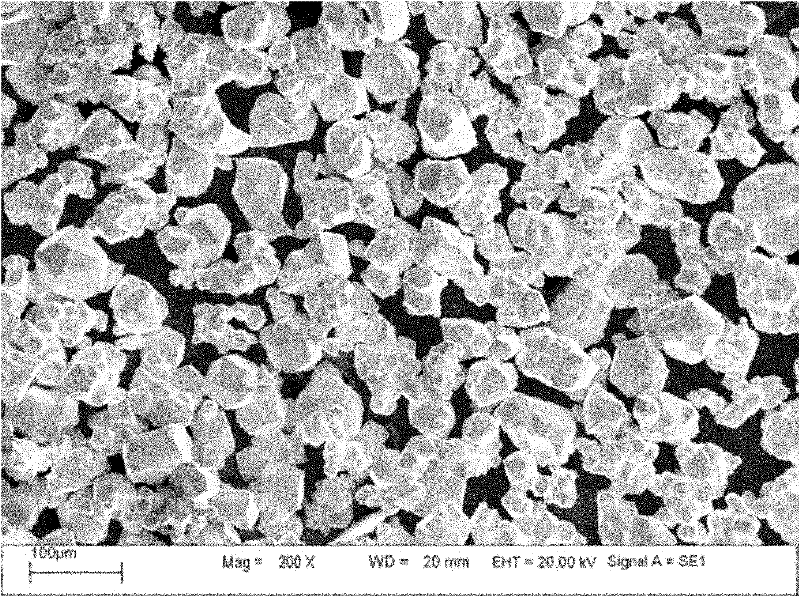

The invention discloses a method for preparing a silicon solar array electrode by electro-brush plating, which comprises the steps of: (1) coating of a protective film; (2) laser grooving; (3) surface activation treatment; (4) electro-brush plating: a general electroplating power supply is adopted; a cathode of the power supply is connected with a pretreated silicon semiconductor; an anode of the power supply is connected with an plating pen immersed with a plating solution; the power supply is started; the electro-brush plating is carried out on the plating pen on the surface of the pretreated silicon semiconductor; and the plating pen is a mobile plating pen or a pictographic plating pen; and (5) the removal of the protective film. The invention obviously enhances the production efficiency by adopting the electro-brush plating and realizes the preparation of the array electrode within a shorter time; the prepared electrode is uniform and bright; at the same time, the electroplating bath solution has easy maintenance; the electrode has high bonding strength with a base body and plating layers have high bonding force, thereby reducing contact resistance between the base body and a conducting wire; and the invention has good automatic degree, high electroplating speed, simple technological operation, easy mastery, relatively lower cost, high efficiency and less required tooling equipment.

Owner:SOUTH CHINA NORMAL UNIVERSITY

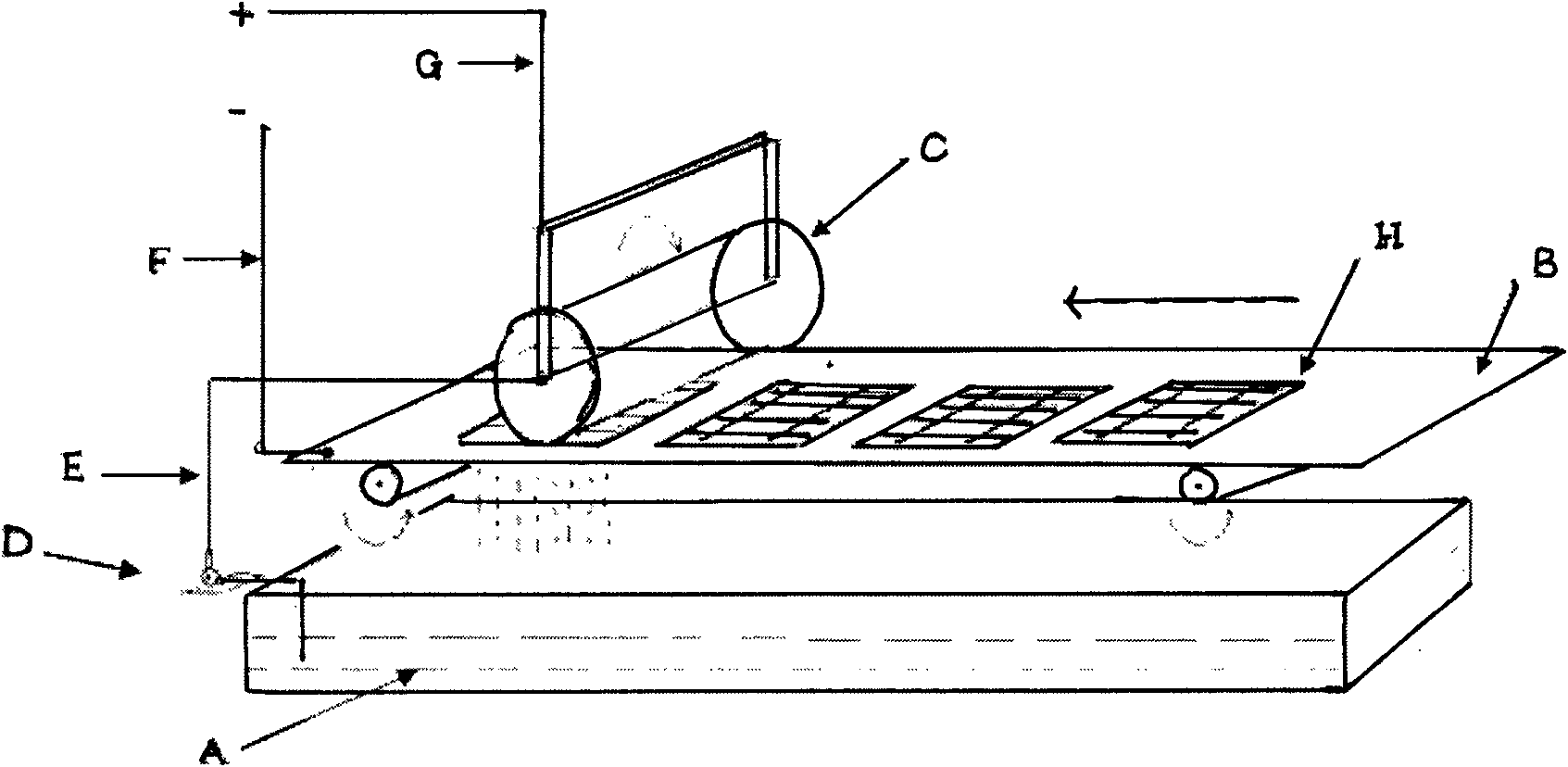

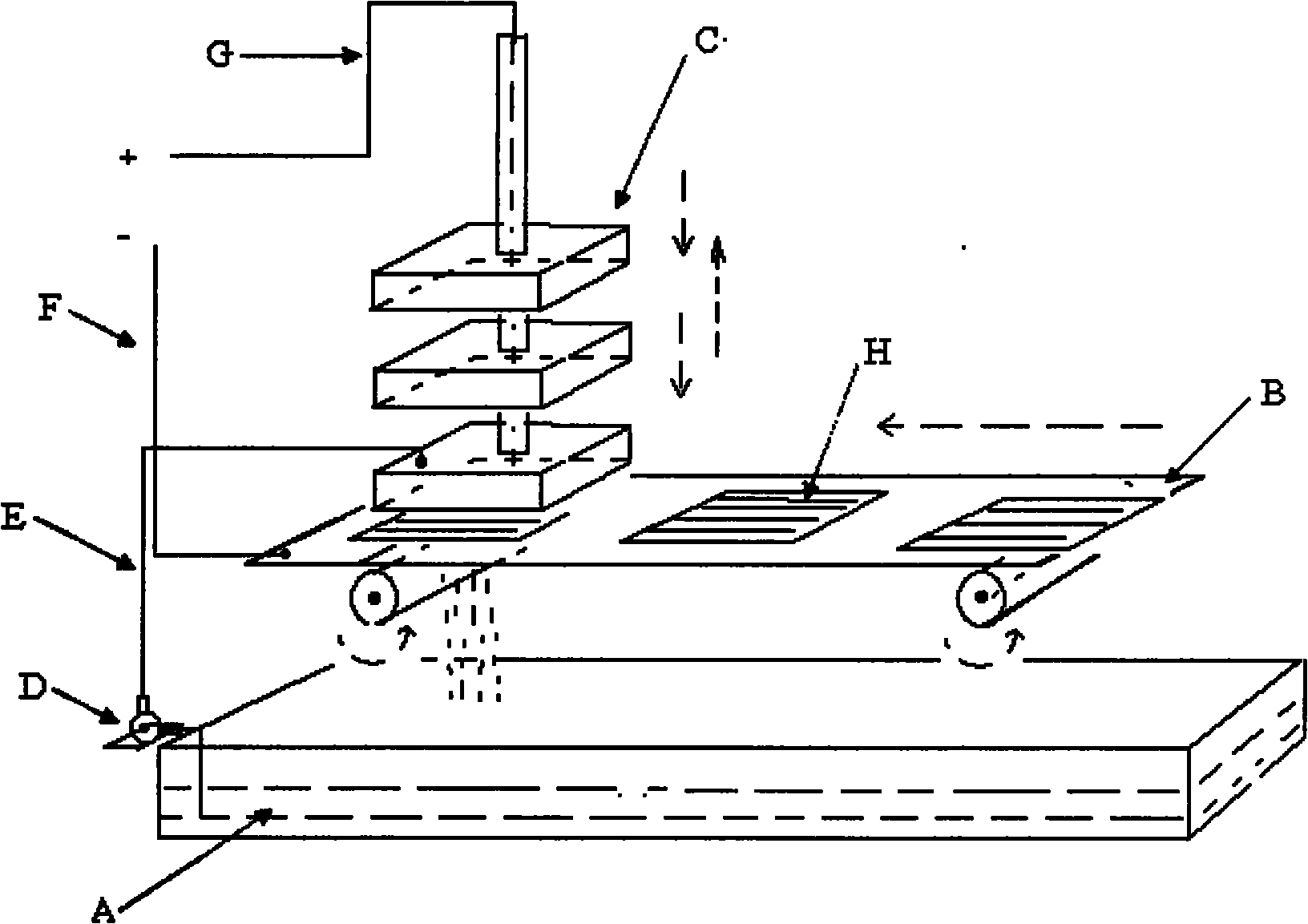

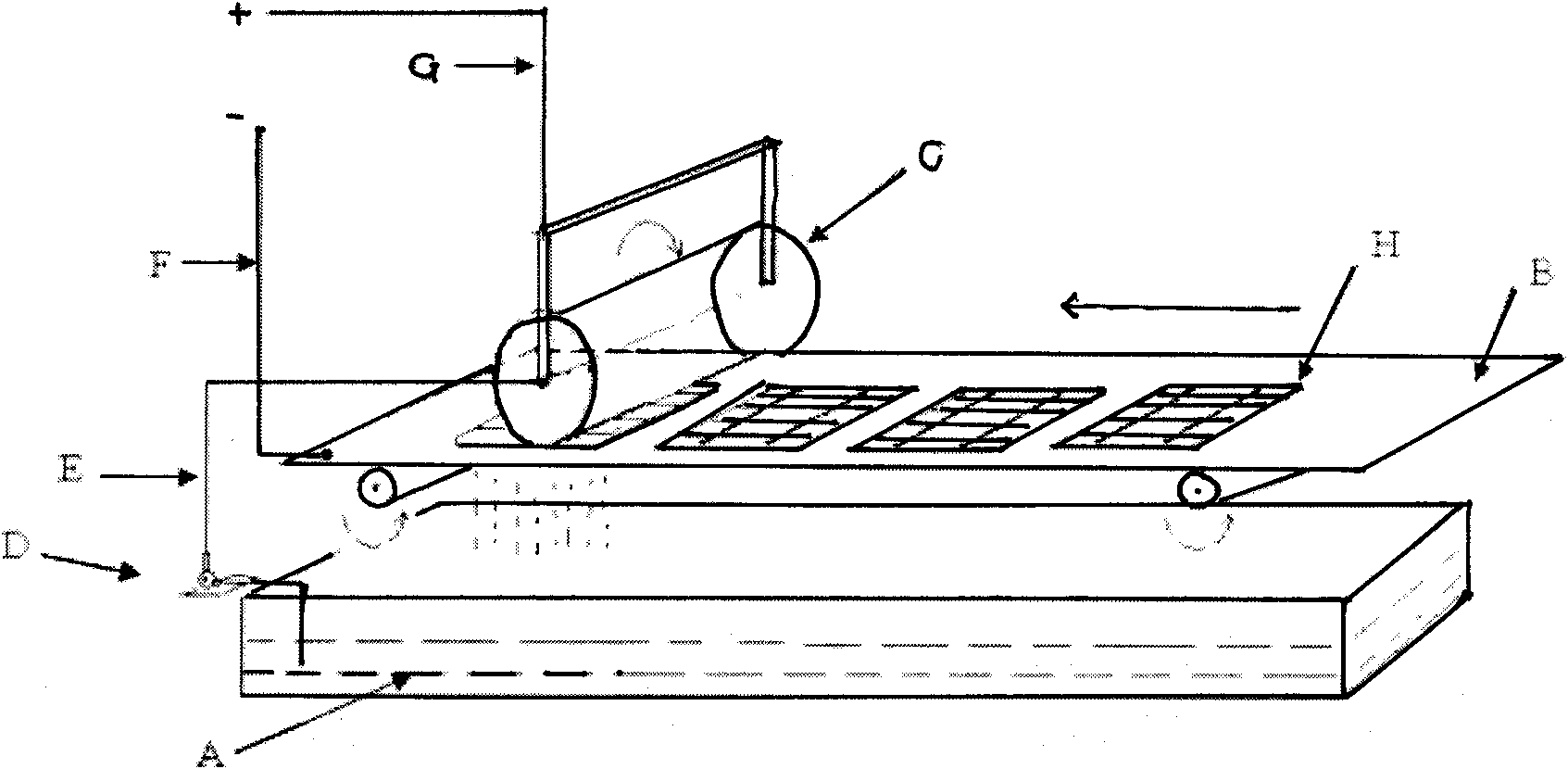

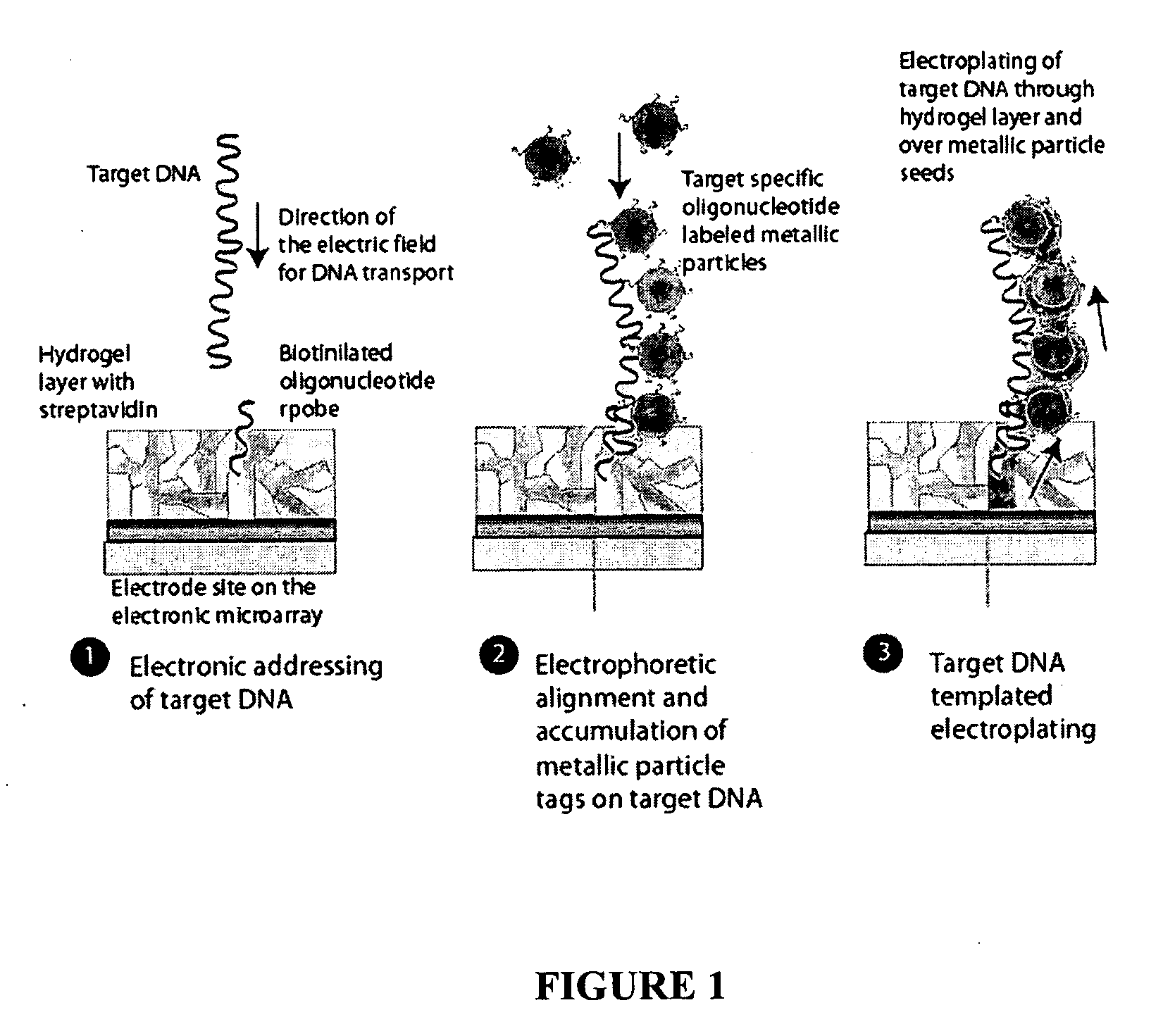

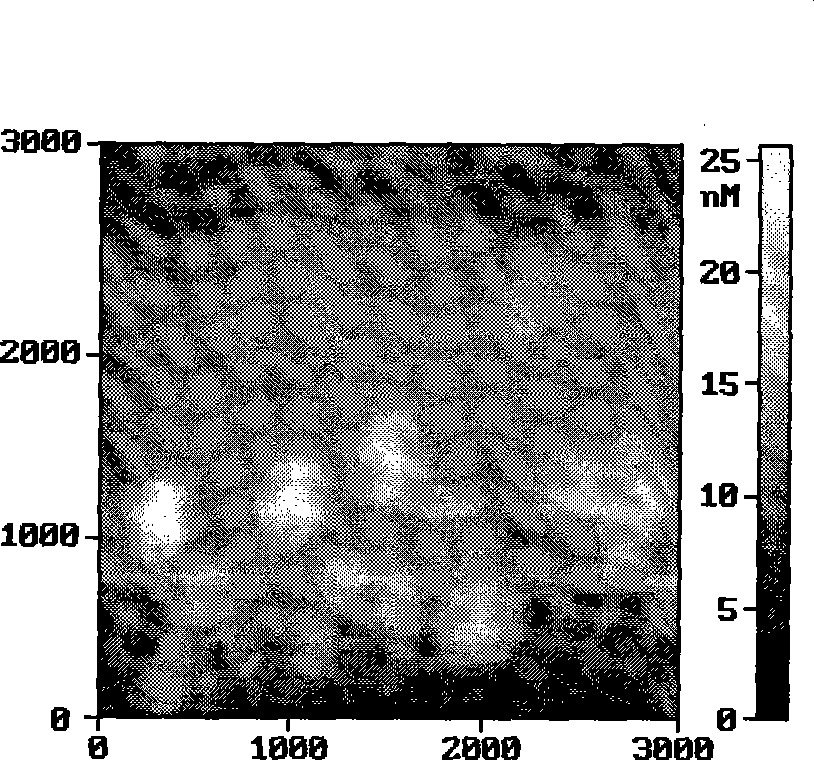

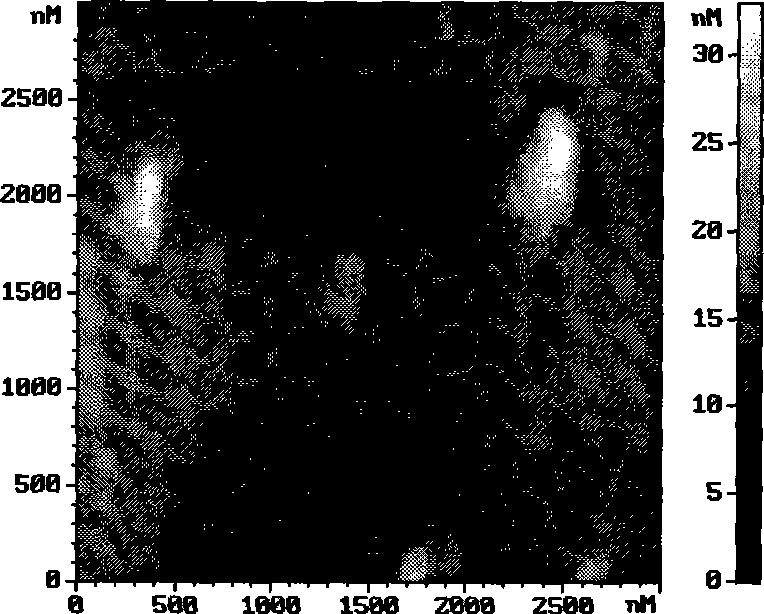

Nanoscale electronic detection system and methods for their manufacture

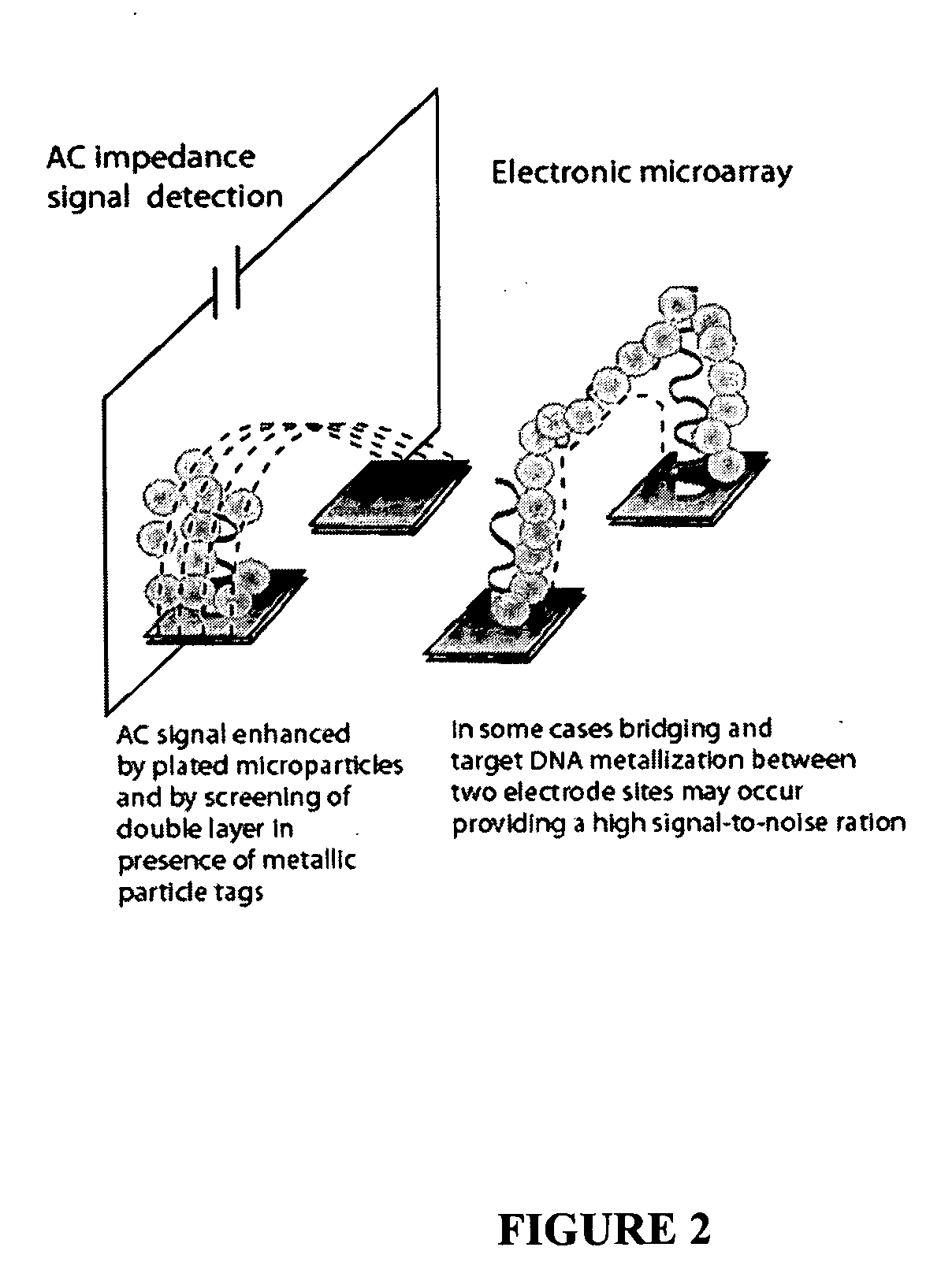

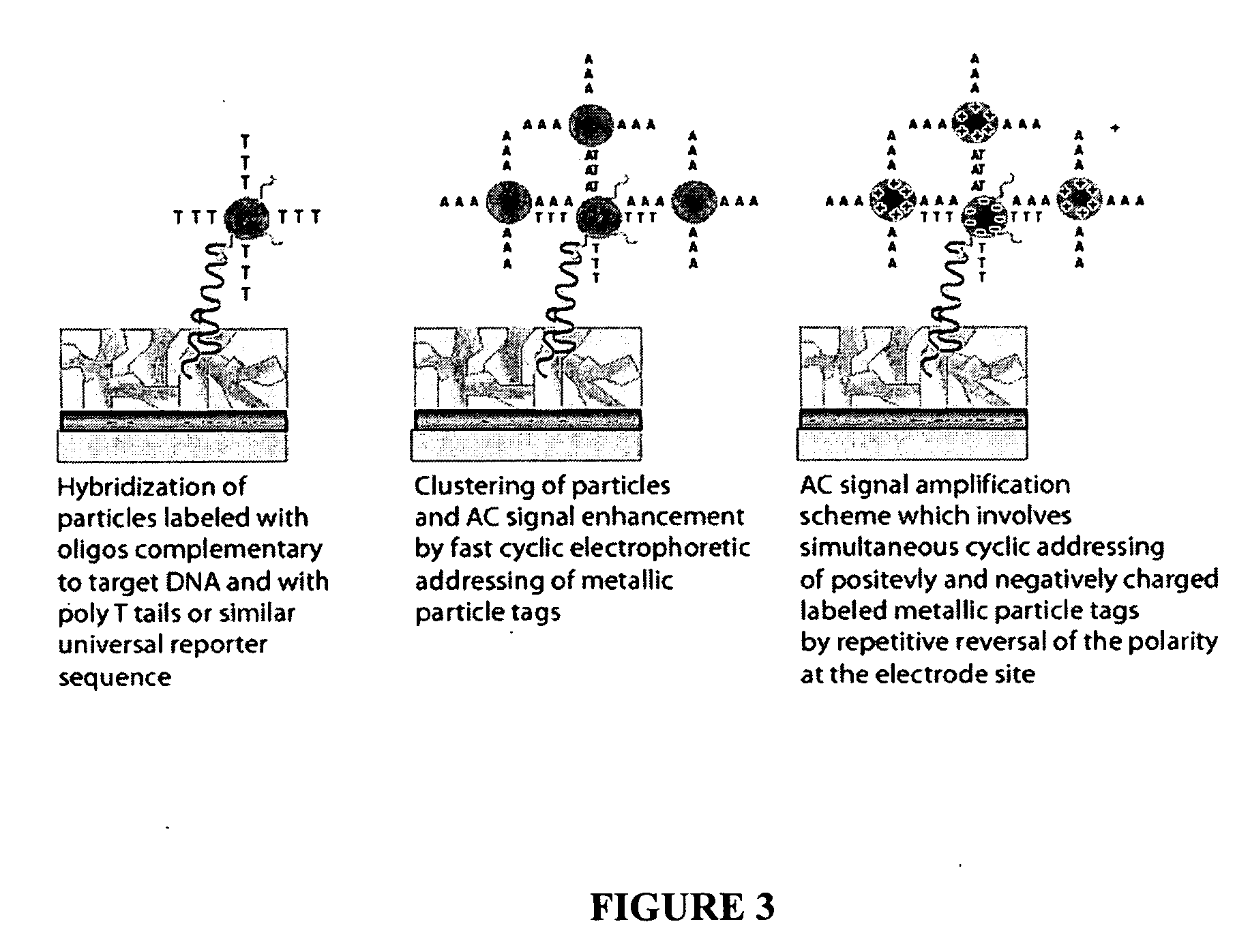

InactiveUS20060134657A1Extraordinary signal-to-noise ratioFast platingMicrobiological testing/measurementMaterial analysis by electric/magnetic meansAc impedanceBiology

A new, extremely sensitive, and rapid electronic detection method for direct detection of hybridized genomic targets to specific probes on the microarray is proposed. The method consists of fast electronic accumulation of the DNA target on a particular electrode site at the micro-electrode array, sequential electronic hybridization of oligonucleotide labeled metallic (nano)particles on the target DNA and monitoring the electrochemical AC impedance changes at the electrode site. The method is enhanced by electroplating over the DNA target which serves as the metallization template and over the particles which provide seeds for rapid electroplating. The AC impedance changes are monitored during the electroplating over the DNA target and between the array electrodes sites. The signal in the absence and presence of the target DNA is a difference between “no connection” and a “short” between the array electrodes

Owner:NANOGEN INC

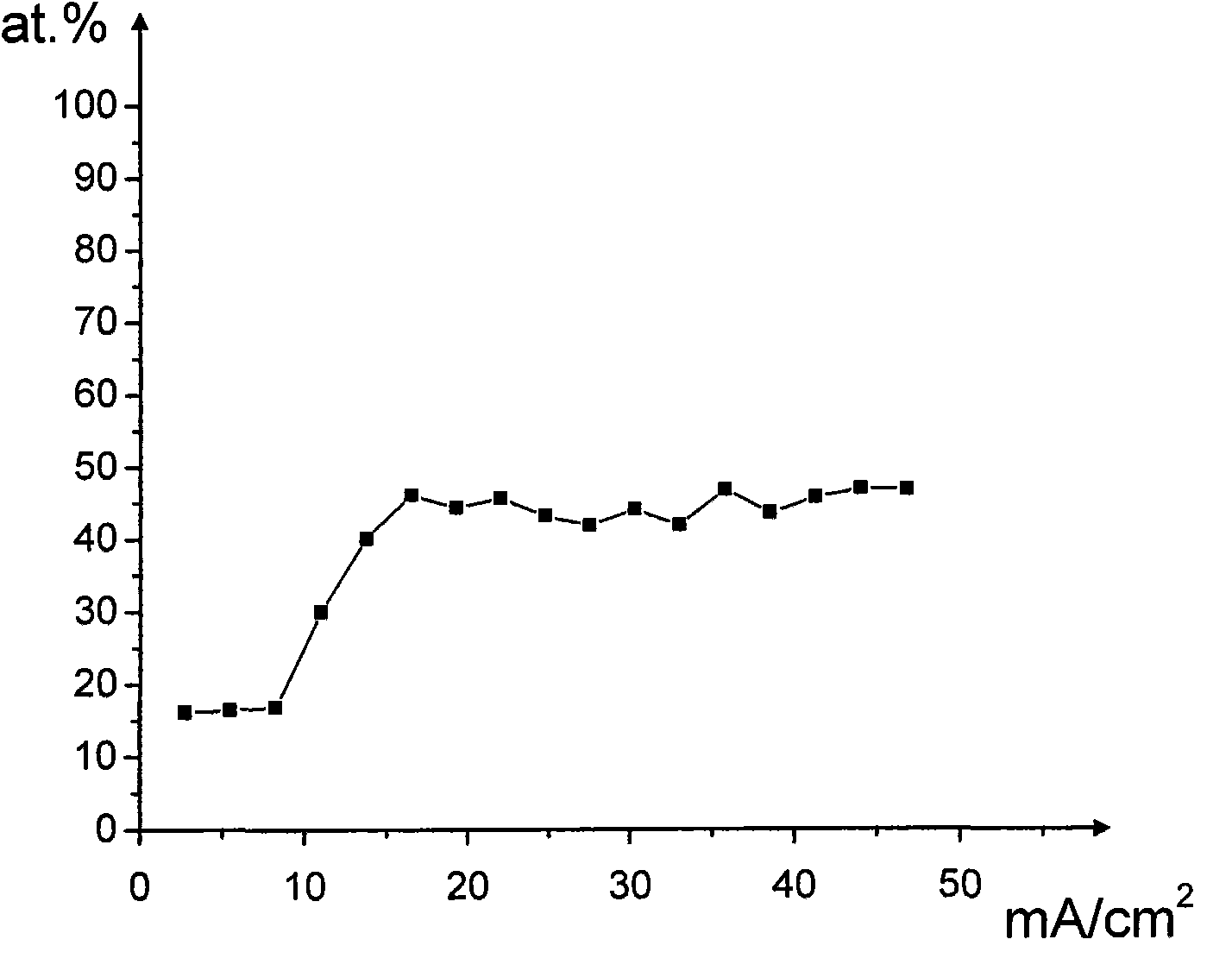

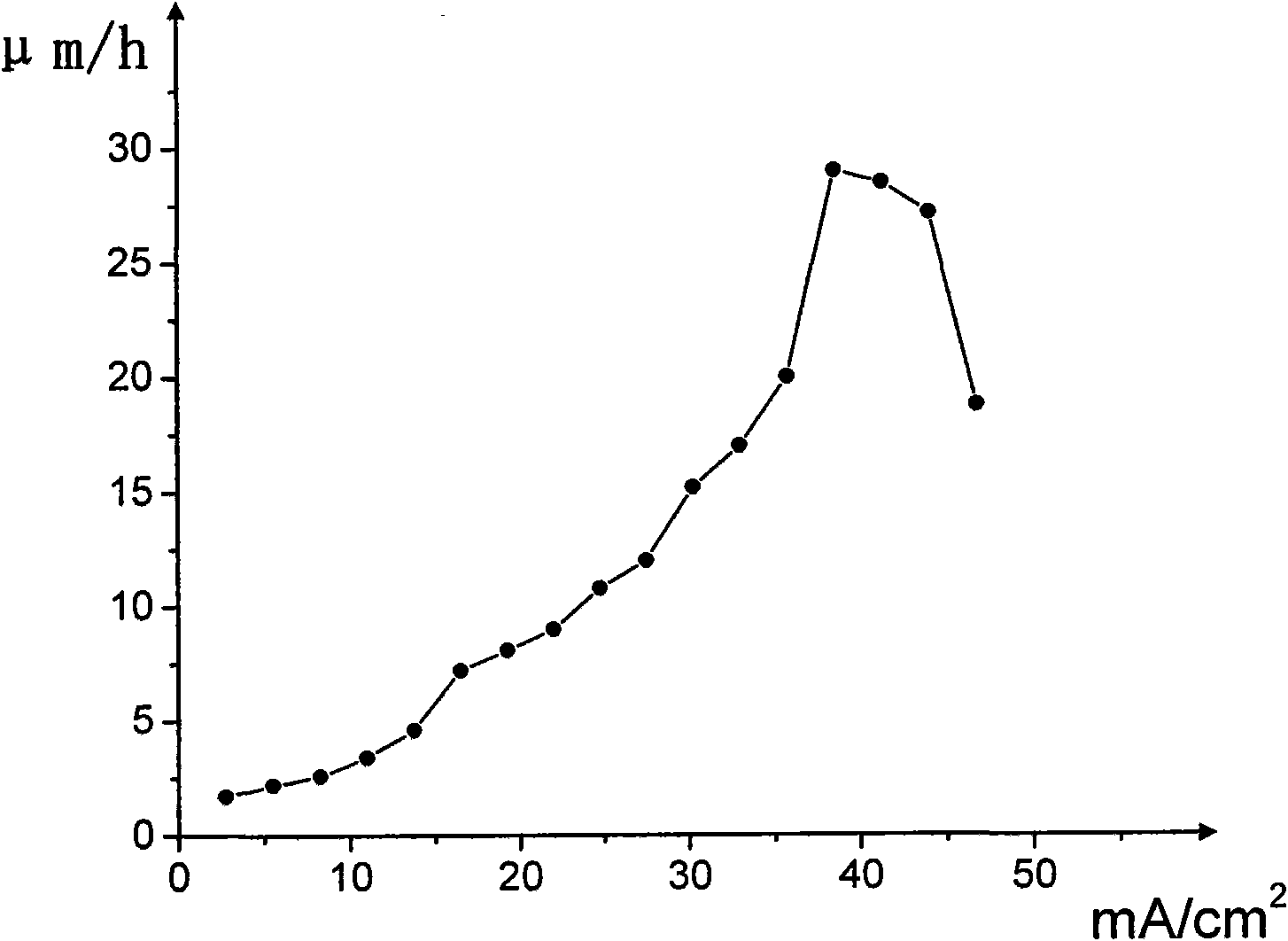

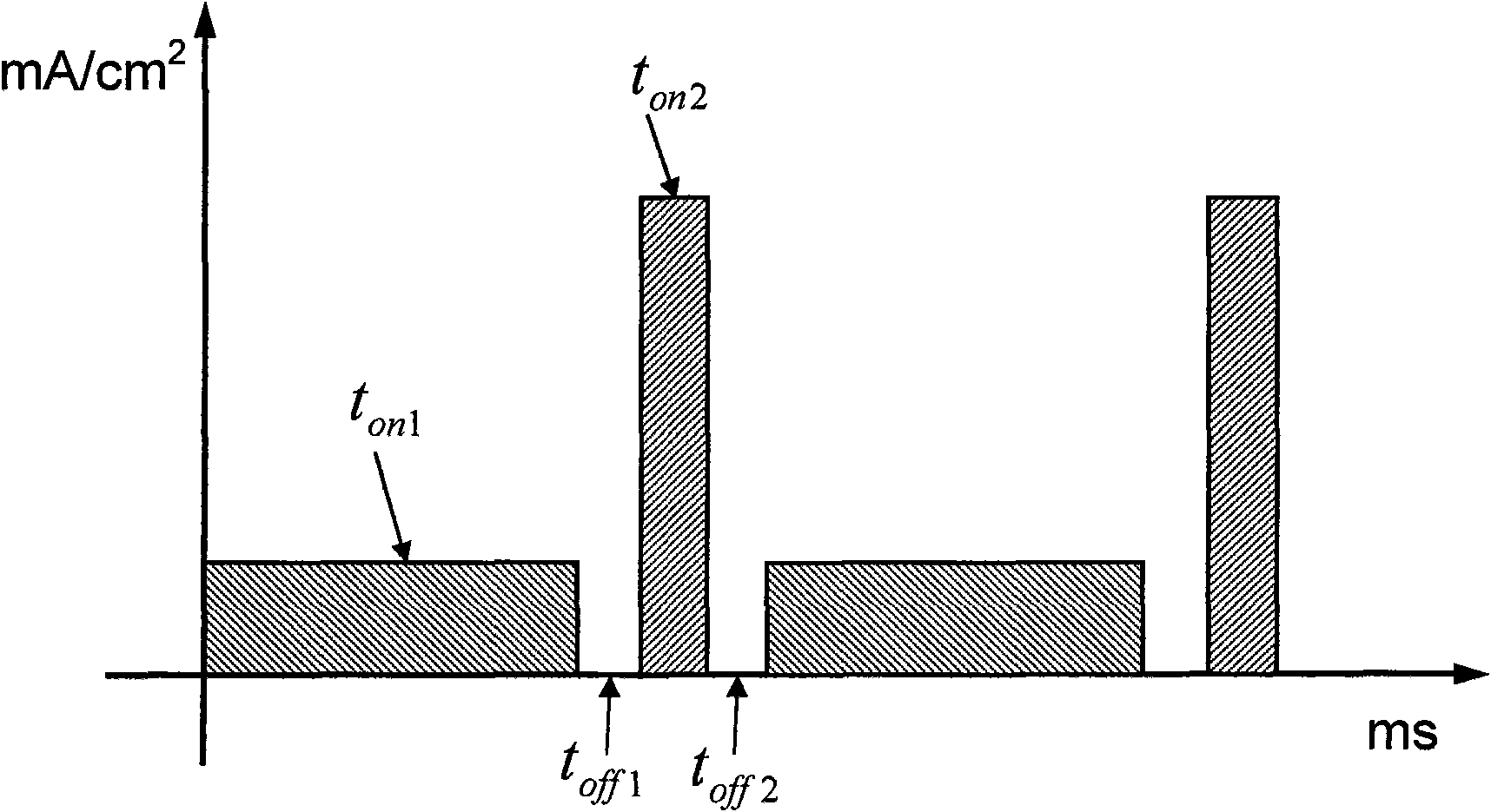

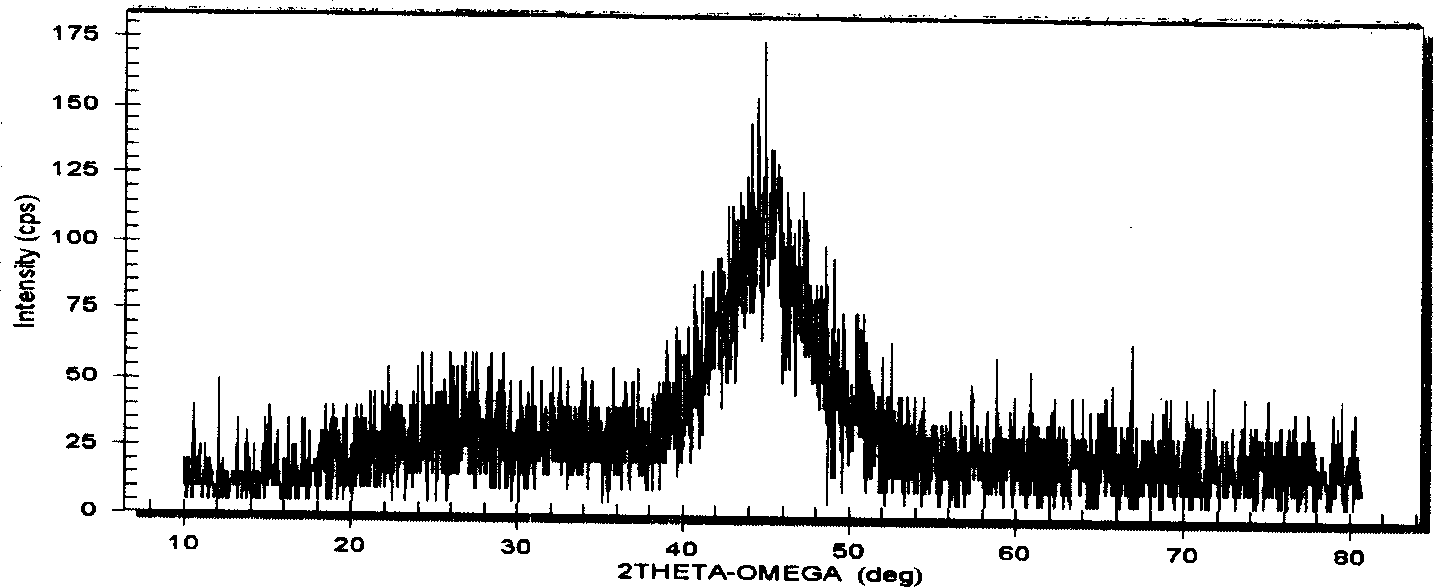

Co-deposition electroplating method with cyanogen-free Au-Sn alloy electrolyte

The invention relates to a co-deposition electroplating method for preparing Au-Sn alloy on an electroplating substrate and a cyanogen-free Au-Sn alloy electrolyte. The wave forms of electroplating current pulses are forward variable-amplitude pulses, namely that two different forward square wave pulses exist in one period, and the peak values and the conducting time of the electroplating current pulses respectively correspond to peak value current density and time which are required for generating Au5Sn and an Au-Sn alloy phase in a plating layer. In the electrolyte, sodium sulfite is adopted as a main complexing agent and ethylene diamine tetraacetic acid is adopted as an auxiliary complexing agent for the gold ion complexing agent, potassium pyrophosphate is used as a tin ion complexing agent, hydroquinone is used as an antioxidant, and the pH value of the electrolyte is from 8 to 9. When the method is used for preparing Au-30at.%Sn eutectic plated layer through electroplating, the plating speed reaches 13 mum / hour, the electrolyte is stable, the operation is simple, and the gold and tin content in the plated layer is easy to control. The method can be applied in microelectronics and photoelectron industry for connecting and encapsulating LED chips, connecting flip chips, forming welding pads or patterns on the surface of semiconductor devices or similar devices, etc.

Owner:DALIAN UNIV OF TECH

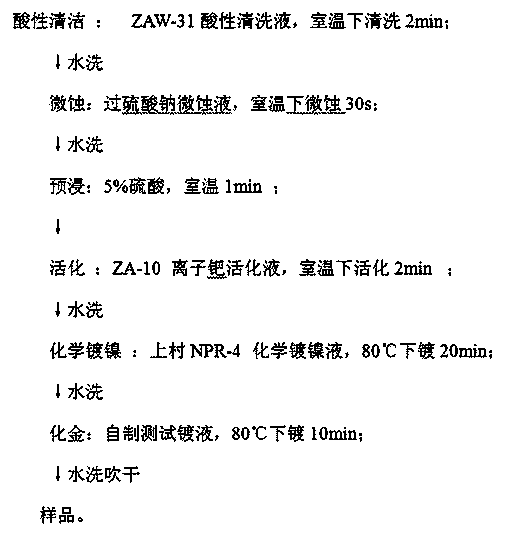

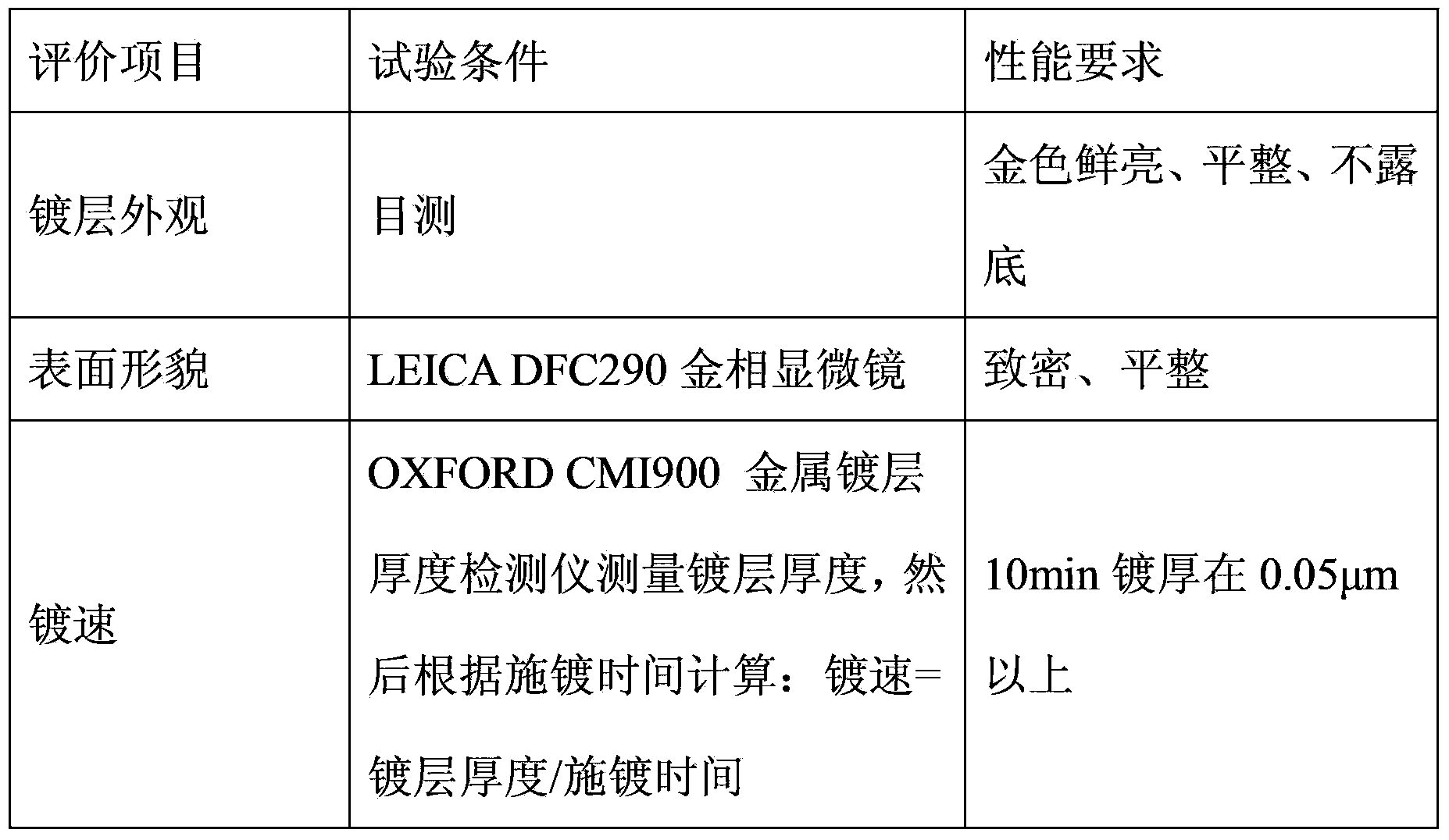

Environmentally-friendly chemical gilding liquid

InactiveCN104109848APlating solution is stableLong storage periodLiquid/solution decomposition chemical coatingIonHeavy metals

The invention discloses an environmentally-friendly chemical gilding liquid. The environmentally-friendly chemical gilding liquid comprises 0.5-5g / L of non-cyanide gold salt, 5-30g / L of gold ion complexing agents, 5-20g / L of an impurity screener, 0.1-10g / L of a stabilizing agent and 15-35g / L of a pH buffering agent. The non-cyanide gold salt is sodium gold sulfide or auric-sodium chloride, a sulfite is used as the main complexing agent, and through combined action of the auxiliary complexing agent, the impurity screener and the stabilizing agent, long-term stabilization of production and storage is realized. The environmentally-friendly chemical gilding liquid does not adopt cyanides and cyanogen-containing substances, does not contain limited heavy metals such as lead and cadmium, has the characteristics of long storage life, high continuous production stability, good weldability, bright color and good corrosion resistance and weatherability, can satisfy functional electron electroplating requirements and can be used as a decorative gilding liquid.

Owner:广东致卓环保科技有限公司

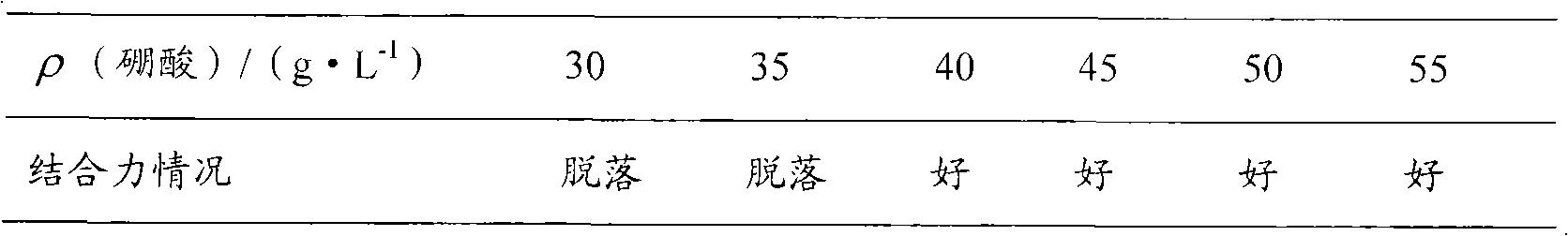

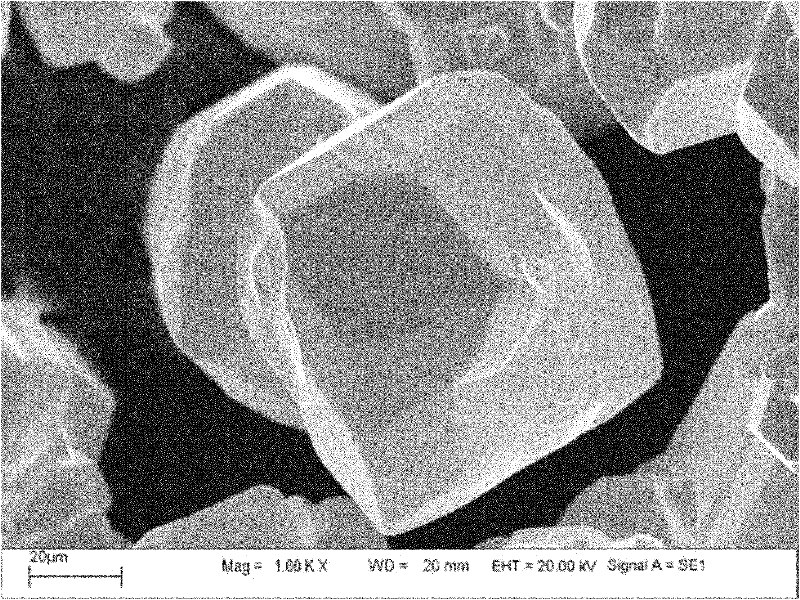

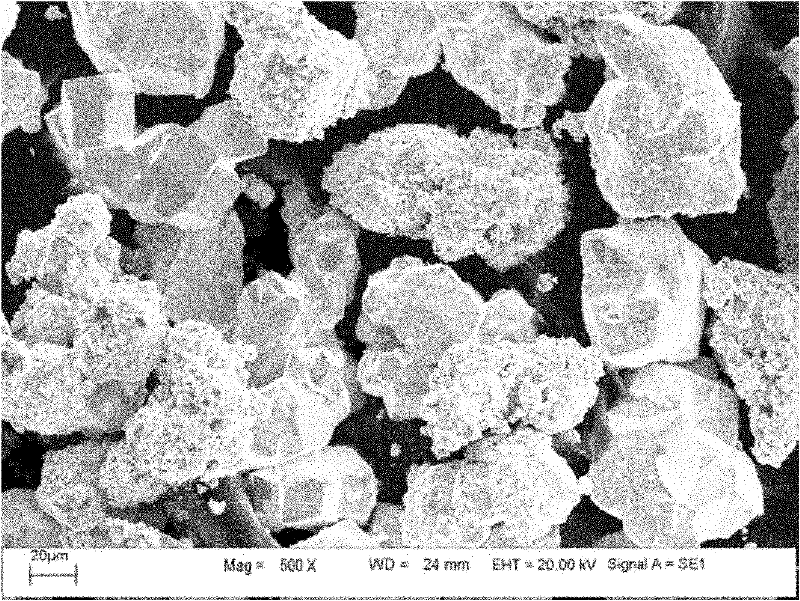

Method for electroplating steel strip with nickel

The invention relates to a method for electroplating steel strip with nickel, particularly for continuously electroplating perforated steel strip or punched steep strip used for manufacturing the electrode with nickel, aiming at solving the technical problem that the fast electroplated coating is not fine and smooth. Electroplating solution comprises NiSO4.7H2O of being more than 350 g / L and less than or equal to 550 g / L, 20-50 g / L of H3BO3, 5-30 g / L of anodal active agent and 0.2-0.8 g / L of lauryl sodium sulfate. The method for continuously electroplating steel strip with nickel has low cost and good cathodic reduction effect and ensures the fast electroplating speed and the fine and smooth electroplated coating.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Chemical gold plating solution

InactiveCN105543816AGolden appearanceBright colorLiquid/solution decomposition chemical coatingThioureaElectron

The invention relates to a chemical gold plating solution for quickly depositing a gold layer. The chemical gold plating solution comprises the following components: 0.5-3g / L of sodium gold sulfite (based on Au), 22-28g / L of sodium sulfite, 13-20g / L of sodium thiosulfate, 1-5g / L of triammonium citrate, 8-12g / L of borax, 0.1-5g / L of thiourea, and 0.01-0.09g / L of benzotriazole. The appropriate pH value of the plating solution is 6.5-7.2, and the appropriate temperature is 75-85 DEG C. The gold plating solution provided by the invention does not contain cyanide, is good in stability and high in plating speed, and can obtain a plated layer with thickness more than or equal to 0.4mu m in 20 minutes, the appearance of the plated layer is golden and bright in color, and the requirement of plating thick gold on most products can be met. The chemical gold plating solution not only can meet requirements of functional electron electroplating, but also can be used as a decorative gold plating solution.

Owner:HARBIN INST OF TECH AT WEIHAI

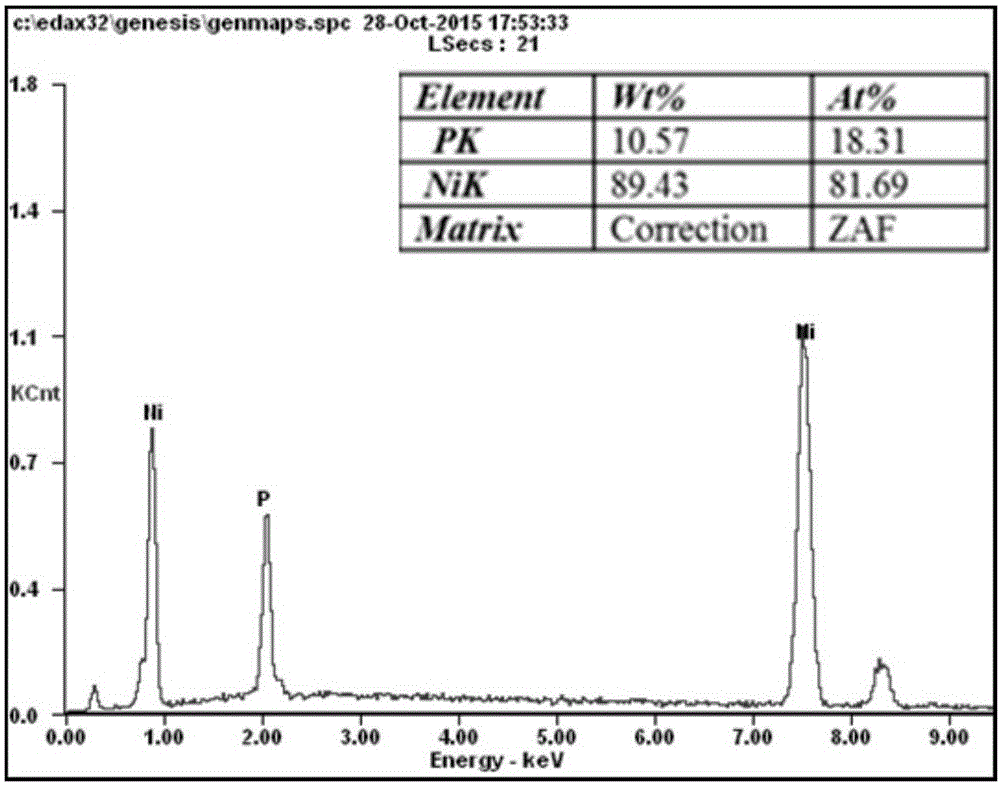

Chemical nickeling phosphorus alloy plating liquid and coating process thereof

InactiveCN1614088AFast plating speedFast platingLiquid/solution decomposition chemical coatingSodium acetateAcetic acid

The invention relates to a chemical Ni-P alloy-plating liquid and its process. The liquid is stable, works fast, has long service life, and does not contain chromium. So, it was widely used in industry. The Ni-P alloy coating is of fine corrosion-proof, containing 10-30g nickel sulfate, 20-40g sodium hypophosphite, 5-20g sodium acetate, 12-60g complexing agent and 0.002-0.01g complex stabilizer, with pH value of 4.5-5.0.

Owner:NANJING UNIV OF TECH

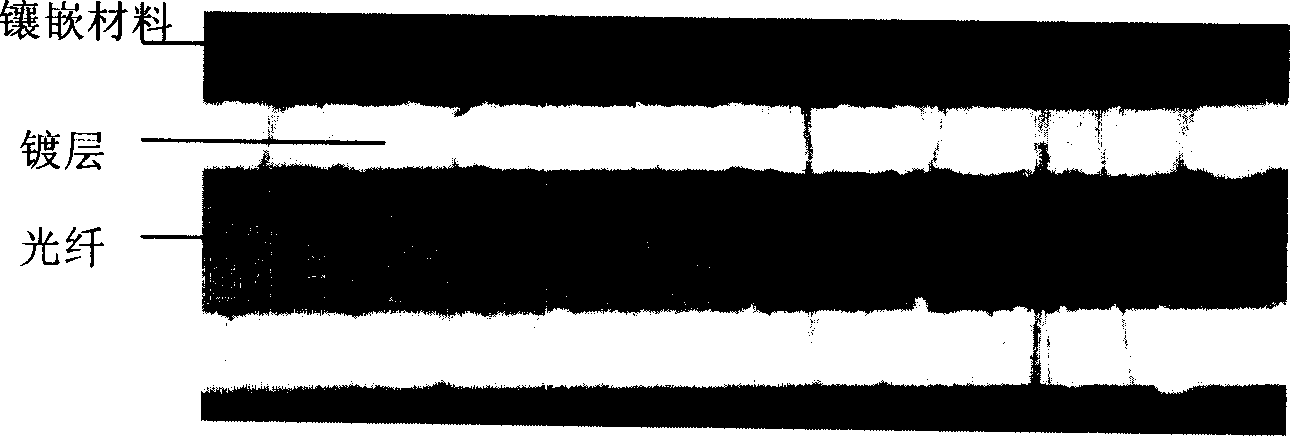

Process for coarsening-free chemical plating of nickel-phosphor alloy on optical fiber surface and chemical plating solution thereof

InactiveCN1827848AImprove bindingNo crack foundLiquid/solution decomposition chemical coatingChemical platingPhosphor

The invention discloses the optical fiber surface chemical plating nickel-phosphorus alloy technology and chemical plating solution, comprising the following steps: pretreating the optical fibre: removing protective coating, deoiling, hypersensitizing and activating, then carrying out chemical plating nickel alloy. The invention has the following advantages: 1 not needing coursing course; 2 fast speed; 3 good stability; 4 continuous coating; 5 simple device and low cost.

Owner:NANCHANG UNIV

A long-acting nano-micro composite layer synthesis liquid and its preparation method

InactiveCN102296286AFast platingStable bath performanceLiquid/solution decomposition chemical coatingDecompositionRare earth

The invention relates to long-acting nano-micron composite layer synthetic solution and a preparation method thereof. The synthetic solution is prepared from a main salt, a reducer, a main complexing agent, an auxiliary complexing agent, a buffer a, a buffer b, silicon carbide, magnesium oxide, a cationic surfactant, a nonionic surfactant, rare earth, a stabilizer, a promoter and deionized water.Compared with the normal conventional chemical composite plating solution, the synthetic solution has the advantages of high plating speed, stable performance of plating solution, no pollution and high economy. The synthetic solution can be recycled by only periodically replenishing loss; and the binding force of the synthetic solution and a matrix reaches up to over 400MPa, is 200MPa higher thanthat of the common alkaline self-decomposition plating solution and is 300Mpa higher than that of electroplating.

Owner:程绍鹏

Chemical nickel-plating method for capacitive touch screen indium tin oxide (ITO) wiring

InactiveCN102776495AFull coverageImprove performanceLiquid/solution decomposition chemical coatingSputteringIndium tin oxide

The invention provides a novel chemical nickel-plating method for capacitive touch screen indium tin oxide (ITO) wiring. Compared with the conventional vacuum sputtering technology, the novel chemical nickel-plating method is low in equipment investment, low in production cost and high in efficiency; and compared with the traditional chemical nickel-plating process on a nonmetallic matrix, the novel chemical nickel-plating method has high solution stability and selectivity. The novel chemical nickel-plating method comprises the following steps of: sequentially deoiling, etching, sensitizing, activating, reducing and performing chemical nickel-plating on the ITO film glass; and the key points are that the selectivity of the ITO film is improved during sensitization by adopting sensitizing solution containing Cu+, and the sensitizing solution is more stable than the traditional Sn2+ sensitizing solution; during etching, the etching process is stabilized by employing etching solution containing S2O82- or HS2O8-, and the etching effect is improved; and the chemical nickel-plating is performed at the low temperature of 55-65 DEG C, the plating solution is stable, and the plating layer is smooth and dense. The results prove that the method is easy to operate and high in speed; the ITO surface nickel layer is completely covered and has high adhesive force, and the glass matrix is not covered by the nickel layer and has high selectivity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

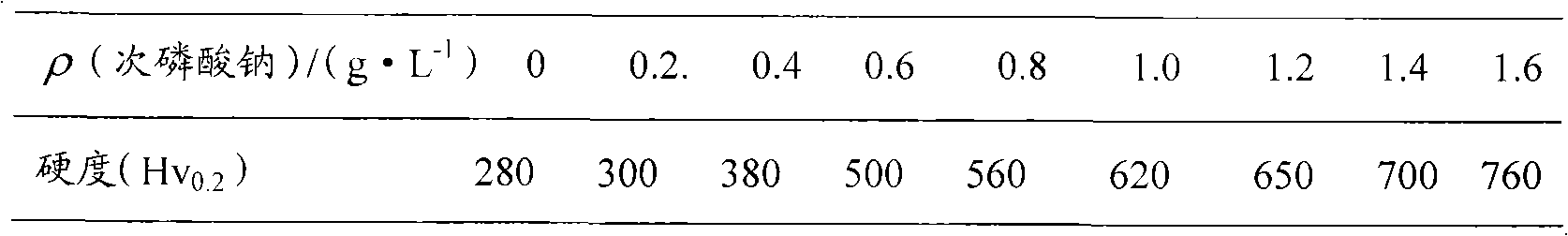

Nickel-silicon carbide composite plating solution for electroplating

The invention discloses a nickel-silicon carbide composite electroplate liquid, which comprises 300 to 400 g / L of nickel sulfamic acid, 40 to 60 g / L of boric acid, 0.7 to 1.0 g / L of sodium hypophosphite and 20 to 30 g / L of silicon carbide, wherein the pH value of the electroplate liquid is between 4.3 and 4.5 and the temperature of the electroplate liquid is between 50 and 55 DEG C. The nickel-silicon carbide composite electroplate liquid has the advantages of high hardness and quick plating speed.

Owner:薛玉田

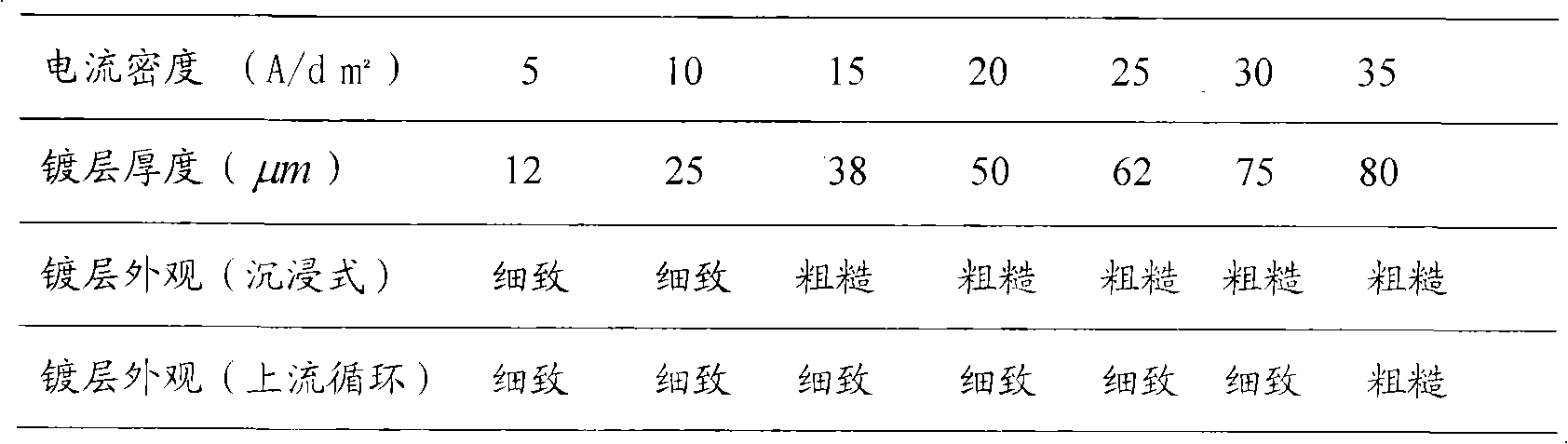

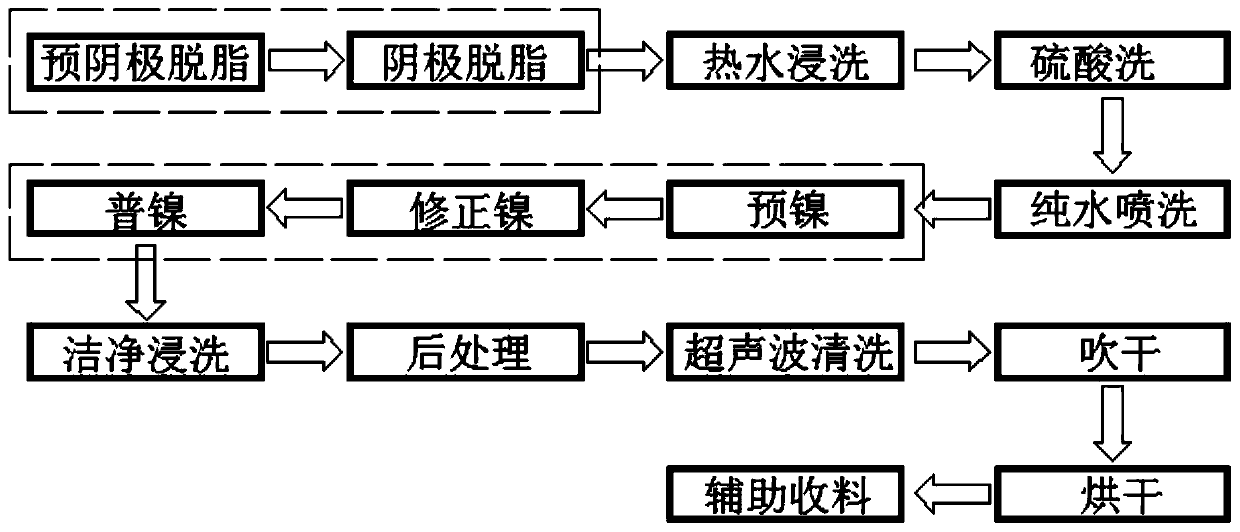

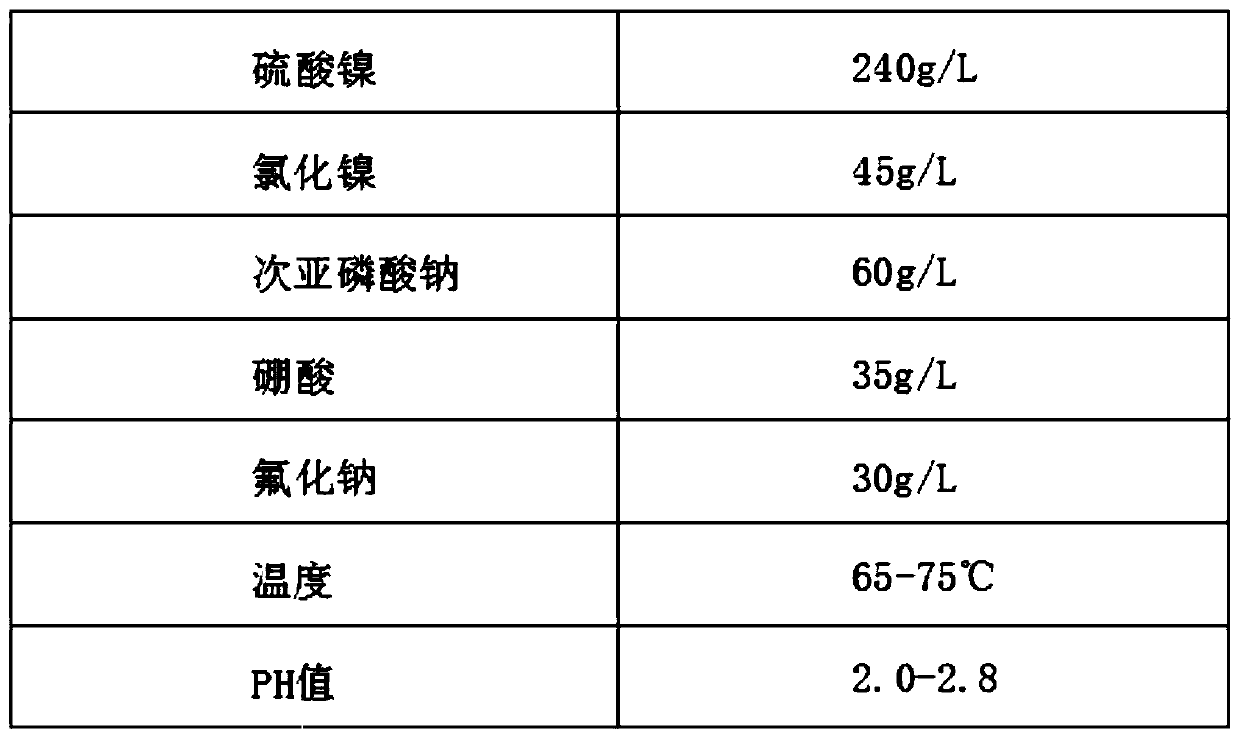

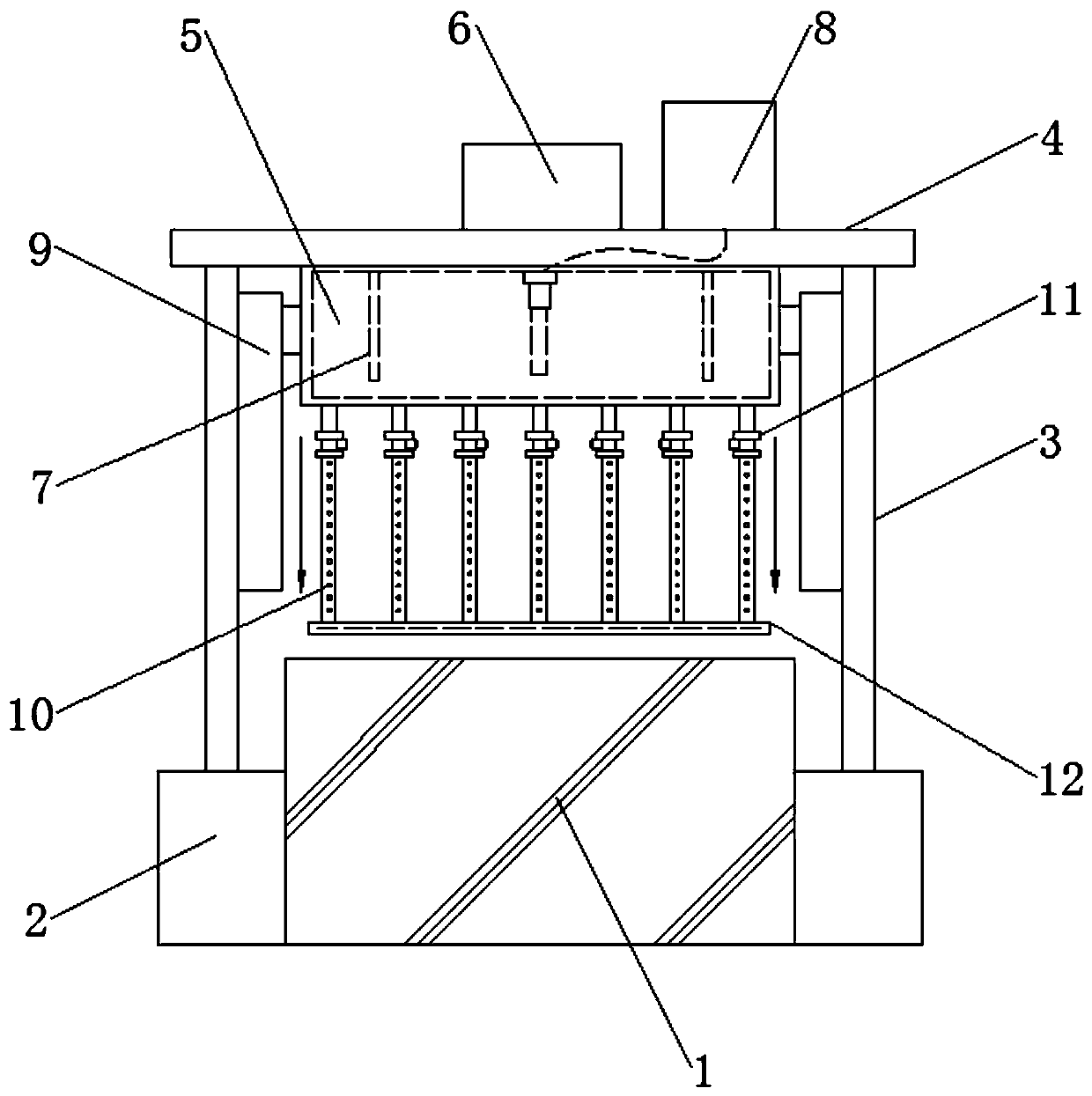

Process for optimizing nickel-plated appearance of ultra-wide stainless steel plate

The invention discloses a process for optimizing the nickel-plated appearance of an ultra-wide stainless steel plate and belongs to the technical field of nickel plating. The process for optimizing the nickel-plated appearance of the ultra-wide stainless steel plate comprises the following steps: step 1, degreasing; step 2, immersion washing with hot water; step 3, washing with sulfuric acid; step4, spray washing with pure water; step 5, nickel pre-plating; step 6, corrective nickel plating; step 7: general nickel plating; step 8, cleaning and immersion washing; step 9, post-treatment; step 10, ultrasonic washing; step 11, blow-drying; step 12, oven-drying; and step 13, auxiliary collecting. By the adoption of the process, the nickel and phosphorus alloying process can be added between the pre-plating operation and the plating operation on a general nickel-plated layer; accordingly, not only can the plated layer deposition speed be improved, but also a lattice of the nickel-plated layer can be remarkably improved, the lattice being compact in structure can be refined, and the plated layer porosity can be reduced; and then, the appearance uniformity and glossiness of the general nickel-plated layer can be guaranteed, the plated layer density, uniformity and bonding strength can be improved, and the corrosion-resistant property can be improved.

Owner:东莞市康圣精密合金材料有限公司

Chemical copper plating solution, preparation method of chemical copper plating solution and nonmetal chemical plating method

ActiveCN106894005AGood chemical plating activityShort initiation periodLiquid/solution decomposition chemical coatingChemical platingCopper plating

The invention relates to a chemical copper plating solution. The chemical copper plating solution is an aqueous solution containing soluble copper salt, a soluble hydroxide, a complexing agent, a stabilizer, an accelerant, a buffering agent and a reducing agent. The reducing agent is a methylene glycol compound and / or an alpha-diol compound. The invention further provides a preparation method of the chemical copper plating solution and a nonmetal surface chemical plating method adopting the chemical copper plating solution. The chemical copper plating solution has a better reduction effect and is good in stability and long in service life.

Owner:BYD CO LTD

Super-hard ceramal chemical compound solution and plating method thereof

InactiveCN102392235AFast platingStable bath performanceLiquid/solution decomposition chemical coatingChemical compoundBoron carbide

The invention relates to super-hard ceramal chemical compound solution and a plating method thereof. The compound solution is prepared by main salt, a reducing agent, a complexing agent, a buffering agent, silicon carbide, magnesium oxide, a cation surface active agent, boron carbide and deionized water. Compared with common conventional chemical compound plating solution, the compound solution is high in plating speed which can be up to 70 microns in each hour and stable in plating solution property. In the invention, the heat treatment manner is described as follows: a 10KW Nd: YAC laser used for pulse oscillation, light spot focusing is carried out by 10mm and scanning is carried out at a speed of 55mm / sec. the hardness can be up to HV3000. The super-hard ceramal chemical compound solution is used for stretching stamping dies and capable of prolonging the life by more than 30 times.

Owner:程绍鹏

Zinc-nickel-phosphorus electroplating liquid and preparation method and electroplating method thereof

The invention relates to zinc-nickel-phosphorus electroplating liquid and a preparation method and electroplating method thereof. The technical problems that an existing zinc-nickel plated layer is low in hardness and does not have the abrasion resistance are solved. The zinc-nickel-phosphorus electroplating liquid contains the following components including, by concentration, 20-30 g / L of nickelaminosulfonate, 4-10 g / L of sodium phosphate, 40-60 g / L of zinc sulfate, 20-40 g / L of potassium hydroxide, 0.1-0.3 g / L of additive and 20-40 g / L of complexing agent, and deionized water serves as a solvent. Meanwhile the invention provides the preparation method and electroplating method of the zinc-nickel-phosphorus electroplating liquid. The zinc-nickel-phosphorus electroplating liquid and the preparation method and electroplating method thereof are widely applied to surface treatment of metal workpieces, and a plated layer formed through the method serves as an anodic protective plated layer, has excellent corrosion resistance and high hardness and achieves the double effects of corrosion resistance and abrasion resistance.

Owner:合鸿新材科技有限公司

Solution for chemically plating nickel on surface of non-catalytic active material and plating process for solution

ActiveCN105695962AQuality improvementThe composition of the plating solution is simpleLiquid/solution decomposition chemical coatingNickel saltWater soluble

The invention relates to a solution for chemically plating nickel on the surface of a non-catalytic active material and a plating process for the solution, and belongs to the technical field of chemical nickel-plating. The solution comprises liquor A, liquor B, liquor C and / or liquor D, wherein the liquor A comprises a water-soluble nickel salt and a buffer agent; the liquor B comprises a reducing agent, a complexing agent, a buffer agent, a stabilizer and a surface wetting agent; the liquor C comprises the water-soluble nickel salt and the complexing agent; and the liquor D comprises the reducing agent and the stabilizer. The plating process for the solution comprises the following steps: preparing the liquor A, the liquor B and a diluent; uniformly mixing the liquor A, the liquor B and the diluent to obtain a mixture, regulating the pH value of the mixture to 7.0-8.0, heating the mixture to a temperature of 82-88 DEG C, and carrying out primary plating by using an iron material as an initiator; filtering plating liquor after carrying out primary plating; recycling filtrate for next-time plating, feeding plating liquor obtained by the next-time plating into the liquor C and the liquor D, and recycling the plating liquor. According to the solution and the plating process thereof, the combination and the process design are reasonable, generation and emission of waste liquor can be greatly reduced, and the utilization rate of the plating liquor can be increased.

Owner:CENT SOUTH UNIV

Environment-friendly high-phosphorus chemical nickel plating solution for airtight glass-sealed binding terminal, and applications thereof

InactiveCN103938193ARefined grain sizeFast platingLiquid/solution decomposition chemical coatingChemical platingBULK ACTIVE INGREDIENT

The invention discloses an environment-friendly high-phosphorus chemical nickel plating solution for an airtight glass-sealed binding terminal. The environment-friendly high-phosphorus chemical nickel plating solution comprises the following active ingredients according to concentration: 25-27g / L nickel sulfate, 19-22g / L sodium hypophosphite, 20-23g / L sodium hydroxide, 41-44g / L lactic acid, 1.5-2.3g / L trisodium citrate, 13-15g / L malic acid, 8-12g / L glycine, 0.2-0.4ml / L OP-10, 0.26-0.3g / L stannous chloride, 0.26-0.34g / L maleic anhydride and 3-5mg / L N,N-diethylaminopropyne. The invention discloses a method for performing chemical plating by adopting the chemical nickel plating solution. A stainless steel needle and an iron cover can be simultaneously subjected to chemical nickel plating and be evenly plated, no nickel nuclear generated on sintered glass can be guaranteed, and the difficulty in keeping the smoothness and cleanness of the surface of glass can be solved.

Owner:深圳市迪凯鑫科技有限公司

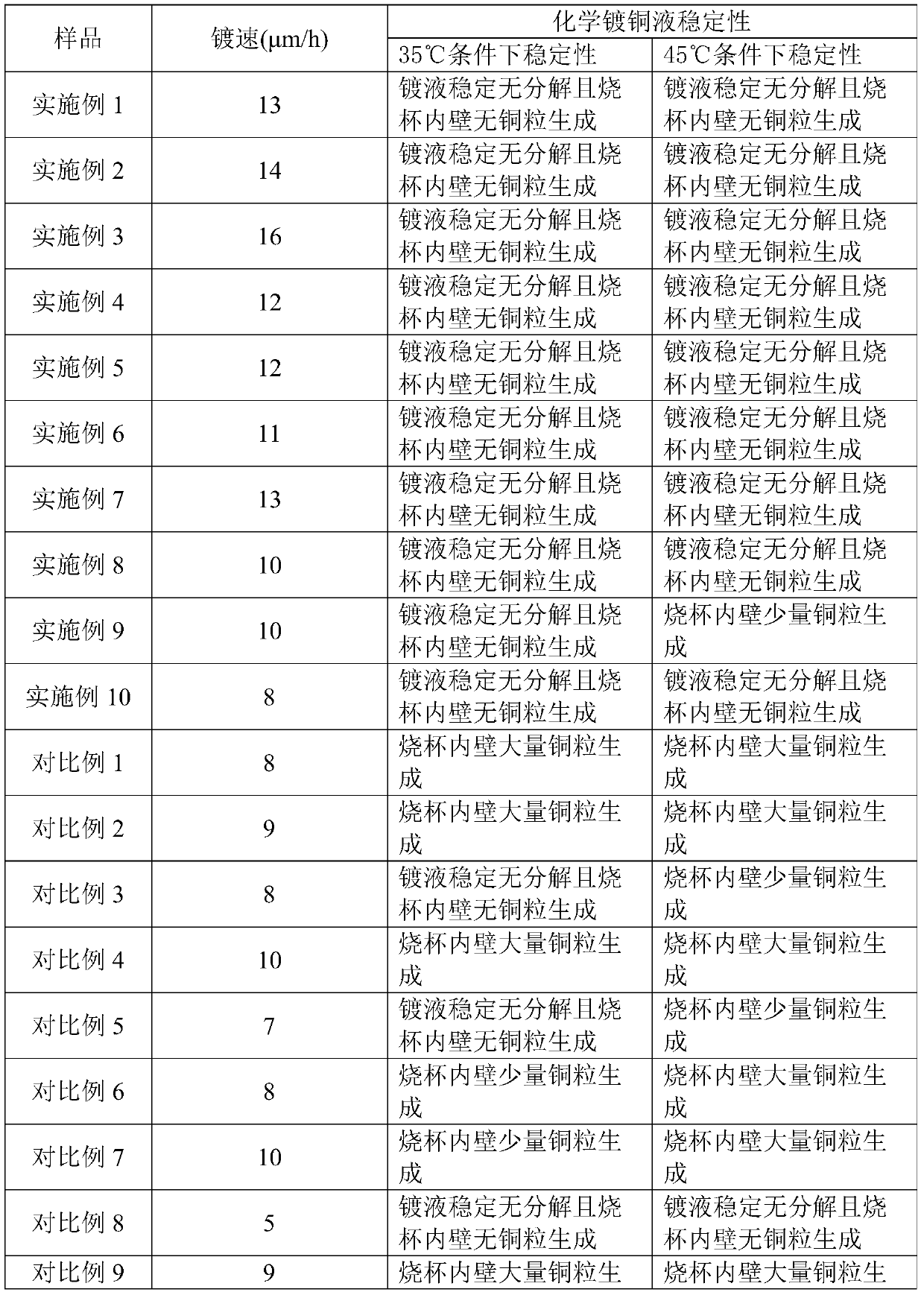

Chemical copper plating liquid and preparation method thereof

InactiveCN110512199AImprove stabilityFast platingLiquid/solution decomposition chemical coatingCopper platingPhysical chemistry

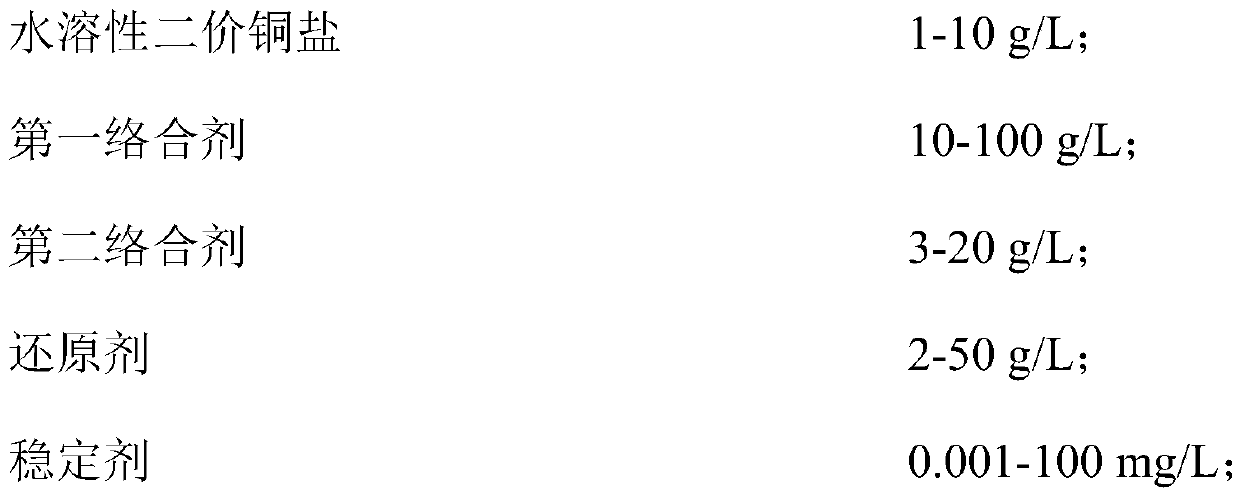

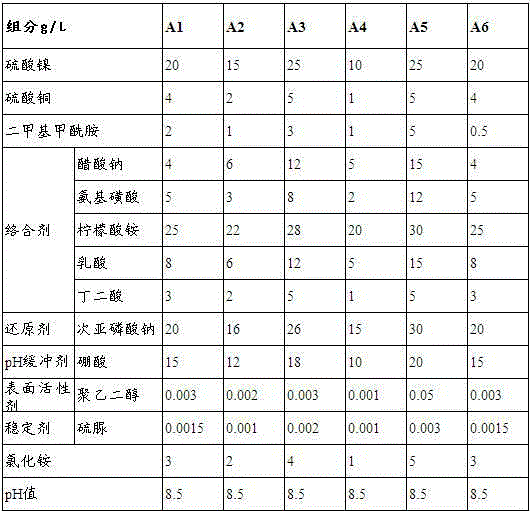

The invention provides chemical copper plating liquid and a preparation method thereof. The chemical copper plating liquid comprises, by mass concentration, 1-10 g / L of water soluble cupric salt, 10-100 g / L of a first complexing agent, 3-20 g / L of a second complexing agent, 2-50 g / L of a reduction agent and 0.001-100 mg / L of stabilizer. According to the chemical copper plating liquid, the specificsecond complexing agent is selected, by means of mutual operation and synergistic interaction between the two complexing agents, thus the obtained chemical copper plating liquid is stable without decomposing in the plating application process, and the plating speed of the chemical copper plating liquid is also increased substantially. In addition, a copper plated film obtained after the chemicalcopper plating liquid applies plating is smooth and uniform, and the requirement for functionality chemical copper plating can be met.

Owner:SUZHOU TIANCHENG CHEM

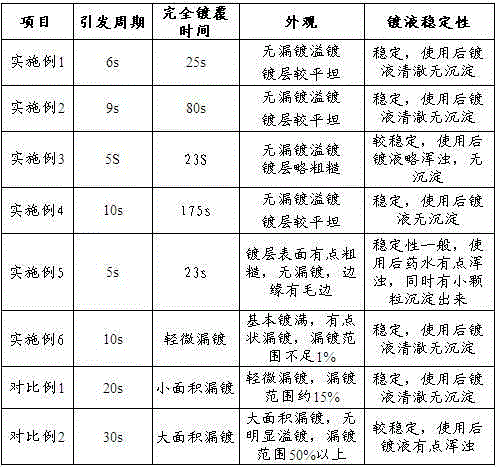

Electroless plating solution, preparation method and nonmetal electroless plating method

ActiveCN106637159AGood chemical plating activityShort initiation periodLiquid/solution decomposition chemical coatingNickel saltAqueous solution

The invention relates to an electroless plating solution. The electroless plating solution is an aqueous solution containing nickel salt, copper salt, a complexing agent, a pH buffer, a surfactant, a reducing agent and dimethylformamide. The invention further provides a preparation method of the electroless plating solution and a nonmetal surface electroless plating method implemented with the electroless plating solution. The electroless plating solution has good reducing effect, better stability and long service life.

Owner:BYD CO LTD

Chemical copper plating solution and chemical copper plating method

InactiveCN108193197AImprove stabilityFast platingLiquid/solution decomposition chemical coatingChemical platingCopper plating

The invention discloses a chemical copper plating solution and relates to the field of chemical plating. According to the chemical copper plating solution, formaldehyde serves as a reducing agent; cuprous salt serves as a copper source; and complexing of the cuprous salt is conducted with phosphine ligand as a complexing reagent. Monovalent copper ions are different from bivalent copper ions in that the monovalent copper ions are likely to be subjected to a disproportionated reaction in water to generate elementary substance copper and bivalent copper, and ligand needs to be added to stabilizethe monovalent copper ions. The monovalent copper ions belongs to soft acid specified in the Louis acid and base theory, and the effect that the monovalent copper ions are matched with traditional nitrogen and oxygen ligand belonging to hard base is poor. According to the chemical copper plating solution, the adopted phosphorus ligand belongs to soft base and is good in coordination with the monovalent copper ions, and the good stabilizing effect can be achieved for the monovalent copper ions; and product quality is improved while the plating speed is increased. The invention further discloses a chemical copper plating method. According to the chemical copper plating method, a to-be-placed workpiece is put in the chemical copper plating solution for chemical plating at the temperature of40-60 DEG C. The method is high in plating speed, good in stability and high in production efficiency.

Owner:四川省劲腾环保建材有限公司

Chemical nickel plating process of Mg-Gd-Y-Zr magnesium alloy

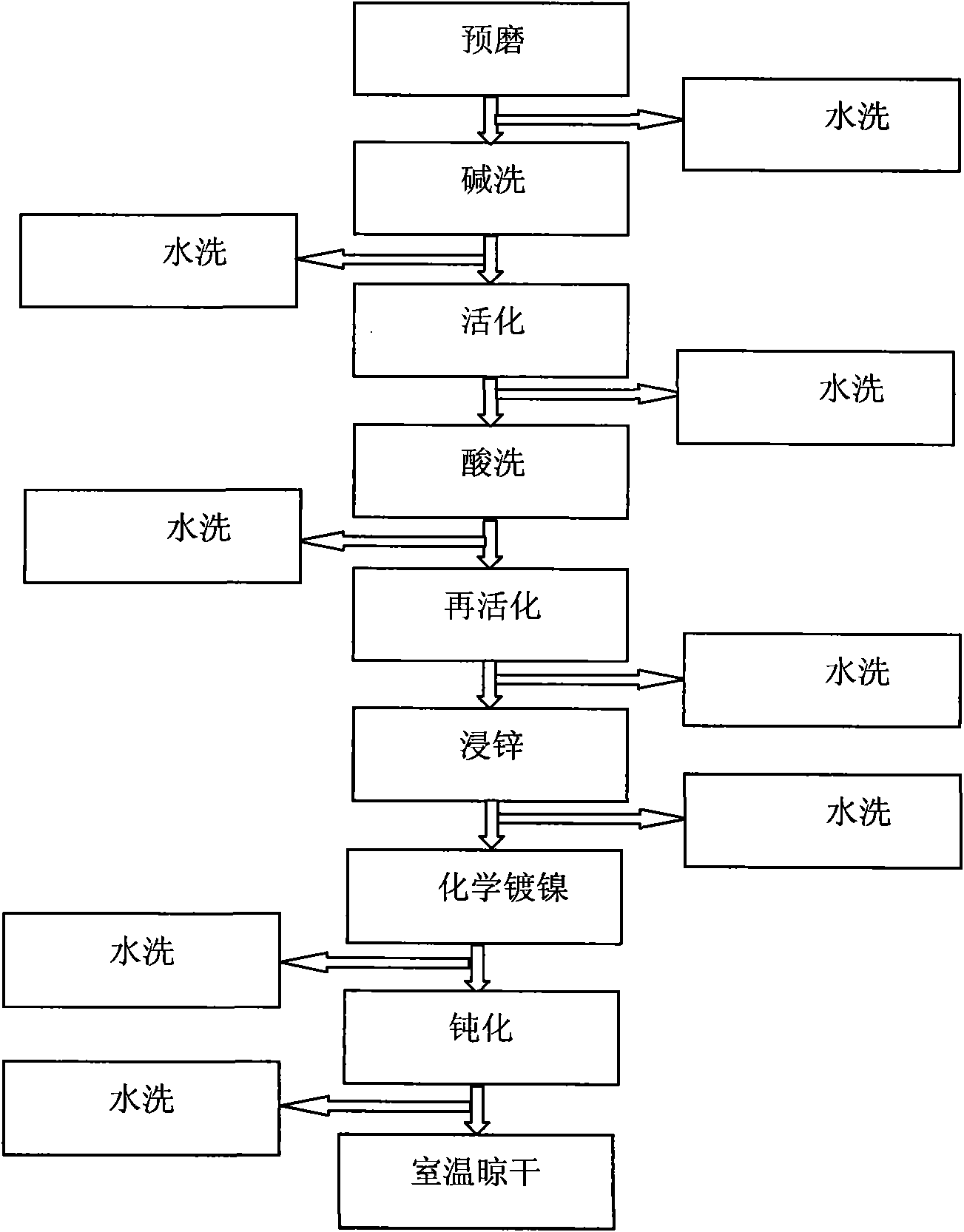

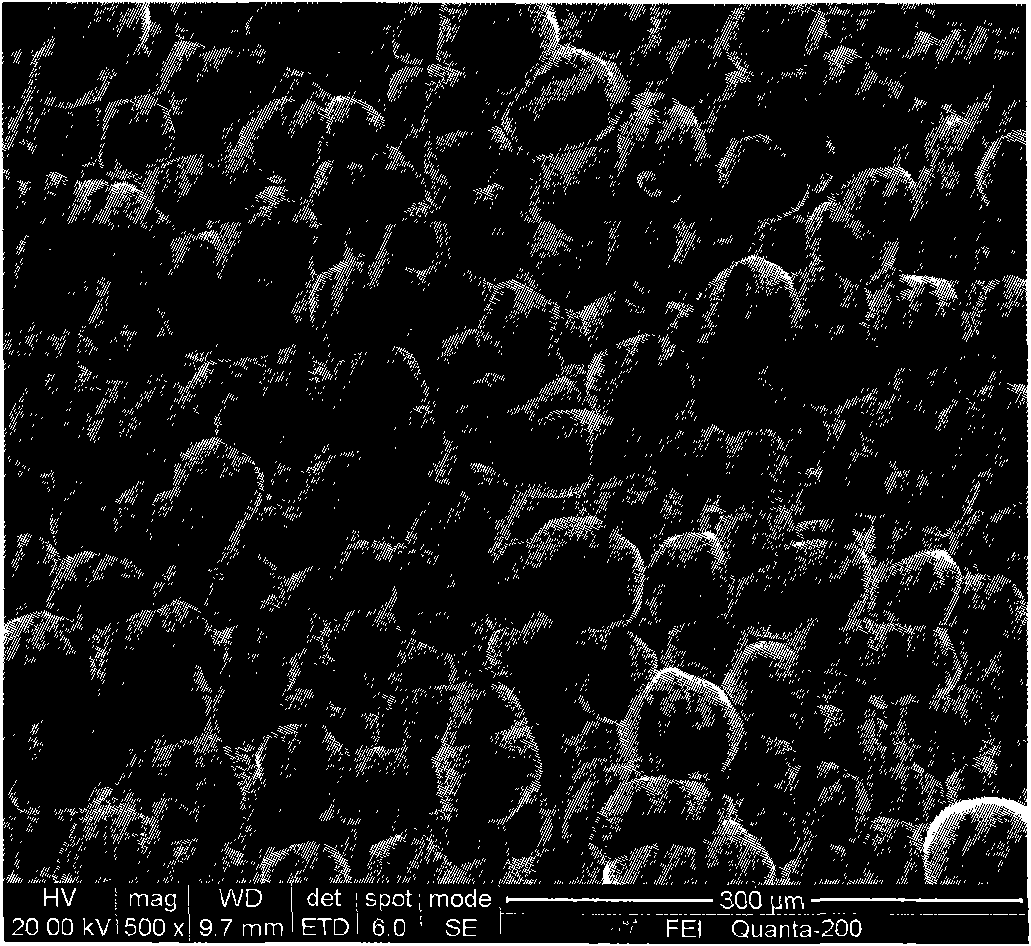

InactiveCN101892471ALess corrosiveImprove corrosion resistanceLiquid/solution decomposition chemical coatingAcid washingReducing agent

The invention relates to a chemical nickel plating method of an Mg-Gd-Y-Zr (wt%) magnesium alloy. The method comprises pre-plating pretreatment of a magnesium alloy matrix and deposition of a chemical nickel plating layer through chemical nickel plating, wherein the pre-plating pretreatment process comprises five steps of removing oil, activating, acid-washing, reactivating and zinc galvanizing; chemical nickel plating solution takes basic nickel carbonate as main salt, sodium hypophosphite as a reducing agent, hydrofluoric acid as a corrosion inhibitor, lactic acid as a complex agent and mixed liquor of cadmium sulfate and potassium iodate as a brightening agent; and a plating component is subject to zinc galvanizing and then electroless plating at the temperature about 85 DEG C to obtain the bright, flat, uniform and compact nickel plating layer. The chemical nickel plating method is applicable to chemical nickel plating on the surface of the Mg-Gd-Y-Zr magnesium alloy, thus achieving the purpose of protecting the magnesium alloy. The chemical nickel plating method has the advantages of fast plating speed, good protectiveness, simple operation and easy control.

Owner:CENT SOUTH UNIV

Method for improving recycling of plating emery of diamond wire

InactiveCN108914182AImprove plating efficiencyReduced peeling rate and brittle fracture rateElectrolytic coatingsAfter treatmentEngineering

The invention provides a method for improving recycling of plating emery of a diamond wire. The method comprises the steps of pretreatment, preplating, emery loading, reinforcing and after-treatment.According to the invention, when a mother wire goes to a reinforcing station from an emery loading station, a linkage station is located in the middle of the emery loading station and the reinforcingstation, and two wiring wheels and a tension arm wiring wheel are arranged at the linkage station; plating emery is left on the wiring wheels due to long-term friction between the linkage station andthe diamond wire; semi-cut pipelines are additionally arranged below the wiring wheel located at the wire outlet of the emery loading station and the wiring wheel located at the wire inlet of the reinforcing station, and the plating emery falling off from the wiring wheels is collected; and a collection box is additionally arranged behind the linkage station to recycle the fallen plating emery. Due to usage of a large number of machines and long operation time, the method provided by the invention can effectively reduce the waste of the plating emery and saves cost for a company.

Owner:安徽卡尔森新材料科技有限公司

Diamond micro-powder chemical nickel-plating formula and process

PendingCN109576687AImprove stabilityControl concentrationLiquid/solution decomposition chemical coatingWater bathsThiourea

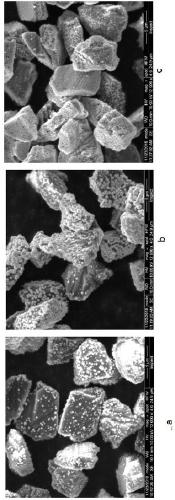

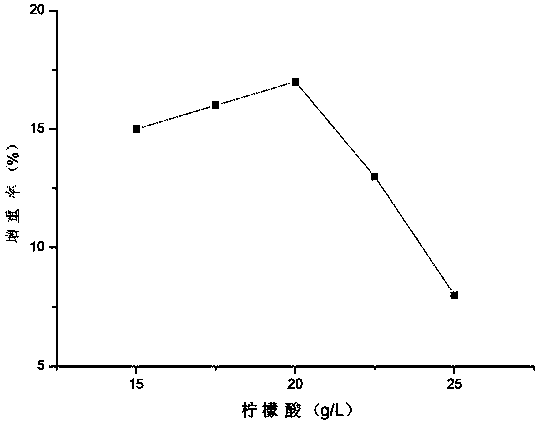

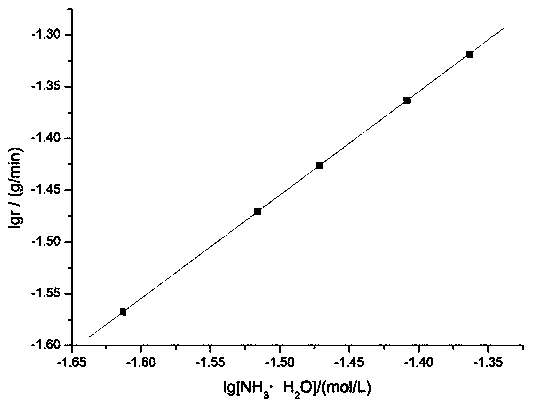

The invention discloses a diamond micro-powder chemical nickel-plating formula and process. The diamond micro-powder chemical nickel-plating formula includes 20-30 g / L of nickel sulfate hexahydrate, 30-35 g / L of sodium hypophosphite, 15-25 g / L of citric acid, 12.5-22.5 g / L of ammonium hydroxide, 12.5-17.5 g / L of sodium citrate, 1-5 mg / L of thiourea, 2-10 mg / L of potassium iodate, 0.1-1.5 g / L of polyethylene glycol 4000 and 0.1-1.5 g / L of dodecylbenzene sulfonic acid. The process comprises the steps of adding diamond micro-powder at the loading capacity of 2-10 g into 400 mL of a plating solution; conducting ultrasonic dispersion for 5 min, then conducting water-bath heating at 75-90 DEG C and conducting chemical nickel plating at the stirring speed of 120 r / min. According to the diamond micro-powder chemical nickel-plating formula and process, citric acid and ammonium hydroxide are added on the basis of sodium citrate; the anti-corrosion capability of a plating coating obtained througha compound complex agent is higher than that of the plating coating obtained through a single complex agent. Interspaces of a single complex compound through the compound complex agent are filled. The structure is more compact. The complex compound becomes stable. Moreover, the deposition velocity is increased to some extent.

Owner:ZHONGYUAN ENGINEERING COLLEGE

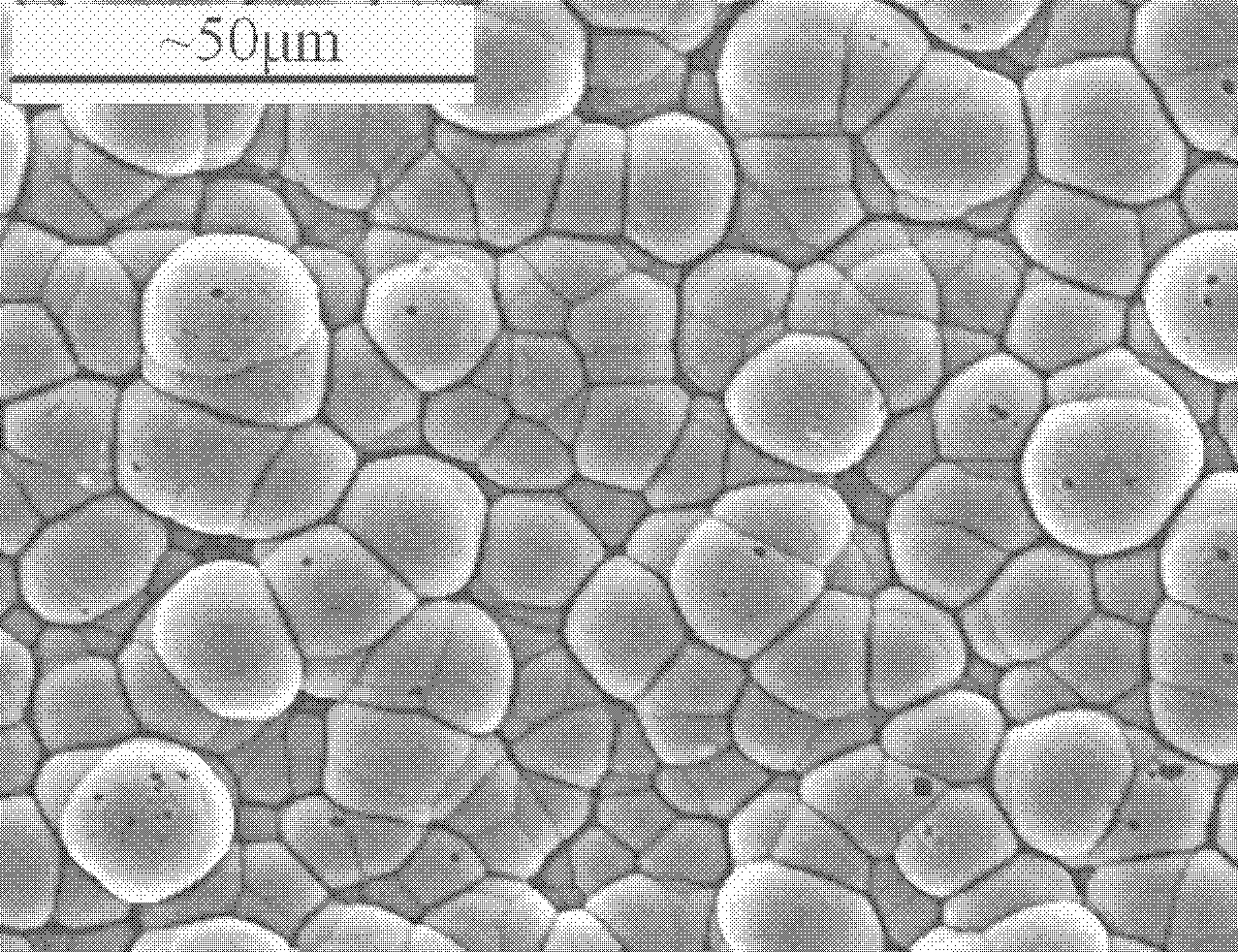

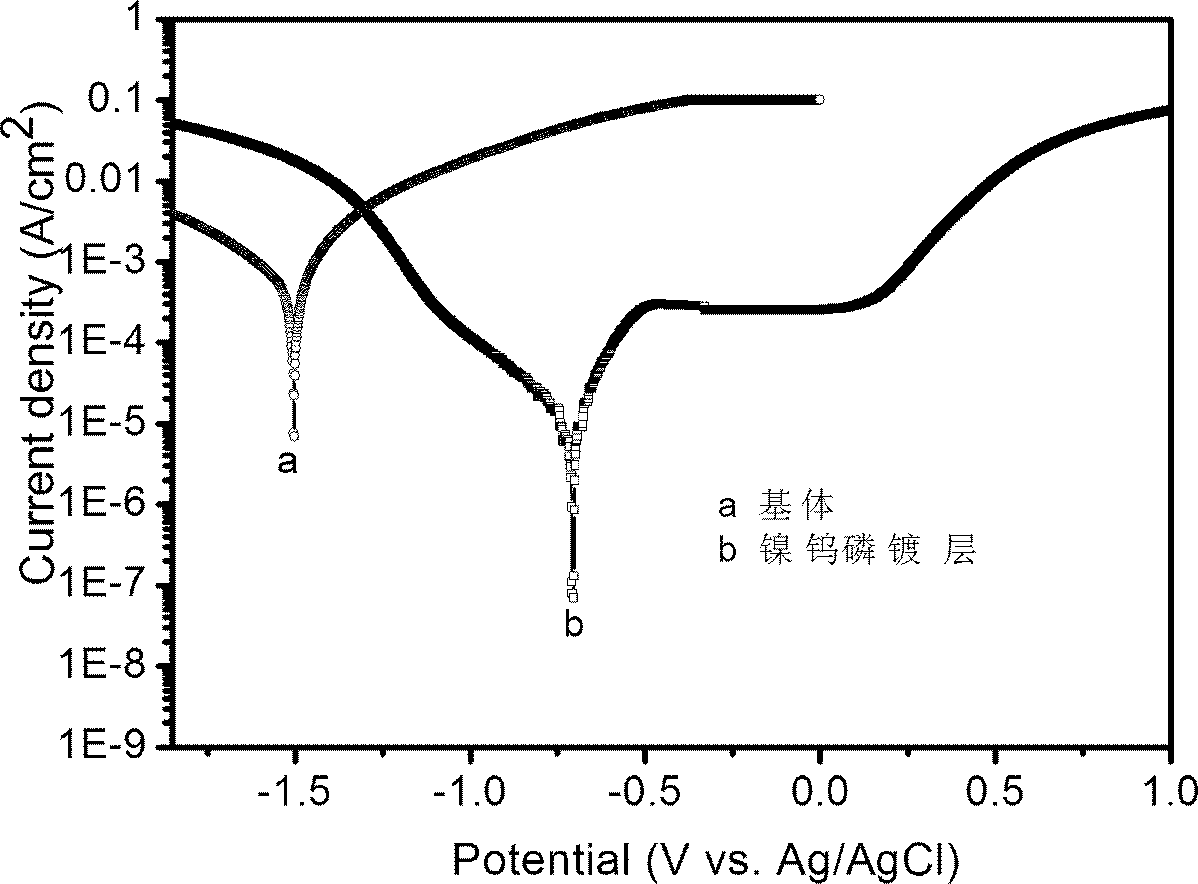

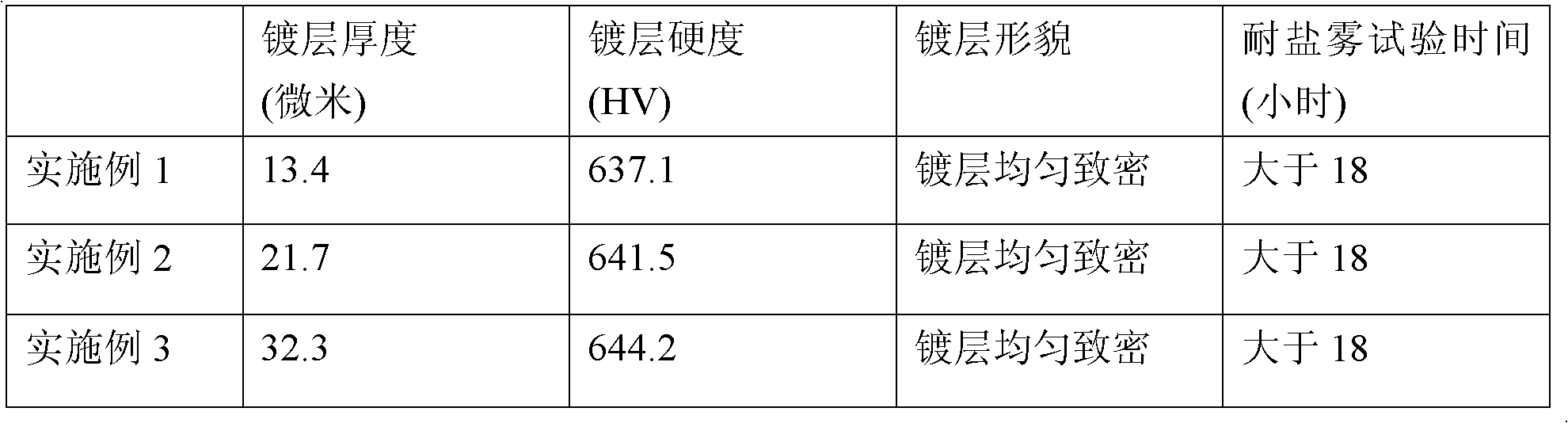

Chemical plating nickel-tungsten-phosphorus alloy solution for magnesium alloy and treatment process thereof

InactiveCN102517572ASimple ingredientsEasy to prepareLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention relates to a chemical plating nickel-tungsten-phosphorus alloy solution for a magnesium alloy surface and a treatment process thereof. The prepared chemical plating nickel-tungsten-phosphorus alloy solution for the magnesium alloy is an aqueous solution; the pH value of the aqueous solution is 8-9; and each liter of aqueous solution contains 5-25g of nickel sulfate, 5-20g of sodium tungstate, 20-60g of sodium citrate, 5-20g of sodium carbonate, 10-30g of hypophosphite, 0.5-0.15mg of thiourea and 6-10g of ammonium bifluoride. A process for treating the magnesium alloy surface comprises the following steps of: treating a magnesium alloy component with a clean surface in a nitric acid solution of which the mass concentration is 15 percent for 40-60 seconds; cleaning in water; treating in hydrofluoric acid of which the mass concentration is 40 percent for 5-10 minutes; and cleaning in water, and soaking into the plating nickel-tungsten-phosphorus solution for performing chemical coating at the temperature of 85-90 DEG C. The chemical plating nickel-tungsten-phosphorus alloy solution has the advantages of simple components, convenience for preparing, low cost, variability of component concentration in a large range, high stability, long-term storage and high plating speed.

Owner:CHANGAN UNIV

Plastic film brush copper plating process

ActiveCN114561674AImprove uniformityImprove continuityVacuum evaporation coatingSputtering coatingImidePolyol

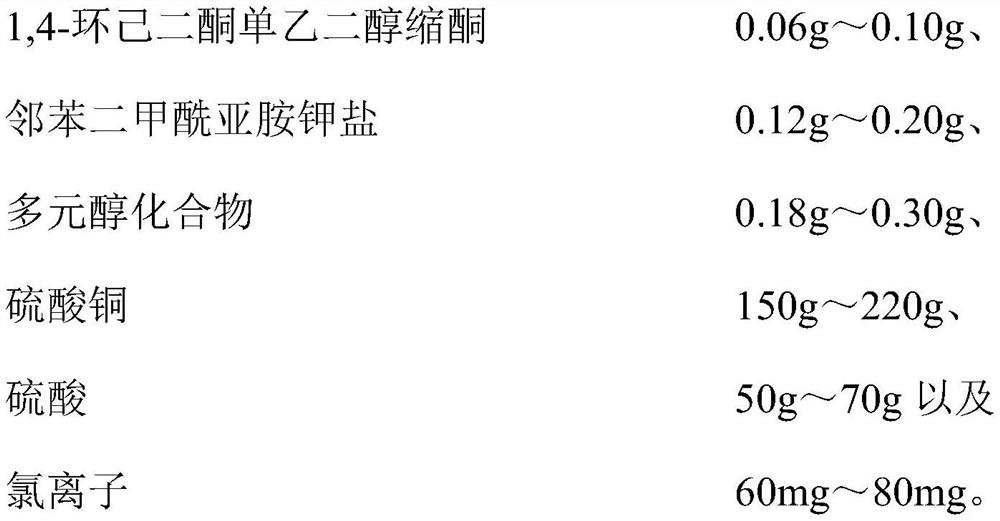

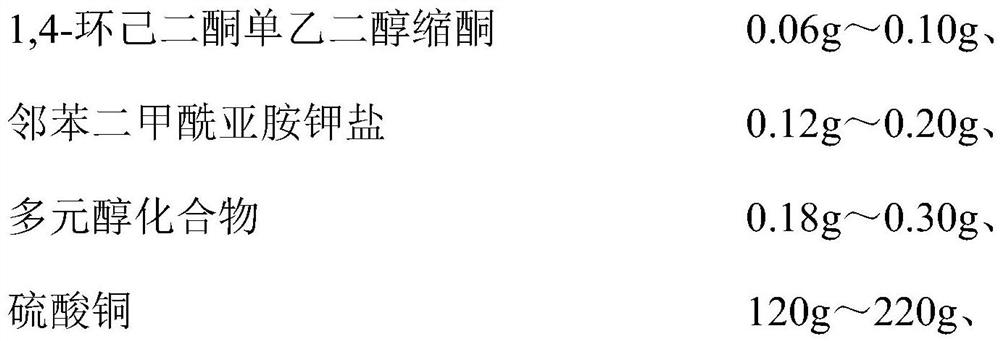

The invention relates to a plastic film brush copper plating process. The process comprises the following steps: carrying out first copper plating treatment on a plastic film by adopting a physical vapor deposition method, preparing a first copper film on one surface of the plastic film, and preparing a second copper film on the other surface of the plastic film; second copper plating treatment is conducted on the first copper film and the second copper film in a brush copper plating mode, a third copper film is prepared on the first copper film, and a fourth copper film is prepared on the second copper film; the anode of the second copper plating treatment is a brush plating roller; and a copper plating solution adopted in the second copper plating treatment comprises water, copper sulfate, sulfuric acid, chloride ions, 1, 4-cyclohexanedione monoethylene ketal, phthalimide potassium salt and a polyol compound. According to the copper plating process, the plating speed is high, the copper film layer with fine, continuous and uniform crystals can be obtained, no adverse effect is generated on the original copper plating film layer, the binding force of the plated film layer is excellent, the film surface sheet resistance can meet the finished product requirement through one-time brush plating film forming, the plastic film is not punctured, and the copper plating process is suitable for amplification application.

Owner:JIANGYIN NANOPORE INNOVATIVE MATERIALS TECH LTD

Environmental friendly chemical plating nickel plating brightener and use thereof

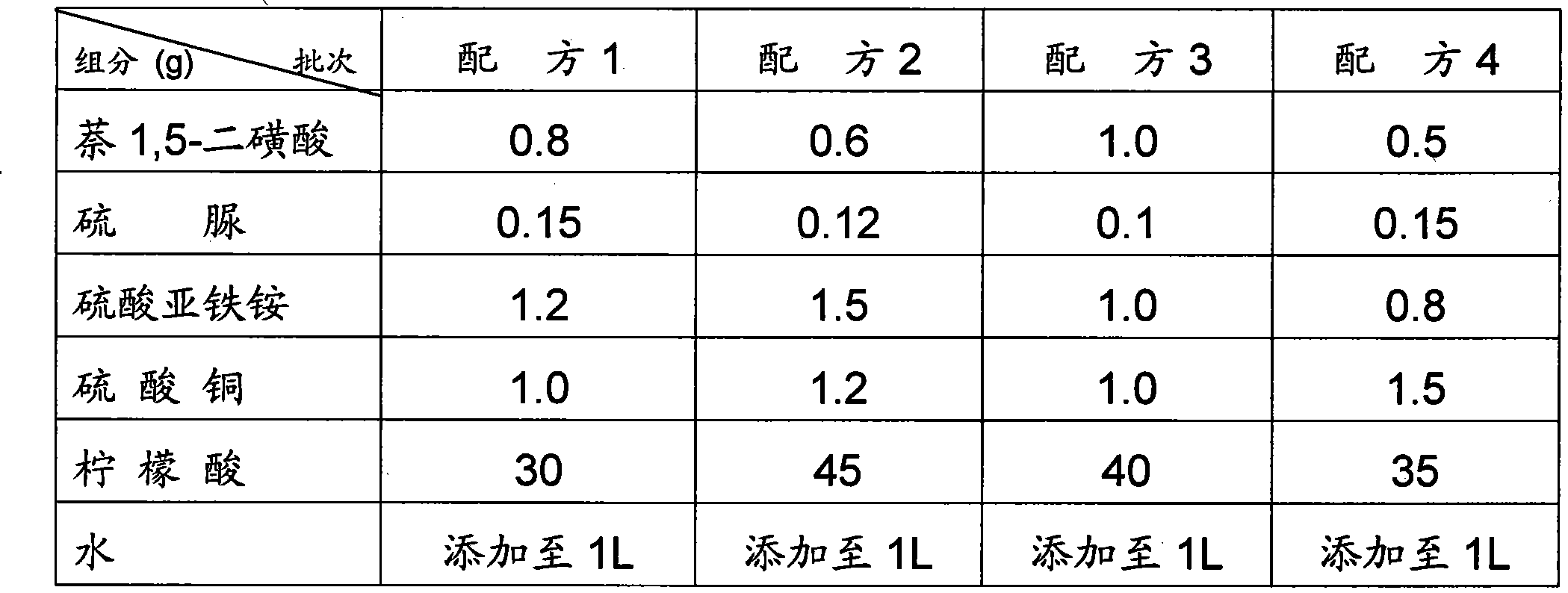

The invention relates to an environment-friendly chemically nickel plating brightener. The brightener consists of 0.5 to 1.0 g / l of 1, 5-naphthalenedisulfonic acid, 0.1 to 0.15 g / l thiourea, 0.8 to 1.5g / l ferrous ammonium sulphate, 1.0 to 1.5g / l of coper sulfate, 30 to 45g / l citric acid, and the residual quantity of water. The ingredient of the brightener is free from heavy metal ions such as lead ion and chromium ion, which is harmless and environment friendly. When the brightener is applied to the chemical nickel plating solution and the to-be-plated work pieces are plated, the brightness of the plating layer can reach or be superior to the brightness effect of a brightener containing CdSO4, and the plating layer is compact, nonporous and hard. Furthermore, the brightener can function as a stabilizer, therefore, when the brightener can be applied to the chemical nickel plating solution without adding a stabilizer.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Technical process of chrome plating overpassing hydraulic mechanical member

InactiveCN1928154AIncrease production capacityGood application effectLiquid/solution decomposition chemical coatingHigh resistanceAlloy

The present invention provides alloy plating solution and corresponding treating process for forming coating with high corrosion resistance, high hardness, high wear resistance and high erosion resistance. The present invention is used in hydraulic part production, and has the outstanding features of high plating speed, low material consumption, low power consumption and no pollution. The alloy plating solution is compounded through dissolving nickel sulfate, amino acetic acid, sodium hypophosphorite, graphite fluoride, boric acid, sodium saccharin, lead ion, ammonia water and sodium hydroxide in the weight ratio of 3 to 2.5 to 0.35 to 0.6 to 3 to 0.3 to 0.003 to 0.35 to 0.15 in pure water of 90 weight portions. During plating, the alloy plating solution is heated to 50-80 deg.c, and the plating time is determined based on thickness to be plated.

Owner:李天忠

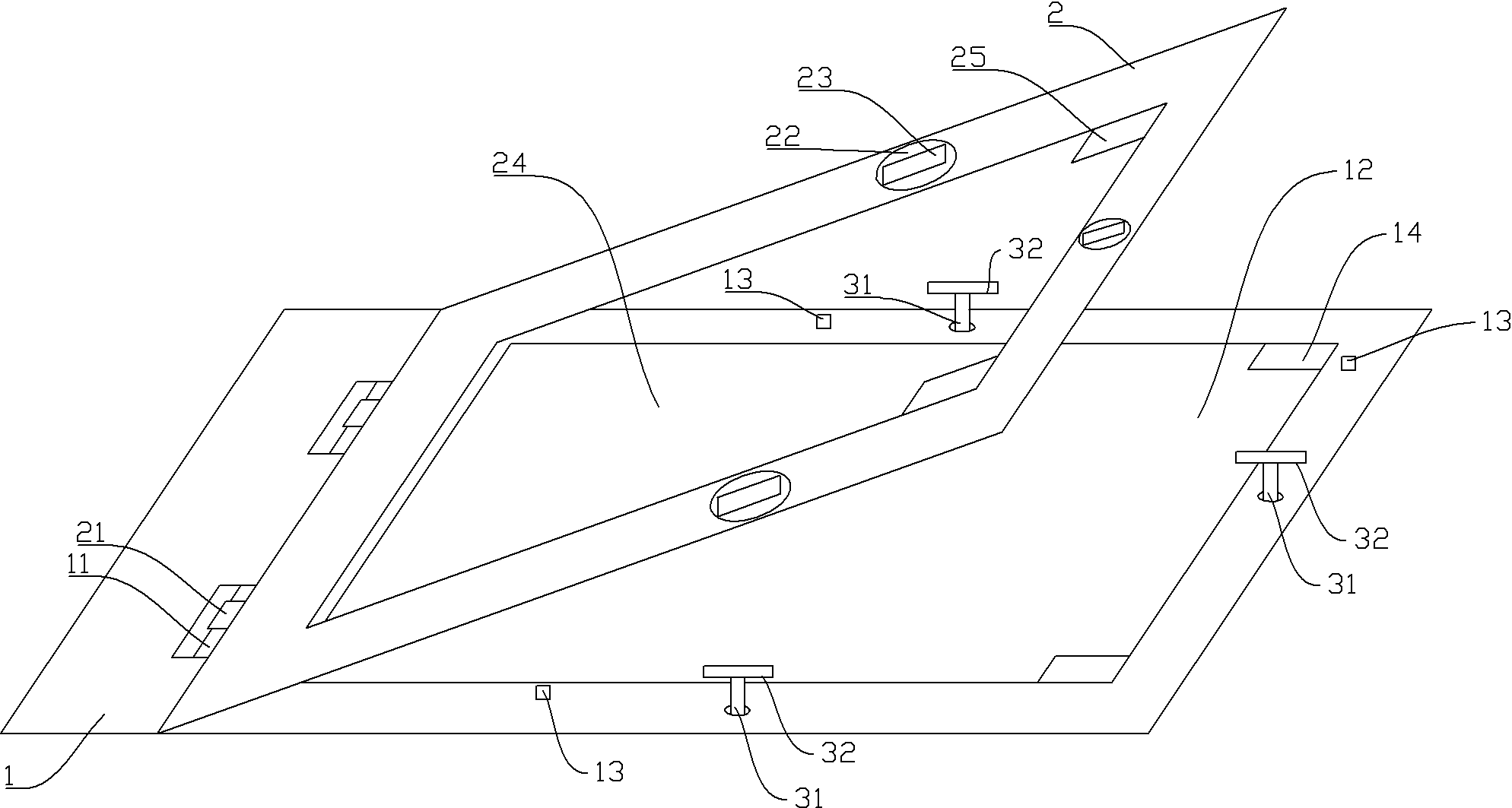

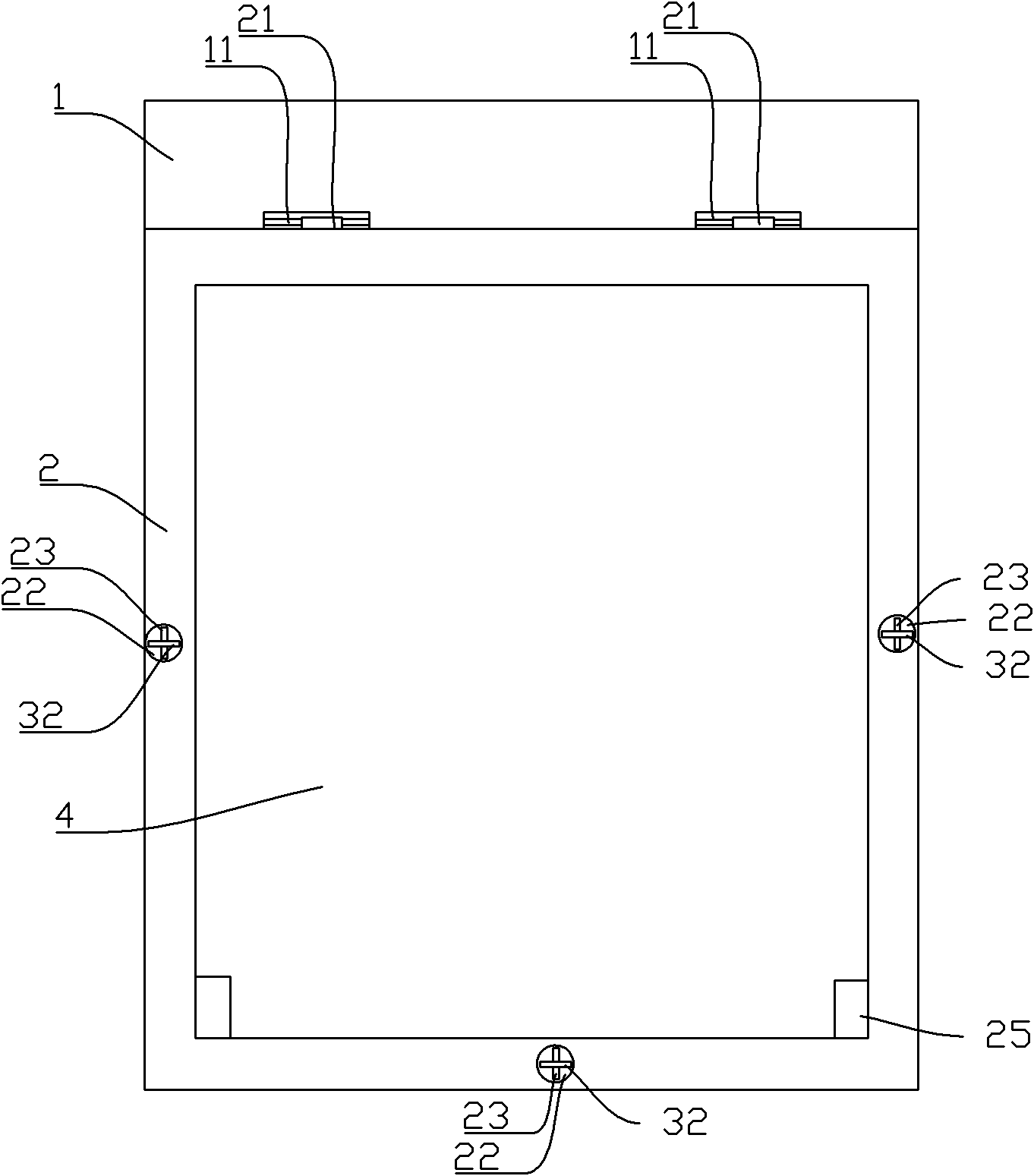

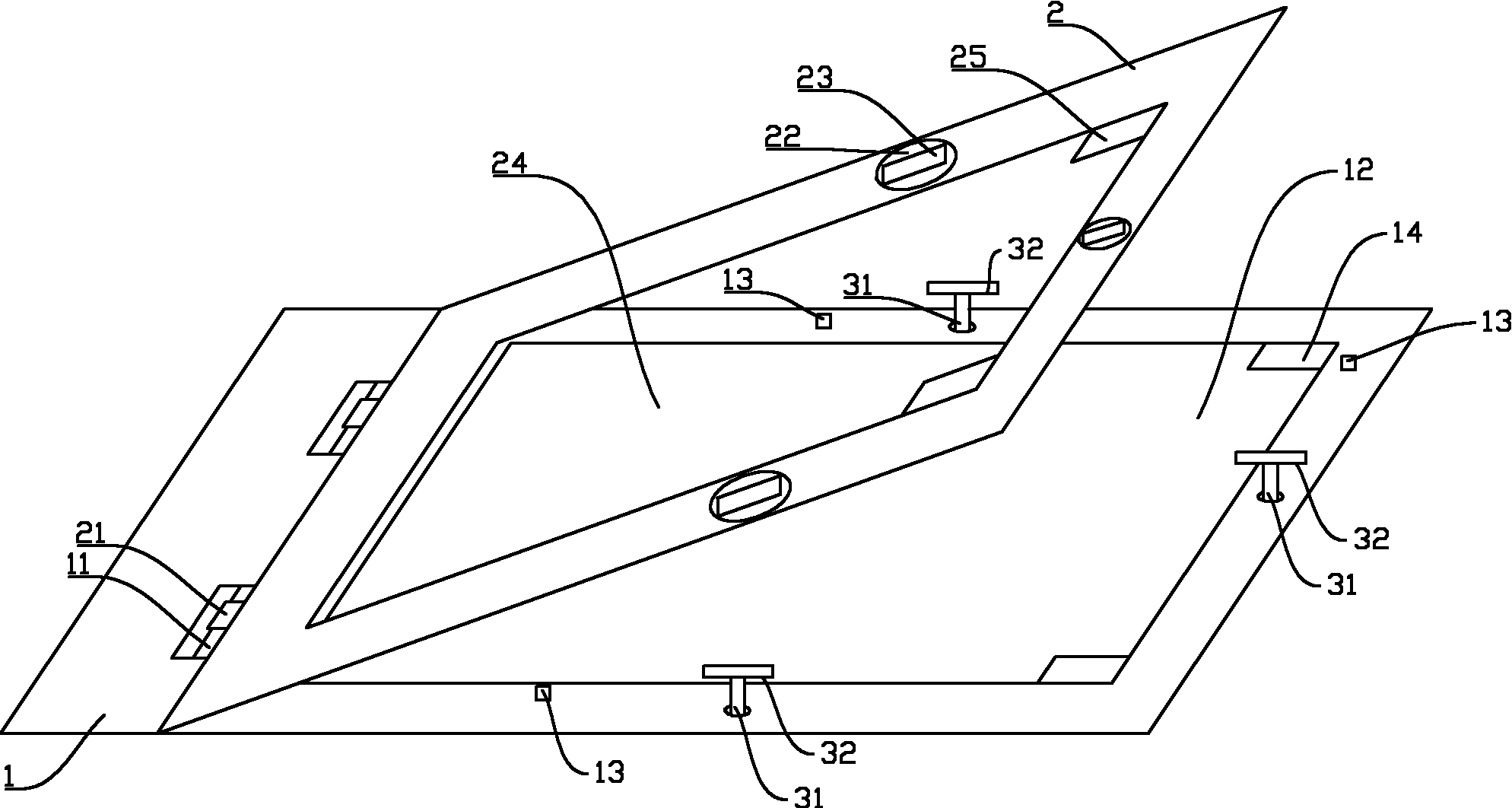

Carrying tool for printed circuit board (PCB)

InactiveCN102134735AFast platingEasy to moveElectrolysis componentsPrinted circuit manufacturePrinted circuit boardElectroplating

The invention discloses a carrying tool for a printed circuit board (PCB), which is characterized by comprising a first clamping frame and a second clamping frame, wherein the first clamping frame is provided with a first through hole, and the second clamping frame is provided with a second through hole; the first clamping frame is connected with the second clamping frame in a relatively rotating way; and the carrying tool for the PCB also comprises a limit device which is used for limiting the PCB between the first clamping frame and the second clamping frame. The carrying tool for the PCB can be used for conveniently clamping the surrounding edge of the PCB, and ensures the PCB to stably move in the moving process without being bended and deformed. More particularly, the carrying tool guarantees the thinner PCB not to be bended and deformed, and realizes rapid electroplating for the thinner PCB.

Owner:SHANGHAI MEADVILLE ELECTRONICS

Method of fabricating an environmentally friendly cladding layer

InactiveUS20060292363A1Fast platingShorten the timeLiquid surface applicatorsSynthetic resin layered productsEvaporation (deposition)Polymer science

A method of fabricating an environmentally friendly cladding layer is provided. A metal layer is deposited on a hydrolysis film by a vacuum evaporation method. Then, after coating a polymer adhesive on the metal layer, the hydrolysis film is immersed in water. After hydrolyzing the hydrolysis film, an electroplate is adhered on the metal layer through the polymer adhesive. Finally, the polymer adhesive, the metal layer and the electroplate are baked for thermosetting the polymer adhesive.

Owner:TSAI SHIH CHUAN

Method for preparing copper-clad tungsten tungsten-copper composite powder

InactiveCN102009173BFast platingWide adjustment range of copper contentLiquid/solution decomposition chemical coatingCopperTungsten

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com