Process for coarsening-free chemical plating of nickel-phosphor alloy on optical fiber surface and chemical plating solution thereof

A technology of surface chemistry and alloy technology, applied in the direction of liquid chemical plating, metal material coating technology, coating, etc., can solve problems such as the influence of optical fiber transmission performance, and achieve the effect of simple equipment and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

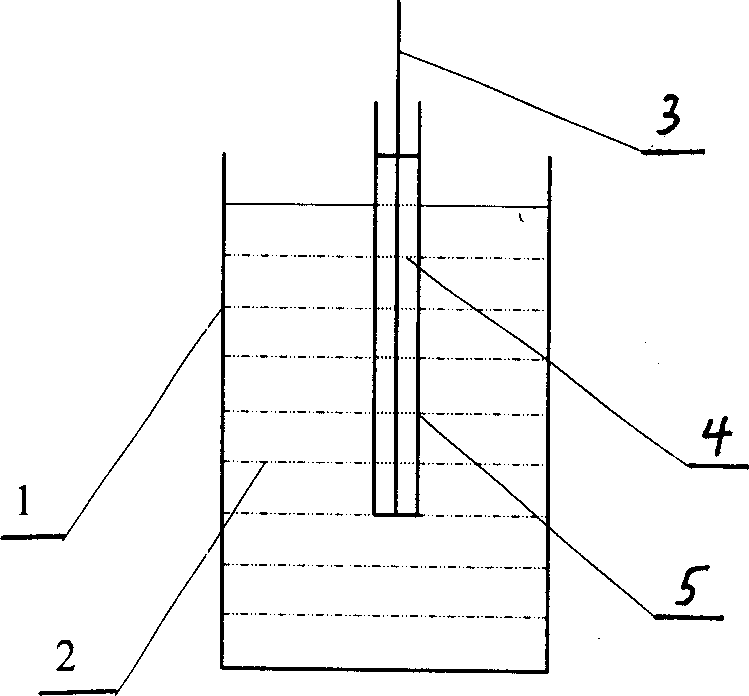

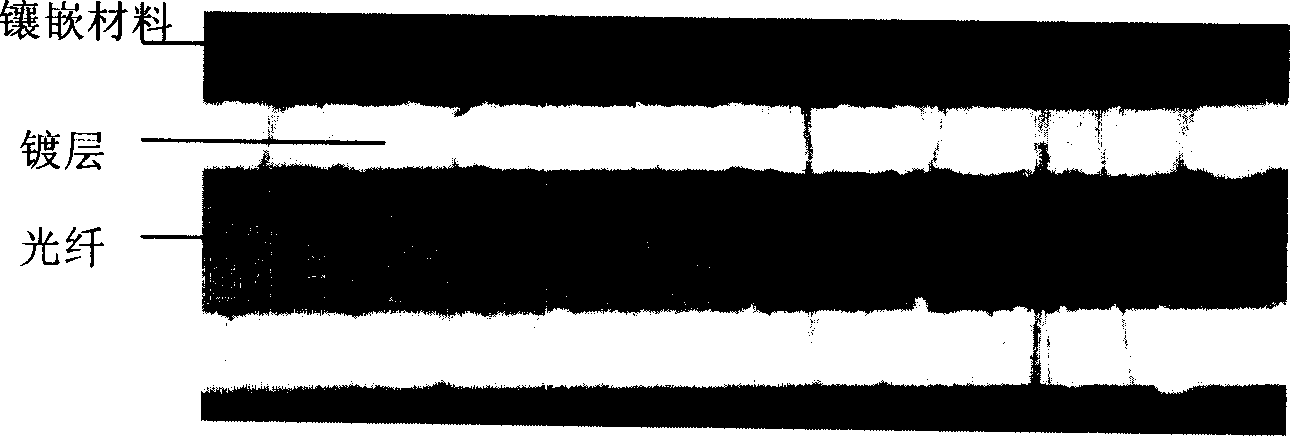

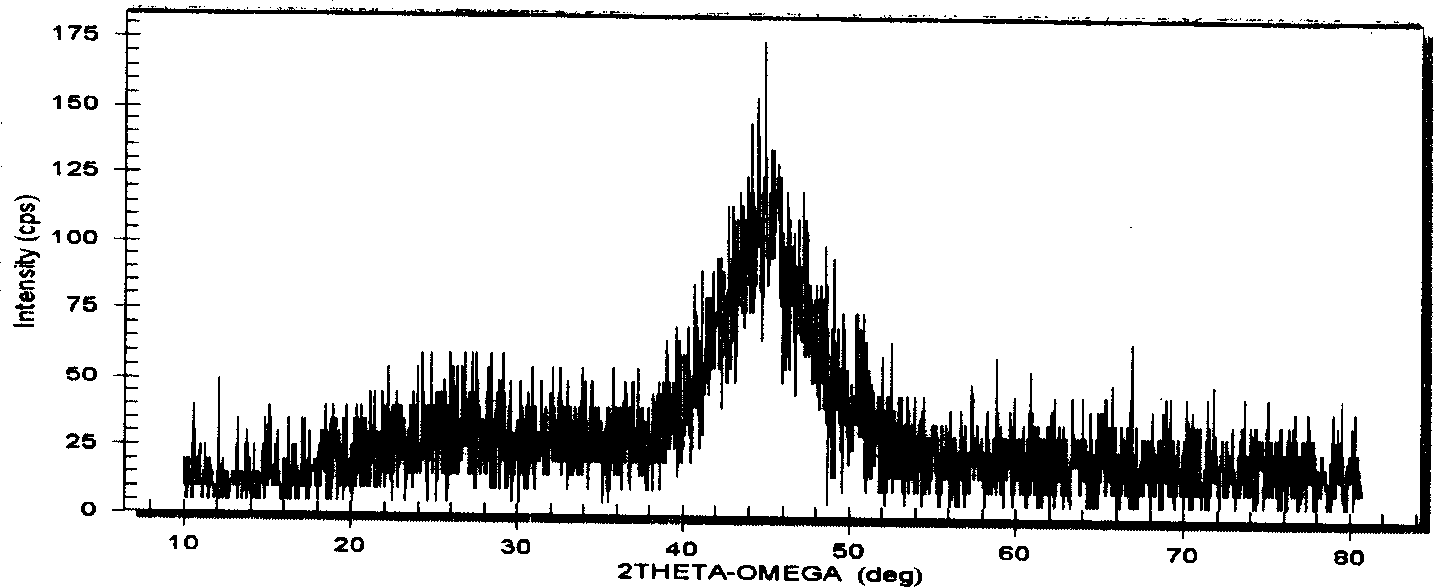

Method used

Image

Examples

Embodiment 1

[0033] (1) Pretreatment before optical fiber plating:

[0034] A. Removing the protective layer: immerse the quartz optical fiber in acetone at room temperature for about 25 minutes, gently peel off the protective layer after taking it out, and then wash it in an ultrasonic cleaner with deionized water for 8 minutes to remove the protective layer. the remains;

[0035] B. Degreasing: Scrub the optical fiber after removing the protective layer with anhydrous alcohol several times, then put it in an ultrasonic cleaner and wash it with anhydrous alcohol for 10 minutes, take it out and rinse it with deionized water several times, and then put it in an ultrasonic cleaner Wash with deionized water for 8 to 10 minutes to thoroughly clean the oil;

[0036] C. Sensitization: Weigh 5 grams of stannous chloride and dissolve it in 5 milliliters of hydrochloric acid, then dilute to 100 milliliters with distilled water, sensitize the optical fiber at room temperature for 10 minutes in the ...

Embodiment 2

[0042] (1) Pretreatment before optical fiber plating:

[0043] A. Removing the protective layer: Immerse the quartz optical fiber in acetone for about 35 minutes at room temperature, gently peel off the protective layer after taking it out, and then wash it in an ultrasonic cleaner with deionized water for 12 minutes to remove the protective layer. the remains;

[0044] B. Degreasing: Scrub the optical fiber after removing the protective layer with anhydrous alcohol several times, then put it in an ultrasonic cleaner and wash it with anhydrous alcohol for 12 minutes, take it out and rinse it with deionized water several times, and then put it in an ultrasonic cleaner Wash with deionized water for 8 to 10 minutes to thoroughly clean the oil;

[0045] C. Sensitization: Weigh 5 grams of stannous chloride and dissolve it in 5 milliliters of hydrochloric acid, then dilute to 100 milliliters with distilled water, sensitize the optical fiber at room temperature for 12 minutes in the...

Embodiment 3

[0051] (1) Pretreatment before optical fiber plating:

[0052] A. Removing the protective layer: Immerse the quartz optical fiber in acetone for about 30 minutes at room temperature, gently peel off the protective layer after taking it out, and then wash it in an ultrasonic cleaner with deionized water for 10 minutes to remove the protective layer. the remains;

[0053] B. Degreasing: Scrub the optical fiber after removing the protective layer with anhydrous alcohol several times, then put it in an ultrasonic cleaner and wash it with anhydrous alcohol for 11 minutes, take it out and rinse it with deionized water several times, and then put it in an ultrasonic cleaner Wash with deionized water for 8 to 10 minutes to thoroughly clean the oil;

[0054] C. Sensitization: Weigh 5 grams of stannous chloride and dissolve it in 5 milliliters of hydrochloric acid, then dilute to 100 milliliters with distilled water, sensitize the optical fiber in the sensitizing solution at room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com