Method for improving recycling of plating emery of diamond wire

A diamond wire and plating technology, applied in the direction of electrolytic paint, coating, etc., can solve problems such as waste and increase production costs, and achieve the effects of improving bonding force, saving costs, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

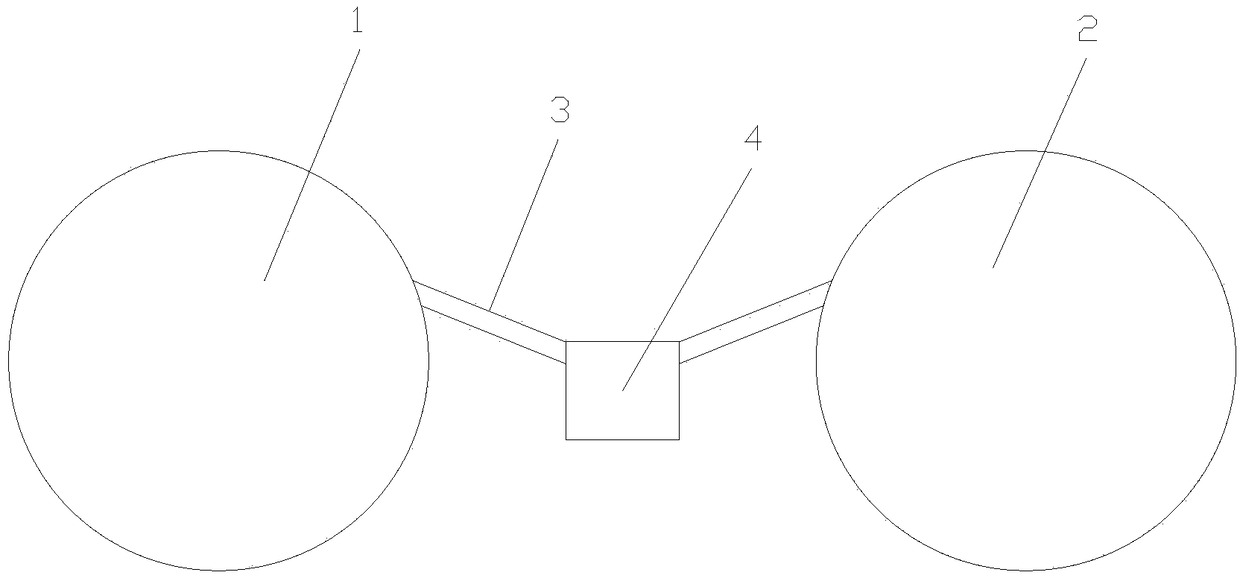

Image

Examples

Embodiment 1

[0031] Embodiment 1: A method for improving the quality of diamond wire, including pretreatment-pre-plating-sanding-reinforcement-post-treatment;

[0032] The pretreatment includes setting out, alkali washing and pickling: for setting out, a steel wire with a diameter of 0.05-0.1 mm is selected as the busbar, and the line is set out by a pay-off machine;

[0033] Alkali washing, the proportioning concentration of the alkali washing tank is 5%, the washing time is 15 seconds, and the temperature is set at 60-65°C.

[0034] Pickling, the above-mentioned pickling, the proportioning concentration is 5%, and the cleaning time is 15 seconds.

[0035] In the pre-plating, the bus bar is placed in an electroplating pool containing an electroplating solution for pre-plating;

[0036] In the sanding, the pre-plated busbar is used as the cathode to pass through the electroplating solution mixed with corundum, and under the action of an electric field (or an electric field plus a magnetic...

Embodiment 2

[0045] Embodiment 2: A method for improving the quality of diamond wire, including pretreatment-pre-plating-sanding-reinforcement-post-treatment;

[0046] The pretreatment includes setting out, alkali washing and pickling: for setting out, a steel wire with a diameter of 0.05-0.1 mm is selected as the busbar, and the line is set out by a pay-off machine;

[0047] Alkali washing, the proportioning concentration of the alkali washing tank is 10%, the washing time is 15 seconds, and the temperature is set at 60-65°C.

[0048] Pickling, the said pickling, proportioning concentration 10%, cleaning time 15 seconds.

[0049] In the pre-plating, the bus bar is placed in an electroplating pool containing an electroplating solution for pre-plating;

[0050] In the sanding, the pre-plated busbar is used as the cathode to pass through the electroplating solution mixed with corundum, and under the action of an electric field (or an electric field plus a magnetic field), the corundum micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com